1 Contents

2 Description ............................................................................................................................................ 4

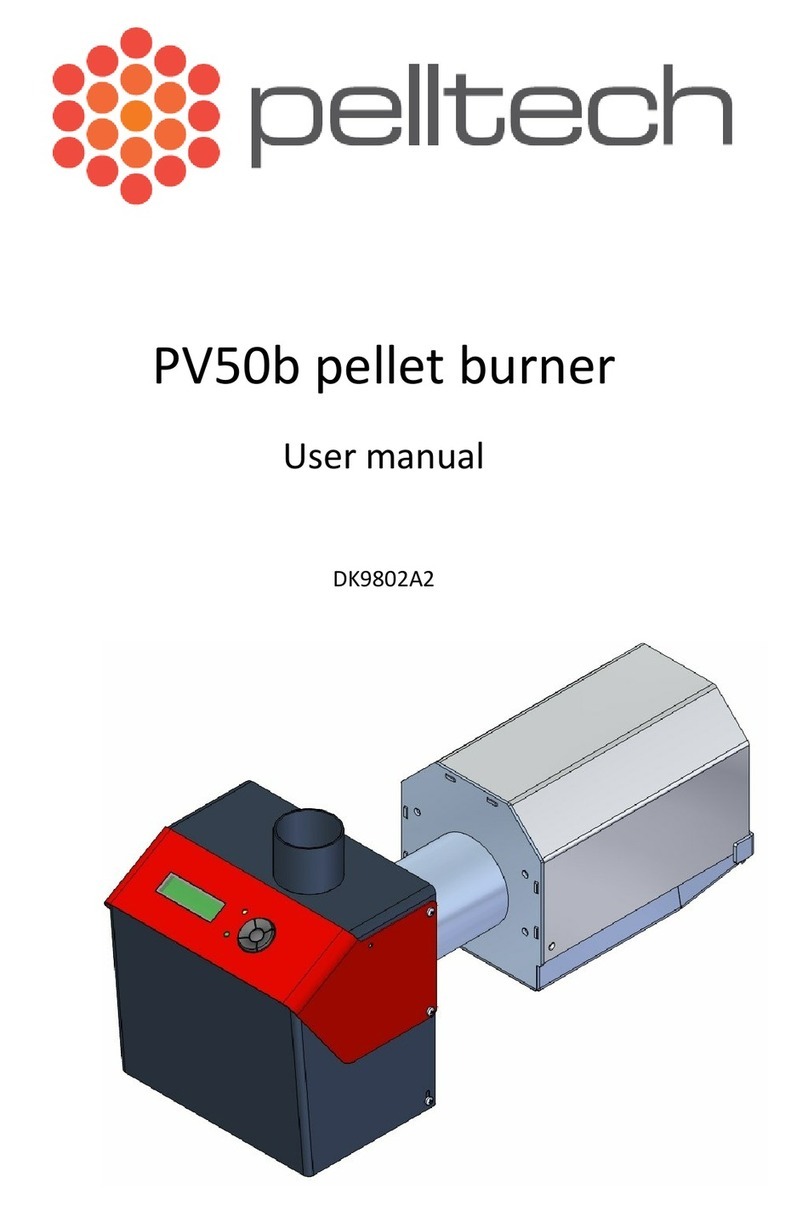

2.1 Main components ......................................................................................................................... 5

2.2 Specifications................................................................................................................................. 7

3 Installation........................................................................................................................................... 10

3.1 Prerequisites................................................................................................................................ 10

3.2 Burner .......................................................................................................................................... 11

3.3 Water sprinkler............................................................................................................................ 20

3.4 External auger ............................................................................................................................. 21

3.5 Pellet storage............................................................................................................................... 22

3.6 Electrical connections.................................................................................................................. 22

3.7 Commissioning ............................................................................................................................ 27

4 Operation and maintenance ............................................................................................................... 28

4.1 User interface.............................................................................................................................. 28

4.2 Starting and stopping .................................................................................................................. 30

4.3 Statuses and parameters............................................................................................................. 30

4.4 Cleaning ....................................................................................................................................... 38

4.5 Replacing components ................................................................................................................ 38

5 Optional components.......................................................................................................................... 40

5.1 GSM Modem ............................................................................................................................... 40

5.2 Flue gas fan.................................................................................................................................. 41

6 Common problems and solutions ....................................................................................................... 42

7 Annex A –Parameters ......................................................................................................................... 43

8 Annex B –Burner status change logic ................................................................................................. 47

9 Annex C –Controller board description .............................................................................................. 49