Safety 2

Important Safety Instructions

SAVE THESE INSTRUCTIONS - This manual contains

important instructions that should be followed during

installation, operation, and maintenance of the product.

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of

the following signal words and be alert to the potential

for personal injury!

indicates a hazard which, if not avoided,

will result in death or serious injury.

indicates a hazard which, if not avoided,

can result in death or serious injury.

indicates a hazard which, if not avoided,

can or may result in minor or moderate injury.

NOTICE addresses practices not related to personal injury.

Carefully read and follow all safety instructions in this

manual and on pumps.

Keep safety labels in good condition. Replace missing or

damaged safety labels.

Battery acid is corrosive. Do not spill on

skin, clothing, or battery charger. Wear eye and head

protection when working with battery. Connect and

disconnect DC output terminals only after removing the

charger from the AC outlet. Never allow the DC

terminals to touch each other.

Hazardous Voltage. Can cause severe or

fatal electrical shock. Do not plug in or unplug battery

charger while standing on a wet floor or in water. Be sure

one hand is free when plugging in or unplugging charger.

If basement floor is wet, disconnect power to basement

before walking on floor. If shut-off box is in basement,

call electric company or hydro authority to shut-off

service to house, or call your local fire department for

instructions. Remove pump and repair or replace. Failure

to follow this warning can result in fatal electrical shock.

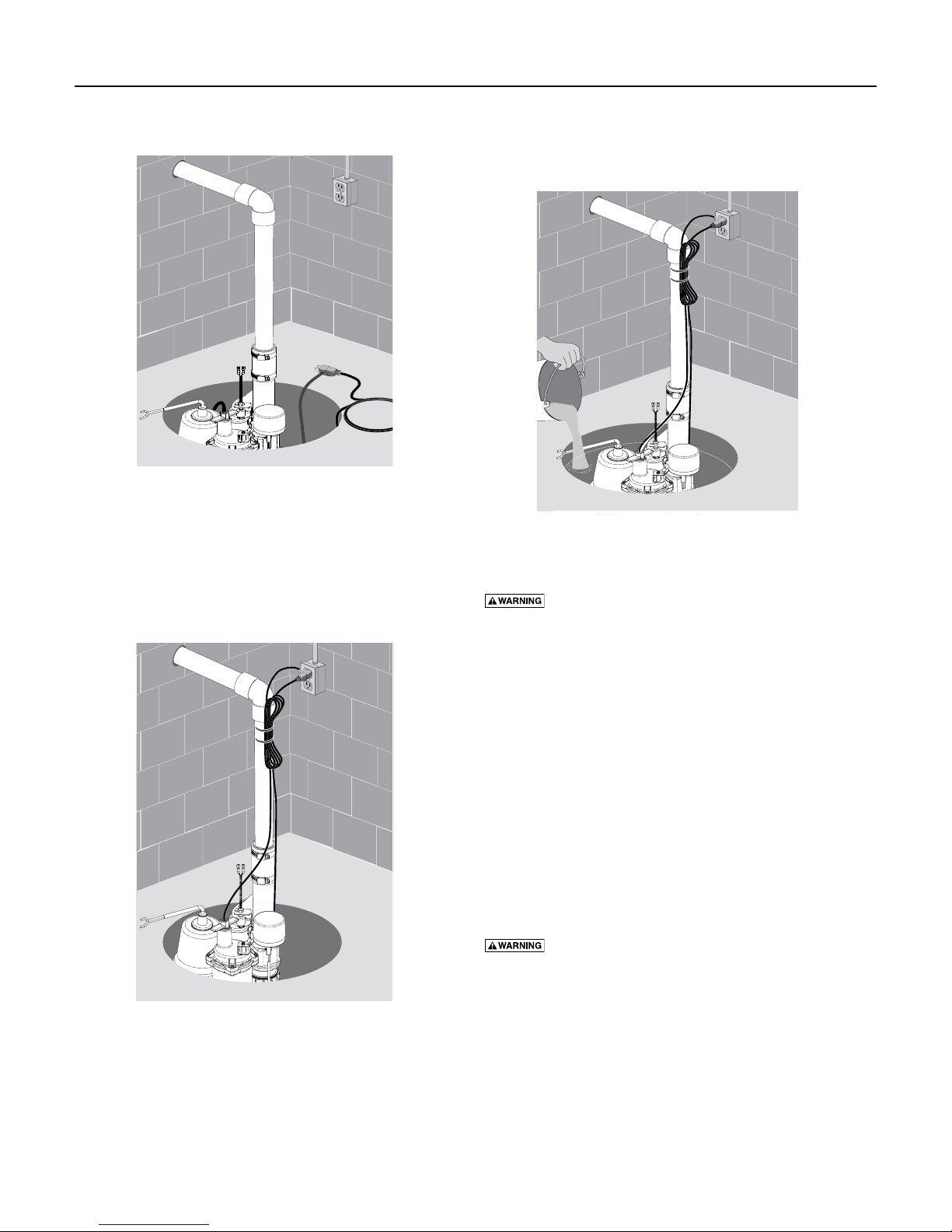

Risk of flooding. Do not run pump dry. To

do so will damage seals and can cause leaking and

property damage.

Risk of electrical shock. Do not lift the

pump by the electrical cord; lift pump only by the

discharge pipe, lifting ring or handle on the pump. Lifting

by the cord can damage the cord.

California Proposition 65 Warning

This product and related accessories contain

chemicals known to the State of California to cause

cancer, birth defects or other reproductive harm.

1. Know the pump application, limitations, and potential

hazards.

2. Do not use in water with fish present. If any oil leaks

out of the motor it can kill fish.

NOTICE This unit is not designed as a waterfall or

fountain pump, or for applications involving salt water

or brine! Use with waterfalls, fountains, salt water or

brine will void warranty.

3. Disconnect power before servicing.

4. Drain all water from system before servicing.

5. Secure discharge line before starting pump. An

unsecured discharge line will whip, possibly causing

personal injury and/or property damage.

6. Check hoses for weak or worn condition before each

use, making certain that all connections are secure.

7. Periodically inspect sump, pump and system

components. Keep free of debris and foreign objects.

Perform routine maintenance as required.

8. Provide means of pressure relief for pumps whose

discharge line can be shut-off or obstructed. Release all

pressure within system before servicing any component.

9. Personal Safety:

j. Wear safety glasses at all times when working with

pumps.

k. Keep work area clean, uncluttered and properly

lighted – replace all unused tools and equipment.

l. Keep visitors at a safe distance from work area.

m.Make workshop child-proof – with padlocks, master

switches, and by removing starter keys.

14. Follow local and/or national plumbing and electrical

codes when installing the system. A ground fault

circuit interrupter (GFCI) is recommended for use on

any electrical appliance submerged in water.

15. All wiring should be performed by a qualified

electrician.

16. This equipment is only for use on 115 volt

(single phase) and is equipped with an approved

3-conductor cord and 3-prong, grounding-type plug.

17. Where a 2-prong wall receptacle is encountered, it

must be replaced with properly grounded 3-prong

receptacle installed in accordance with codes and

ordinances that apply.

18. Make certain power source conforms to requirements of

your equipment.

19. Protect electrical cord from sharp objects, hot surfaces,

oil, and chemicals. Avoid kinking cord. Replace or

repair damaged or worn cords immediately.

20. Do not touch an operating motor. Modern motors can

operate at high temperatures.

21. Pump clear water only with this pump.

22. Pump is permanently lubricated at the factory. Do

not try to lubricate it!

23. This pump is designed for use in a residential sump

only.