PF Polymatic User manual

S c h w e i ß t e c h n o l o g i e G m b H

Ka r l - B r ö g e r -St r . 1 0 D E-3 6 3 0 4 A l s f e l d Te l : + 4 9 -6 6 3 1 -9 6 5 2 -0 F a x : + 4 9 -6 6 3 1 - 9 6 5 2 -5 2

Barcode Electro Fusion Control Box

Barcode Electro Fusion Control BoxBarcode Electro Fusion Control Box

Barcode Electro Fusion Control Box

PF

PF PF

PF –

––

– polymatic

polymatic polymatic

polymatic

PF

PF PF

PF –

––

– polymatic light

polymatic light polymatic light

polymatic light

PF-Schweißtechnologie GmbH – Karl-Bröger-Str. 10 – DE-36304 Alsfeld

Tel.: +49-(0)6631-9652-0 Fax.: +49-(0)6631-9652-52

Rev.: 2004-001-GB

Rev.: 2004-001-DE

2

Rev.: 2004-001-DE

3

Table of contents

1

Introduction .................................................................................... 4

1.1

Maintenance periods.............................................................................................................. 4

2

Scope of application and technical data ...................................... 5

2.1

Scope of application............................................................................................................... 5

2.2

Input of welding parameters................................................................................................... 5

2.3

Range of fitting dimensions.................................................................................................... 5

2.4

Technical data........................................................................................................................ 6

2.5

Technical File – Polymatic / Polymatic Light (ISO/FDIS 12176-2 ) ........................................ 7

3

Important safeguards..................................................................... 8

4

Controls and Plugs......................................................................... 9

5

Power Connection........................................................................ 10

5.1

Generator suitability ............................................................................................................. 11

6

Starting a welding process.......................................................... 11

6.1

Preparation........................................................................................................................... 11

6.2

Welding with the Barcode-Mode .......................................................................................... 13

6.3

FUSAMATIC

©

-Mode ............................................................................................................ 15

7

Other Functions............................................................................ 17

7.1

Function menu ..................................................................................................................... 17

7.2

Adjusting the display contrast............................................................................................... 17

7.3

System configuration / Change language ............................................................................ 18

8

Trouble shooting .......................................................................... 19

8.1

Using and servicing the reading pen.................................................................................... 19

8.2

Replacing Welding Terminals .............................................................................................. 19

8.3

Adapter................................................................................................................................. 19

8.4

Start messages .................................................................................................................... 20

8.5

Error messages.................................................................................................................... 21

9

Conformity Declaration ................................................................ 23

Please note the safeguards in chapter 3

Rev.: 2004-001-DE

4

1 Introduction

Dear customer,

we thank you for the confidence in our product and wish you a contented work with it.

The present instructions manual includes, beside the description of the use of the devices, important

notes for your safety and the scope of application. Therefore, you should read carefully the present

instructions manual before the first use of the device. In case of failure or interruption of the workflow

read the appropriate chapter of this manual. Self-evidently we are ready to assist you at any time:

PF-Schweißtechnologie GmbH

Karl-Bröger-Str. 10

DE-36304 Alsfeld

Tel.: +49-6631-9652-0

Fax: +49-6631-9652-52

All notes and technical specification in this instructions manual were prepared with all necessary care.

The manufacturer keeps the right to make technical changes at the device, which are not directly

included into the present instructions manual.

1.1 Maintenance periods

Please note, that the bought product is a technically demanding machine for field application. In

accordance to the applicable standards like DVS 2208-1, BGV A2, ISO 12176-2 and most national and

international standards, these machines have to be subjected to a periodical maintenance. The

maintenance period is 12 month. When the machine is used quite often the maintenance should be

carried out more often.

During the maintenance the machine will be upgraded to the current technical state. Additionally you

get a 3-month function guarantee for the maintained device.

The maintenance and the related checks are important for you safety and the continuous working

reliability of the control unit. Therefore the maintenance and all necessary repairs, have to be carried

out by the manufacturer or a authorised service point.

Rev.: 2004-001-DE

5

2 Scope of application and technical data

2.1 Scope of application

The electro fusion control units of type Polymatic / Polymatic Light are exclusively for the electro

fusion of thermoplastic pipes (e.g. made of PE-HD, PE80. PE100 or PP) by use of electro fusion

fittings with an welding voltage lower than 48V . The control units are conform to the standard DVS

2208-1 as well as the ISO 12176-2, which refer to the standards applicable for the electro fusion fittings

to be used.

It is not allowed to use the electro fusion controllers, to which the present instruction manual refers to,

for an application not covered by the above stated terms. The manufacturer is not liable for the use of

the machine out of the scope of application.

2.2 Input of welding parameters

The electro fusion controllers of type Polymatic / Polymatic Light provide the following means for

entering the welding parameters:

BARCODE (ISO-TR 13950, Type 2/5i, 24 digits)

The barcode attached on the most electro fusion fittings in the market contains all necessary data for

processing them. After reading the barcode with the reading device, the process data is automatically

taken over by the control unit. The barcodes contains mainly the following data: Manufacturer, type,

diameter, fusion voltage, fusion time (with temperature correction, if applicable), resistance and

resistance tolerance.

FUSAMATIC-System:

By reading out the reference resistance in the connector pins of the FUSAMATIC-Fitting the control

unit automatically takes over the welding data of the fitting.

2.3 Range of fitting dimensions

For which range of fitting dimensions a electro fusion control unit can be used depends essentially on

the power consumption to the used fittings itself. Since the power consumption of the fittings are

different for different fitting manufacturers, a general statement concerning this point is hardly to make.

In case of doubt, each single case has to be checked separately. For electro fusion control units of the

type Polymatic / Polymatic Light the following general statement can be made, with the assumption,

that all welding processes were made one after the other, i.e. that the control unit is able to cool down

during the preparation time of the next fitting:

Polymatic: Use for dimension 20-630mm without any limit.

Polymatic Light: Use for dimension 20-355mm without any limit.

For larger diameters there must be provided longer off-times to ensure a cooling down of the control

unit (Error message “Device too hot”). Before processing fittings in this dimension range, you have to

check that the welding current of the fitting does not exceed the maximum output current of the control

unit.

All above made statements refer to an ambient temperature of 20°C.

Rev.: 2004-001-DE

6

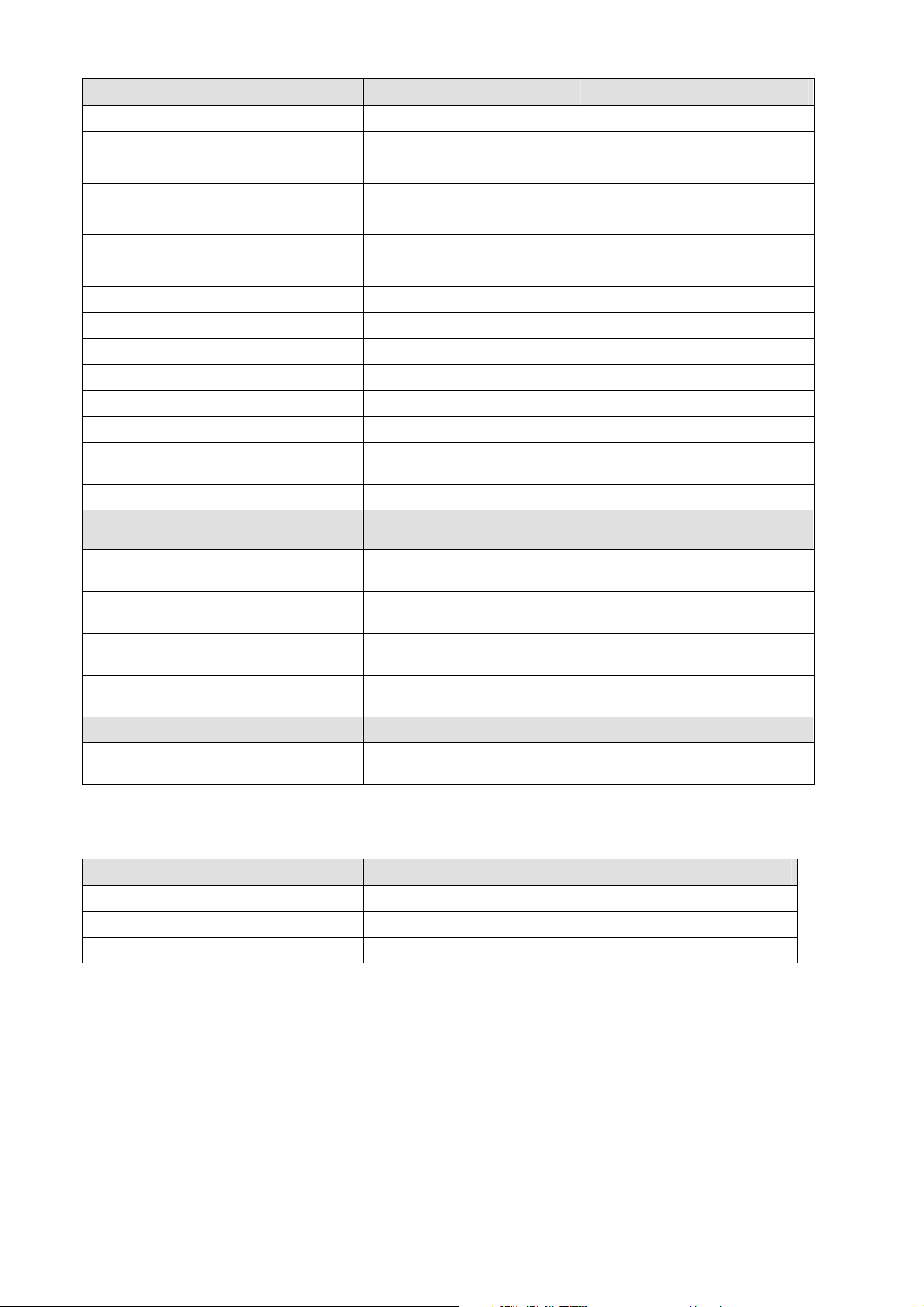

2.4 Technical data

Technical Data – Technische Daten

Polymatic Polymatic Light

ISO 12176-2 Class - Klassifizierung

P

2

4 U S

1

V A X P

2

3 U S

1

V A X

Input Voltage -Eingangsspannung

230V ~/AC, (185V-300V)

Input Current – Eingangsstrom

16A

Input Frequency - Eingangsfrequenz

50Hz (40-70Hz)

Output Voltage - Ausgangsspannung

8-48V

Output Current - Ausgangsstrom

80A (max.: 110A) 60A (max. 80 A)

Power Consumption - Leistungsaufnahme

3600VA 3200VA

Temperature Range -Arbeitstemperatur

-10°C - +50°C

Protection Class - Gerätesicherheit

IP54, Class 2

Weight incl. Cables - Gewicht inkl. Kabel

20kg 18kg

Main Supply Cable - Netzkabel

4,5 m (Euro-Plug – Euro-Stecker)

Welding Cable - Schweißkabel

5m (fixed – fest) 3m (fixed – fest)

Welding Terminals - Anschlußkontakt

4,0mm (opt. 4,7mm)

Display – Display

4 x 20 Characters (alphanum.), background lighting

4 x 20 Zeichen (alphanumerisch), Hintergrundbeleuchtung

Dimension – Abmessungen

440mm x 380mm x 320mm

Monitoring Functions -

Überwachungsfunktionen

Input – Eingang

Voltage / Current / Frequency

Spannung / Strom / Frequenz

Output – Ausgang

Voltage / Resistance / Contact / Short circuit / Current Monitoring

Spannung / Widerstand / Kontakt / Kurzschluß / Stromüberwachung

Other – Sonstige

System / Working Temperature / Service

System / Arbeitstemperatur / Wartung

Error Messages - Fehlermeldung

Plain Text / Acoustic Signal

Klartext im Display / Dauerwarnton

Enclosed Parts – Lieferumfang

Control Box, Transport Box, Adapter 4.0/4.7mm, Instructions Manual

Gerät, Transportbox, Adapter 4.7/4.0mm, Bedienungsanleitung

Technical Data for 110V Control Units

Technical Data – Technische Daten

Polymatic / Polymatic Light

Input Voltage -Eingangsspannung

110V ~/AC, (90V-150V)

Input Current - Eingangsstrom

40A

Input Frequency - Eingangsfrequenz

50Hz (40-70Hz)

Rev.: 2004-001-DE

7

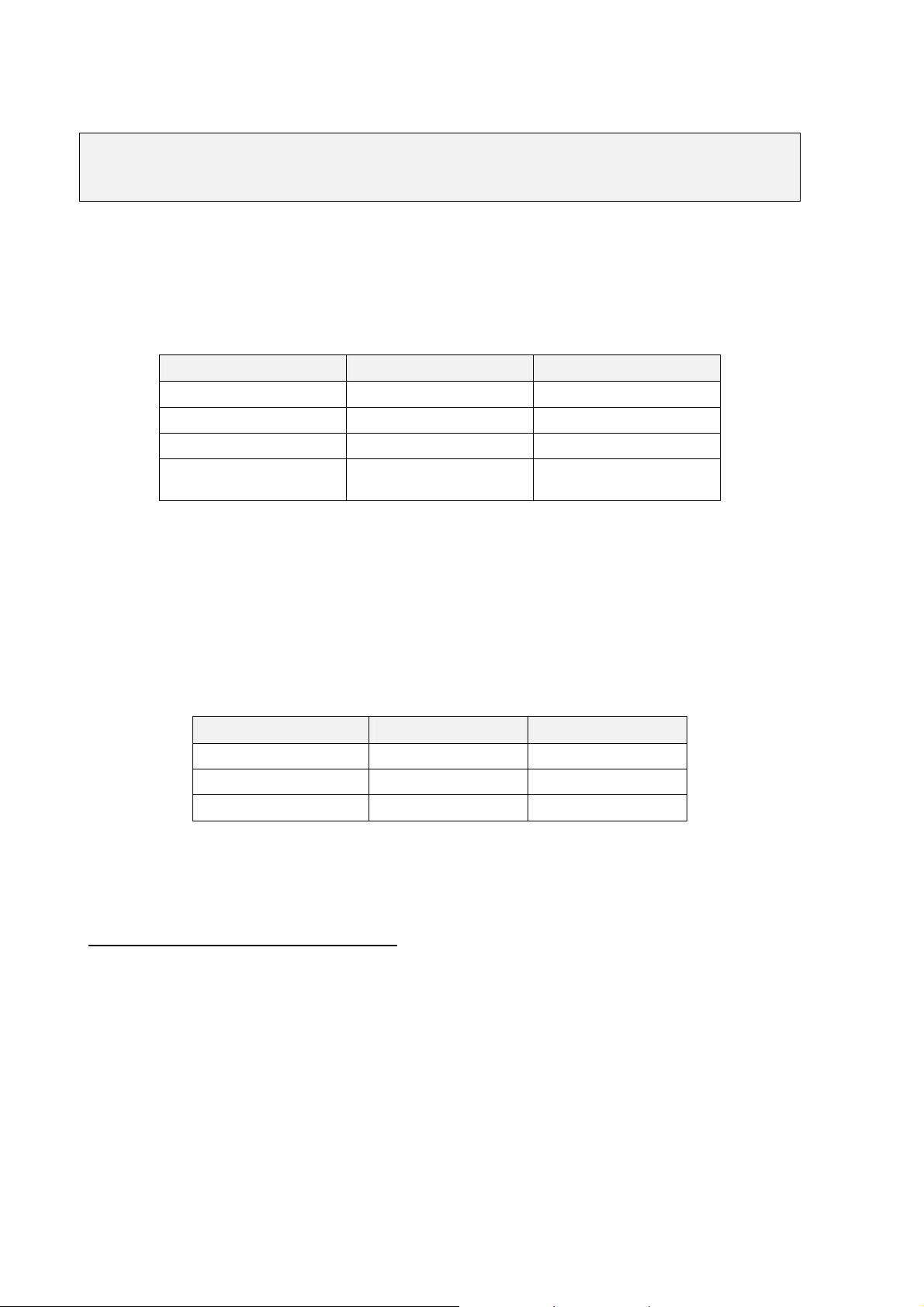

2.5 Technical File – Polymatic / Polymatic Light (ISO/FDIS 12176-2 )

Classification

Machine Type Classification

Polymatic

P

2

4 U S

1

V A X

Polymatic light

P

2

3 U S

1

V A X

Simulation Curved at 24V (Output voltage)

Polymatic Polymatic Light

Duty Cycle at 100%, 60% and 30%

Polymatic Polymatic Light

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

1500W

2000W

2500W

3000W

3500W

4000W

Duty Cycle (ISO 12176-2) at

U

ref

=36V

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

1500W

2000W

2500W

3000W

3500W

Duty Cycle (ISO 12176-2) at

U

ref

=36V

Additional Information

Polymatic (Light)

Soft Start: 2sec ramped

Ambient Temperature Compensation: As stated in ISO/TR 13950

Fitting Temperature Compensation: No

Fusion Data Recorder: No

Rev.: 2004-001-DE

8

3 Important safeguards

Before turning on the welding device, please, read this operating instructions as well

as the relevant safety and processing directions carefully.

Warning! With the use of electric tools you have to note the following basic

safety direction to protect against electric shock, injury and fire.

1. Keep your working area in order !

Disorder involves a certain danger.

2. Consider the influence of environment !

Do not expose electro tools to rain. Do not use electro tools in wet or damp surroundings or in the

neighbourhood of combustible liquids or gases.

3. Protect yourself against electric shock !

Avoid body contact with grounded components (e.g. radiators, metal pipes) or live cables. Do not carry

the device, with the finger on the power switch. Pull out the plug when you do not use the tool or when

changing the adapters and attachments.

4. Keep unauthorized people and children away !

Do not allow other people touch the device or cables – keep them away from your working place.

5. Store up your device safely !

Unused machines should be kept in a dry and locked room, inaccessible for children and unauthorized

people.

6. Use permitted accessories only!

Do only use accessories, especially current sources and lengthening cables, that are stated in the

operating instructions or recommended by us. The use of attachments, that are not stated in the

operating instructions, involves a certain danger for you. Do only use permitted and marked

lengthening cables outdoors.

7. Do not expose the cables to avoidable loads !

Do not carry the machine with the cable and do not use the cable to pull out the plug. Protect the

cables against heat, oil and sharp edges.

8. Lock after your tools carefully !

Keep your device clean. Follow the servicing instructions and the instructions for changing the tools.

Keep oil and grease away from the straps.

9. Check your device for damages !

Check your tools before every use for damages and function of the protection devices and machine

parts. All parts have to be mounted in the right way. They have to fulfil all conditions for a impeccable

running of the tool. Damaged protection devices and machine parts have to be repaired or replaced by

an authorized service point.

Rev.: 2004-001-DE

9

4 Controls and Plugs

(1) Display

(2) START (green)

(3) STOP (red)

(4)

(5)

(6)

(7)

(4) Power Switch

(5) Welding Cable

(6) Cable Holder

(7) Power Supply Cable

Rev.: 2004-001-DE

10

5 Power Connection

The connecting conditions of EVU, the VDE-directions, the accident prevention

regulations, DIN/CEN-regulations as well as national regulations have to be

considered.

Electro Fusion Control Units have to be used by operators, which are trained and authorised conform

the national and international standards and directives, only. The operator has to supervise the electro

fusion control box during the whole fusion process.

The electro fusion control unit has to be used within the following ranges:

Parameter 230V Control Units 110V Control Units

Input Voltage: 185V – 300V (AC) 90V – 150V (AC)

Input Frequency:: 40Hz – 70Hz 40Hz – 70Hz

Ambient Temperature: -10°C – +50°C -10°C – +50°C

Max. Output Power: Polymatic: 4000W

Polymatic Light: 3600W

Polymatic: 4000W

Polymatic Light: 3600W

Caution: 110V Control Units shall not be used at 230V power supply and vice versa.

When operating on a electric distributor or the main power supply of nominal 230V, a min. 16 Amps

slow fuse comprising a residual current-operated protective device (RCCB) should be used (110V:

min. 32Amps).

Extension Cables:

To extend the power supply cable you have to follow the following rules:

Cable length Cross Section (230V) Cross Section (110V)

Up to 20m 3 x 1.5mm² 3 x 4mm²

20 to 50m 3 x 2.5mm² 3 x 4mm²

50-100m 3 x 4mm² -

It is not allowed to extend the welding cable!

Important notes for the use of generators:

•First start generator, then plug in the device.

•No other machine or device shall be connected to the generator

•The idle running voltage should be regulated to 240V – 260V (AC) at nominal 230V

(nominal 110V: 120V – 130V (AC)).

•Plug out welding device before turning off the generator.

•The usable generator power will decrease by 10% per 1000m height.

•Check the fuel lever before starting the welding process.

Rev.: 2004-001-DE

11

5.1 Generator suitability

The Electro Fusion Controllers of type Polymatic / Polymatic Light provide the following means to

increase the generator suitability:

•Wide tolerance for input voltage and Input frequency.

•Display of current input voltage and frequency.

•Soft-Start for limitation of the generator load.

Despite this characteristics, the generators to be used have to fulfil the following requirements and

recommends, in order to avoid damaged of the control unit and to ensure that the internal monitoring

function of the control unit will not interrupt the welding process:

•suitable to drive inductive loads and phase cut systems

•no-load voltage adjustable to 240V – 260V at nominal 230V (nominal 110V: 120V – 130V (AC)).

•output current of 18 Amps at one phase at nominal 230V (nominal 110V: 36Amps).

•stable output voltage and engine speed, also at fast alternating loads

•synchronous generators with mechanical speed control preferred

•voltage peaks must no exceed 800V

Min. required generator output power 230V, 50Hz, 1-phase

Diameter Output Power

20-75 mm 2kW

90-160 mm 3,2kW

180-710mm 4.5kW (mechanically controlled)

5kW (electronically controlled)

For generators with insufficient control performance or voltage control it has to be selected 3-3.5 times

higher output power than the stated ones to achieve an undisturbed operation. Electronically controlled

generators tent to oscillate with the control of the welding process, which can lead to high output

voltage peaks. Please, test suitability before using that kind of generators.

Manufactures like HONDA, EISEMANN, GEKO, FISCHER, PANDA and KIRSCH provide generators

performed especially for this kind of application.

Caution: 110V Control Units shall not be used at 230V power supply and vice versa.

6 Starting a welding process

6.1 Preparation

Before starting you have to carry out the following steps in the given order:

1. Check the device, cables and adapters visually. If necessary you have to replace them.

2. Plug in Detachable welding cables.

3. Unroll welding, power and extension cables completely.

4. Switch of the Power Switch of the control unit.

5. Start the generator before you plug in the control unit. Wait until the generator

output voltage has stabilized.

6. Plug in the power cable of the control unit.

7. Switch on the power switch.

Rev.: 2004-001-DE

12

Caution: 110V Control Units shall not be used at 230V power supply and vice versa.

After this procedure, the control unit signals its readiness with two bleeps. In addition the display

backlight is turned on automatically. The following display message appears:

PF polymatic

Version 2.04ah

25 Working hours

Line 1 and 2 show the type and version of the control unit.

Line 3 shows the total amount of working hours of the control unit.

If there occurred any error or change of the system configuration at the last weld before turning off the

device, this will be indicated by a message in the display once again. After pressing the red STOP-key

you are able to carry out a new welding process.

As long as no fitting is connected, no welding process can be started. The Message No contact

prompts you to connect a fitting.

Connect Fitting

Voltage: 230 V

Frequency: 50 Hz

No contact

Welding Terminals:

-The contacts of the welding connector and the fitting plug must be clean – dirty or coated

contacts can lead to overheating and burn at the connectors.

-Generally the terminals have to be protected against dirt. If there is a coating or loss of

stick force on the connectors they have to be replaced.

-Use Adapters to connect certain fitting types. Adapters wear out with the time and have to

be checked before every use.

Connect the welding terminals of the control unit to the pins of the fitting. Take care on a firm and

proper fit.

FUSAMATIC-System

The welding with the FUSAMATIC

©

-Mode is only possible with FUSAMATIC

©

-fittings. The Option

FUSAMATIC of the system configuration has to be enabled. The red terminal must be put on the

fitting pin which is marked with the red ring.

Rev.: 2004-001-DE

13

6.2 Welding with the Barcode-Mode

Pay attention to the installation instructions of the fitting, special instructions (ISO,

CEN, DVGW, DVS), European and national directions as well as the instructions of

the manufacturers!

After preparing and connecting the fitting, the following message demands you to read in a fitting

barcode with the scanner or reading pen:

Fitting code

Voltage: 230 V

Frequency: 50 Hz

Temperature: +23V

Error messages will be shown in the last row. In case of generator use check that the voltage is at

about 240-260V at nominal 230V (nominal 110V: 120V – 130V (AC)).

For welding in the Barcode-Mode, read in the barcode label, which is attached to the fitting you want to

process. If it is not readable because of damage, you can use by the way of exception the readable

barcode of an identical fitting of the same manufacturer. In any case it is forbidden to use the

barcode of a different fitting. If you read in a barcode which is defect or invalid the error will be

displayed and indicated by a bleep. You read in the barcode by using the scanner or reading pen.

Using the reading pen:

Place the tip of the reading pen left or right beside the bar code. Move the reading pen with a constant

speed over the whole barcode. Do not stop the movement or lift the reading pen off.

You read-in the barcode by using the scanner or reading pen. If the device detects a valid barcode, it

indicates its readiness by showing the following message:

Start

Nom. time: 0200s

+PF+ [d063 +23°C

Row 1 indicates that you have to press the green START-key to start the welding process. Before that

you are obliged to check and compare the shown values with the ones given on the connected coupler.

Row 2 shows the nominal welding time.

Row 3 shows the manufacturer, type and diameter decoded from the barcode. The type information is

shown like follows:

ICoupler TTee

]End cap YReducer

.†. Saddle >Ray Trans

(Elbow לTWD Tapping Saddle

There is also given the ambient temperature. If the fitting barcode provides temperature compensation,

the nominal fusion time will be adapted to the ambient temperature.

Row 4 shows possible error messages.

Rev.: 2004-001-DE

14

After pressing the green START-key a message will remind you of your duty to fix and prepare the

pipes according to the general guidelines:

Is the pipe scraped ?

If you have any doubt about the right preparation, you can break off the procedure by actuating the red

STOP-key. Confirm the proper preparation by pressing the green START-key.

Resistor Error

Now, the welding device begins to measure the fitting resistance. In the case that it is outside the valid

range, the error will be indicated by a bleep and a appropriate message will appear in the display:

1,68< 2,00 < 1,93

Nom. time: 200 s

+PF+ [ d063

Resistor error

Row 1 shows in the middle the measured resistance. At the left and right the borders of the resistance

range given in the barcode is shown.

Row 2 shows the nominal welding time.

Row 3 shows the report number of the faulty process.

Plug the welding terminals out of fitting plugs. Check the connectors of the fitting and welding cable for

dirt or coating. If the fitting causes another resistor error, it maybe defect. Replace it.

If no resistor error occurs, the welding device starts the welding process automatically. To avoid

danger for your health, do not touch the fitting or cables during the welding process. The

display shows the actual and nominal welding time:

Act. time: 0099 s

Nom. time: 0200 s

+PF+ [ d063

Row 1 shows the actual welding time, which is counted upwards.

Row 2 shows the nominal welding time.

Row 3 shows the manufacturer, type and diameter.

Row 4 shows possible error messages.

Rev.: 2004-001-DE

15

The welding process will stop automatically when the actual time reaches the nominal time. This will be

indicated by two bleeps and the following message:

Act. time: 0200s

Nom. time: 0200s

+PF+ [d063 20°C

+ OK +

Pull off the welding connectors to go back to the start message.

6.3 FUSAMATIC

©

-Mode

Pay attention to the installation instructions of the fitting, special instructions (ISO,

CEN, DVGW, DVS), European and national directions as well as the instructions of

the manufacturers!

The welding with the FUSAMATIC

©

-Mode is only possible with FUSAMATIC

©

-fittings.

As long as no fitting is connected, no welding process can be started. When connecting the welding

terminals to the pin at the fitting pay attention to a firm a proper fit. Connect the red welding terminal

to the fitting connector with the red marking. Thus the welding device can detect the fitting type

and its welding parameters. It will switch to the FUSAMATIC

©

-Mode automatically. This will be

indicated by the following message:

START

Nom. time: 200 s

FUSA 40V 20°C

Row 1 indicates that you have to press the green START-key to start the welding process. Before that

you are obliged to check and compare the shown values with the ones given on the connected coupler.

In the case that these deviate or if a contact error is indicated in the lowest row of the display, a faulty

or invalid reference resistance is read. Pull off the welding connector from the fitting plugs. Check the

connectors of the fitting and welding cable for dirt or coating. If the fitting causes another contact error

or differing parameters, it is defect. Replace it.

Row 2 shows the nominal welding time.

Row 3 shows the manufacturer FUSA and 40V to indicate the FUSAMATIC

©

mode and the ambient

temperature.

Row 4 shows possible error messages.

Rev.: 2004-001-DE

16

You can confirm the correctness of the welding parameters by pressing the green START-key. The

following message will remind you of your duty to fix and prepare the pipes according to the general

guidelines:

Is the pipe scraped?

If you have any doubt about the right preparation, you can break off the procedure by actuating the red

STOP-key.

Confirm the proper preparation by pressing the green START-key.

The welding device starts the welding process automatically. To avoid danger for your health, do

not touch the fitting or cables during the welding process. The display shows the actual and

nominal welding time:

Act. time: 0099 s

Nom. time: 0200 s

PLAS 40V

Row 1 shows the actual welding time, which is counted upwards.

Row 2 shows the nominal welding time.

Row 3 shows the manufacturer PLAS and 40V to indicate the FUSAMATIC

©

mode

Row 4 shows possible error messages.

The welding process will stop automatically when the actual time reaches the nominal time. This will be

indicated by two bleeps and the following message:

Act. time: 0200 s

Nom. time: 0200 s

PLAS 40V

+OK+

Pull off the welding connectors to go back to the start message.

Rev.: 2004-001-DE

17

7 Other Functions

7.1 Function menu

After connecting the control unit to the power supply and switching on, wait until the machine indicates

it readiness by two bleeps . Then aboard all error messages by pressing the red STOP-button.

by simultaneous pressing of the START and STOP-key the following two menu items will be shown in

the display:

>Contrast

System config.

> (Cursor) Marks the active menu item.

START (short) Moves the cursor upwards.

STOP (short) Moves the cursor downwards.

START (3 sec.) Selects the marked menu item.

STOP (3 sec.) Cancels the function menu.

7.2 Adjusting the display contrast

By selecting the contrast function of the function menu you can adjust the display contrast to your

needs:

Contrast

240

The shown value is only given for your orientation. It can show numbers from 100 to 250. At high

values the belong to strong contrast.

START (short) Increases the display contrast.

STOP (short) Decrease the display contrast.

START (3 sec.) Accepts the shown display contrast.

STOP (3 sec.) Cancels the function.

Rev.: 2004-001-DE

18

7.3 System configuration / Change language

To show the system configuration menu, you have to select the System config. function:

Language GB <

To change the display language press START (short).

After selecting the language function from the system configuration menu the display will show a list of

language indicators.

>GB

SE

ES

The indicators stand for: GB = English, SE = Swedish, ES = Spanish, IT = Italian, DK = Danish, PT =

Portuguese, DE = German, FR = French, PL = Polish, TR = Turkish, RO = Romanian, etc. Please

note that only 7 languages are available.

START (short) Moves the cursor upwards.

STOP (short) Moves the cursor downwards.

START (3 sec.) Selects the marked language item.

STOP (3 sec.) Cancels the language menu.

Rev.: 2004-001-DE

19

8 Trouble shooting

8.1 Using and servicing the reading pen

Attention: Do not touch the contacts of the welding cable with the reading pen.

Using the reading pen:

Place the tip of the reading pen left or right beside the bar code. Move the reading pen with a constant

speed over the whole barcode. Do not stop the movement or lift the reading pen off.

Replace reading pen:

If the reading pen does not works properly you can replace it on your own. Slit open the shirk tube

which protects the plug with a sharp knife. Pay attention on the cables. Replace the reading pen and

test it before you mount the new shirk tube.

8.2 Replacing Welding Terminals

The welding plugs should be checked frequently. If necessary they can easily replace in no time.

1. Switch off the device and disconnect it from the mains supply or generator!

2. Slip off the PVC-cap over the welding terminal.

3. Hold the front part of the brass contact with a pipe wrench and screw the welding terminal with a 8mm-

wrench out of the brass contact.

4. The red welding cable has to be equipped by a welding terminal with detection tip! You have to use welding

terminals that are delivered by PF only!

5. Screw the new welding terminal tight into the brass contact and slip the PVC-cap over the welding terminal.

Pay attention, that the PVC-cap is slipped over so far, that the welding terminal is left blank for about 15mm.

1_0200_001 Welding Terminal 4.7mm, standard

1_0200_003 Welding Terminal 4.0mm, standard

2_0200_003 Welding Terminal 4.7mm, Fusamatic (with detection tip)

2_0200_004 Welding Terminal 4.0mm, Fusamatic (with detection tip)

1_0410_004 PVC-Cap, red

1_0410_003 PVC-Cap, black

8.3 Adapter

For different fitting types different adapters are needed. In the following table you will find a selection of

available adapters:

1_0300_009 Adapter 4.7/4.7 angle

1_0300_001 Adapter 4.7/4.0 angle

1_0300_004 Adapter 4.0/4.7 angle

1_0300_011 Adapter 4.0/4.0 angle

1_0200_005 FUSAMATIC-Adapter 4.7/4.7

1_0200_006 FUSAMATIC-Adapter 4.7/4.0

1_0200_007 FUSAMATIC-Adapter 4.0/4.7

1_0300_010 Adapter 4.0/4.7, straight

1_0300_003 Adapter 4.7/GF (lose ends)

1_0300_014 Adapter 4.0/GF (lose ends)

1_0300_002 Adapter 4.7/FF-flat

1_0300_012 Adapter 4.0/FF-flat

1_0300_008 Adapter 4.7/FF-pin

1_0300_013 Adapter 4.0/FF-pin

Rev.: 2004-001-DE

20

8.4 Start messages

After switching on the device the following message appears on the display:

PF Polymatic

Version 2.04ah

25 Working hours

Row 1 and 2 show the type and firmware revision of the control box.

Row 3 counts the total amount of working hours (summed up fusion times).

After ten seconds the above shown display will disappear.

If there occurred any error or change of the system configuration at the last welding before turning off

the device (e.g. Resistor error), this will be indicated by a message in the display once again:

Resistor error

at the last welding

process

After pressing the red STOP-key you are able to carry out a welding process.

This manual suits for next models

1

Table of contents

Other PF Welding System manuals