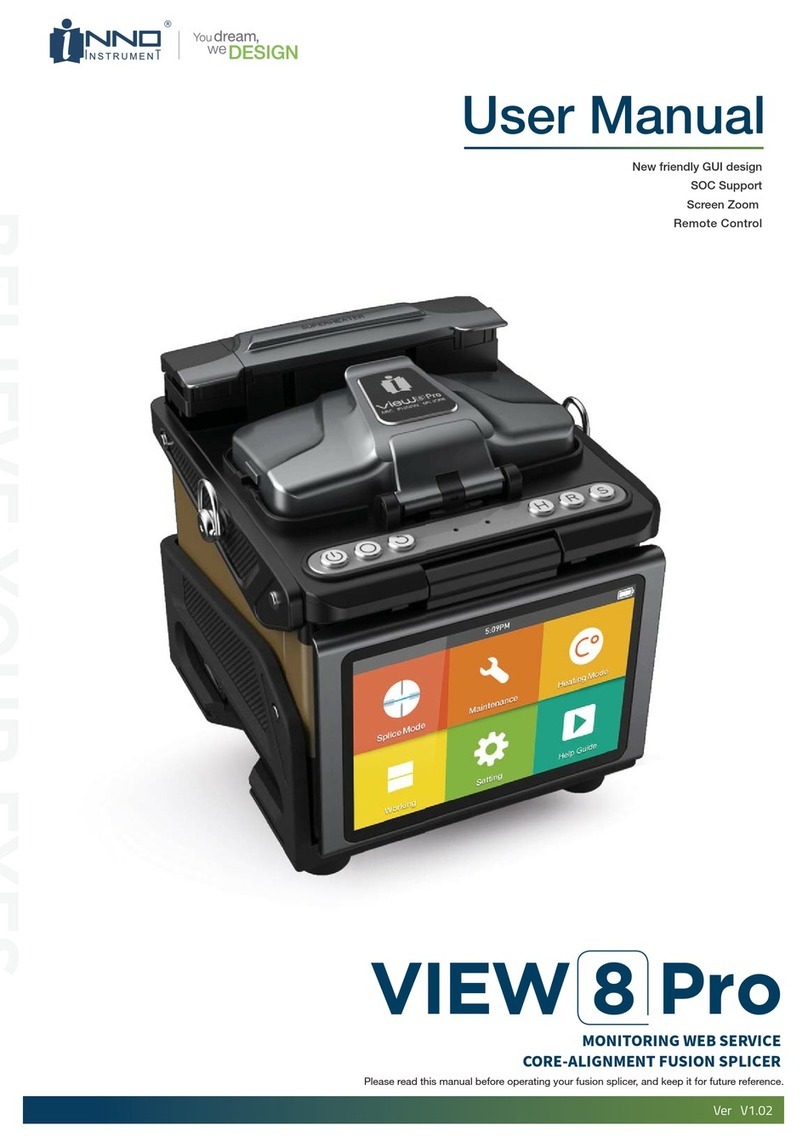

Cleaning before splicing

Maintenance menu

Maintenance

Diagnostic test

In case of trouble, proceed this procedure.

Operation procedure :

•Select [Diagnostic Test] in [Maintenance Menu] and execute [Diagnostic Test].

•LED Check

Measure and adjust the brightness of the illumination LED.

•Dust Check

Check the optical path for dust or dirt and judges whether they disturb ber observation.

If contamination exists, this function indicates the location.

•Motor Calibration

Automatically calibrate press motor movement.

•Arc Calibration

Automatically calibrate the arc power value.

•Upon completion of all checks and adjustments, a list of results is displayed. If the dust check result

is not good, clean the objective lenses. If the cleaning cannot eliminate contamination, there is a

possibility that the contamination may be in the inside of the optical path. Please contact your

sales agency for additional instructions. The dust check and motor calibration functions

exist as independent instructions in [Maintenance Menu]. It is possible to execute them

independently.

Note : Before you start test, remove the bers from the splicer. When the above item No. 2

(dust check) is completed, prepare and load the bers onto the splicer and press “SET”

V-grooves

Fiber clamp chips Wind proof cover mirrorsObjective lens

When lens is dirty, clean it.

Important: 1) Always use SM ber only 2) To keep in best splice condition, following the procedure.

CAUTION

During cleaning,

•Do not contact the electrode tips.

•Use only 99% or better purity alcohol.

•Clean by clean wipes (dustproof)

!

Objective lens

If lens is dirty, clean it periodically, with alcohol moistened thin cotton swab. Otherwise, the lens can

make trouble.

Electrodes

When “Replace Electrodes” message appears, or when the tip is damaged, replace electrodes.

•Execute [Replace Electrodes]

•Press “SET”. than automatically turns off

•Loosen screws

•Take out electrodes

•Put new electrodes

•Reassemble the electrode cover

•Tighten screws

•Turn splicer on

•Install prepared bers

•Execute [Stabilize Electrodes]

•Execute [Arc Calibration]

Battery pack

•Discharge battery pack completely every 3 months before recharging.

•When storing battery pack in long term;

•Storing temperature should be -20~30°C (-4~86°F)

•Recharge battery pack every 6 months, not to be empty.

Periodical maintenance

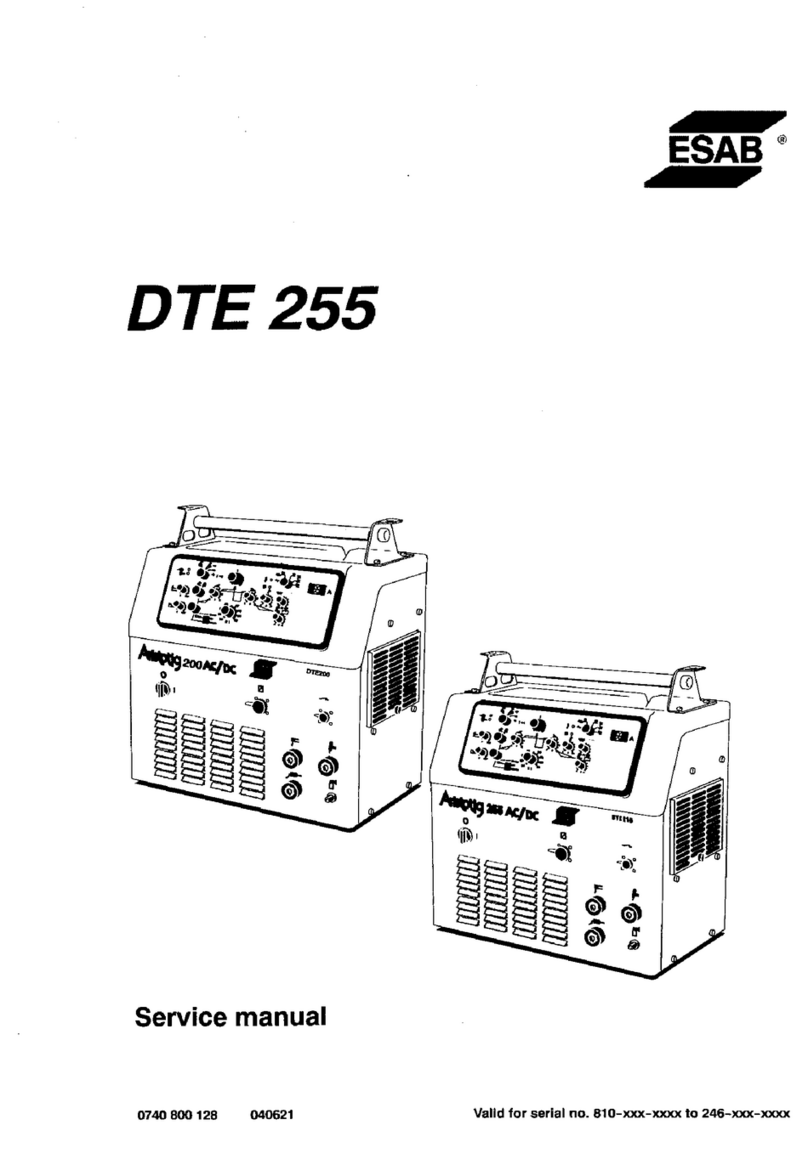

ARC Calibration

Standard value Value of machine

Start ARC calibration

Put the SM ber

Check the power of ARC

Value:

22 ± 2

Massage

“ARC Calibration Passed”

End the ARC calibration

Massage

“Place optical ber(SM),

press SET key”

Readjust the ARC value

up to effective range

Yes

No

IFS-10

Prepare SM ber and

go to “Main Menu”

Execute

[1.Quick Optimize]

Execute

[4. Stabilize Electrodes]

Execute

[9. Arc Calibration]