Index

Contents ..................................................................................Page

1Proper use............................................................................................................................. 4

2Specifications ....................................................................................................................... 5

3Disposal of Machine ............................................................................................................ 6

4Explanation of symbols....................................................................................................... 7

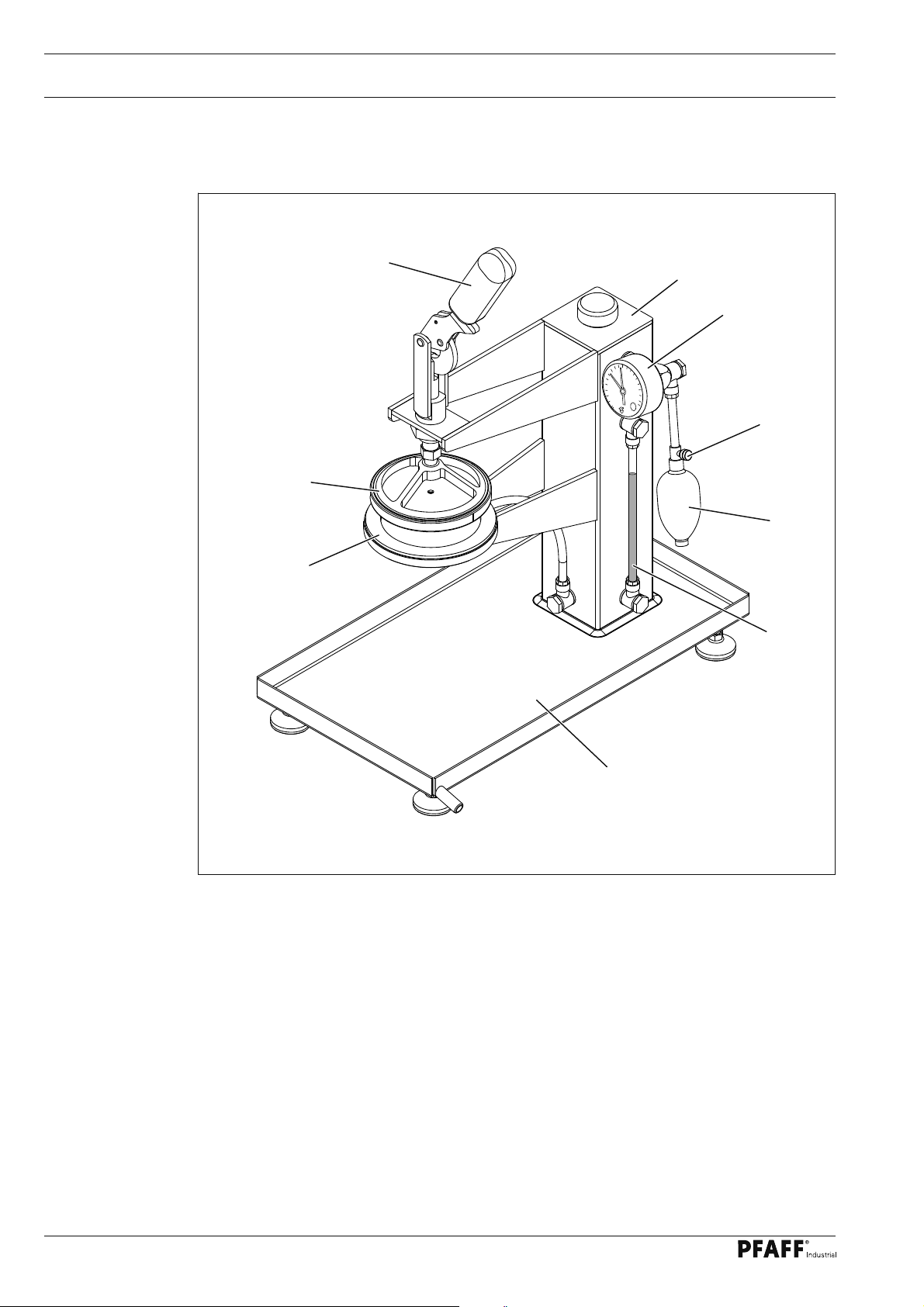

5Controls ................................................................................................................................ 8

5.01 Summary of controls (Version without pneumatics connection) ........................................... 8

5.02 Summary of controls (Version with pneumatics connection) ................................................ 9

6Preparation ......................................................................................................................... 10

6.01 Setting the test material thickness ...................................................................................... 10

6.02 Filling the water tank ........................................................................................................... 10

7Testing..................................................................................................................................11

7.01 Testing (Version without pneumatics connection) ............................................................... 11

7.02 Testing (Version with pneumatics connection)..................................................................... 12

8Maintenance....................................................................................................................... 13

8.01 Maintenance intervals.......................................................................................................... 13

8.02 Lubrication ........................................................................................................................... 13

8.03 Manometer replacement ..................................................................................................... 13

9Parts list .............................................................................................................................. 14