1

Introduction

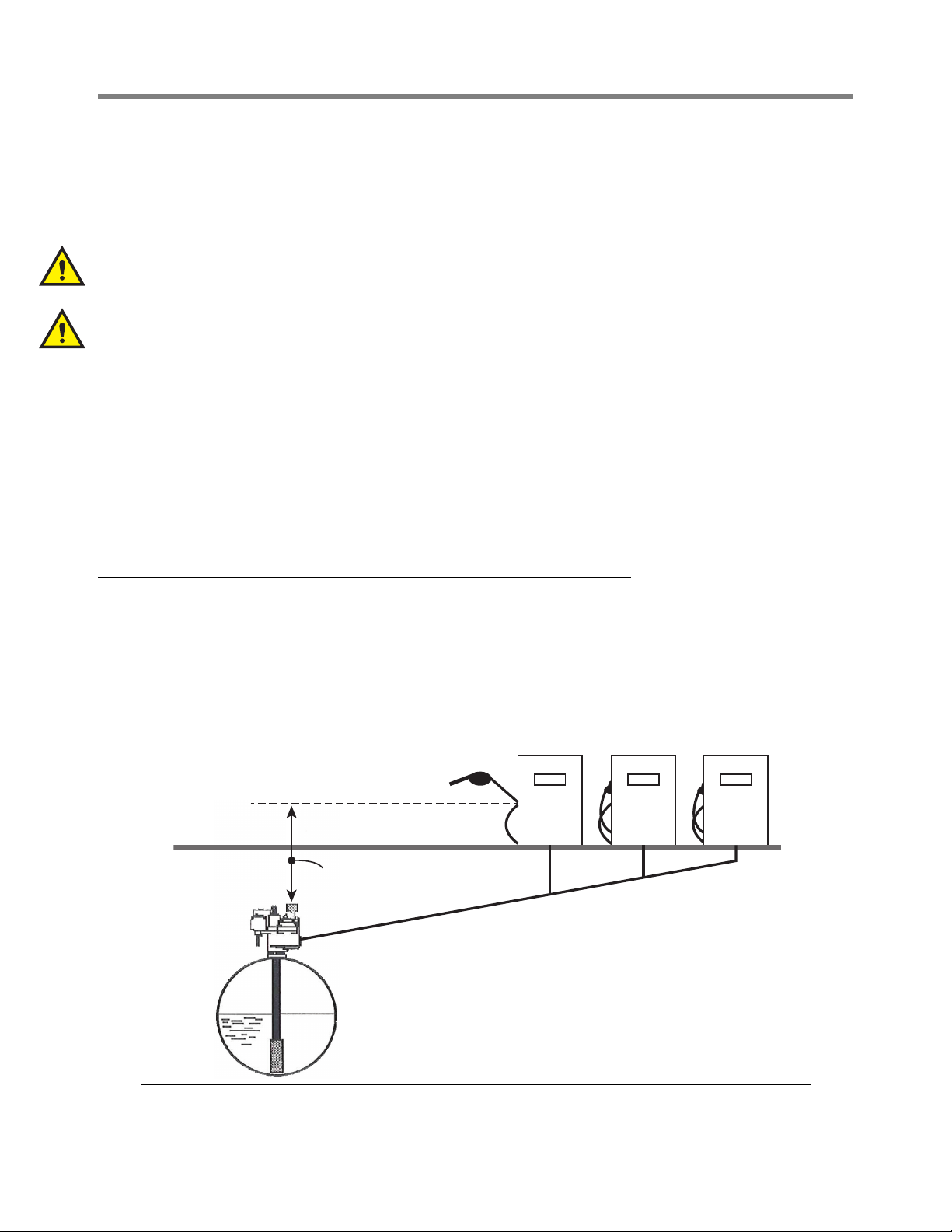

The FX Tester (FXT) has been specially designed to work with mechanical leak detectors to offer quick, clean,

easily performed, functional checks. Unique, secondarily contained dry break fittings, called Snap Tap Connectors,

attach to FX2V, and FX2DV (FX2 Series) leak detectors and the tank test port of the submersible pump, or at the

shear valve under the dispenser.

The FX2 Series allows the FXT to be connected to the piping system and perform a leak detector functionality test

without shutting down the submersible pump. Product spillage that occurs when installing other leak detector

testing equipment is avoided. Because the FXT system returns product to the tank during the test period, direct

handling of product used to simulate a leak is eliminated.

FXT Description

This report provides the procedure for functional testing of V-R mechanical leak detectors utilizing the FXT. In

addition to establishing that the unit is functioning, it provides for a demonstration of the leak detectable by subject

system under current conditions. The characteristics of the pumping system in which the line leak detector (LLD) is

installed will affect its performance. This procedure provides some evaluation of the pumping system as well as the

LLD. It can be utilized for further evaluation of the pumping system. Please note that the performance of the

procedures set forth in Section II, A and B is intended to satisfy functionality check requirements for

annual inspection of leak detectors. Section IV of Option A (RJ-21) and Section V-VI of option (RJ-20)

are also intended to satisfy the minimum requirement. For information on this as well as reference

information on the LLD and the pumping system in which it is installed, including symptoms, probable causes,

suggested action, see Red Jacket Mechanical Leak Detector Manual, #5191, and/or 5190

Option A, utilizing the Apparatus to Verify Operation (AVO) will provide a more basic, less extensive approach to

evaluating the V-R LLD. See Form RJ-21 for this basic procedure. Option B, utilizing the Field Test Apparatus

(FTA) offers a finite testing method, See Form RJ-20.

U.S. Environmental Protection Agency (EPA) Information

Under 40CFR280.44(a), EPA has:

1. Defined laboratory performance standards for automatic LLDs (out-of-the-box) prior to installation. V-R

mechanical leak detectors have been constructed to meet the EPA requirements as outlined in

40CFR280.44(a). A copy of our third-party certification is available upon request.

2. Stated that an annual test of the operation of the LLD must be conducted in accordance with the

manufacturer’s requirements.

The EPA requires “...that the LLDs be tested annually to insure that they are properly installed and maintained and

have not been tampered with and are operating in accordance with the manufacturer’s requirements”. In addition,

to assure maintenance of LLD capability, V-R requires that operation of the mechanical leak detector be verified

upon start-up and that testing of the LLD be performed routinely - at least annually. Section IV of Option A (RJ-21)

or Sections V and VI of Option B (RJ-20) or section II of this manual, are intended to meet the minimum

requirement for verifying the functionality of the LLD.

This report, as well as reports RJ-21 and RJ-20, provide the manufacturer’s requirements for testing V-

R mechanical LLDs. The procedures covered in this form and reports RJ-21 and RJ-20, supersede

previously issued procedures for testing V-R LLDs.

Competent mechanical leak detector evaluation requires A) that testing be performed by trained,

qualified personnel and B) consistent, proper procedures involving good maintenance and quality

control of equipment are utilized.

Education on this and all technical aspects of V-R petroleum submersible pumping and monitoring systems is

available.

NOTE