Pfaff Industrial 8306 User manual

8306

INSTRUCTION MANUAL

296-12-18 659/002

Instruction Manual engl. 11.11

Reprinting, reproduction and/or translation of PFAFF instruction manuals

(including parts thereof) is only permitted with our prior agreement and

citation of the source.

PFAFF Industriesysteme

und Maschinen AG

Hans-Geiger-Str. 12 - IG Nord

D-67661 Kaiserslautern

Table of Contents

Contents ..................................................................................Page

3

1Safety .................................................................................................................................... 5

1.01 Directives............................................................................................................................... 5

1.02 General safety instructions .................................................................................................... 5

1.03 Safety symbols ...................................................................................................................... 6

1.04 Special points of attention for the owner-operator ................................................................ 6

1.05 Operating personnel and technical staff ................................................................................ 7

1.05.01 Operating personnel .............................................................................................................. 7

1.05.02 Technical staff........................................................................................................................ 7

1.06 Danger warnings.................................................................................................................... 8

2Proper Use............................................................................................................................ 9

3Technical Datas................................................................................................................. 10

4Disposal of the Machine.................................................................................................... 11

5Transport, Packaging and Storage ................................................................................... 12

5.01 Transport to the customer's premises ................................................................................ 12

5.02 Transport within the customer's premises.......................................................................... 12

5.03 Disposal of the packaging materials .................................................................................... 12

5.04 Storage ................................................................................................................................ 12

6Work Symbols.................................................................................................................... 13

7Operating Controls ............................................................................................................ 14

7.01 Overview of the operating controls ..................................................................................... 14

7.02 Main switch ........................................................................................................................ 15

7.03 Roller feed of the belt transport .......................................................................................... 15

7.04 Control for the hot air pressure and feed roller pressure .................................................... 16

7.05 Control panel ....................................................................................................................... 16

7.06 Pedals ................................................................................................................................. 17

8Set-up and Initial Commissioning .................................................................................... 18

8.01 Set-up .................................................................................................................................. 18

8.02 Mounting the sealing tape reel bracket ............................................................................... 19

8.03 Connecting the compressed air........................................................................................... 19

8.04 Initial start-up ....................................................................................................................... 20

8.05 Switching the machine on/off.............................................................................................. 20

9Set-up.................................................................................................................................. 21

9.01 Inserting the sealing tape ................................................................................................... 21

9.02 Entering the sealing temperature ....................................................................................... 22

9.03 Entering the sealing speed ................................................................................................. 23

9.04 Further settings ................................................................................................................... 23

Table of Contents

Contents ..................................................................................Page

4

10 Sealing ................................................................................................................................ 24

10.01 Sealing principle................................................................................................................... 24

10.02 Sealing process.................................................................................................................... 24

11 Maintenance and Care....................................................................................................... 25

11.01 Maintenance intervals.......................................................................................................... 25

11.02 Cleaning ............................................................................................................................... 25

11.03 Checking / setting the air pressure ...................................................................................... 25

11.04 Emptying / cleaning the maintenance unit's water tank...................................................... 26

11.05 Fuses ................................................................................................................................... 26

12 Circuit Diagram .................................................................................................................. 27

Safety

5

1 Safety

1.01 Directives

The machine was built in compliance with the European regulations specified in the

conformity declaration and the manufacturer's declaration of conformity. As a supplement

to this instruction manual, please also observe the generally applicable, legal and other

regulations and legislation – also in the country of use – and the valid environmental

protection regulations! Always comply with the locally applicable regulations of the

professional associations and other supervisory authorities!

1.02 General safety instructions

●The machine may only be operated after you have become acquainted with the associ-

ated instruction manual and only by operating personnel who have received appropriate

training!

●Always follow the hazard and safety instructions attached to the machine!

●The machine may only be operated for its intended purpose and only with the associated

safety covers, while adhering to all the relevant safety requirements.

●Isolate the machine by pulling out the mains plug from the power supply when replacing

the feed rollers or hot air nozzle, when leaving the work station and for maintenance and

adjustment work!

●The daily maintenance work may only be carried out by suitably qualified personnel!

●The machine must be isolated from the power supply and pneumatic supplies before any

servicing work or repairs are performed! The only permitted exceptions are for adjust-

ment work and functional tests by appropriately trained technical staff!

●Repairs and special maintenance work may only be carried out by technical staff or peo-

ple with appropriate training!

●Work on electrical equipment may only be carried out by qualified technical staff!

●Work on parts and equipment under voltage is not permitted! Exceptions are regulated

by the EN 50110 standards.

●Modifications and changes to the machine may only be made in compliance with all of

the relevant safety requirements!

●Only the replacement parts approved by us for usage may be used for repairs! We warn

you expressly that spare parts and accessories that are not supplied by us are also not

tested and approved by us. Fitting and/or using these products may therefore have neg-

ative effects on features which depend on the machine design. We are not liable for any

damage caused by the use of non-Pfaff parts.

Safety

6

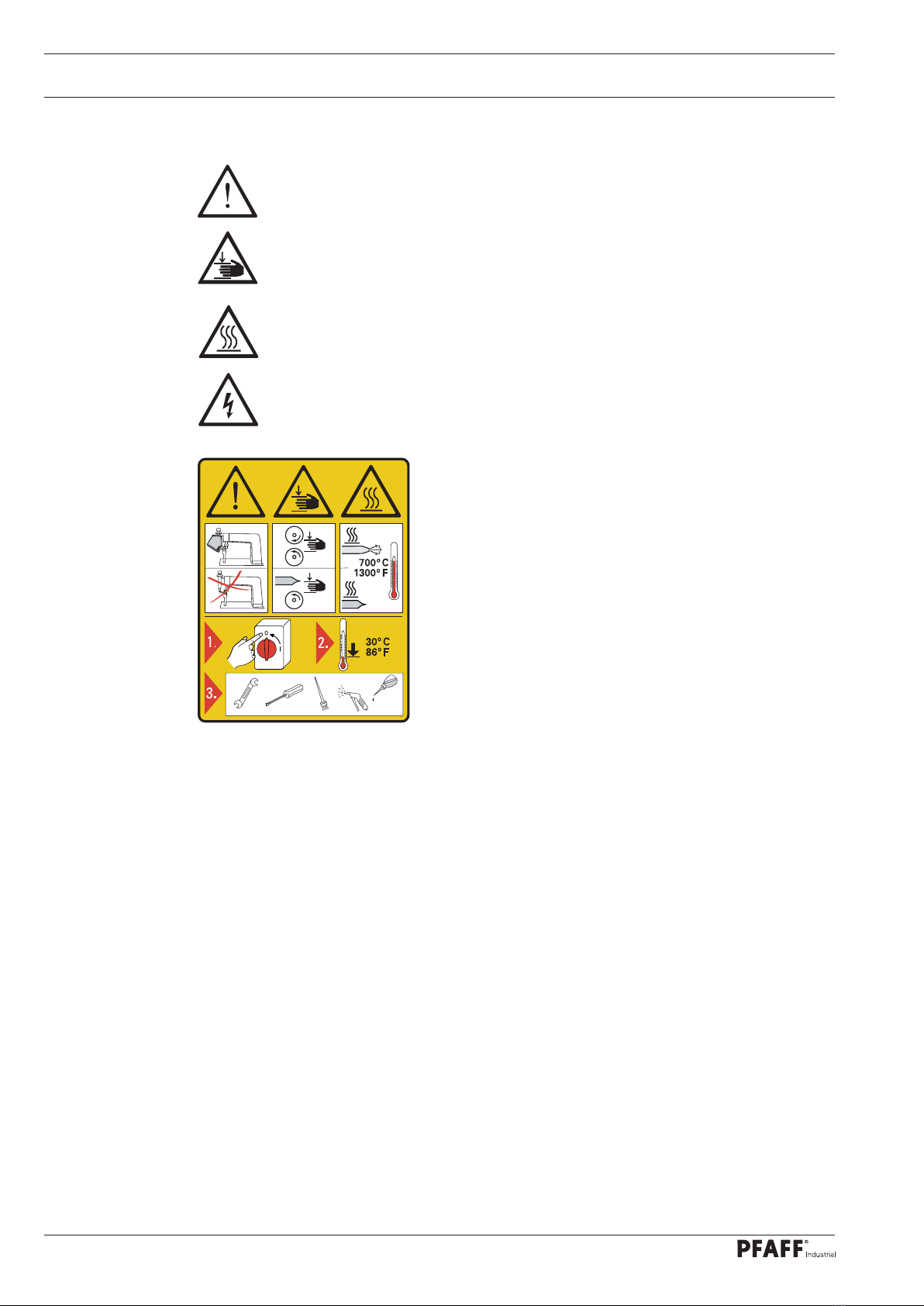

1.03 Safety symbols

Hazard point!

Special points of attention

Danger of hands being crushed!

Danger of burns from hot surface!

Fatal danger from electric voltage.

Caution!

Do not operate without finger guard and safety covers!

Turn off the main switch and let the machine cool

down before any set-up, maintenance and cleaning

work!

1.04 Special points of attention for the owner-operator

●This instruction manual is a part of the machine and must be made available to the

operating personnel at all times.

●The instruction manual must have been read before the initial start-up.

●The operating personnel and technical staff must be instructed about the machine's

safety covers and about safe working methods.

●The owner-operator may only operate the machine in a flawless condition.

●The owner-operator must ensure that no safety covers are removed or disabled.

●The owner-operator must ensure that only authorised persons work on the machine.

●The owner-operator must make sure there is no high-frequency sealing equipment be-

ing operated in direct proximity to the machine that exceeds the EMC limit values for the

machine according to EN 60204-31.

Additional information can be requested from the responsible sales centre.

Safety

7

1.05 Operating personnel and technical staff

1.05.01 Operating personnel

Operating personnel are persons responsible for setting up, operating and cleaning the ma-

chine and for clearing faults in the sealing section.

The operating personnel are obligated to comply with the following points:

●The safety instructions provided in the instruction manual must be followed for all work!

●Any work method jeopardising machine safety must be refrained from!

●Tight-fitting clothing must be worn. The wearing of jewellery such as chains and rings is

prohibited!

●Care must be taken to ensure that no unauthorised persons are located in the machine's

hazard zone!

●Any changes occurring on the machine which impair its safety must be reported to the

owner-operator immediately!

1.05.02 Technical staff

Technical staff are persons with technical training in electricity/electronics and mechanics.

They are responsible for lubricating, servicing, repairing and adjusting the machine.

The technical staff are obligated to comply with the following points:

●The safety instructions provided in the instruction manual must be followed for all work!

●Turn off the main switch and secure it against reactivation before starting any adjustment

and repair work!

●Never work on live parts and equipment! Exceptions are regulated by the EN 50110

standards.

●Reattach the safety covers following repair and maintenance work!

Safety

8

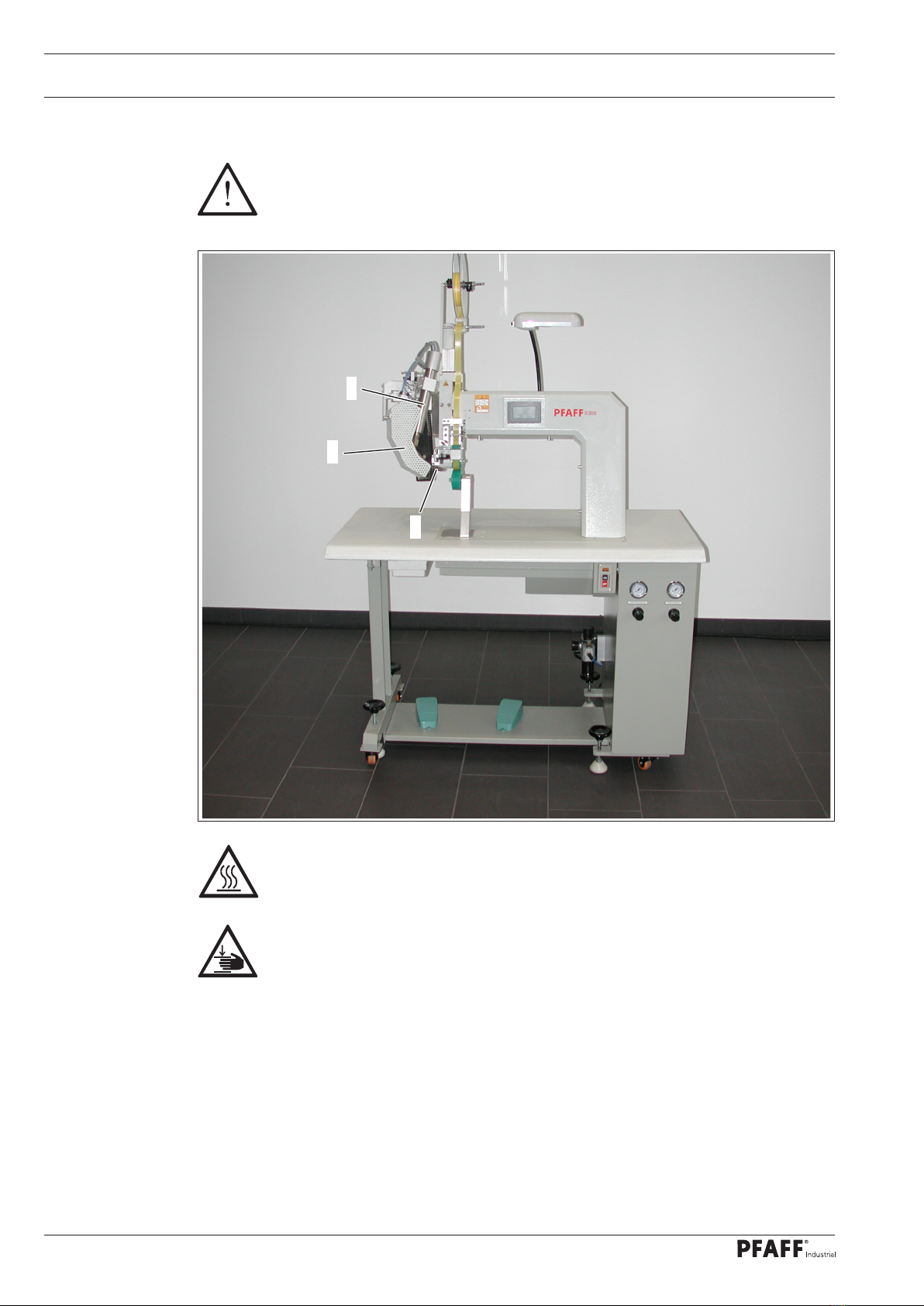

Fig. 1 - 01

1.06 Danger warnings

A work area of 1 m must be kept free in front of and behind the machine to

ensure unobstructed access at all times.

Do not operate the machine without the protective cover 1! Risk of burns when

touching the heating element 2!

Do not reach into the swivel range of the heating element 2and the swivel unit

3! Danger of crushing when engaging and disengaging the heating element!

1

2

3

Proper Use

9

2 Proper Use

The PFAFF 8306 is a hot air sealing machine with post.

The machine is used to heat-seal seams on water-repellent and breathable membrane

sheeting of all types, using a heat-sealing tape.

Any usage not approved by the manufacturer is deemed misuse! The manufac-

turer shall assume no liability for damage caused by misuse! Proper use also

includes compliance with the operating, maintenance, adjustment and repair

measures specified by the manufacturer!

Technical Data

10

3 Technical Datas

Dimensions and weights

Length:...........................................................................................................approx. 1350 mm

Width: ..............................................................................................................approx. 550 mm

Height (without tape reel bracket): ................................................................approx. 1780 mm

Passage width: ................................................................................................ approx. 420 mm

Passage between the rollers: ............................................................................approx. 20 mm

Working air pressure:............................................................................. min. 5.5 - max. 6.0 bar

Air consumption:.................................................................................................. 60 - 120 l/min

Sealing speed: ................................................................................................... max. 25 m/min

Sealing temperature: ................................................................................................. 0 - 700 °C

Connection data

Mains voltage (set for): ......................................................... 230 V ± 10 %, 50/60 Hz, 1 phase

Power consumption:.........................................................................................approx. 3600 W

Leakage current: .......................................................................................................... < 5 mAu

Noise data

Noise emission level at workplace: .................................................................. LpA < 70 dB(A)n

(Noise measurement in accordance with

DIN 45 635-48-A-1, ISO 11204, ISO 3744, ISO 4871)

Ambient temperature85% rel. humidity (condensation not permitted)....................... 5 - 40 °C

Net weight: ........................................................................................................ approx. 145 kg

sSubject to alterations

nKpA = 2.5 dB

uDue to the use of network filters there is a nominal leakage current of < 5mA

Table of contents

Popular Welding System manuals by other brands

Hobart Welding Products

Hobart Welding Products AirForce 375 owner's manual

GF

GF MSA 330 instruction manual

Hakko Electronics

Hakko Electronics FX-888D instruction manual

Abicor Binzel

Abicor Binzel ABIPLAS WELD 100 W operating instructions

EWM

EWM Taurus 355 Basic TDM operating instructions

Thermal Dynamics

Thermal Dynamics PakMaster 100 XL plus operating manual