User Manual

S310T0001, valid for S-310, S-311, S-314, S-315 and S-316

KSch, 10/15/2019

Physik Instrumente (PI) GmbH & Co. KG, Auf der Roemerstrasse 1, 76228 Karlsruhe, Germany Page 2 / 36

Phone +49 721 4846

Contents

About this Document 4

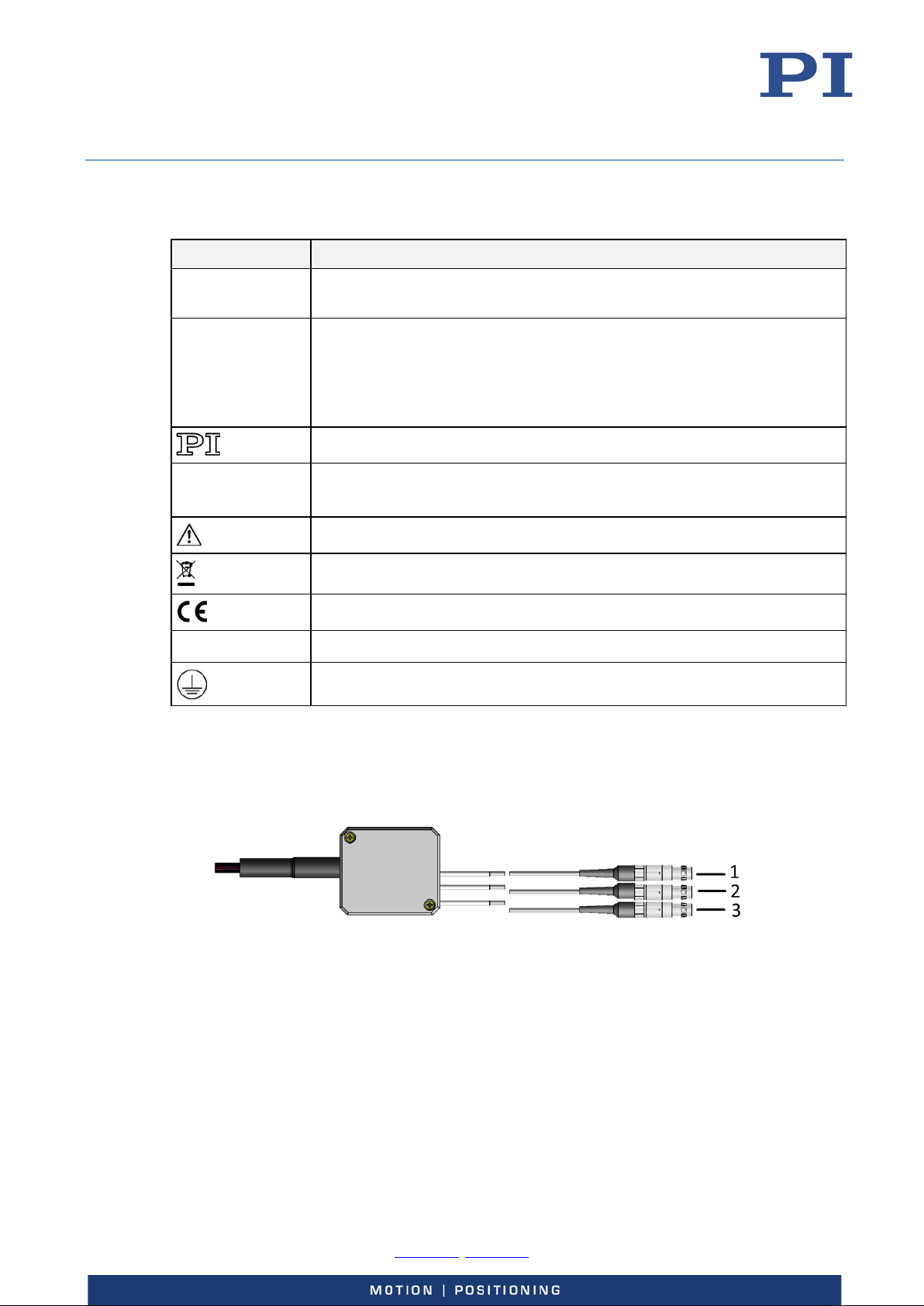

Symbols and Typographic Conventions............................................................................................................... 4

Other Applicable Documents .............................................................................................................................. 5

Downloading Manuals......................................................................................................................................... 5

Safety 6

Intended Use ....................................................................................................................................................... 6

General Safety Instructions ................................................................................................................................. 7

Organizational Measures..................................................................................................................................... 7

Product Description 7

Model Overview .................................................................................................................................................. 7

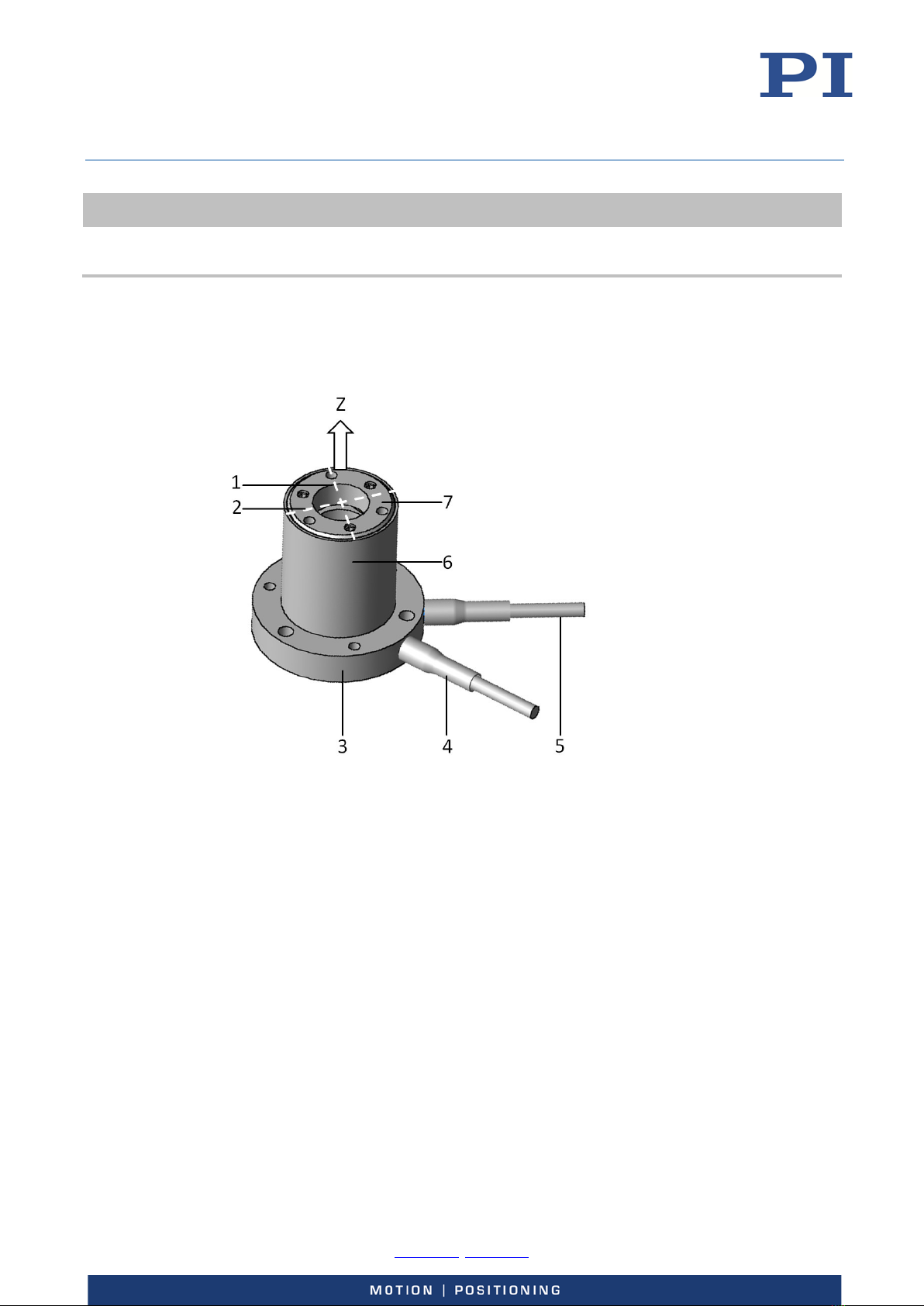

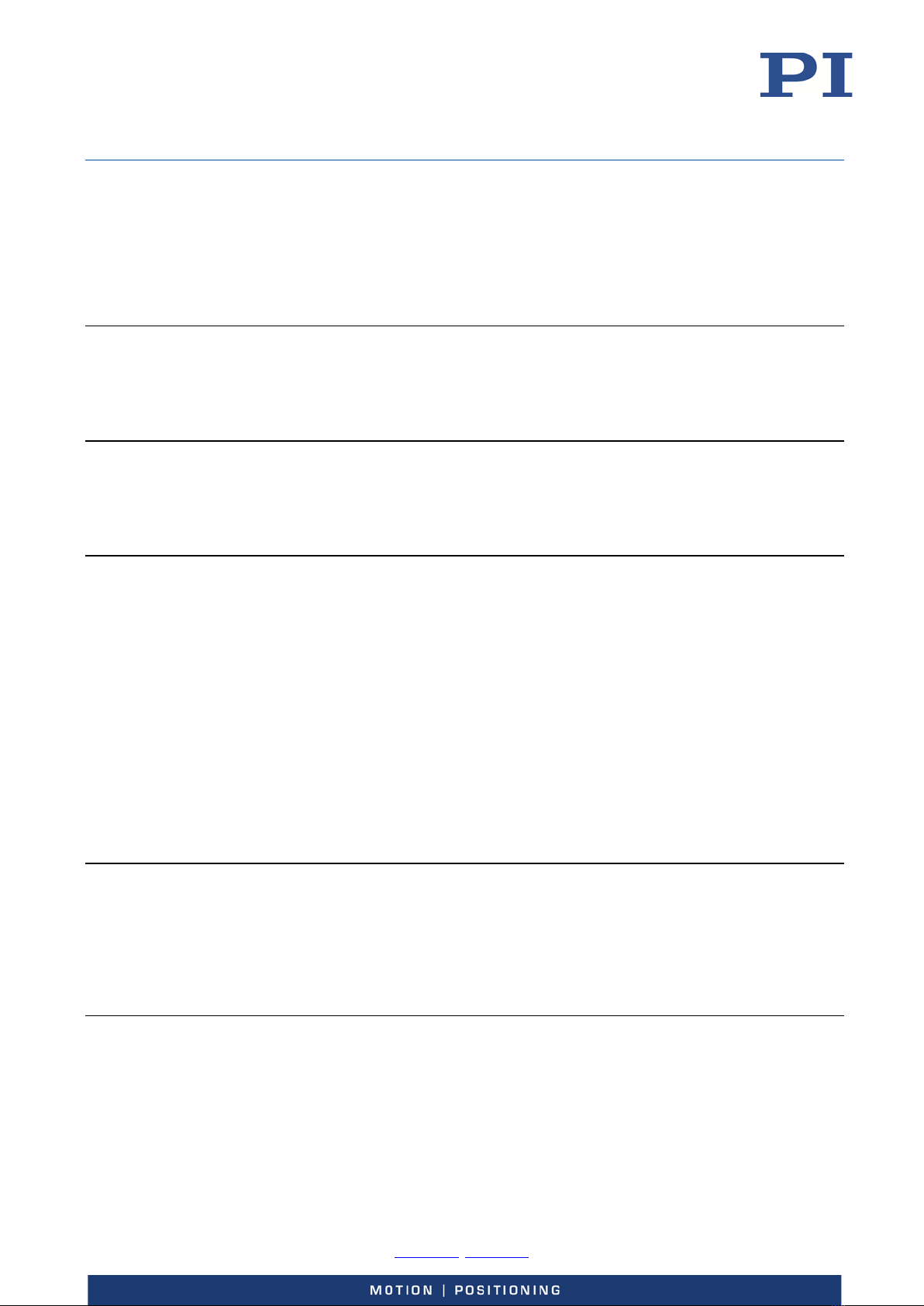

Product View ....................................................................................................................................................... 8

Product Labeling.................................................................................................................................................. 9

Scope of Delivery............................................................................................................................................... 10

Suitable Electronics ........................................................................................................................................... 11

S-310.10, S-314.10 ........................................................................................................................................................ 11

S-311.10, S-315.10 ........................................................................................................................................................ 11

S-316.10 ........................................................................................................................................................................ 11

S-316.10H...................................................................................................................................................................... 12

Control............................................................................................................................................................... 12

Dynamic Behavior.............................................................................................................................................. 15

Calculating Moments of Inertia for Mirror and Mirror Mount .....................................................................................15

Calculating the Resonant Frequency of the Tip/Tilt Platform.......................................................................................17

Installation 19

General Notes on Installation............................................................................................................................ 19

Grounding the S-31x.......................................................................................................................................... 20

Attaching the Mirror onto the S-31x ................................................................................................................. 21

Mounting the S-31x ........................................................................................................................................... 24

Connecting the S-31x to the Electronics............................................................................................................ 25

Start-Up and Operation 26

General Notes on Start-Up and Operation........................................................................................................ 26

Starting Up and Operating the S-31x................................................................................................................. 27

Discharging the S-31x ........................................................................................................................................ 27