Big Lift Big Joe M22 User manual

OPERATOR’S MANUAL

Big Lift LLC

www.bigjoeforklifts.com Manual Part No. 901638

08/16/2018

MANUAL PROPELLED

SEMI-ELECTRIC

STRADDLE

LIFT TRUCK

1

FOREWORD

As a lift truck operator, you are responsi-

ble for a machine that is useful, powerful,

and can be hazardous if not operated as

described. Your Big Joe truck may weigh

more than some cars, depending on the

model. Observing and practicing the

safety warnings in this manual cannot be

overemphasized. Just knowing the warn-

ings, however, is no substitute for common

sense. Using your common sense will, in

almost all cases, prevent accidents. Think

of the truck as your own. In this way you

will learn its capabilities and limitations.

This manual is intended to remain with the

truck at all times as a handy reference

guide to operation. Detailed maintenance

procedures are found in the parts and ser-

vice manual for the specific truck model,

and are to be performed only by a quali-

fied technician. For further information on

obtaining a complete parts and service

manual, see page 21 of this manual. The

operator who knows his truck will learn to

spot problems as they develop. This is

accomplished by performing the Daily

Checks and reporting any problems to the

designated authority.

TABLE OF CONTENTS

FOREWORD..........................................................................................................1

SAFETY SYMBOLS..............................................................................................2

GENERAL DESCRIPTION....................................................................................2

LOAD CAPACITY..................................................................................................4

BEFORE OPERATION..........................................................................................5

INSTRUMENTS AND CONTROLS.......................................................................7

OPERATION..........................................................................................................8

TRANSPORT............................................................................................8

OPERATING THE LIFT ............................................................................9

LOADING AND UNLOADING..................................................................9

PARKING..................................................................................................9

BATTERY CHARGING ...........................................................................10

MOVING A DISABLED TRUCK.............................................................10

.............................................................................................................................10

2

SAFETY SYMBOLS

WARNING and CAUTION are both signal words intended to alert the viewer to the exis-

tence and relative degree of a hazard. They are both preceded by a safety alert symbol

consisting of an exclamation mark enclosed by a triangle.

A Warning indicates a hazard which could result in injury or death if proper precautions are

not taken.

A Caution indicates a reminder of routine safety practices.

A prohibition slash (circle with diagonal slash through it) indicates a procedure or action

that should not be performed under any circumstances, as both personal injury and/or dam-

age to equipment will result.

GENERAL DESCRIPTION

Big Joe LLC M22 utilize the straddle leg

configuration, which normally straddles

the load.

The mast handles are used to help control

the lift truck. The control handle is used to

propel and steer the lift truck. Lift and

Lower are controlled by a lever located

near the operator.

The model number will be found on the

name plate along with the serial number,

lifting capacity and load center.

If the name plate or warning decal are lost

or damaged they should be replaced

immediately. Have your supervisor or the

designated authority contact Big Joe

Authorized Dealer for replacement

.

Name Plate

N

3

This truck is equipped with a battery. Read and heed the following warning plus any other

warnings located near or on the battery. An example is shown here:

WARNING:

4

LOAD CAPACITY

The further the load center is from the

backrest, the lower the load capacity. The

load center must also be no higher than

that specified above the lifting surface

(Top side of forks). For example, a load

capacity of 2200 pounds with a load cen-

ter of 24 inches means that the truck can

be used to lift 2200 pounds only when the

load’s center of gravity is no more

than 24 inches from the face of the forks

or 24 inches above the top side of the

forks. Note that a truck under-going speed

changes is less stable than a standing

truck. If you are not sure that the truck can

lift a certain load, consult your supervisor

or the designated authority.

An overload can cause machine damage

and stability loss or tipping of the lift truck.

Load Center

R3814

5

BEFORE OPERATION

The table on page 6 covers important

inspection points on the truck which

should be checked prior to operation.

Depending on use, some trucks may

require additional checks.

The illustration below shows a sample for-

mat for an Operator Checklist, which can

be modified as necessary to fit your opera-

tion.

Periodicmaintenanceofthistruckby

a QUALIFIED SERVICE TECHNI-

CIAN is required.

A QUALIFIED SERVICE TECHNI-

CIANshouldcheckthetruckmonthly

for proper lubrication, proper fluid

levels, brake maintenance, motor

maintenance and other areas spec-

ified in the parts and service manual

maintenance section.

Ifthetruckisfoundtobeunsafeand

inneedofrepair,orcontributestoan

unsafe condi-tion, report it immedi-

atelytothe designated authority. Do

not operate it until it has been

restored to a safe operating condi-

tion. Do not make any unauthorized

repairs or adjust-ments. All service

must be performed by a qualified

maintenance technician.

If the truck has not been used for a long

time (more than a month), regular battery

maintenance should be performed.

Sample of Operator Check List

WARNING:

WARNING:

WARNING:

6

Operator Checks

ITEM PROCEDURE

Key Switch Check that key switch disconnects & restores

truck power when turned off and on.

Battery capacity Before operation, turn on key switch and

check that the electric capacity is enough. If

low, recharge the battery.

Hydraulic system Check for signs of fluid leakage.

Forks Check for cracks and damage and that they

are properly secured.

Chains, cables and hoses Check that they are in place, properly secured

and not damaged.

Guards Check that safety guards are in place, prop-

erly secured and not damaged.

Safety signs Check that warning labels, nameplate, etc.,

are in good condition and legible.

Wheels Check drive wheel for cracks or damage.

Move truck to check load wheels and casters

for freedom of rotation.

Lift and Lower Check operation of lift and lower to their maxi-

mum positions.

Floor Lock Check that floor lock holds the truck station-

ary.

7

INSTRUMENTS AND CONTROLS

The instrument panel contains the key

switch,lift/lowercontrollever,voltmeterand

charging indicators.

The foot actuated floor lock is used to hold

thetruckstationary.Theoperatormasthan-

dles located on each side of the mast are

used to help control the truck.

Thespringloadedsteeringhandleisusedto

propel and steer the lift truck. It is linked to

the left caster to provide steer tracking.

Control Handle

Battery Indicator

R6733

8

OPERATION

TRANSPORT

Moving and Stopping

NOTE: Thetruckshouldonlybeoperated

on a level surface.

1. Turn on the key switch and check that

the electric capacity is enough. If low,

recharge the battery

2. Checkthattheloadisinthedownposi-

tion before traveling.

3. Release the floor lock.

4. Apply pressure to the steering handle

andmasthandlestomovethetruckfor-

ward. Pull evenly on the steering han-

dle to move the truck backward.

5. To stop the lift truck, hand restraint

against the steering handle and mast

handles is usually adequate.

6. After the lift truck has stopped, always

engage the floor lock before lifting or

lowering and when parking.

7. Turn off the key switch to prevent bat-

tery drain and to prolong the service

life.

M22 Lift Truck

R6733

9

Turning

1. Release the floor lock.

NOTE: Turning and maneuvering the lift

truck is made easier if the truck is

in motion.

2. Begin rolling the truck and simultane-

ously apply side pressure to the steer-

ing handle to cause the caster wheels

to swivel.

OPERATING THE LIFT

WARNING: Check the space above

the load on the forks to

ensure that the load will

notstrikeanyobstruction

while being raised.

1. Turn the key switch ON.

2. To raise the forks, pull the lift con-trol

back and hold until the forks reach the

desiredheight.Theforkswillraiseata

fixed speed. Return the lift control to

the neutral position.

3. To lower the forks, push the lift control

forward and hold until the forks reach

the desired level. The lowering speed

can be controlled by the lever. Return

the lift control to the neutral position.

LOADING AND UNLOADING

1. Move the truck to the location where

the load is to be picked up.

2. Adjust the forks to the maximum prac-

tical width to support the load.

3. Raisetheforkstothedesiredheightfor

entry under the load.

4. Move the lift truck into position so that

the forks are centered under the load.

5. Move the lift truck forward to place the

loadasfarbackaspos-sibletowardthe

lift carriage. Raise the forks to lift the

load.

CAUTION: To avoid spilling the load,

moveslowlyand useextra

caution when turning.

6. Move the lift truck backward from the

loading position.

7. Whentheloadisclearofitsrack,lower

the load, leaving enough floor clear-

ance to maneuver the truck.

8. Push or pull the truck carefully to the

area where the load is to be placed.

9. Alignthelifttruckwithits new position.

10. Raise the forks to the desired height

andslowlymovethe lifttruckinto posi-

tion for off-loading.

CAUTION:Theloadmustrestsquarely

on its rack when it is low-

ered into position.

11. When the load is in position, lower the

forksuntilthepalletrestsonitsrackand

the forks are free.

12. Slowly move the lift truck back-ward,

checkingthattheforksdonotcatchon

the pallet or rack.

13. Lower the forks when they are clear.

14. Proceed to move the next load.

PARKING

When finished with moving loads, lower

the forks and move the lift truck to its

maintenance or storage area. Engage the

floor lock. Turn off the key switch. Charge

the battery if required.

10

BATTERY CHARGING

Refer to DOC 245 for battery safety and

maintenance.

Turn on the key switch when charging the

battery. Charge for 3 to 5 hours (but not

more than 24 hours).

NOTE: Battery charging instructions are

contained in the service manual.

MOVING A DISABLED TRUCK

Do not attempt to move a disabled truck;

notify your supervisor or proper authority.

11

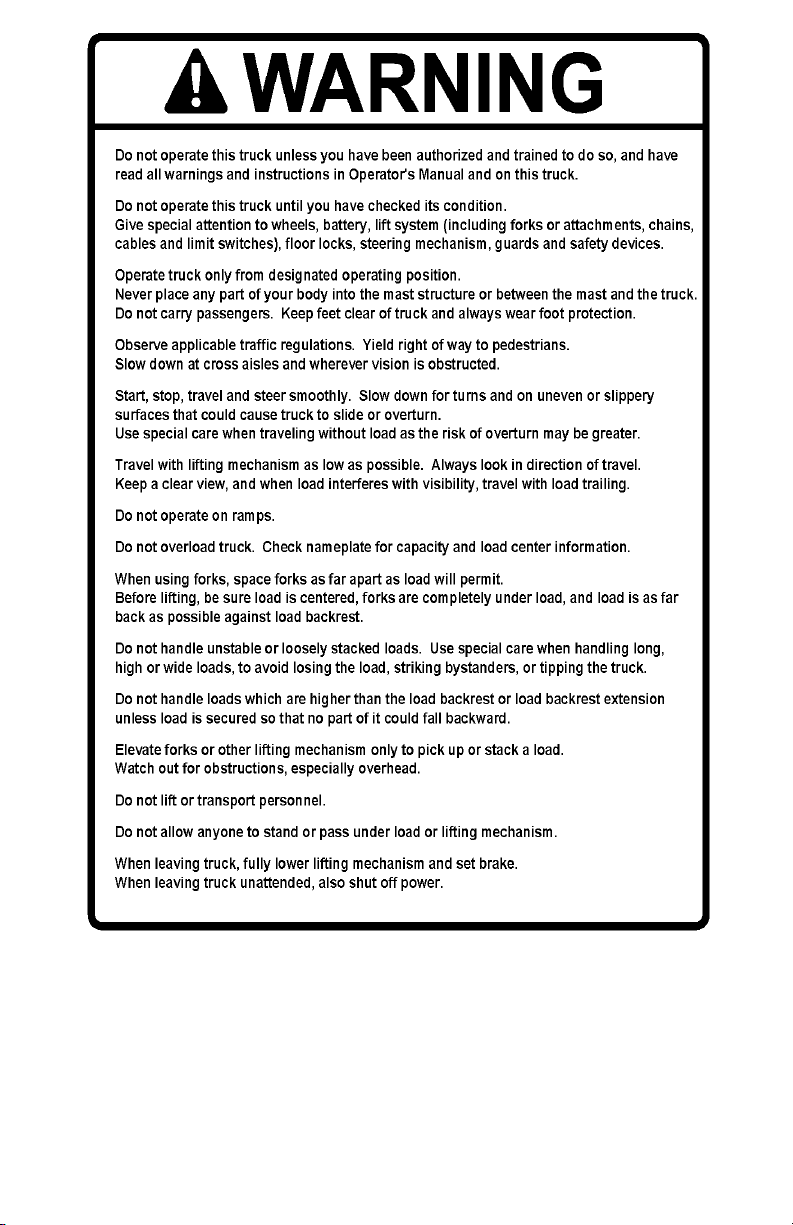

The following operating instructions should be followed at all times when using truck.

Do not operate this truck

unless you have been

trained and authorized to do

so, and have read and un-

derstand all warnings and

instructions contained in

this operator’s manual.

R6733

Do not operate this truck un-

til you have checked its con-

dition. Give special attention

to tires, horn, lights, battery,

controller, lift systems (in-

cludingforksorattachments,

chains, and cables), floor

lock, steering mechanism,

guards and safety devices. If

you have any questions, no-

tifyyoursupervisor or proper

authority.

R6733

12

R7184

Never place any part of the

body into the mast structure.

R7185

Do not carry passengers.

13

R7186

Keep feet clear of truck and

always wear foot protection.

R7187

Observe applicable traffic

regulations. Yield right-of-

way to pedestrians. Slow

down and at cross aisles

and wherever vision is ob-

structed.

14

R7188

Start, stop, travel, steer

and brake smoothly. Slow

down for turns and on un-

even or slippery surfaces

that could cause truck to

slideoroverturn.Usespe-

cial care when traveling

without load as the risk of

overturn may be greater.

R7189

Travel with lifting mecha-

nism as low as possible.

Alwayslookindirectionof

travel. Keep a clear view,

and when load interferes

with visibility, travel with

load or lifting mechanism

trailing.

15

R7190

Do NOT operate on Ramps!

R7191

Donotoverloadtruck.Checknameplateforloadweight

capacity and load center information.

16

R7192

When using forks,

space forks as far apart

as load will permit. Be-

fore lifting, be sure load

is centered, forks are

completely under load,

andloadisasfarbackas

possible against load

backrest.

R7193

Do not handle unstable or

loosely stacked loads. Use

special care when handling

long, high or wide loads to

avoid losing the load, strik-

ing bystanders or tipping

the truck.

17

R7194

Do not handle loads which

are higher than the load

backrest or load backrest

extensionunlessloadisse-

cured so that no part of it

could fall backward.

R7195

Elevate forks or other lift-

ingmechanismonlytopick

up or stack a load. Watch

out for obstructions, espe-

cially overhead.

18

R7196

Donotliftpersonnelwith

this truck. It is not de-

signed for this function

and someone could get

seriously injured if they

fell off. Use the correct

equipment for this task.

R7197

Donotallowanyonetostand

orpassunderaloadorlifting

mechanism.

Table of contents

Other Big Lift Lifting System manuals