2

CONTENTS

INTRODUCTION .............................................................................................................................................................3

PREREQUISITES ................................................................................................................................................................4

INTENDED USE ................................................................................................................................................................4

INSTRUCTIONS FOR USE ...........................................................................................................................................4

DEFINITION .......................................................................................................................................................................4

SAFETY ...............................................................................................................................................................................4

ELECTRICAL SPECIFICATIONS ....................................................................................................................................5

MIXER SPECIFICATIONS ...............................................................................................................................................5

THERMOSTATIC MIXER SPECIFICATIONS ...........................................................................................................5

TRANSPORT AND STORAGE ..................................................................................................................................... 6

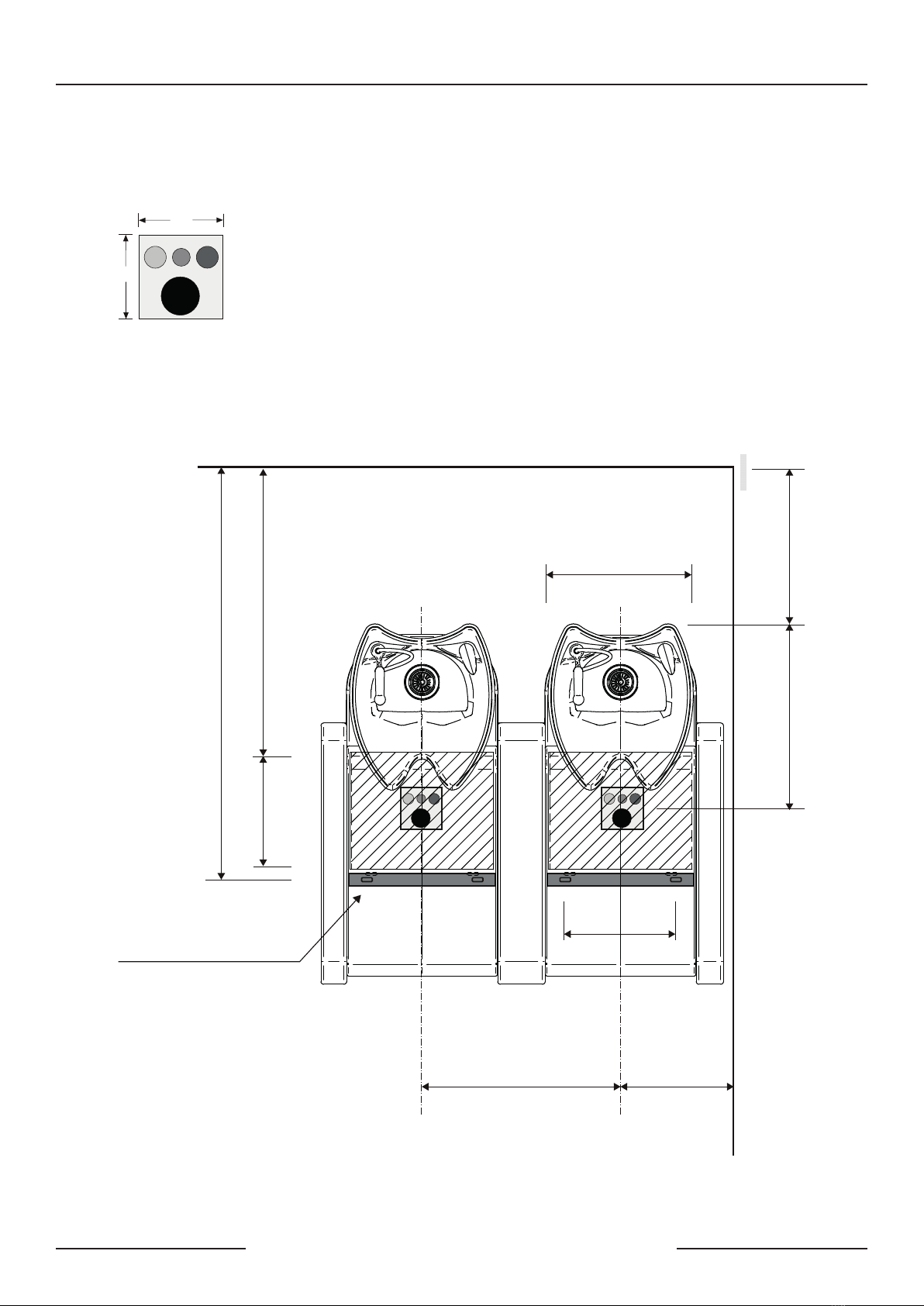

DIMENSIONS ....................................................................................................................................................................6

INSTALLATION SURFACE ..............................................................................................................................................7

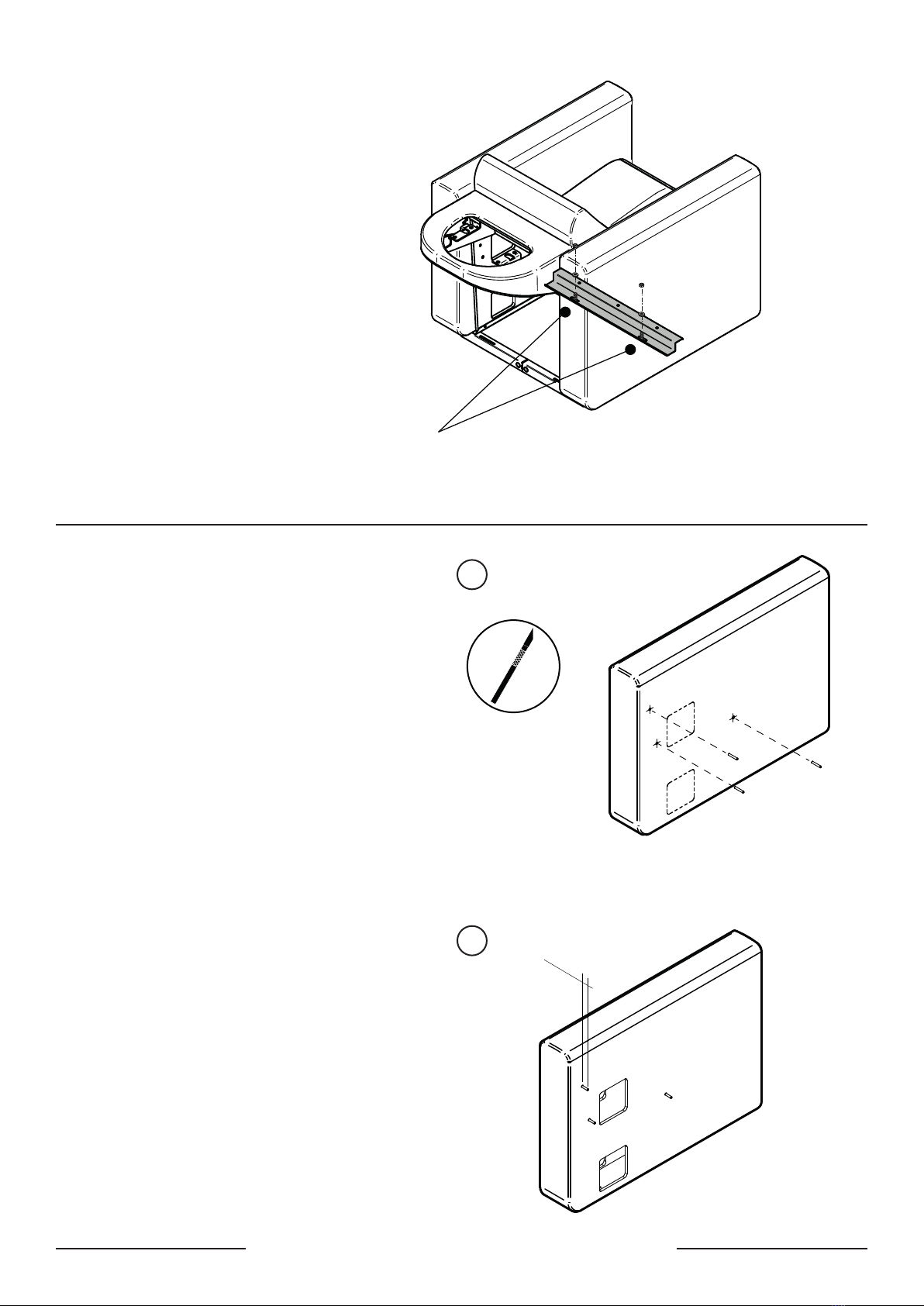

PREPARATION ..................................................................................................................................................................9

WASH UNIT ATTACHMENT ........................................................................................................................................9

BASIN ASSEMBLY .........................................................................................................................................................10

DRAIN ASSEMBLY ........................................................................................................................................................12

FLOOR DRAIN ...............................................................................................................................................................13

WALL DRAIN ..................................................................................................................................................................14

ELECTRICAL CONNECTION ........................................................................................................................................15

TESTING ...........................................................................................................................................................................16

USE .....................................................................................................................................................................................16

SWITCHING ON THE EQUIPMENT .........................................................................................................................16

RELAX CONTROLS ........................................................................................................................................................17

JET MASSAGE CONTROLS .........................................................................................................................................18

ROUTINE MAINTENANCE ..........................................................................................................................................19

CHAIR ...............................................................................................................................................................................19

WASHBASIN UNIT .........................................................................................................................................................20

CLEANING THE SURFACES .........................................................................................................................................20

ELECTRICAL FUNCTIONS ........................................................................................................................................21

IDENTIFICATION OF THE EQUIPMENT ................................................................................................................21

INSTRUCTIONS FOR DISPOSAL .............................................................................................................................21

Instructions for Installation, Use and Maintenance