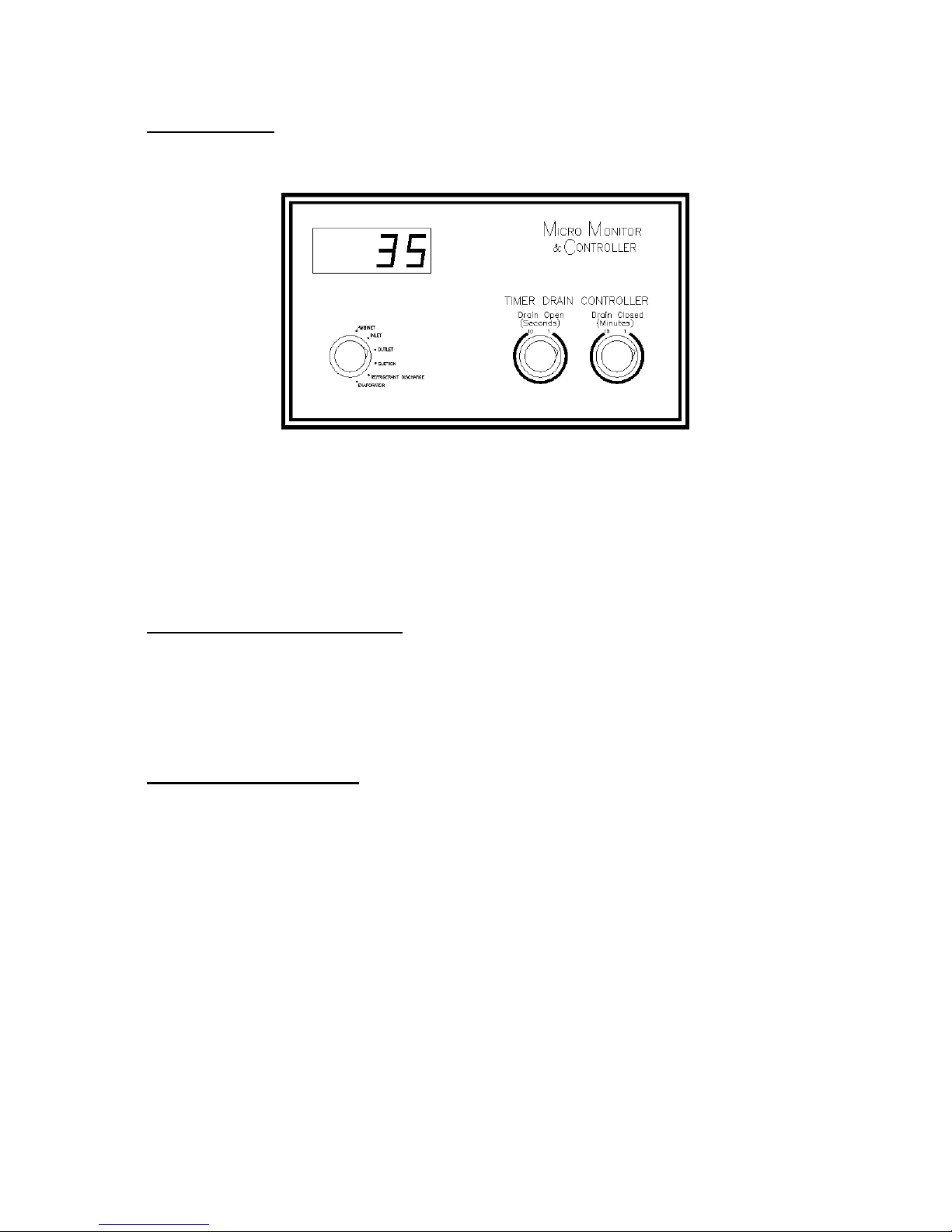

Micro-Monitor: The Pioneer Micro-Monitor is standard in models R75/ADR40 and larger

(optional in smaller sizes). The dryer operation and performance are shown at a glance by selecting the

desired reading.

Maintenance

To maximize system performance and reliability, the following maintenance procedure is required:

Air and water cooled condensers must be inspected and cleaned periodically. Inspect and replace

prefilter and after-filter elements periodically (recommended monthly). To avoid downtime, always

keep spare elements in stock.

Automatic Drain Maintenance: The float type automatic drain is standard in models R10 and

R15. Clean drain periodically to ensure proper functioning. Remove air pressure before loosening the

separator bowl. In models R20 and larger, the three step automatic drain is standard. It includes an

isolation valve, a cleanable strainer, and a timer operated solenoid valve. Close the isolation valve before

removing and cleaning the strainer. Models R800/ADR400 and larger have an additional manual drain

on the air-air heat exchanger.

10-year Limited Warranty

A 10-year prorated heat exchanger warranty (through R5000/ADR2500) and a 10-year prorated

compressor warranty apply on standard Pioneer products. Pioneer standard dryers are warranted to be

free from defects in material and workmanship for a period of one year from the date of shipment (15

months for distributor stock units), provided the equipment is used according to the company’s

recommended usage. Liability is limited to the repair, refund, or replacement in kind at the company’s

sole option. In no event will Pioneer be liable or responsible for incidental and consequential damages,

even if the possibility of such has been made known to the company. The usual maintenance and

replacement-type products are not covered by this warranty. To protect this warranty, use genuine

Pioneer accessories and spare parts. One year mechanical parts only warranty applies to equipment

outside the U.S.A., Mexico, and Canada. Extended warranties are available. Contact your distributor for

details.

Please notify your distributor or the factory before working on equipment. Unauthorized work may

not be covered and may void the warranty. Please contact the factory to obtain a return merchandise

authorization number (RMA#) before returning equipment.

Caution: A refrigerant compressor operating under sustained overload conditions caused by excessive

airflow, high inlet air temperature, and/or ambient temperature will continue to work at a higher

8