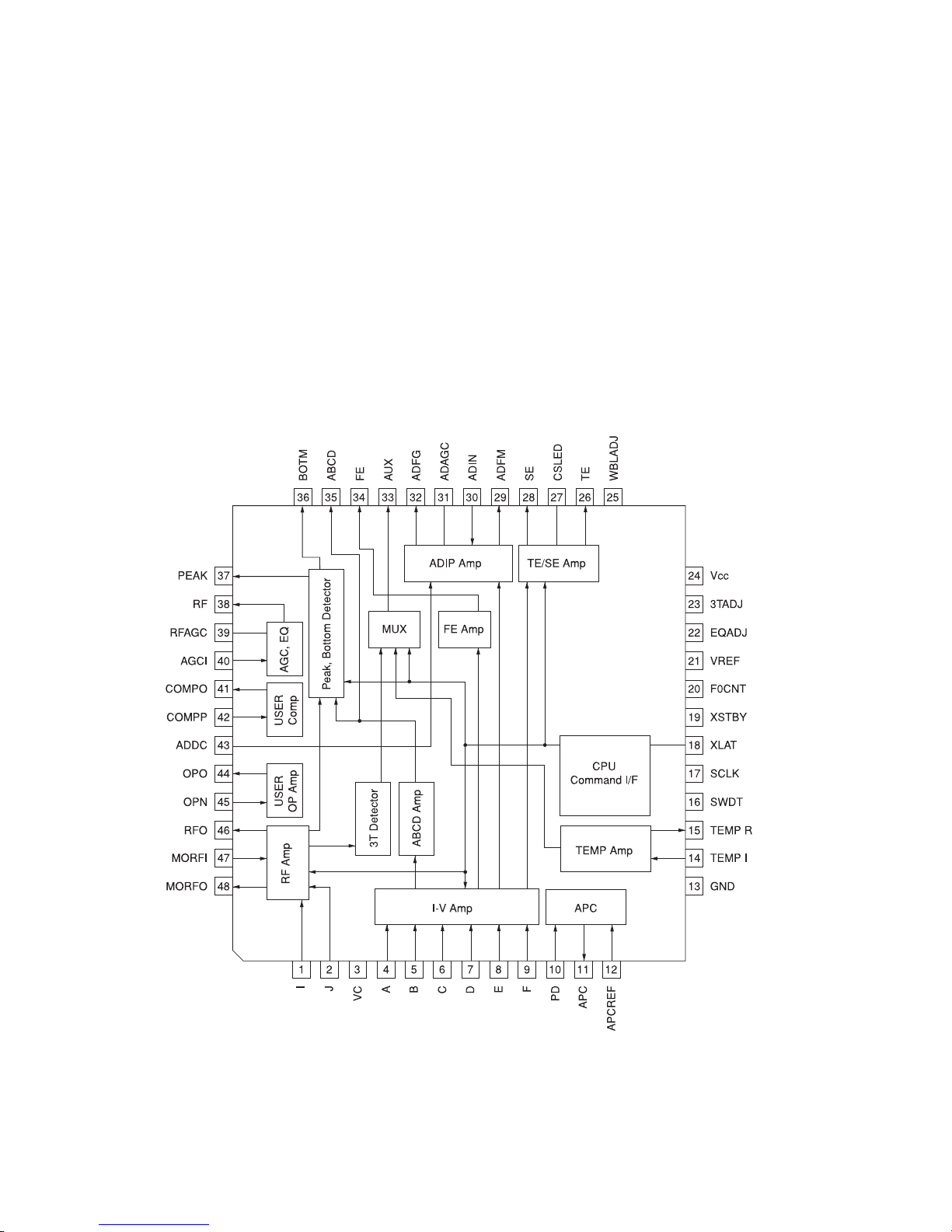

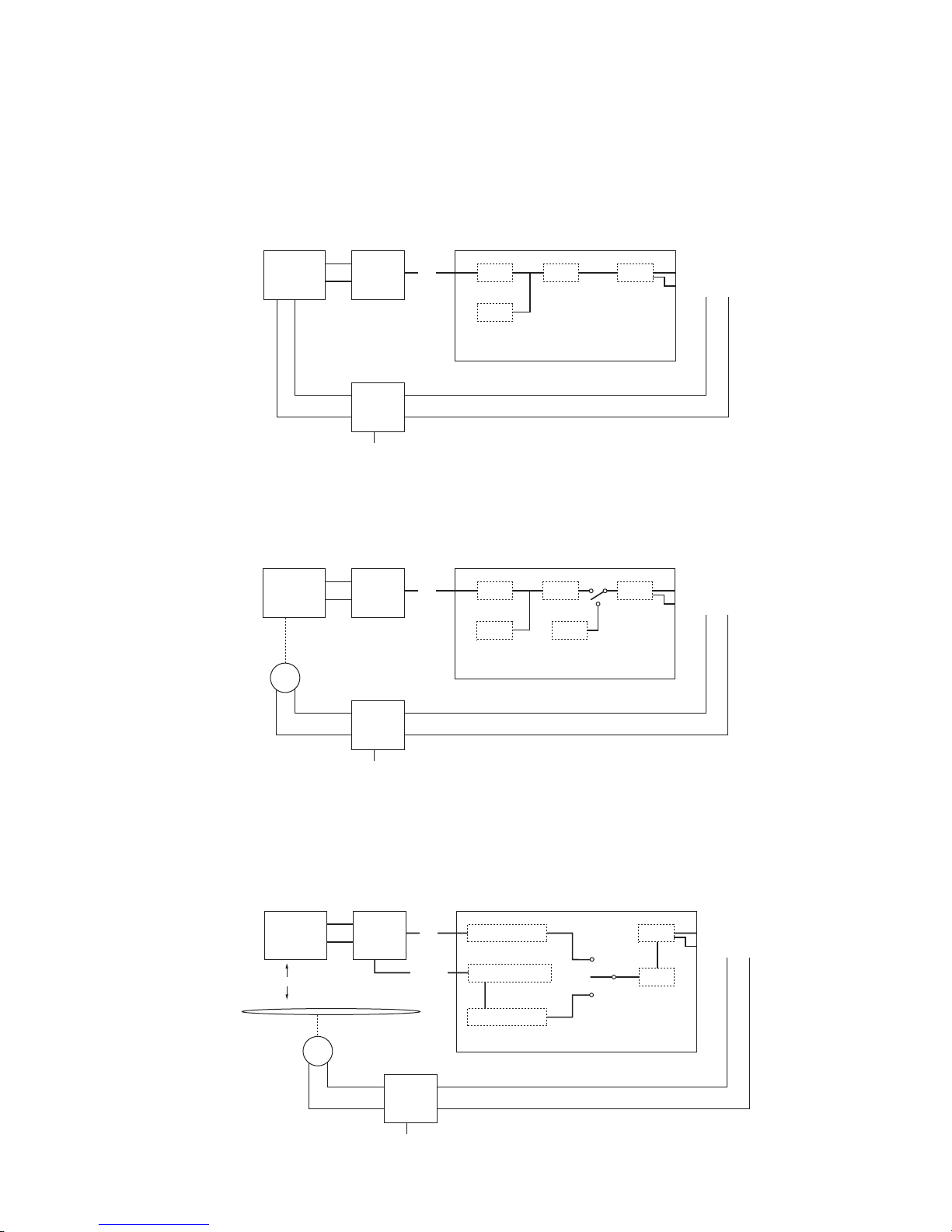

2) Automatic Adjustment Function

This mechanical module implements the following automatic adjustments using the RF amplifier, servo IC and

microcomputer. This function is intended at ensuring stable play by eliminating variations in sounds that can result

from conditions of given environment or discs as well as aged deterioration of the module.

Whenever a disc is inserted, this adjustment is carried out in the following sequence.

1) Offset adjustment

* Electric offset being output from the RF amplifier is adjusted to 0V seen from the reference voltage.

* This adjustment is automatically executed in the IC according to VC, FE and ABCD instructions from the microcomputer.

2) IV adjustment

* Gain of the RF amplifier’s current/voltage converter AD is adjusted to approximately 500 mV for pre_disc and

approximately 800 mV for rec_disc using the ABCD (full quantity of light) signal (64 pin) at LD_off as the reference.

* This adjustment is automatically carried out when the IC sends the command to the RF amplifier in response to the

instruction from the microcomputer.

3) Tracking balance (EF.B) adjustment

* In this adjustment, gain of E signal on the RF amplifier is varied so that TE signal may become evenly balanced

against VC (reference voltage, 67 pin) in terms of both plus and minus.

* This adjustment is automatically carried out when the IC sends the command to the RF amplifier in response to the

instruction from the microcomputer.

4) Focus AGC (F.AGC)

* This adjustment is done to maintain loop gain of the focus servo at a constant level so that stable focus servo

function may be ensured.

* Gain adjustment is done by injecting disturbance generated in the IC to the focus servo loop.

* This adjustment is automatically implemented by the IC according to the instruction from the microcomputer.

5) Focus bias adjustment (F.BIAS)

* This function is used for adjusting jitter of EFM signal to an optimum level by optimizing the focus point during play.

The microcomputer performs this adjustment by detecting phase and level of I3 signal from the RF amplifier and that

of FE signal.

6) Tracking AGC (T.AGC)

* This function maintains loop gain of the tracking servo at a constant level to ensure its stable function.

* Gain of the tracking servo is adjusted to a constant level by injecting disturbance generated in the IC to the tracking

servo loop.

* The IC automatically implements this adjustment according to the instruction from the microcomputer.