Pirate C Series User manual

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

User’s Manual

Read Manual

Failure to read, understand &

follow all safety and operation

procedures in this manual can

cause serious injury or death.

Manuals that are lost,

incomplete, or damaged must

be replaced immediately.

Manual P/N: PB-MAC001

Abrasive blasting can create dust that may contain

toxic materials from abrasive material and the

surface being blasted. NEVER use abrasives

containing high amounts of crystalline silica

including silica sand/beach sand for abrasive

blasting. Airborne crystalline silica causes silicosis,

a fatal respiratory disease. Abrasive blasting can

create high levels of noise that may cause hearing

damage. Always use proper safety equipment

including respiratory protection, hearing protection,

and comply with local, regional and national safety

codes. Ensure all operators of the equipment are

properly trained and everyone in the area including

bystanders are protected from the hazards of

abrasive blasting. The manufacturer, wholesaler

and distributor assume no responsibility arising

from the failure to comply with this warning.

C-Series - 3.0 / 6.0 Cu Ft Abrasive Blasters

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

2

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

Using This Manual

Thank you for your purchase of a Pirate Brand® CPR Series Blaster. It is important to note that

all Pirate Brand® blasting equipment is designed to be safe when used properly, however, misuse of any

abrasive blasting equipment is dangerous and can result in the severe injury or death of the operator and

others in the vicinity of the blasting equipment. In order to protect yourself and those around you, read

and follow all sections of this manual & warning labels located on the blasting equipment.

Denition Of Terms Used In This Manual

Abrasive: A granular material used for blasting the surface of an object. Also referred to as “Media.”

Blow-down: The automatic or manual release of air from a pressurized vessel. Also referred to as “Depressurize.”

Control Handle: A required device that allows the blaster to be remotely started and stopped. Also referred to as

“Deadman.”

Depressurize: The automatic or manual release of air from a pressurized vessel. Also known as “Blow-down”.

Pressure Hold System: Any blasting system in which the Pressure Vessel remains pressurized when the control

handle is released. Also known as a Manual Blow-down System.

Pressure Release System: Any blasting system in which the Pressure Vessel is automatically depressurized when

the control handle is released. Also known as an Automatic Blow-down System.

Pressure Vessel: The enclosed area of the blaster in which abrasive is contained and lled with pressurized air when

blasting.

Pressurize: To ll the pressure vessel with compressed air.

Properly Trained: A person who can be considered “properly trained” must have successfully completed a

sandblasting training course that focuses on the safe operation of stationary or portable abrasive blasters in the 0.5 -

6.0 cu ft capacity range. They must also have read and understood this manual in its entirety.

Silica: A hazardous substance which is contained in many naturally occurring abrasives. Dust produced by blasting

with abrasives containing silica can cause respiratory disease. Do not use abrasive containing silica under any

circumstance, even when respiratory protective equipment is being used.

Safety Symbols

The safety symbols shown below exist for the safety and protection of the operator and those in the

vicinity of the Abrasive Blaster. The descriptions below explain how they are used in relation to the

blasting equipment.

WARNING: This symbol calls attention to a

potentially hazardous situation that could result

in serious injury or death if the instructions

associated with the symbol are not followed. The

warning triangle will be displayed throughout the

manual to denote instructions to which special

attention should be paid.

DANGER: This symbol calls attention to a

potentially hazardous situation that WILL result

in serious injury or death if the instructions

associated with the symbol are not followed. The

warning triangle will be displayed throughout the

manual to denote instructions to which special

attention should be paid.

OR OR

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

3

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

• All persons who will be operating or will be in the vicinity of the Abrasive Blaster during its

operation must receive proper training on how to safely operate the equipment and be informed

of the potential hazards involved. In addition to proper training, all persons who will be operating

or will be in the vicinity of the Abrasive Blaster during its operation must read, understand and

follow all procedures described in the user’s manual. For replacement manuals, please contact

your distributor or visit www.pirate-brand.com.

• Respiratory protection is mandatory for all persons operating or located in the vicinity of the

Abrasive Blaster. Follow all OSHA and NIOSH requirements for breathing equipment and

supplied air standards.

• Pressurized Vessels contain large amounts of stored energy and can cause severe injury or

death if safety procedures are not followed. Never perform maintenance or attempt to open

a Pressure Vessel for any reason while it is Pressurized. Always Depressurize and properly

disconnect equipment from its air source before performing any maintenance. Do not modify,

grind or weld on the pressure vessel for any reason. Doing so will void the ASME certification.

Do not use damaged pressure vessels.

• The use of proper remote control systems (commonly referred to as Dead-man controls) are

required when using abrasive blasters. Never operate the Abrasive Blaster without remote

controls.

• All persons who will be operating or will be in the vicinity of the Abrasive Blaster during its

operation must protect themselves with the proper safety equipment and use of common sense.

Safety equipment including but not limited to Hearing, Eye, Body and Lung protection are

required. Abrasive blasters and the objects being blasted can be heavy and can lead to severe

injury or death if they fall over. Always follow all safety requirements of OSHA and NIOSH.

• Use only Genuine Pirate Brand® replacement parts when performing maintenance on the

Abrasive Blaster. Do not modify the equipment for any reason. Use of modified or non-Pirate

Brand® parts can cause an unsafe situation and will void your warranty.

• Never use malfunctioning or damaged equipment. Before each use, inspect the Abrasive

Blaster for proper function.

• Supply only cool, dry, compressed air that is free of debris to the Abrasive Blaster. Moisture

or debris that reaches the remote control system can cause an unsafe situation. Do not supply

compressed air to the blaster that exceeds 150 psi.

• Do not use abrasive blasters in areas that could be considered a hazardous location as

described in the National Electric Code NFPA 70, Article 500. Never use the Abrasive Blaster in

wet environments. Always connect electrically controlled abrasive blasters to a Ground Fault

Circuit Interrupter (GFCI).

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

4

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

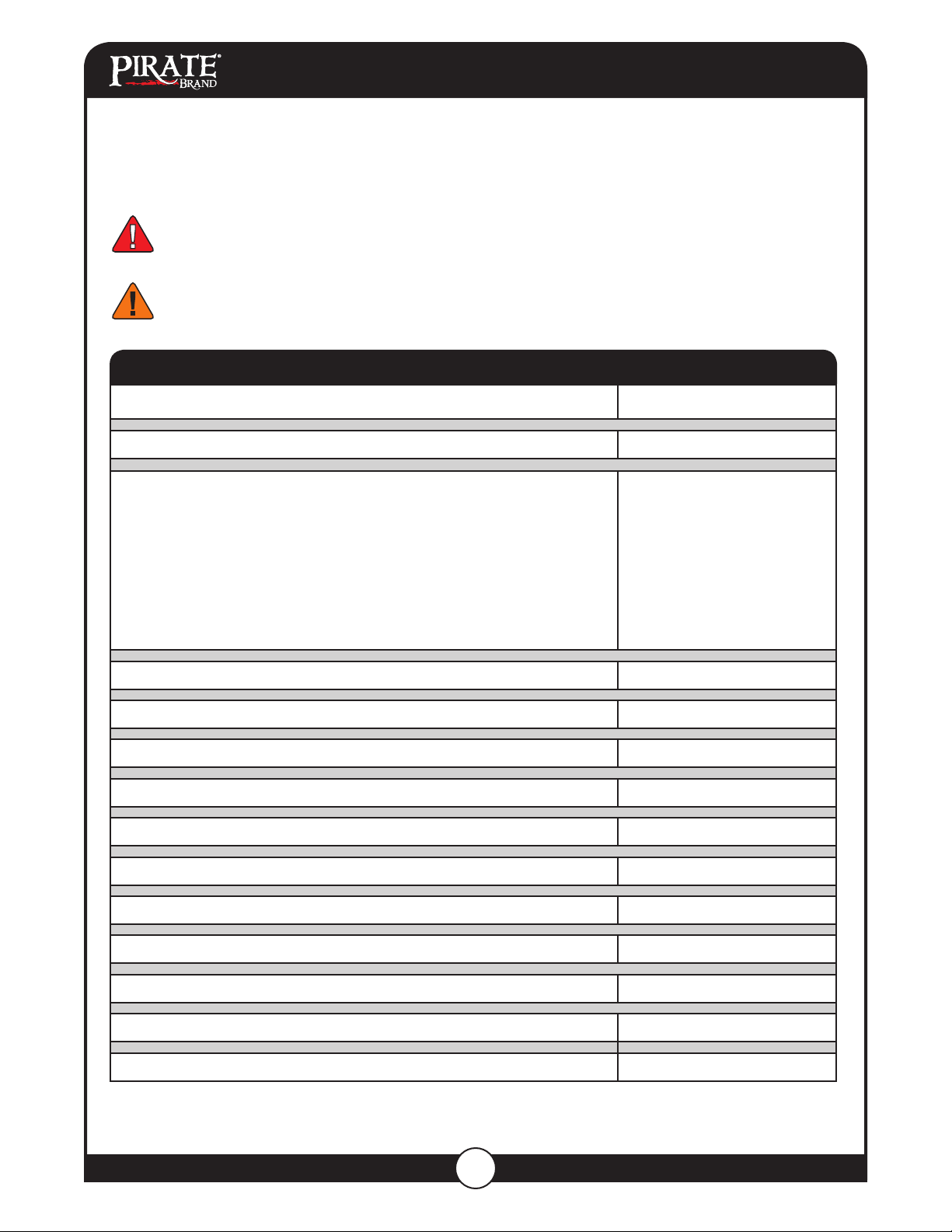

Table Of Contents

Using This Manual

Denition Of Terms

Safety Symbols

WARNINGS

Safety Label Information

How CPR Systems Work

OPERATING PROCEDURES

Set-Up 8

Before You Blast 9

Blasting 10

MAINTENANCE PROCEDURES

TROUBLESHOOTING

Warranty

Pressure Vessel Parts Lists

Pipe String Parts Lists

3.0 Cu Ft Pneumatic Controls 18

6.0 Cu Ft Pneumatic Controls 20

Electric Controls 22

MPV Metering Valve Option 23

Valve Parts Lists

Control Handle Parts Lists

Blasting Set-Up

Available Accessories

Blasting Chart

2

2

2

3

5

6

8

12

14

16

17

18

24

31

32

34

36

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . .

. . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

Distributed By:

Contact Info:

For manual updates visit the

Pirate Brand® website at:

www.pirate-brand.com

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

5

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

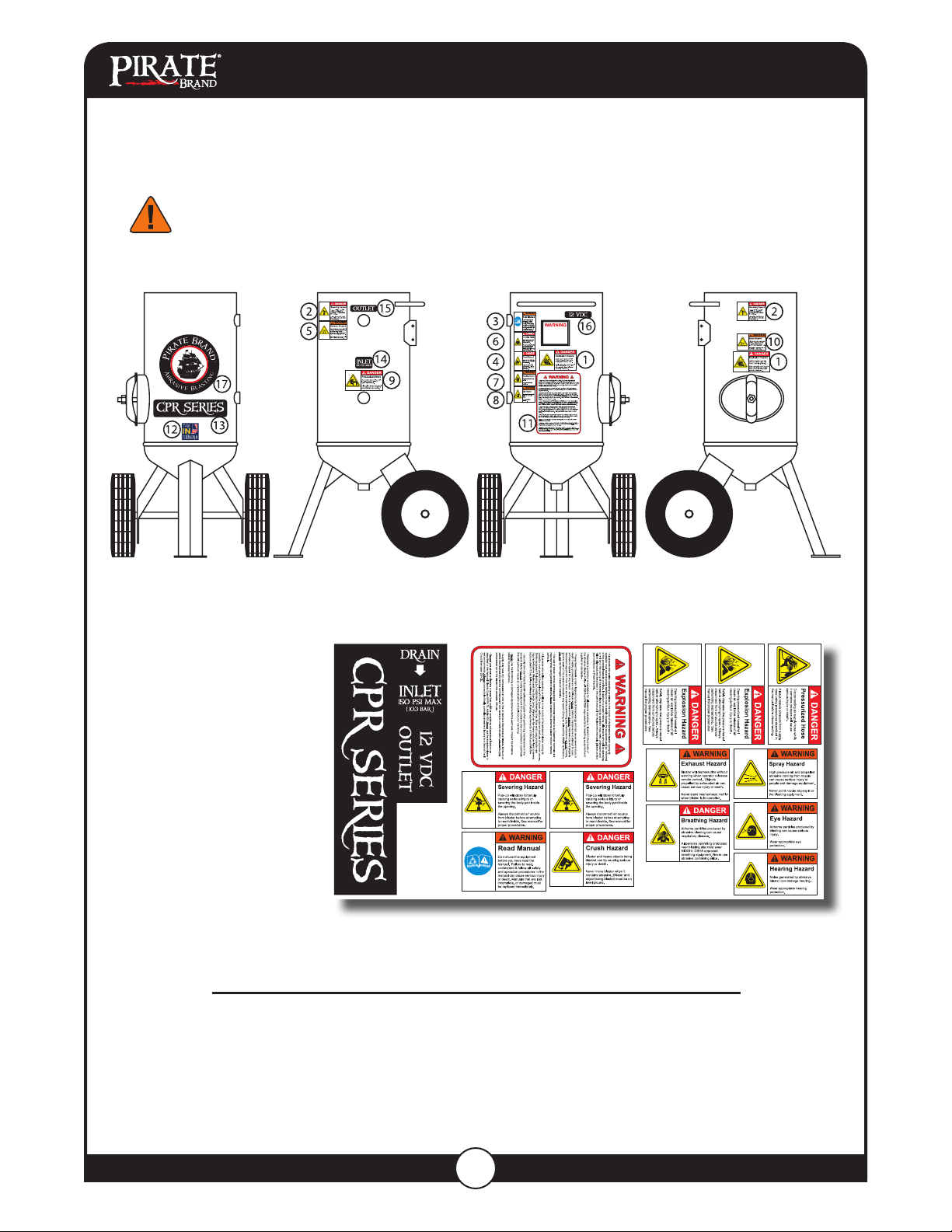

Warning Label Locations

1 - Explosion Hazard (X2)

2 - Severing Hazard (X2)

3 - Read Manual

4 - Crush Hazard

5 - Exhaust Hazard

6 - Breathing Hazard

7 - Hearing Hazard

8 - Eye Hazard

9 - Pressurized Hose

10 - Spray Hazard

11 - WARNING Label

12 - Made In Indiana

13 - CPR Series Label

14 - Inlet Label

15 - Outlet Label

16 - 12VDC Label

17 - Pirate Brand® Label

Instructions For Installing Replacement Label Pack

1. Completely remove old label and clean area thoroughly before applying new label.

2. Apply replacement labels in locations as described above or as close as possible if area is obstructed

3. 12 VDC Label (#16) is only to be used on electric remote controlled systems. DO NOT apply label to systems with pneumatic remote

controls.

Labels must be replaced when they are no longer readable!

Replacement Label Pack P/N: PB-LPC001

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

6

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

How CPR Systems Work

(Pressure Release)

WARNING: This section of the manual is designed to give you a general understanding of how

the Abrasive Blaster functions. All sections of this manual must be read and understood before

operating the equipment.

Flow of Compressed Air

Flow of Abrasive

Flow of Exhaust Air

During Blow-down

ADDING ABRASIVE

Abrasive is added through the hole in the top of the Abrasive Blaster where the Pop-up and its seat are

located. When abrasive is added, it ows down through the hole, around the Pop-up, and down to the

bottom of the pressure vessel where it will exit through the Metering Valve when blasting is started.

PRESSURIZATION

When a compressed air source (such as an air-compressor) is connected to the inlet of the Abrasive

Blaster and the Inlet Shut-Off Valve is opened, compressed air ows to the Inlet Valve where it is stopped.

When the control handle is activated, the Inlet Valve opens and air ows into the Pressure Vessel causing

the Pop-up (located internally) to seal against its seat. Simultaneously, the Diaphragm Valve (Outlet Valve

on older models) closes sealing the Pressure Vessel allowing it to hold pressure. Air will also continue

past the Choke Valve, through the Pusher Line, and nally to the “Y” under the Metering Valve where it

is mixed with abrasive. The mixture of compressed air and abrasive will now exit the Abrasive Blaster

through a blast hose and nozzle connected to the coupling under the Metering Valve and blasting begins.

It is important to note that, some abrasive will collect at the base of the Metering Valve causing the blast

hose to pulsate and spray abrasive erratically for a short time while pressure builds up in the pressure

vessel. This is normal and will not damage the Abrasive Blaster.

DEPRESSURIZATION (BLOW-DOWN)

When the control handle is released in a pressure release (CPR) system, the Inlet Valve automatically

closes stopping the ow of compressed air into the Pressure Vessel. Simultaneously, the Diaphragm

Valve (Outlet Valve on older models) opens allowing the compressed air in the pressure vessel to exit the

Abrasive Blaster through the Diaphragm Valve (Abrasive Trap & Outlet Valve on older models), and nally

through the Mufer. When all the pressure in the Pressure Vessel is released, blasting stops.

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

7

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

Compressed

Air Inlet

Air

/ Abrasive Mix

To

Blasting Nozzle

Loaded Abrasive

Inlet

Valve Inlet

Shut-Off

Valve

Choke

Valve

Metering

Valve

Pressure

Vessel

Pop-up

Pusher

Line

Exhausted

Air

Diaphragm

Valve

(Outlet Valve /

Abrasive Trap On

Older Models)

Muffler

How CPR Systems Work

(Pressure Release)

Some items moved or rotated for clarity.

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

8

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

Inlet

Valve

Inlet

Shut-Off

Valve

Choke

Valve

Metering

Valve

Pressure

Vessel

Pop-up

Pusher

Line

Inlet Valve

Petcock

Nozzle

Blast

Hose

Control

Handle

Compressed

Air Supply

Hose

Diaphragm

Valve

(Outlet Valve /

Abrasive Trap On

Older Models)

Muffler

Operating Procedures

WARNING: The Procedures provided in the Operating Procedures section of the manual are designed to

provide basic information on how to safely operate the features of Pirate Brand® CPR Series Abrasive

Blasters. Only personnel thoroughly trained in abrasive blasting should operate the Abrasive Blaster.

Setting-Up The Blaster

INSPECT PRESSURE VESSEL

When you receive your Abrasive Blaster, remove the

Handway Assembly and check for foreign items that may

have fallen into the Abrasive Blaster through the Pop-up

opening. Remove any foreign materials and reinstall the

Handway Assembly.

DANGER: Never perform any maintenance or

attempt to open the Abrasive Blaster in any way

while it is pressurized. The violent release of

compressed air and propelled objects will cause

serious injury or death.

RE-TIGHTEN HANDWAY ASSEMBLY

After the Abrasive Blaster has been pressurized for the rst

time, tighten the nut on the Handway Assembly. Tightening

the nut on the Handway Assembly should also be done any

time after the handway has been removed for maintenance

before and after the next pressurization.

DANGER: Never perform any maintenance or

attempt to open the Abrasive Blaster in any way

while it is pressurized. The violent release of

compressed air and propelled objects will cause

serious injury or death.

PURGE AIR SUPPLY HOSE

Before connecting the Air Supply Hose to the Abrasive

Blaster, purge the hose of any moisture or foreign debris.

Standing water or moisture in the air line will cause

degraded performance of the Abrasive Blaster. Air supplied

to the Abrasive Blaster must be clean, dry and cool.

ATTACH REMOTE CONTROL HANDLE

Attach the Remote Control Handle to the Blast Hose near

the Nozzle with hose clamps or heavy wire ties. Form a loop

of Twinline/Control Cord that comes 6” away from the Blast

Hose, runs 6” parallel to the Blast Hose, and comes 6” back

to the Blast Hose. Using duct tape, attach the Twinline/

Control Cord to the Blast Hose where the loop ends by

wrapping the tape around the Twinline/Control Cord twice

and then around the Blast Hose. This creates a strain-relief

attachment and is only necessary on the rst connection

near the Control Handle. Starting from the Nozzle end of

the Blast Hose, attach the Twinline/Control Cord to the blast

hose by wrapping duct tape around both every 3 feet.

6”

6”

6”

See page

11 for larger

diagram

of blaster

components

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

9

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

Operating Procedures

PRE-BLAST CHECK

Before each use of the Abrasive Blaster, it must be checked

to ensure it is in a safe condition to be used. Closely

examine all components of the Abrasive Blaster for signs

of excessive wear, worn out seals and hoses, or damaged

components. If any component of the Abrasive Blaster is

found to be damaged or worn, it must be replaced before

blasting.

WARNING: Never use an Abrasive Blaster if any

components are damaged or worn. Damaged or

worn parts must be replaced before use.

ADDING ABRASIVE

Before lling the Abrasive Blaster, make sure the Inlet Shut-

Off Valve is closed, the Inlet Valve Petcock is open, and

the pressure vessel is in a depressurized state. Abrasive

is added by pouring it into the top of the Abrasive Blaster

where it can ow around the Pop-up and into the pressure

vessel. Do not overll the Abrasive Blaster. Do not allow

foreign materials to enter the Abrasive Blaster. It is

recommended that a screen be used to prevent foreign

objects from entering the Abrasive Blaster.

DANGER: Never reach into the Pop-up opening

while lling the Abrasive Blaster. It can close

without warning causing severe injury or death.

WARNING: Pirate Brand® Abrasive Blasters may

not be used with abrasives containing silica.

Never use abrasives containing silica.

WARNING: Never ll the abrasive blaster with

the Inlet Shut-Off Valve in the open position.

Always close the Inlet Shut-Off Valve before

lling.

WARNING: Electrically conductive abrasives

may not be used with the abrasive blasters using

Electric Remote Control Systems without

changing to sealed strain relief connectors.

WARNING: Never attempt to move or transport

the Abrasive Blaster when it contains Abrasive.

REMOTE CONTROL SYSTEM

Abrasive Blasters must use a Remote Control System

(commonly known as a deadman) to start and stop

abrasive blasting. Remote Control Systems can be electric

or pneumatic.

Electric: Connect the Remote Control Handle to the

Abrasive Blaster’s female twist-lock connector. Connect a

12 VDC power source (12V Battery or Optional 120 VAC to

12 VDC converter) to the Abrasive Blaster’s male twist-lock

connector.

Pneumatic: Connect the Remote Control twinline hose to

the Abrasive Blaster using the supplied threaded ttings.

It is not recommended that Pneumatic Remote Control

Systems are used when the Blast Hose length will be

longer than 100 feet.

WARNING: Never operate the Abrasive Blaster

without a Remote Control System.

DANGER: Always use caution around electric

sources to avoid electric shock. Do not operate

electrical remote controlled Abrasive Blasters in

wet or other hazardous environments

CONNECTING HOSES

Before connecting hoses to the Abrasive Blaster, make

sure the Inlet Shut-Off Valve is closed and the compressed

air supply is shut off. Connect the hose coming from the

compressed air supply to the inlet on the Abrasive Blaster

and secure with safety clips. Connect the blast hose to the

coupling by the Metering Valve at the base of the Abrasive

Blaster and secure with safety clips.

WARNING: Always use safety devices like clips

and whip-checks (safety cables) at hose

connections.

Before You Blast

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

10

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

PRESSURIZING THE ABRASIVE BLASTER

Before pressurizing the Abrasive Blaster make sure the

following conditions occur:

• All “BEFORE YOU BLAST” procedures have

been followed.

• The Inlet Shut-Off Valve is closed.

• The Inlet Valve Petcock is closed.

• The Remote Control Handle is released.

• All hose connections are secure and have a

safety clip installed.

• The Abrasive Blaster is set up in a safe and

level location where all people in the vicinity

are aware of its presence.

• All necessary safety equipment is present and

being worn by all people in the vicinity of the

Abrasive Blaster.

• Only personnel who have been thoroughly

trained and have read and understand the

manual are in the vicinity of the Abrasive

Blaster

When these conditions are met, turn on the compressed air

source and open the Inlet Shut-Off Valve on the Abrasive

Blaster. The Abrasive Blaster is now ready to begin blasting.

DANGER: Never perform any maintenance or

attempt to open the Abrasive Blaster in any way

while it is pressurized. The violent release of

compressed air and propelled objects will cause

serious injury or death.

DANGER: Never supply compressed air

exceeding 150 PSI (10.3 BAR) to the Abrasive

Blaster.

WARNING: The Blast Hose may kick back when

Remote Control Handle is activated. Be

prepared and brace yourself for kick back.

Blast Hoses will normally kick back erratically for

a short time when the Abrasive Blaster is started.

WARNING: All those who will be in the area

while blasting is to occur must be properly

trained, read the manual, and wearing safety

equipment to protect from the hazards described

by the WARNING and DANGER labels located

on the Abrasive Blaster. If any labels are worn

or missing they must be replaced.

WARNING: 100 PSI Minimum. Failure to provide

a constant air supply of at least 100 PSI can

cause excessive wear to multiple components

and the control system to operate improperly.

USING THE ABRASIVE BLASTER

After pressurizing the Abrasive Blaster, it is ready to begin

blasting. Fold down safety ap lever lock and squeeze the

Remote Control Handle to start the ow of abrasive and

compressed air. Adjustments to the air/abrasive mixture

can be made by swinging the handle/turning the knob on

the Metering Valve. There will be a delay between a change

made at the Metering Valve and what comes out of the

Nozzle depending on the length of Blast Hose being used.

To stop the ow of compressed air and abrasive, release

the Remote Control Handle and blasting will stop after a

short time. How long it takes for blasting to stop will depend

on the length of Blast Hose being used. The pressure vessel

will automatically exhaust through the Exhaust Mufer

causing a rush of compressed air that can propel any loose

objects, debris or spilled abrasive at nearby personnel.

For this reason, personnel must not be located near the

Abrasive Blaster when blasting is taking place.

DANGER: Airborne particles produced by

abrasive blasting can cause respiratory disease.

All persons operating or located near the blasting

site must wear approved NIOSH / OSHA

approved breathing equipment. Never use

abrasive containing silica.

DANGER: Never stand near an Abrasive Blaster

when it is in operation. The release of the

Remote Control handle will cause a sudden

release of compressed air from the Exhaust

Mufer without warning. Only Adjust the

Metering Valve after the Abrasive Blaster has

completely depressurized.

WARNING: Only personnel thoroughly trained in

abrasive blasting should operate the Abrasive

Blaster. This manual only provides basic

information on how to safely operate the features

of Pirate Brand® CPR Series Abrasive

Blasters.

WARNING: Never point the blast Nozzle at

yourself, other people, or the Abrasive Blaster.

WARNING: The Choke Valve must be completely

open when blasting or damage to equipment will

occur.

Operating Procedures

Blasting

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

11

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

Operating Procedures

Blasting

DRAINING THE MOISTURE SEPARATOR (if equipped)

During blasting, the Moisture Separator must be periodically

drained. The best way to accomplish this is to leave the

drain valve slightly open all the time so it constantly leaks

air and forces moisture out.

WARNING: The Abrasive Blaster must be

supplied with clean, cool, dry compressed

air in order to function properly.

SHUTTING DOWN THE ABRASIVE BLASTER

When blasting is complete, the Abrasive Blaster will need

to be shut down. Make sure the Remote Control Handle is

released then close the Inlet Shut-Off Valve and open the

Inlet Valve Petcock.

WARNING: Never operate the Abrasive Blaster

without an Exhaust Mufer. Without the mufer,

the sudden release of compressed air can cause

severe injury.

DISCONNECTING AIR SUPPLY HOSE

After the Abrasive Blaster has been depressurized and the

Inlet Valve has been closed, the Compressed Air Supply

Hose may still contain pressure which must be released

before disconnecting the hose. To do this shut off the

compressed air at its source and open the Inlet Shut-Off

Valve on the Abrasive Blaster.

Next, open the petcock at the top of the Inlet Valve. For

systems with electric remote controls, you must be

connected to a power source and hold down the Remote

Control Handle to allow air to bleed out through the Inlet

Valve Petcock.

When you no longer hear air escaping through the Inlet

Valve Petcock, squeeze the Compressed Air Supply Hose

to conrm it is soft and does not contain compressed air.

After conrming the absence of compressed air in the

Compressed Air Supply Hos,e it is ready to be disconnected.

DANGER: Never disconnect any compressed air

supply hose without rst performing the

“DISCONNECTING AIR SUPPLY HOSE”

procedure described above. Failure to do so

can cause the hose to blow off violently injuring

or killing nearby people.

Inlet

Valve

Inlet

Shut-Off

Valve

Choke

Valve

Metering

Valve

Pressure

Vessel

Pop-up

Pusher

Line

Inlet Valve

Petcock

Nozzle

Blast

Hose

Control

Handle

Compressed

Air Supply

Hose

Diaphragm

Valve

(Outlet Valve /

Abrasive Trap On

Older Models)

Muffler

Some items

moved or

rotated for

clarity.

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

12

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

Maintenance Procedures

WARNING: Maintenance procedures are to be performed by experienced qualied personnel only. Failure to

perform maintenance procedures correctly at the intervals specied below can lead to performance problems

and equipment failure, and will void the equipment warranty.

DANGER: Never perform any maintenance or attempt to open the Abrasive Blaster in any way while it is

pressurized. The violent release of compressed air and propelled objects will cause serious injury or death.

Descriptions of maintenance procedures referenced in this table are located on the next page.

Procedure To Be Performed Maintenance Interval

1 - Inspect & Empty Abrasive Trap (If Equipped) Every 4 Hours Of Use

2 - Inspect Personal Protective Equipment (PPE)

Every 8 Hours Of Use

Including but not limited to: Respirators, Airline Filters, Carbon-Monoxide Monitors,

Hearing Protection, Eye Protection, Foot Protection, Protective Clothing & Gloves

Reference www.osha.gov 29 CFR 1910.132 - General Requirements (PPE)

29 CFR 1910.133 - Eye (PPE)

29 CFR 1910.134 - Respiratory (PPE)

29 CFR 1910.136 - Feet (PPE)

29 CFR 1910.138 - Protective Clothing & Gloves (PPE)

29 CFR 1926.101 - Hearing (PPE)

3 - Inspect Remote Control Handles & Control Hose/Cord Every 8 Hours Of Use

4 - Inspect Blast Hose, Couplings & Gaskets Every 8 Hours Of Use

5 - Inspect Blasting Nozzle Every 8 Hours Of Use

6 - Inspect Air Hose, Couplings & Gaskets Every 8 Hours Of Use

7 - Inspect & Clean Blow-Down Mufer Every 40 Hours Of Use

8 - Lubricate Inlet Valve Every 40 Hours Of Use

9 - Inspect Pop-Up & Pop-Up Gasket Every 200 Hours Of Use

10 - Service Inlet Valve Every 200 Hours Of Use

11 - Service Diaphragm Valve / Outlet Valve Every 200 Hours Of Use

12 - Service Metering Valve Every 600 Hours Of Use

13 - Service Control Valve(s) (If Equipped) Every 600 Hours Of Use

Maintenance Schedule

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

13

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

Maintenance Procedures

Procedure Details

1. Inspect & Empty Abrasive Trap (If Equipped - Standard On Older Models)

Disassemble, clean out any abrasive & inspect the Abrasive Trap. Replace any worn components and reassemble.

IMPORTANT: Replace screens that can not be cleaned to open up all holes, never reuse clogged screens.

2. Inspect Personal Protective Equipment (PPE)

Inspect ALL Personal Protective Equipment (PPE) for proper t, condition & operation as designed. Replace, repair, or

be tted as needed.

3. Inspect Remote Control Handles and Control Hose/Cord

Pneumatic Remote Control Systems:

Inspect Control Handle for damage making sure the Safety Flap/Lever Lock is in good working order and replace

or repair as needed. Inspect twinline hoses and replace if leaks, areas that show abrasion, or soft spots are found.

Electric Remote Control Systems:

Inspect Control Handle for damage making sure the Safety Flap/Lever Lock is in good working order and replace

or repair as needed. Inspect control cord and replace if damaged plug ends, areas that show abrasion, exposed wires, or

cracks are found.

4. Inspect Blast Hose, Couplings & Gaskets

Inspect Blast Hose for leaks, abrasion & soft spots, and replace as needed. Inspect couplings for damage, leaks & wear,

and replace as needed. Inspect coupling gaskets for leaks & wear, and replace as needed. Always use safety clips &

whip checks (safety cables) at Blast Hose connections.

5. Inspect Blasting Nozzle

Inspect the Blasting Nozzle for wear and proper bore diameter. Replace the Blasting Nozzle when the bore diameter has

worn to 1/16” wider than its original diameter. Example: replace a #5 nozzle (5/16” bore) when the bore reaches 3/8”.

6. Inspect Air Hose, Couplings & Gaskets

Inspect Air Hose for leaks, abrasion & soft spots, and replace as needed. Inspect couplings for damage, leaks & wear,

and replace as needed. Inspect coupling gaskets for leaks & wear, and replace as needed. Always use safety clips &

whip checks (safety cables) at Air Hose connections.

7. Inspect & Clean Blow-down Mufer

Remove the Blow-down mufer, turn it with the open end down and tap on a hard surface to free trapped debris. If mufer

is clogged and can’t be cleaned out sufciently, it must be replaced.

8. Lubricate Inlet Valve

Add 2 drops of light machine oil through the Inlet Valve Petcock while open to lubricate the Inlet/Outlet Valve system.

9. Inspect Pop-Up & Pop-Up Gasket

Inspect the Pop-Up & Pop-Up Gasket for wear and replace as necessary.

10. Service Inlet Valve

Disassemble, clean & inspect for proper operation and worn components. Replace any worn components found.

Lubricate the piston and cylinder with silicone paste before reassembling.

11. Service Diaphragm Valve / Outlet Valve

DIAPHRAGM VALVE (If Equipped) - Remove cover and inspect diaphragm disk and other components. Replace any

worn components found.

OUTLET VALVE (If Equipped - Standard On Older Models) - Disassemble, clean & inspect for proper operation and worn

components. Replace any worn components found. Lubricate the piston and cylinder with silicone paste before

reassembling.

12. Service Metering Valve

Disassemble, clean & inspect the Metering Valve for proper operation and worn components. Replace any worn

components found.

13. Service Control Valve(s)

Disassemble, clean & inspect for proper operation and worn components. Replace any worn components found.

Lubricate with silicone paste before reassembling.

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

14

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

Troubleshooting

NO ABRASIVE FLOW WHEN BLASTING (AIR ONLY)

Possible Causes:

1. The Abrasive Blaster is empty or has no Abrasive in it.

2. The Metering Valve is closed or has not been adjusted

properly.

3. There is an obstruction in the Metering Valve. To clear the

obstruction, perform the following procedure:

Open the Metering Valve to its fully open position. Depress the control

handle and have a second qualied person close the choke valve

for 2 seconds, and then open it again immediately. This will push

minor obstructions such as a small amount of wet abrasive, a piece

of paper from a bag, or bridged paint chips through the Metering

Valve and out the Nozzle. Readjust the Metering Valve back to the

desired setting for blasting, and check to see if the obstruction has

been cleared.

If there is still an obstruction, depressurize the Abrasive Blaster.

For blasters equipped with the Abrasive Metering Valve II (AMVII),

remove the inspection plate. For blasters equipped with the

Manual Plunger Valve (MPV), completely remove the MPV Valve.

The remaining abrasive in the pressure vessel should pour out in a

steady stream. If you do not see a steady stream of abrasive, then

there is a large obstruction such as a large piece of paper from a

bag of abrasive.

If you have determined there is a large obstruction, then the

obstruction must be removed from inside the Pressure Vessel. To do

this, make sure the Abrasive Blaster is depressurized and remove

the Handway Assembly. Scoop or vacuum out all the abrasive from

inside the pressure vessel and remove the obstruction. Reinstall the

Handway Assembly and Metering Valve and tighten them securely,

then Rell the Abrasive Blaster.

It is recommended that a screen be used to prevent foreign

objects from entering the Abrasive Blaster and causing an

obstruction.

4. The Abrasive Blaster has wet abrasive in it. The wet abrasive

must be removed by depressurizing the Abrasive Blaster, removing

the Handway Assembly, and scooping or vacuuming it out.

Dry abrasive must always be used. Clean, cool, dry air must be

supplied to the Abrasive Blaster in order to prevent the abrasive

from getting wet. For Abrasive Blasters being used outside, it

is recommended that a lid be used to keep water from entering

the Abrasive Blaster.

ABRASIVE STREAM IS TOO HEAVY OR

THROBBING WHEN BLASTING

Possible Causes:

Note: CPR Systems may throb temporarily when starting up

if abrasive has collected in blast hose from previous use. This is

normal and requires no action to correct.

1. Choke Valve is partially closed. Never run the Abrasive Blaster

with the Choke Valve in any other position except fully open or

damage to the Abrasive Blaster will occur.

2. The Metering Valve needs to be adjusted.

LOW PRESSURE AT THE NOZZLE

Possible Causes:

1. Air compressor is the wrong size (too small) or the load

button has not been pushed or turned on. (100 PSI Minimum)

2. Nozzle is worn out and the compressor cannot keep up with

the increased demand.

3. Air supply hose to the blast machine is too small.

4. There is a hole in the blast hose.

5. Control hoses and/or ttings are leaking.

6. Pop-up is not sealing properly.

7. Handway Assembly is leaking.

8. Choke Valve is partially closed. Never run the Abrasive Blaster

with the Choke Valve in any other position except fully open or

damage to the Abrasive Blaster will occur.

9. Abrasive Metering Valve is open too far.

10. Obstruction in Nozzle.

11. Regulator needs adjustment (if equipped).

12. Inlet Valve / Diaphragm Valve / Outlet Valve is not opening/

closing fully due to inadequate control pressure. (100 PSI

Minimum)

13. Inlet Valve is damaged, defective, worn out, or not lubricated

properly causing it to not open fully.

14. Diaphragm Valve / Outlet Valve is damaged, defective, worn

out, or not lubricated properly causing it to not close fully.

ABRASIVE BLASTER WILL NOT TURN ON OR

IS SLOW TO TURN ON

Possible Causes:

1. Air compressor is the wrong size (too small) or the load

button has not been pushed or turned on. (100 PSI Minimum)

2. Inlet Valve Petcock is open.

3. Nozzle is worn out and the compressor cannot keep up with

the increased demand.

4. Air supply hose to the blast machine is too small.

5. Inlet Valve is damaged, defective, worn out, or not lubricated

properly causing it to not open fully.

6. Diaphragm Valve / Outlet Valve is damaged, defective, worn

out, or not lubricated properly causing it to not close fully.

7. Control hoses and/or ttings are leaking.

8. Obstruction in Nozzle.

9. The Pneumatic Control Handle is damaged, defective or worn

out (if equipped).

10. The Electric Control Handle is damaged, defective or worn

out (if equipped).

11. Power Source (battery or AC-DC converter) is not providing

sufcient power to open electric control valves (if equipped).

12. The Electric Control Cord is damaged, defective or worn out

(if equipped).

13. The Electric Control Valve is damaged, defective or worn out

(if equipped).

14. There is an obstruction in the 1/16” orice (See Inlet Valve

Parts Lists - PN 101-9450)

DANGER: Never attempt to open the Abrasive Blaster in any way while it is pressurized. Use extreme

caution when performing troubleshooting procedures that involve pressurizing the Abrasive Blaster.

Troubleshooting procedures are to be performed by experienced qualied personnel only.

Performance Related Issues

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

15

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

Troubleshooting

Operational Related Issues

BLAST MACHINE TURNS ON ACCIDENTALLY

OR WITHOUT WARNING

Possible Causes:

1. The safety ap, lever or lock button on the Control Handle

is damaged or missing.

2. The Pneumatic Control Handle is damaged, defective or

worn out (if equipped).

3. The 1/16” orice (See Inlet Valve Parts Lists - PN 101-9450)

tting is missing from the Inlet Valve’s outlet port (pneumatic

controls only.)

4. The Electric Control Handle is damaged, defective or worn

out (if equipped).

5. The Electric Control Cord is damaged, defective or worn

out (if equipped).

6. The Electric Control Valve is damaged, defective or worn

out (if equipped).

BLAST MACHINE IS SLOW TO TURN OFF OR WILL NOT

TURN OFF WHEN CONTROL HANDLE IS RELEASED

Possible Causes:

1. The screen in the Abrasive Trap (if equipped) is clogged and

needs to be cleaned or replaced.

2. The Abrasive Trap (if equipped) is full and needs to be

emptied. Abrasive traps must be emptied every 4 hours of

use.

3. The Inlet Valve is damaged, defective, worn out, or not

lubricated properly causing it to not close fully.

4. The Diaphragm Valve / Outlet Valve is damaged, defective,

worn out, or not lubricated properly causing it to not open

fully.

5. The Pneumatic Control Handle is damaged, defective or

worn out (if equipped).

6. The Electric Control Handle is damaged, defective or worn

out (if equipped).

7. The Electric Control Cord is damaged, defective or worn out

(if equipped).

8. The Electric Control Valve is damaged, defective or worn

out (if equipped)

9. Blow-down Mufer is clogged slowing the release of air.

DANGER: Never attempt to open the Abrasive Blaster in any way while it is pressurized. Use extreme

caution when performing troubleshooting procedures that involve pressurizing the Abrasive Blaster.

Troubleshooting procedures are to be performed by experienced qualied personnel only.

Inlet

Valve

Inlet

Shut-Off

Valve

Choke

Valve

Metering

Valve

Pressure

Vessel

Pop-up

Pusher

Line

Inlet Valve

Petcock

Nozzle

Blast

Hose

Control

Handle

Compressed

Air Supply

Hose

Diaphragm

Valve

(Outlet Valve /

Abrasive Trap On

Older Models)

Muffler

Some items

moved or

rotated for

clarity.

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

16

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

Warranty

PIRATE BRAND® ABRASIVE BLAST POT EQUIPMENT 5 YEAR / 10 YEAR LIMITED WARRANTY

5 YEAR LIMITED ABRASIVE BLAST POT WARRANTY. Manufacturer warrants the complete abrasive blast

pot it manufactures to be free of defects in material and workmanship for a period of ve (5) years from the

date of invoice.

10 YEAR LIMITED PRESSURE VESSEL WARRANTY. Manufacturer warrants the abrasive blast pot

pressure vessel it manufactures to be free of defects in material and workmanship for a period of ten (10)

years from the date of invoice.

LIMITATION OF WARRANTIES AND REMEDIES. THIS WARRANTY IS EXTENDED ONLY TO THE

BUYER WHO PURCHASES THE ABRASIVE BLAST POT DIRECTLY FROM THE MANUFACTURER OR

ITS AUTHORIZED DISTRIBUTORS AND IS NON-TRANSFERABLE. THE PURCHASER’S EXCLUSIVE

REMEDY ARISING FROM ITS PURCHASE OR USE OF THE PRODUCT SHALL BE STRICTLY

LIMITED TO THE REPAIR OR REPLACEMENT OF THE PRODUCTS, AT THE DISCRETION OF THE

MANUFACTURER, AND ALL WARRANTY CLAIMS OR REQUESTS MUST BE MADE IN WRITING TO THE

MANUFACTURER WITHIN TEN (10) DAYS AFTER FAILURE OF THE PRODUCT. ALL OBLIGATIONS OR

LIABILITIES OF MANUFACTURER OR SELLER FOR DAMAGES ARISING OUT OF OR IN CONNECTION

WITH THE PRODUCT AND USE OR PERFORMANCE OF THE PRODUCTS, EXCEPT AS EXPRESSLY

PROVIDED HEREIN, ARE FULLY DISCLAIMED AND EXCLUDED, AND NO SELLER OR DISTRIBUTOR

HAS ANY AUTHORITY TO MAKE ANY WARRANTY OR ASSUME ANY LIABILITY ON BEHALF OF THE

MANUFACTURER IN CONNECTION WITH THE SALE OF THE PRODUCT EXCEPT AS STATED HEREIN.

AS A CONDITION OF THE PURCHASE, PURCHASER AGREES THAT MANUFACTURER AND

SELLER SHALL NOT, UNDER ANY CIRCUMSTANCES, BE LIABLE FOR ANY COST OF FREIGHT,

SHIPPING OR TRANSPORTATION, LABOR, SPECIAL CHARGES, NORMAL MAINTENANCE SERVICES,

LOST OPERATING TIME, LOSS OF USE, LOST PROFITS, LOSS OF GOODWILL, CONSEQUENTIAL

DAMAGES, PUNITIVE OR EXEMPLARY DAMAGES, OR OTHER DAMAGES OR LOSS. OTHER THAN

AS DESCRIBED HEREIN, MANUFACTURER AND SELLER MAKE NO WARRANTY OF ANY KIND,

EXPRESS OR IMPLIED, WITH RESPECT TO THE PRODUCTS, AND SPECIFICALLY DISCLAIM ANY

WARRANTY OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, OR OTHER WARRANTY.

PURCHASER ASSUMES ALL RISK AND LIABILITY RESULTING FROM THE USE OF THE PRODUCTS.

PURCHASER FURTHER AGREES AS A CONDITION OF THE SALE AND THE USE OF THE PRODUCT,

THAT ANY DAMAGES OR RISK OF LOSS OTHER THAN AS DESCRIBED HEREIN ABOVE, SHALL

BE THE EXCLUSIVE RESPONSIBILITY OF THE PURCHASER AND NOT THE MANUFACTURER OR

SELLER. MANUFACTURER AND SELLER SHALL NOT BE LIABLE FOR ANY DAMAGES INCURRED

BY ANY PERSON AS A RESULT OF MISUSE, IMPROPER INSTALLATION, IMPROPER APPLICATION,

IMPROPER OPERATION OF THE PRODUCTS, NORMAL WEAR AND TEAR, ALTERATIONS OR

MODIFICATIONS MADE TO THE PRODUCTS, OR ACCIDENT. THE USE OF REPLACEMENT PARTS

NOT PROVIDED OR AUTHORIZED BY THE MANUFACTURER VOIDS ALL WARRANTIES.

A COMPLETELY FILLED OUT WARRANTY CARD MUST BE RETURNED TO THE MANUFACTURER

WITHIN THIRTY (30) DAYS OF PURCHASE OF THE PRODUCT OR ALL WARRANTIES ARE VOID.

PRODUCT MUST BE MAINTAINED IN ACCORDANCE TO THE MAINTENANCE SCHEDULE PROVIDED

IN THE PRODUCT MANUAL, FAILURE TO MAINTAIN THE PRODUCT IN ACCORDANCE WITH THE

MAINTENANCE SCHEDULE VOIDS ALL WARRANTIES. THIS WARRANTY DOES NOT COVER

FACTORY INSTALLED OR CUSTOMER INSTALLED ACCESSORIES.

WARRANTY CLAIMS. Warranty claims must be submitted to the manufacturer within ten (10) days after

failure of the product. Contact information for warranty claims:

Forecast Sales, Inc.

2719 Tobey Dr.

Indianapolis, IN 46219

317-829-0147

Effective July 8, 2015

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

17

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

Pressure Vessel Parts Lists

1

2

3

4

56, 7, 8, 9

10

11

12 Stationary Vessel Only

13 Stationary Vessel Only

1

109-9100

VESSEL, PORTABLE, 3.0 CU. FT. (85 LI-

TERS), 150 PSI (10.3 BAR), 13-1/2" CLEAR-

ANCE, 16" DIA, INCLUDES HANDWAY

ASSEMBLY, WHEELS, POP-UP & POP-UP

GASKET

109-9110

VESSEL, PORTABLE, 6.0 CU. FT. (170 LI-

TERS), 150 PSI (10.3 BAR), 13-1/2" CLEAR-

ANCE, 24" DIA, INCLUDES HANDWAY

ASSEMBLY, WHEELS, POP-UP & POP-UP

GASKET

109-9090

VESSEL, STATIONARY, 3.0 CU. FT. (85 LI-

TERS), 150 PSI (10.3 BAR), 13-1/2" CLEAR-

ANCE, 16" DIA, W/4" UMBRELLA, INCLUDES

HANDWAY ASSEMBLY, POP-UP & POP-UP

GASKET

109-9120

VESSEL, STATIONARY, 6.0 CU. FT. (170 LI-

TERS), 150 PSI (10.3 BAR), 13-1/2" CLEAR-

ANCE, 24" DIA, W/4" UMBRELLA, INCLUDES

HANDWAY ASSEMBLY, POP-UP & POP-UP

GASKET

2 103-6990 POP-UP VALVE, 4” FEMALE

3 102-3250 POP-UP VALVE, SEAT

4 888-7000-00106PB GASKET, HANDWAY, 6” x 8”

5 888-7000-00111PB HANDWAY CRAB ASSY 6” x 8”

6 120-4270 WHEEL AND TIRE, 16” x 4” BLACK

7 103-8250 WASHER, 1” THRUST

8 103-8240 RETAINING RING, 1”

9 102-4020 AXLE, 16” DIA BLAST MACHINE 888-5010-060PB AXLE, 24” DIA BLAST MACHINE

10 102-3350 LID, 16” DIA, W/HANDLE, POWDER COATED

BLACK 888-5011-060PB LID, 24” DIA, W/HANDLE, POWDER COATED

BLACK

11 103-0990 SCREEN, LOW PROFILE, 16” (1/4” MESH),

POWDER COATED BLACK 102-3180 SCREEN, LOW PROFILE, 24” (1/4” MESH),

POWDER COATED BLACK

12 102-3180 4” POP UP VALVE UMBRELLA

13 102-4160 LEG PADS (2)

3.0 Cu Ft CPR Abrasive Blasters 6.0 Cu Ft CPR Abrasive Blasters

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

18

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

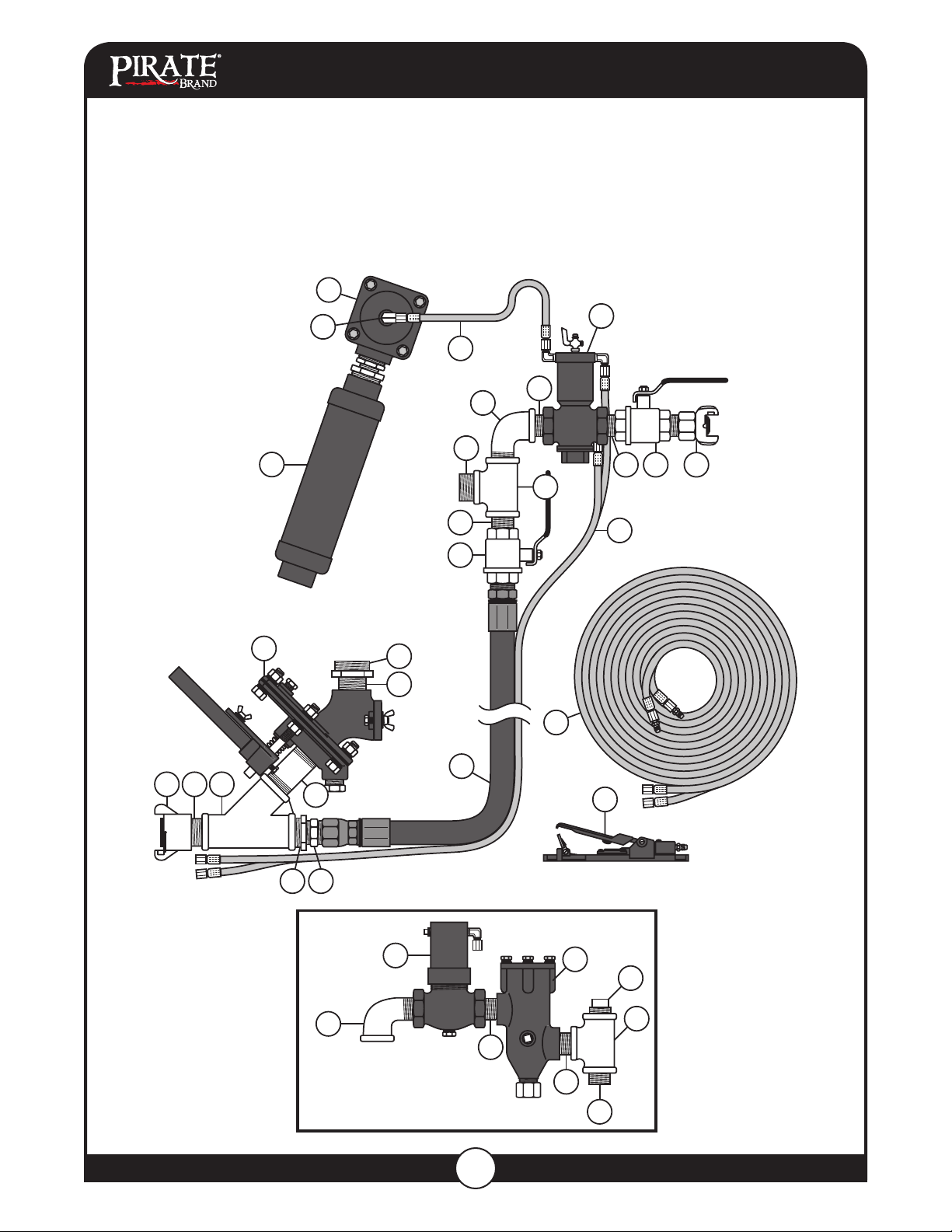

Pipe String Parts Lists

CPR SERIES - 3.0 Cu Ft Pneumatic Controls

1

2

3

4

4

4

5

6

24

8

11

12

13

14

13

15

1716

181320 19

21

22

23

2

4

4 910

4

10

7

25

Legacy Outlet Valve / Abrasive Trap Setup

26

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

19

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

Pipe String Parts Lists

CPR SERIES - 3.0 Cu Ft Pneumatic Controls

* See “Valve Parts Lists” Section for detailed parts list.

** See ”Control Handle Parts Lists” Section for detailed parts list.

1888-2011-006PB MUFFLER, BLOWDOWN, 1" MNPT (SHOWN)

888-2011-006SPB MUFFLER, BLOWDOWN, SHORT, 1” MNPT

2 888-3006-106PB ELBOW, STREET, 90°, GALV, 1"

3* 101-9670 VALVE, OUTLET, 1", COMPLETE

4 888-3029-10699PB NIPPLE, TBE, GALV, 1" x CLOSED

5* 100-3530 ABRASIVE TRAP II, 1" COMPLETE, X-TREME DUTY

6 888-3014-106PB PIPE PLUG, GALV, 1"

7 888-3011-10607PB TEE, GALV, 1" x 1" x 1-1/4"

8 200-002 HOSE, AIR, COUPLED, NOMINAL 3/16" ID x 2'

9 UM100 AIR HOSE COUPLINGS, 2 LUG, 1" MALE NPT

10 VB100 BALL VALVE, FULL PORT, 1" NPT

11 200-005 HOSE, TWINLINE CONTROL, ASSEMBLY, YEL/YEL W/BLACK STRIP, NOMINAL 3/16" ID x 5',

W/UNIONS

12* 101-9800 VALVE, INLET, 1", COMPLETE

13 888-3028-10799PB NIPPLE, TBE, SCHEDULE 80, GALV, 1-1/4" x CLOSE

14 888-3026-10807PB BUSHING, GALV, 1-1/2" x 1-1/4"

15 123-6730 PUSHER LINE (FLEX) REPLACEMENT 1" x 28", OAL 33"

16 888-3026-10706PB BUSHING, GALV, 1-1/4" x 1"

17 111-7200 FITTING, 1" MNPT x 1" M-FLARE

18 888-3012-107PB WYE, GALV, 1-1/4"

19 888-3028-10714PB NIPPLE, TBE, SCHEDULE 80, GALV, 1-1/4" x 4"

20 SB-1S-IR THREADED COUPLING, STD NPS, IRON, 1-1/4"

21* 102-4350 AMVII, COMPLETE VALVE, X-TREME DUTY, 1-1/4" NPT (DB1000)

22 200-050 HOSE, TWINLINE CONTROL, ASSEMBLY, YEL/YEL W/BLACK STRIP, NOMINAL 3/16" ID x

50', W/UNIONS

23** 354-4289 PNEUMATIC CONTROL HANDLE

24 888-3011-106PB TEE, GALV, 1"

25* 103-3710 VALVE, OUTLET, 1”, DIAPHRAGM, COMPLETE

26 102-5130 ELBOW, BRASS, 1/4” x 3/16”

3.0 Cu Ft CPR Abrasive Blasters - Pneumatic Controls - Parts List

Manual Revision: Feb 18 Copyright © 2011-2018 Pirate Brand®, All Rights Reserved

20

C-Series - 3.0 / 6.0 Cu Ft User’s Manual

Pipe String Parts Lists

CPR SERIES - 6.0 Cu Ft Pneumatic Controls

9101110

12

13

14

15

14

23

23

16

17

18

19

20

21

222325 24

26

27

28

1

2

3

4

4

4

5

6

7

8

Legacy Outlet Valve / Abrasive Trap Setup

29

30

Other manuals for C Series

1

This manual suits for next models

11

Other Pirate Power Tools manuals

Popular Power Tools manuals by other brands

SCOPREGA

SCOPREGA GE BP instructions

tekton

tekton 24340 Operator's manual

Cres Cor

Cres Cor Star Series Carving Stations IFW61RR Installation and operating instructions

JMA

JMA ECCO-COMBI instruction manual

Powerfix

Powerfix POWERFIX KH4055 operating instructions

Craftsman

Craftsman 315.175170 Operator's manual