Specac Atlas Lightweight Evacuable Pellet Die User manual

Atlas™ Lightweight

Evacuable Pellet Dies

User Manual

2I-25410 Issue 3

Atlas™ Lightweight

Evacuable Pellet Dies

User Manual

2I-25410 Issue 3

User Manual

4

Atlas™ Lightweight Evacuable Pellet Dies

P/N’s GS25 10 and GS25 11

CONTENTS

1.

INTRODUCTION

................................................................................. 5

2.

UNPACKING AND CHECKLIST

.............................................................. 6

3.

SAFETY AND DIE CARE

.......................................................................

4.

PREPARING THE DIE FOR USE

............................................................. 7

5.

FILLING THE DIE WITH SAMPLE

.......................................................... 11

6.

MAKING THE PELLET

........................................................................ 12

7.

REMOVING THE PELLET FROM THE DIE

.............................................. 13

.

CLEANING AND STORAGE OF THE DIE

................................................ 14

9.

LEGEND FOR THE LIGHTWEIGHT DIE

.................................................. 14

10.

SPARE PARTS FOR THE LIGHTWEIGHT DIE

....................................... 15

© December 2017 Specac Ltd. All rights reserved.

Brilliant Spectroscopy is a trademark of Specac Ltd.

Other product names mentioned herein may be trademarks

of their respective owners.

Atlas™ Lightweight Evacuable Pellet Dies

5

1. Introduction

Thank you for purchasing a Specac product.

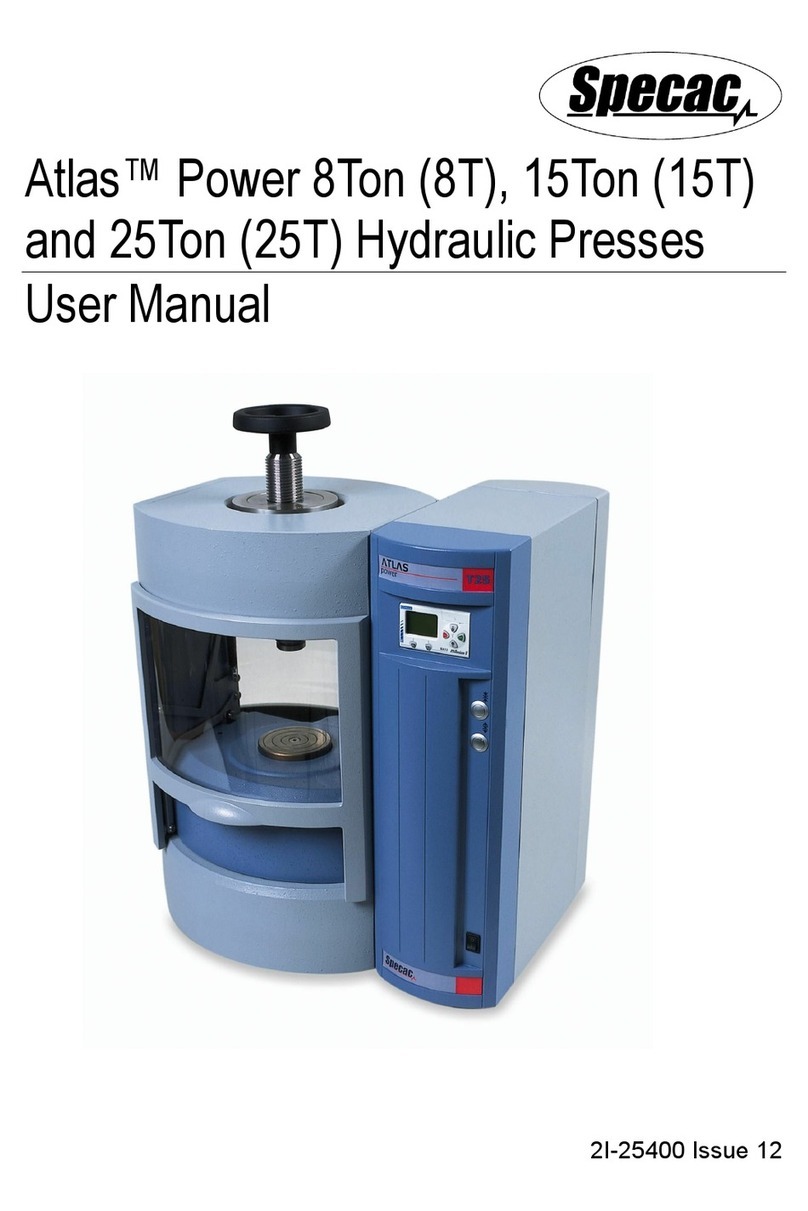

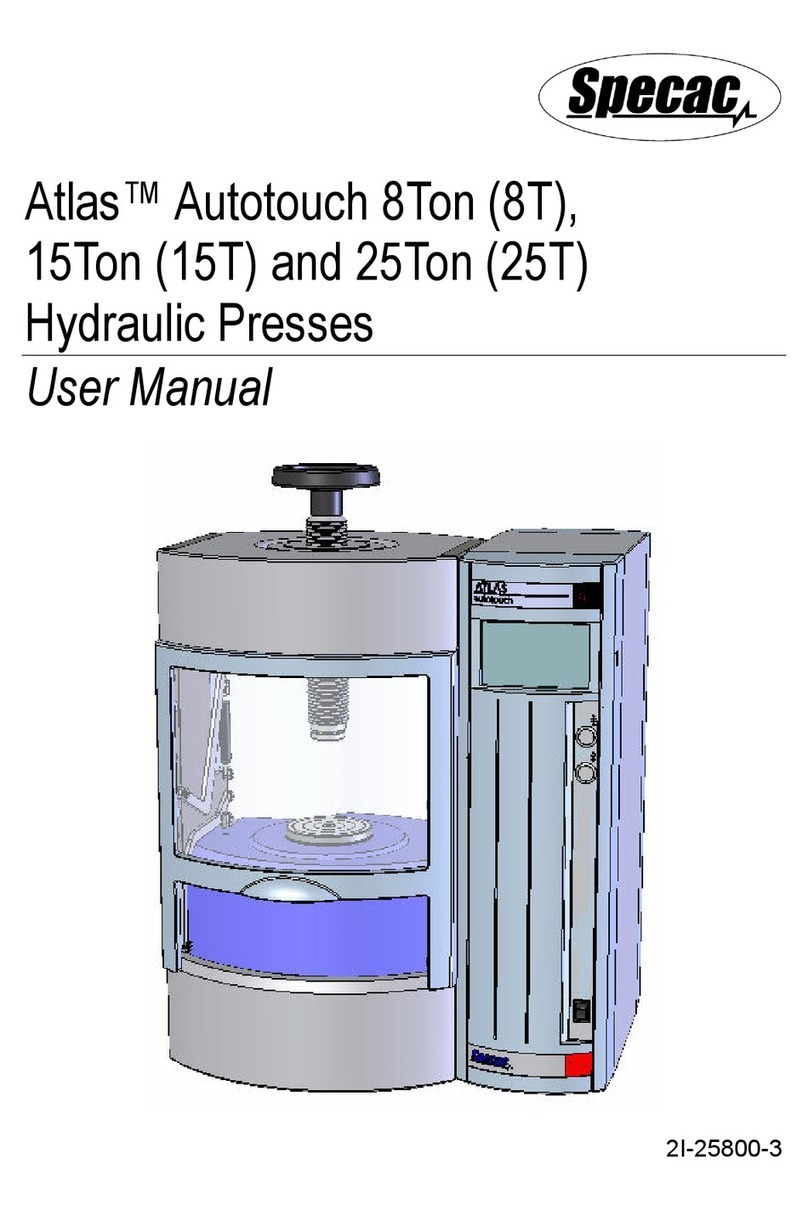

The Atlas™ Lightweight Evacuable Pellet Dies have been specifically

designed to work with the range of Atlas™ Power and Autotouch

Presses up to a maximum load rating of 40 tons. The Lightweight Dies

are also compatible for use with Specac’s 15 and 25 tons Atlas™

Manual Hydraulic Presses.

The Dies are made of 440C stainless steel and offered to prepare

pellet discs of 32mm or 40mm diameter size. They are well suited for

the preparation of solid pellets for study by X-Ray Fluorescence

spectroscopy. When many samples are to be prepared for study, the

physical effort required to load and remove an Atlas™ Lightweight

Evacuable Pellet Die into a press is greatly reduced, as the Dies

themselves are physically smaller and lighter in weight by comparison

to conventional 32mm and 40mm diameter pellet dies.

To aid in the weight reduction there are no individual internal pressing

pellets as with conventional Dies and so a sample is compressed

between the plunger and the base pieces of the Lightweight Die

assembly. For this reason, both the plunger and base have a highly

polished surface that contacts with the sample. The highly polished

faces help in producing an even surface finish to the sample pellet and

in release of the sample from the Die components.

The Lightweight Dies have an evacuation port and can be operated

using a partial vacuum for the compression of samples into pellets that

may be moisture sensitive.

These user instructions are based upon the 40mm Lightweight Die P/N

GS25411 shown as an example throughout. The same instructions

apply for use of the 32mm Lightweight Die P/N GS25410.

User Manual

6

2. Unpacking and Checklist

Remove the Atlas™ Lightweight Evacuable Pellet Die from its

protective packaging.

Please check that the following have been supplied:

• A 32mm or 40mm Lightweight Evacuable Pellet Die complete.

To include the following parts:

• Die body.

• Plunger.

• Base with O-ring.

Atlas™ Lightweight Evacuable Pellet Dies

7

• O-ring for Plunger.

• Extractor cap.

Check the parts over and proceed to use them from the following

instructions.

User Manual

3. Safety and Die Care

Safety

The Atlas™ Lightweight Evacuable Pellet Dies are inherently safe from

correct use. It may be that the sample type to press within the Die

could pose the most risk, so any health and safety instructions

pertaining to the sample type itself in its handling should be observed.

However, when the Die is being used in a Press, any safety

precautions involved with operation of the Press itself must also be

observed. An Atlas™ Lightweight Die must always be placed as

centrally as possible within the pressing area of a Press to provide a

correct and consistent evenness in loading when being compressed.

Warning!

Never exceed the stated maximum safe load of 40 tons

when pressing using an Atlas™ Lightweight Die.

Die Care

The Atlas™ Lightweight Dies are made from corrosion resistant steel

(440C), but because of the nature of certain materials that may be

used with the Dies, it is necessary to take certain precautions. Any

sample to press that is harder than stainless steel in having a Mohs

value of higher than 7.5, risks damage to the parts. Similarly, pressing

of very fine particulate samples (smaller than the minimum tolerance

clearance values for the Dies), risks damage to certain components.

The Atlas™ Lightweight Die parts can usually be cleaned between

samples initially with warm or cold water, then rinsed in methanol and

finally dried with soft tissue. When not in use always ensure that the

Lightweight Die and its component parts are thoroughly clean and dry,

and if possible store the Lightweight Die in a desiccator. When

cleaning the internal pressing pellets, do not wipe their polished faces

with a cloth that has a hard, abrasive texture. Always use a soft cloth

or tissue.

Atlas™ Lightweight Evacuable Pellet Dies

9

.Preparing The Die For Use

The Atlas™ Lightweight Evacuable Pellet Die and its component parts

are packed from the factory in such a way that they do not suffer

damage during transit. The optically polished surfaces of the plunger

and the base are covered in a protective material and the die may be

lightly coated with oil.

1) Before use the protective material on the plunger ( ) and base (2)

should be removed and all component parts must be thoroughly

cleaned with an organic solvent to ensure that the protective oil is

fully removed. The parts should be wiped dry taking care to use

non-abrasive cleaning cloths on the polished faces of the plunger

() and the base (2).

2) Place the base (2) onto the bench top. Ensure the base O-ring

seal (3) is correctly positioned in the groove on the base (2) and is

not damaged.

3) Assemble the Cylinder Body (4) by pressing down onto the base

(2). A tight fit between the parts is achieved from contact with the

base O-ring seal (3). (See Exploded Diagram page 10.)

The Die is now ready to accept a sample for compression. The sample

can be either a solid powder material alone or a solid powder material

contained in a support cup.

Note: For X Ray Fluorescence analysis, solid powder samples are

usually contained in an aluminium or plastic support cup of

32mm or 40mm diameter corresponding to the particular

diameter size of die. A variety of support cups for this purpose

can be purchased through Specac.

User Manual

10

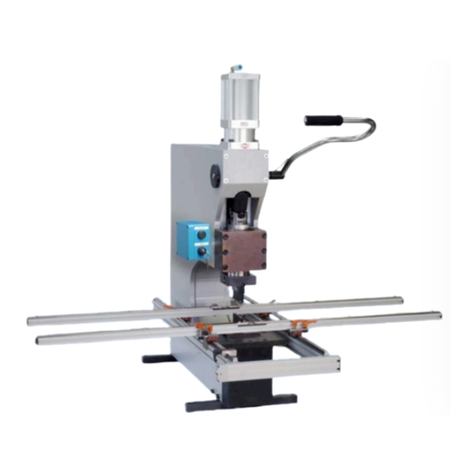

Exploded Diagram of Atlas™ Lightweight Evacuable Pellet Die

5

4

6

3

2

Atlas™ Lightweight Evacuable Pellet Dies

11

5. Filling The Die With Sample

A solid powder sample can be transferred for filling the Die using a

spatula or a by making a paper chute or funnel.

If using an aluminium or plastic support cup with a solid sample,

ensure that an empty support cup is first placed into the die and

pushed towards the base (2). You can use the plunger ( ) to gently

guide the support cup down inside the cylinder body (4).

If using a support cup the amount of solid sample powder that you can

place into the die should never be at a level higher than the lip of the

support cup.

When the sample powder to be compressed has been placed into the

cylinder body (4) use the tip of a spatula to spread the powder such

that it has a flat, evenly distributed surface. Preparation of the

uncompacted powder surface helps to produce a more homogenously

compressed sample pellet.

Note: If filling the cylinder body to a depth of circa 10mm with a

powder sample, a circa 8mls volume of sample is used with a

32mm die and circa 12.5mls of sample with the 40mm die.

The plunger ( ) is now inserted into the cylinder body (4) ensuring that

the optically polished face of the plunger is contacting the sample

powder.

When the plunger ( ) has reached the limit of its travel take the plunger

O-ring seal (5) and press it into place around and over the plunger ( )

and into the recessed chamfer at the top of the cylinder body (4).

The complete Die assembly is now ready to be placed in a Press.

User Manual

12

6. Making the Pellet

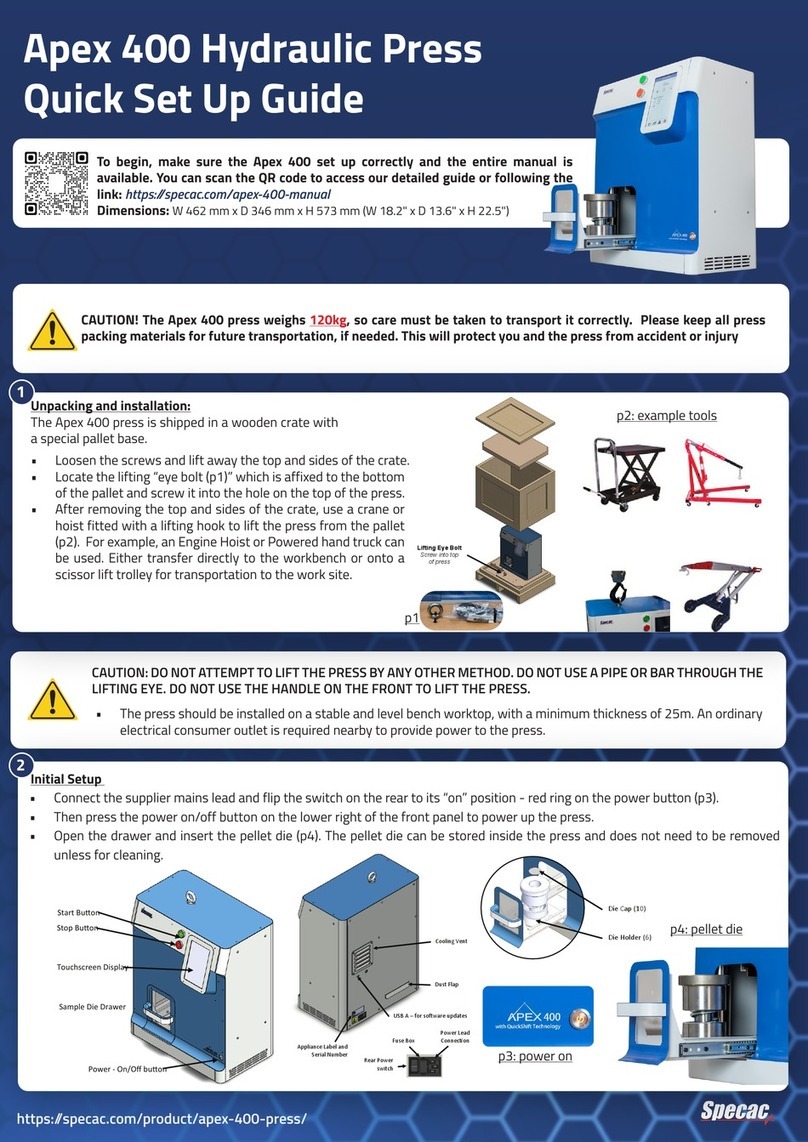

Place the prepared Die assembly in its upright position (as seen as

Exploded Diagram and on front cover) carefully and centrally into a

hydraulic Press.

At this stage, the Die assembly may be connected to a vacuum

pumping system via the evacuation port (6) on the cylinder body (4).

Vacuum quality rubber tubing can be routed through to the pressing

area of any Specac Press to fit over the evacuation port (6) whilst the

Die is being compressed. A regime for evacuation time and application

may be devised for a specific sample or set of samples to be

compressed. If using a vacuum, apply evacuation to the Die assembly

prior to compression in the Press.

Note: Evacuation of the Die assembly can help in the production

quality of certain pellets depending on the dryness of a sample.

Follow the specific instructions for operation of your Press to apply a

load to the die assembly. The Atlas™ Lightweight Evacuable Pellet

Dies have a maximum load limit of 40 tons.

Warning: DO NOT EXCEED THE MAXIMUM LOAD.

Keep the load applied to the Die assembly for however long it is

necessary to produce an acceptable sample pellet.

If using a vacuum pump system, evacuation should proceed during the

application of load and be maintained for a further minute after the load

has been released.

Atlas™ Lightweight Evacuable Pellet Dies

13

7. Removing The Pellet From The Die

When the Die assembly with powder sample has been compressed

and the load has been released, remove the Die assembly from the

Press. (Disconnect any vacuum tubing to the Die if this has been

used.)

The following procedure is adopted to remove the compacted powder

pellet from the Die.

1) Remove the base (2) from the cylinder body (4) leaving the plunger

in position.

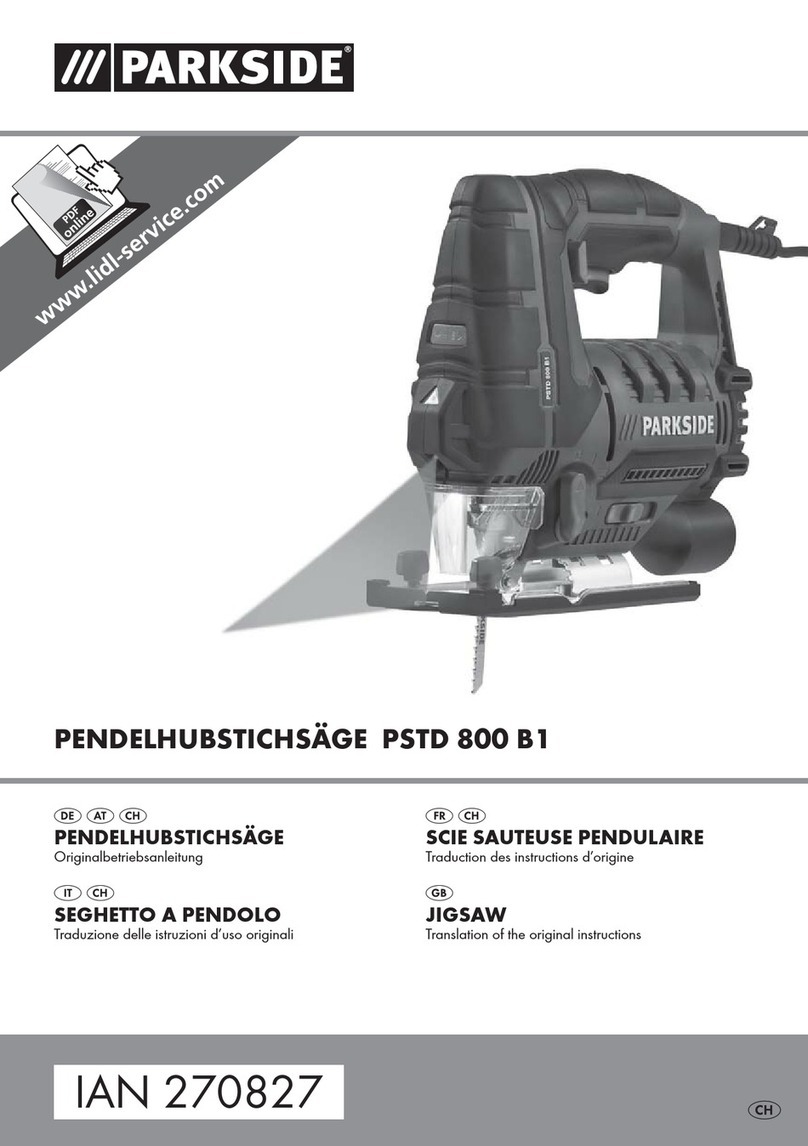

2) Invert the Die assembly and place the hollow, open end of the

extractor cap (7) onto the underside of the cylinder body (4). This

configuration of parts creates a space for the compacted pellet to

be pushed into after further travel of the plunger ( ).

3) Place this new inverted assembly back into the Press and apply a

light load between the extractor cap (7) and the plunger ( ).

Note: The compacted pellet will emerge first from the cylinder body

(4) followed by the plunger (1).

4) When the compacted pellet is accessible, release any applied load

and remove the Die assembly very carefully from the Press.

The prepared compacted pellet sample can now be analysed by an

appropriate technique.

View of hollow end of extractor cap used for pellet removal

7

User Manual

14

8. Cleaning And Storage Of The Die

When the Atlas™ Lightweight Evacuable Pellet Die is not in use,

ensure it is clean and stored correctly.

Depending on the sample types (inorganic or organic chemicals), that

have contacted the parts of the Die, the sample can usually be

removed by a combination of washing with warm water, then distilled

water and finally with methanol.

The Die parts are then dried and can be stored in a desiccator,

warming cabinet or left on a warm (35°C) hot plate. When drying with a

cloth ensure the material is non-abrasive to protect from scratches to

the polished faces of the plunger ( ) and die base (2).

9.Legend For The Lightweight Die

( ) Plunger.

(2) Base.

(3) Base O-ring seal.

(4) Cylinder body.

(5) Plunger O-ring seal.

(6) Evacuation port.

(7) Extractor cap.

Atlas™ Lightweight Evacuable Pellet Dies

15

10.Spare Parts For The Lightweight Die

Complete Dies

P/N GS25410 Atlas™ 32mm Lightweight Evacuable Pellet Die.

P/N GS25411 Atlas™ 40mm Lightweight Evacuable Pellet Die.

Individual Spares

P/N GS25412 Atlas™ 32mm Lightweight Die Body.

P/N GS25413 Atlas™ 32mm Lightweight Die Plunger.

P/N GS25414 Atlas™ 32mm Lightweight Die Base.

P/N GS25415 Atlas™ 32mm Lightweight Die O-ring Kit.

P/N GS25416 Atlas™ 40mm Lightweight Die Body.

P/N GS25417 Atlas™ 40mm Lightweight Die Plunger.

P/N GS2541 Atlas™ 40mm Lightweight Die Base.

P/N GS25419 Atlas™ 40mm Lightweight Die O-ring Kit.

P/N GS03297 Extractor cap for Atlas™ Lightweight Evacuable

Pellet Dies.

User Manual

16

Notes

Worldwide Distribution

France

Eurolabo - Paris.

Tel.01 42 0 01 2

Fax 01 42 0 13 65

email: contact@eurolabo.fr

Germany

L.O.T. - Oriel GmbH & Co,

KG - Darmstadt

Tel: 06151 060

Fax: 06151 06 9

email:info@LOT-Oriel.de

Website: www.LOT-Oriel.com/de

Japan

Systems Engineering Inc. -Tokyo

Tel: 03 3946 4993

Fax: 03 3946 49 3

email:systems-eng@systems-eng.co.jp

Website: www.systems-eng.co.jp

Spain

Teknokroma S.Coop C. Ltda

Barcelona

Tel: 93 674 00

Fax: 93 675 2405

email: comercial@teknokroma.es

Switzerland

Portmann InstrumentsAG

Biel-Benken

Tel: 061 726 6555

Fax: 061 726 6550

email: info@portmann-instruments.ch

Website:www.portmann-instruments.ch

USA

SPECAC INC.

414 Commerce Drive

Suite 175,

Fort Washington,

PA 19034, USA

Tel: 215 793 4044

Fax: 215 793 4011

United Kingdom

Specac Ltd. - London

River House, 97 Cray Avenue,

Orpington

Kent BR5 4HE

Tel: +44 (0) 16 9 73134

Fax: +44 (0) 16 9 7 527

Registered No. 100 6 9 England

Brilliant Spectroscopy™

www.specac.com

SPECAC INC.

414 Commerce Drive

Suite 175,

Fort Washington,

PA 19034, USA

Tel: 215 793 4044

Fax: 215 793 4011

SPECAC LTD.

River House, 97 Cray Avenue,

Orpington

Kent BR5 4HE

Tel: +44 (0) 16 9 73134

Fax: +44 (0) 16 9 7 527

Registered No. 100 6 9 England

This manual suits for next models

2

Table of contents

Other Specac Power Tools manuals

Specac

Specac Atlas GS15800 User manual

Specac

Specac GS03940 User manual

Specac

Specac Apex 400 Press User manual

Specac

Specac Atlas Autotouch 40T User manual

Specac

Specac Atlas Automatic 40 Ton User manual

Specac

Specac Apex 400 User manual

Specac

Specac Atlas 15T User manual

Specac

Specac Atlas Power 8Ton User manual

Specac

Specac Atlas Power 8Ton User manual