1-2 SV61314 Rev. A

1 • Introduction

This document provides guidelines for the proper setup of a scanning job (OMR

or Barcode) on the DI900/DI950 inserting system. It can be used by the District

Technical Sales Consultant (DTSC) to help evaluate if and how a customer's ap-

plication can be run on the inserter; and by the Customer Service Representative

(CSR) to assist in implementing the application as an actual job on the inserter.

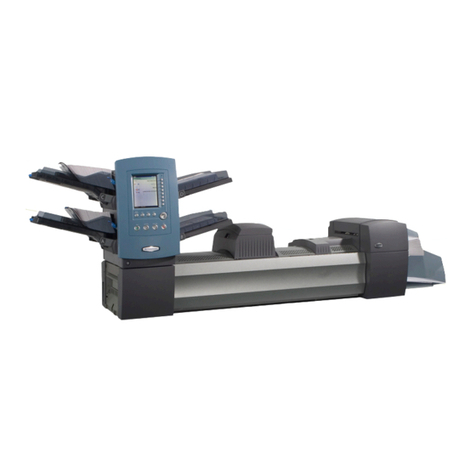

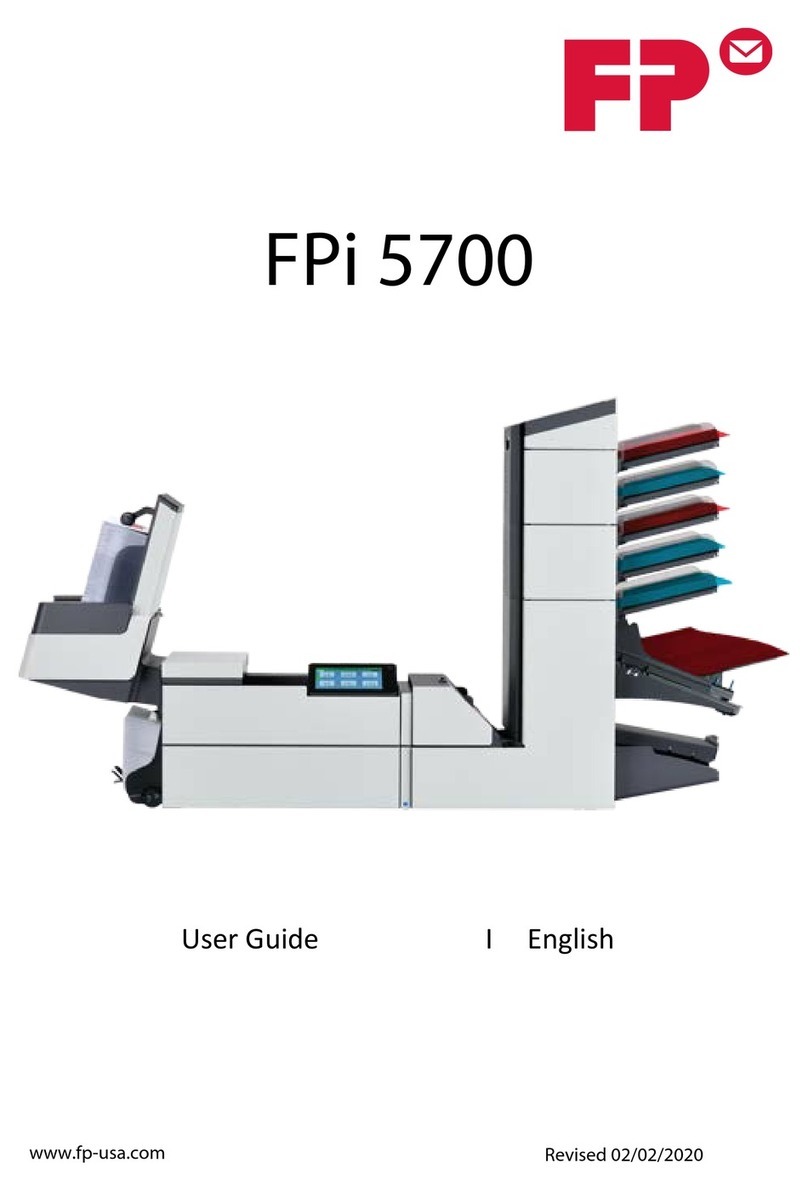

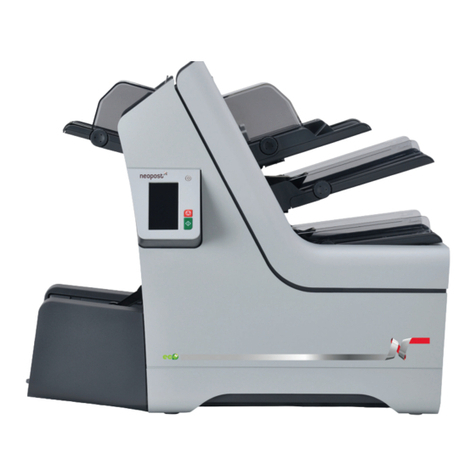

The DI900/DI950 Inserter System is the flagship model of our tabletop in-

serters, and hence, has the most flexibility and scanning features of any of

our current or past models. Unlike our other tabletop inserters whose pre-

progammed presets are closer to the customer's application right "out-of the

box", the DI900/DI950 scanning presets merely give an overview of its ability

(suitable for demos and offering general guidelines only).Also, for most Pitney

Bowes Service personnel, barcode symbology is a relatively new subject. All

of our tabletop inserters previous to the DI900/DI950 inserter used OMR sym-

bology to increase the integrity of the mailpiece (with the exception of a small

number of DI800 ProPack systems in the field which use barcode). Conse-

quently, you need to have a thorough understanding of scan codes (OMR and

barcode) and be familiar with the implementation strategy on the machine in

order to successfully run a customer's application on it.

In addition, because of its scanning flexibility (and hence, increased complex-

ity for implementation), we highly recommend PB FIRST™ (either classic or

PD versions) as the application creation program for those customers starting

new jobs. PB FIRST™ can create and position the marks according to the

DI900/DI950 specifications, reducing the tedious hours of trial-and-error when

trying to create a successful scanning application on your own. However, you

are free to copy the specification section of this guide and give it those cus-

tomer who wish to program it themselves.

IMPORTANT: Some customers' applications cannot be run on this inserter "as

is" due to incompatibility with the machine's specifications. The most common

issues so far:

• Scanning across two columns simultaneously. Only one scanning column

at a time is possible on the DI900/DI950.

• Excessive characters in the barcode symbology. Characters (bytes) great-

er than 18 in a Interleaved 2 of 5 barcode and 12 for Code 3 of 9 barcode

are not supported.

• Excessive number of OMR marks. More than 19 OMR marks are not sup-

ported.

• OMR line is too thick. Line thickness of 1 mm or more, although able to

run on a DI800 inserter, falls outside the DI900/DI950 specifications and

will be disregarded by the software. This is particularly a problem if the

only mark used is EOC, because when the mark is missed, collations are

combined in one mail piece.

• Scanning area on page is outside of spec. Scanning on the DI900/DI950

is allowed on the left and right columns on the sides of the page (not in the

middle).

In these cases, they (or we) will need to alter their application to meet our speci-

fications.

Purpose

✍

TIP: Pitney Bowes

requires that all

applications for a

DI900/DI950 inserter

be pre-approved by

Technical Service

to ensure that no

material or process-

ing problems will be

encountered. Any

application under

consideration should

be approved as early

as possible in the

planning stages.

✍

TIP: Complete scan

code specifications

can be found in

Chapter 4, Scan Code

Specifications.