PAGE5 98646C (Rev. C - 12/12)

4430BF FOUNTAIN

1. Thisfountainistobemountedonasmooth,flat,finishedsurfacewithadequatesupportstructure.NOTE:Mountingstructuremustbe

capableofsupporting300lb.loadonfountain.

2. Refertorough-inforplumbing.

3. Installshut-offvalveonwatersupply.(Valvenotfurnished)

4. Locateandinstallfountainusing3/8"minimum screwsorbolts,(Screwsorboltsnotfurnished).

5. Priortoinstallingthebottlefillertothe centermountingpositionoffountain,insertdrainpipe(Item#10)bypositioningtheshortendof

drainpipethroughmountingplateofbottlefiller. Installbottlefillerto fountainandsecurewithsuppliedhardware.

6. Priortoinstallingthebottletothearmmountoffountain,insertthedrainpipe(Item#11)intothearmtunnel andadjustdraintoleanto

theleftside of the arm when facing the button. Installbottlefillertoarmbeingsuredraintubeisabovemountingplateoffiller.

Secure filler to fountain withsuppliedhardware.

7. Connectfountaintosupplylinewithashut-offvalveandinstalla3/8"unplatedcopperwaterlinebetweenthevalveandthecooler.

Removeanyburrsfromoutsideofwaterline.Push the tubes straight intothefittingsuntiltheyreachapositivestop,approximately

3/4"(SeeFig.2).DO NOTSOLDERTUBESINSERTEDINTOPLASTICFITTINGSASDAMAGETOTHEO-RINGSMAY

RESULT.

8. Watersupply3/8"O.D.unplatedcopper tube.Waste1-1/2"IPS.Contractortosupplywastetrapandservice stopvalvein

accordancewithlocal code.

9. Connectwatersupplyandfountaindrain.Connectdrainwaste"Tee"tofountaindraintubes.Connectoutletof"Tee"todrainage

system.Waterconnectionanddrainmustcomplywithlocalcodes.

10. Turnonwatersupplyandcheckall connections forleaks. Threadeddrainfittingsmayrequirethreadsealertocreatealeakfree

connection. Applythreadsealertothreadedconnectionfittingsonly,not theslipconnectionfittings.

CAUTION:Thisfountainisratedforinletwaterpressureof20-105PSI.Apressurereducingregulatorshouldbeusediftheinletwater

supplyexceeds105PSI.Anydamage caused byreasonof connecting thisproductto supply linepressureslower than

20 psig orhigher than 105 psigis not covered bywarranty.

11. Connectinglinestobemadeofunplatedcopperandshouldbethoroughlyflushedtoremoveallforeignmatterbeforebeingcon

nectedtofountain.Thisfountainismanufacturedinsuch a mannerthatitdoesnotinanywaycausetaste,odor,color,orsediment

problems.

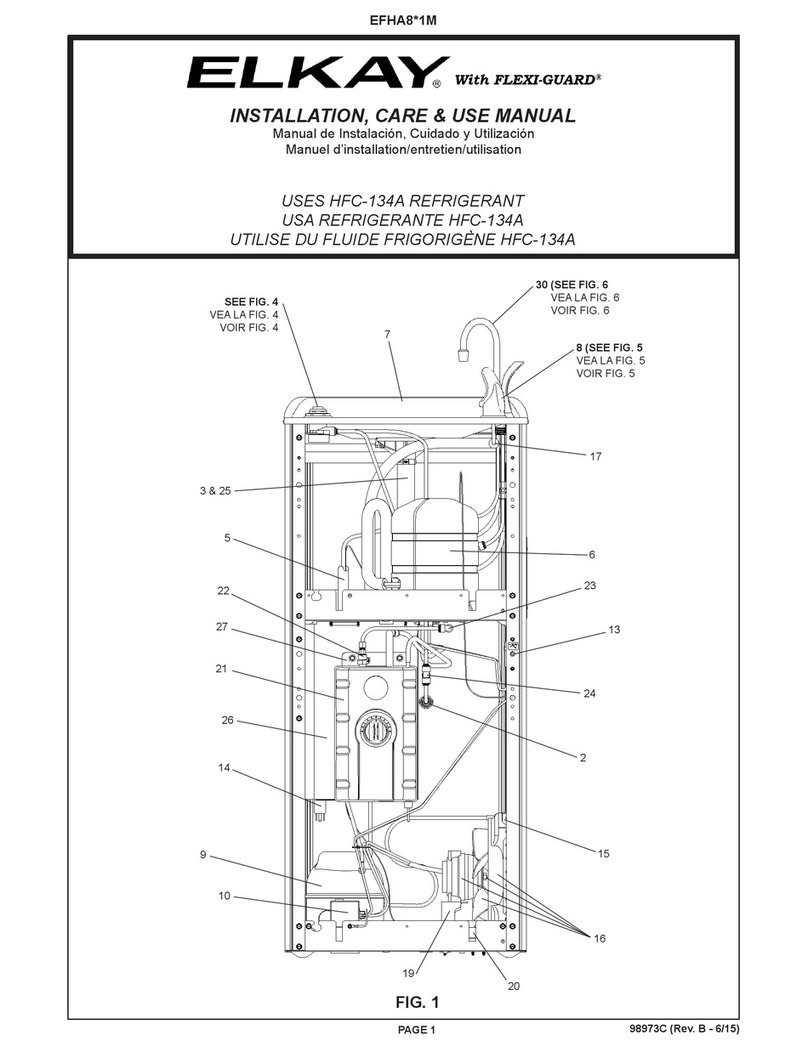

FIG. 1

NOTE:WATER FLOW

DIRECTION

BUILDINGWATERINLET

SERVICESTOP

(NOT FURNISHED)

1/4"O.D.TUBE

WATERINLET

TOCOOLER

3/8"O.D.UNPLATED

COPPERTUBE CONNECT

COLDWATERSUPPLY

FIG. 2

Actuation of Quick Connect Water Fittings:

Fountainis provided withlead-free connectorswhich utilizean

o-ringwater seal.To removetubing from thefitting, relievewater

pressure, push in on the gray collar while pulling on the

tubing.(see Fig.2) To insert tubing, push tube straight into fitting

until it reaches a positive stop, approximately 3/4".

TROUBLE SHOOTING AND MAINTENANCE

STREAMHEIGHTADJUSTMENT:

Stream height is factory set at 35 PSI. If supply

pressure varies greatly from this, insert a small straight

bladedscrewdriver through the access hole in the

center of the push button and turn the adjustment

screw. Clockwise adjustment will raise the stream and

counterclockwiseadjustment will lower the stream. For

best adjustment, the stream should be approximately

1 1/2" above the top of the bubbler . (See Fig. 3)

FIG. 3