- 5 /18 - MI01 Rev. 06 dated 08/11/2019

This document is the property of PolyKeg S.r.l. - Unauthorised copying and use is prohibited

USER MANUAL FOR POLYKEG KEGS

3.

HANDLING - STORAGE - TRANSPORT OF EMPTY KEGS

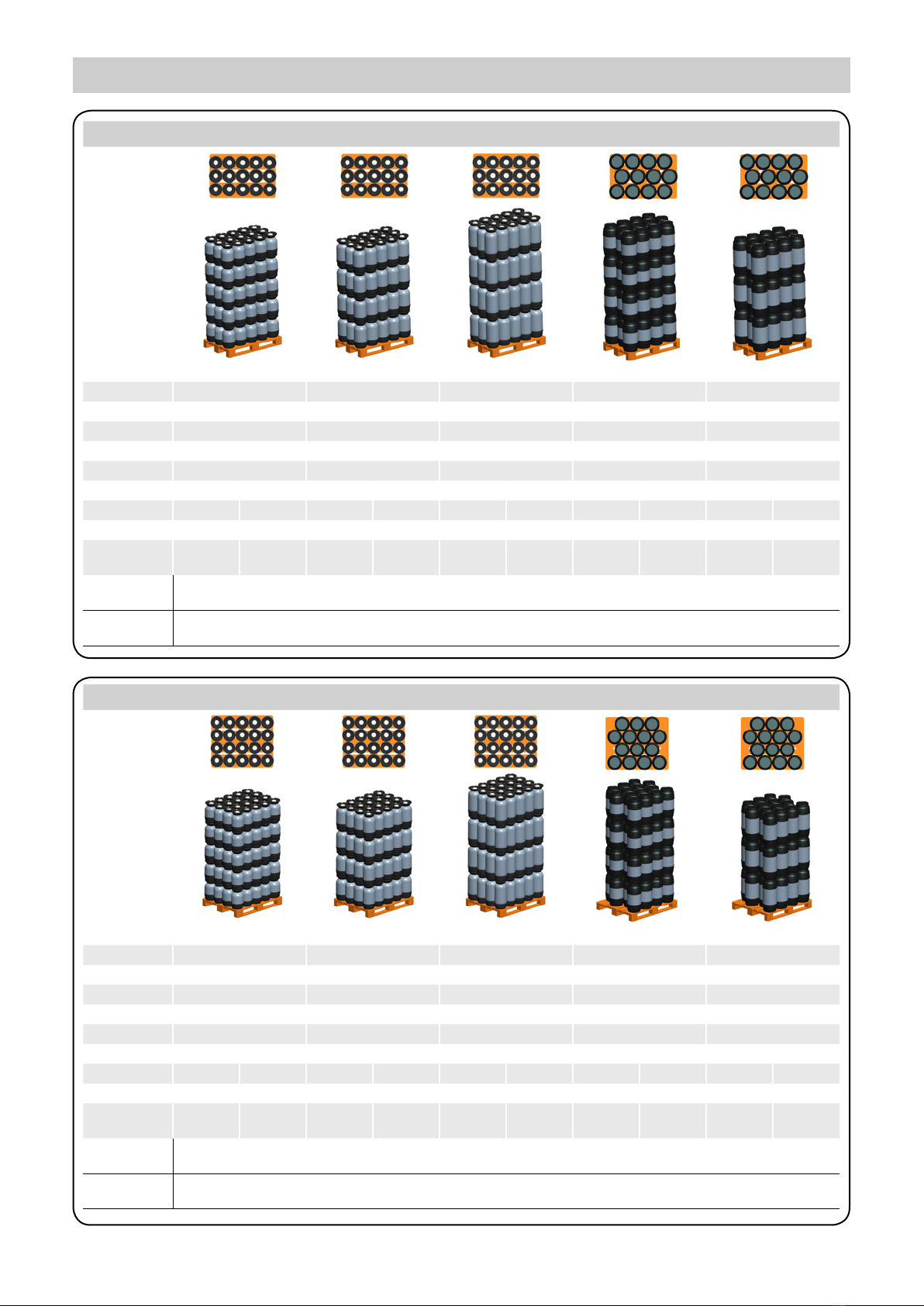

Empty kegs 800x1200 mm PALLETS

Palleting

12 L 16 L 20 L 24 L 30 L

N° layers 5 4 4 4 3

Kegs per layer 15 15 15 12 12

Kegs per pallet 75 60 60 48 36

Height (mm) 2124 mm 2090 mm 2442 mm 2402 mm 2152 mm

Height (inch) 83.62” 82.28” 96.14” 95.56” 84.72”

n° pallets n° kegs n° pallets n° kegs n° pallets n° kegs n° pallets n° kegs n° pallets n° kegs

Lorry (13.6m) 33 2475 33 1980 33 1980 33 1584 33 1188

Container 20 ft 11 825 11 660 11 660 11 528 11 396

Container 40 ft

High Cube 24 1800 24 1440 24 1440 24 1152 24 864

Notes The pallets are wrapped and covered with white stretch film. For the Basic version, a cardboard layer pad is inserted between the

various layers. Position of kegs: valve upwards.

Recommendations

Any stacking of pallets must be carried out in consideration of the mechanical properties of the kegs as shown on the technical sheet,

of local regulations, of the vehicles and methods for handling and the conditions of the storage areas.

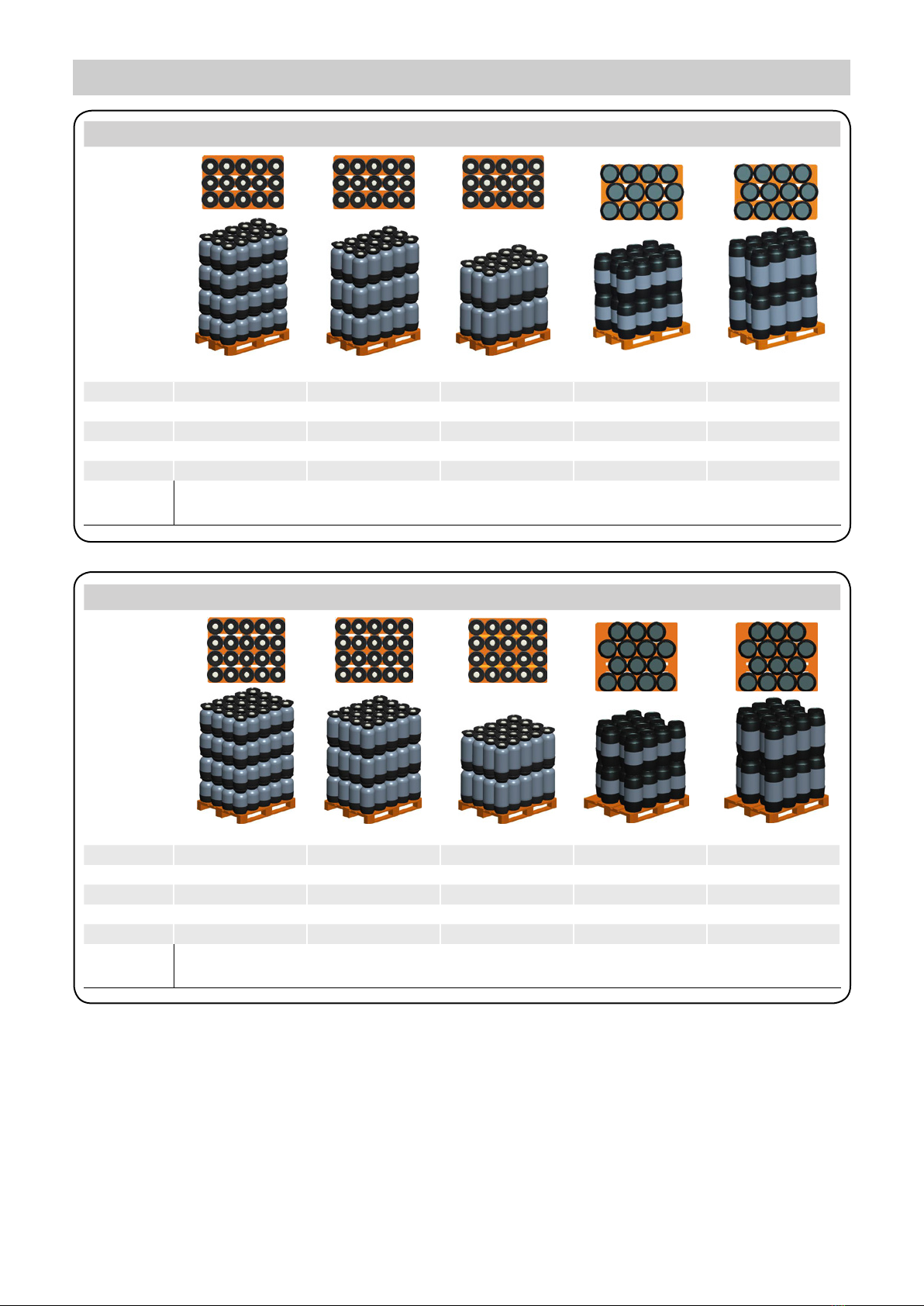

Empty kegs 1000x1200 mm PALLETS

Palleting

12 L 16 L 20 L 24 L 30 L

N° layers 5 4 4 4 3

Kegs per layer 20 20 20 14 14

Kegs per pallet 100 80 80 56 42

Height (mm) 2124 mm 2090 mm 2442 mm 2402 mm 2152 mm

Height (inch) 83.62” 82.28” 96.14” 95.56” 84.72”

n° pallets n° kegs n° pallets n° kegs n° pallets n° kegs n° pallets n° kegs n° pallets n° kegs

Lorry (13.6m) 26 2600 26 2080 26 2080 26 1456 26 1092

Container 20 ft 10 1000 10 800 10 800 10 560 10 420

Container 40 ft

High Cube 21 2100 21 1680 21 1680 21 1176 21 882

Notes The pallets are wrapped and covered with white stretch film. For the Basic version, a cardboard layer pad is inserted between the

various layers. Position of kegs: valve upwards.

Recommendations

Any stacking of pallets must be carried out in consideration of the mechanical properties of the kegs as shown on the technical sheet,

of local regulations, of the vehicles and methods for handling and the conditions of the storage areas.