PolyKeg PRO User manual

Other PolyKeg Kegerator manuals

Popular Kegerator manuals by other brands

Nostalgia Electrics

Nostalgia Electrics KEG9000DTSS instruction manual

Nostalgia Electrics

Nostalgia Electrics KRS2100 SERIES instruction manual

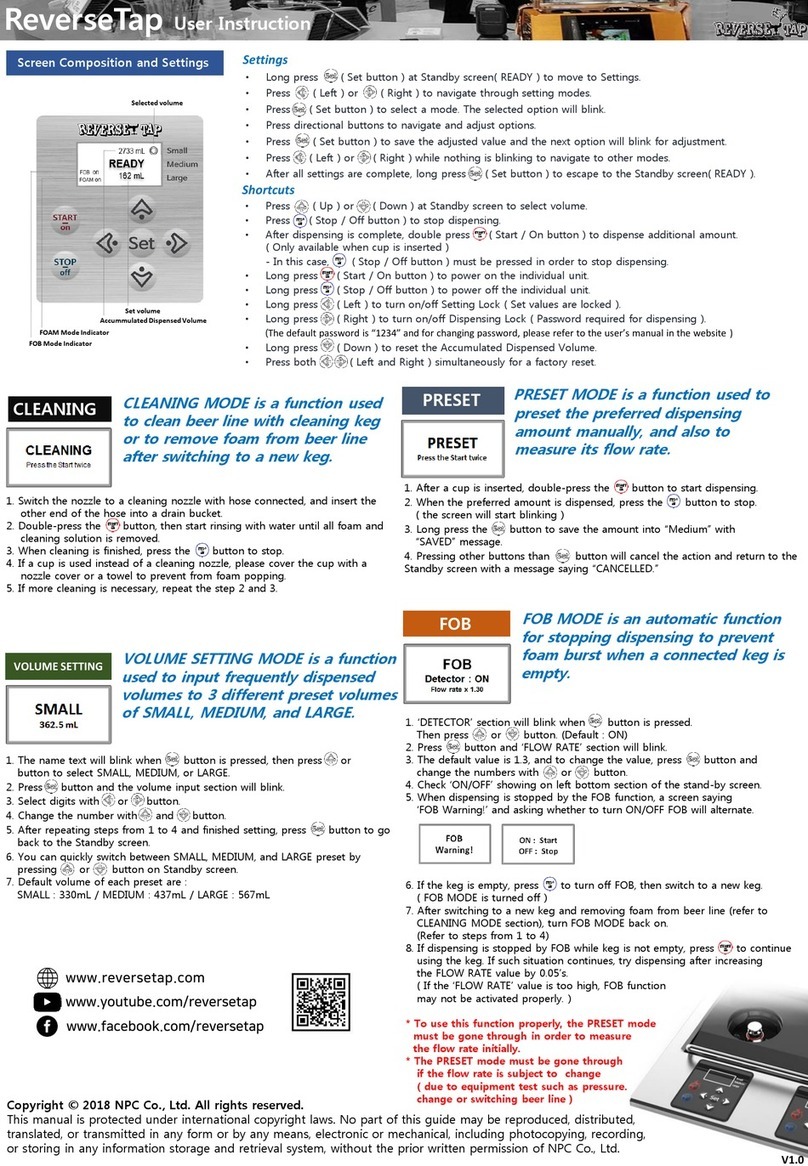

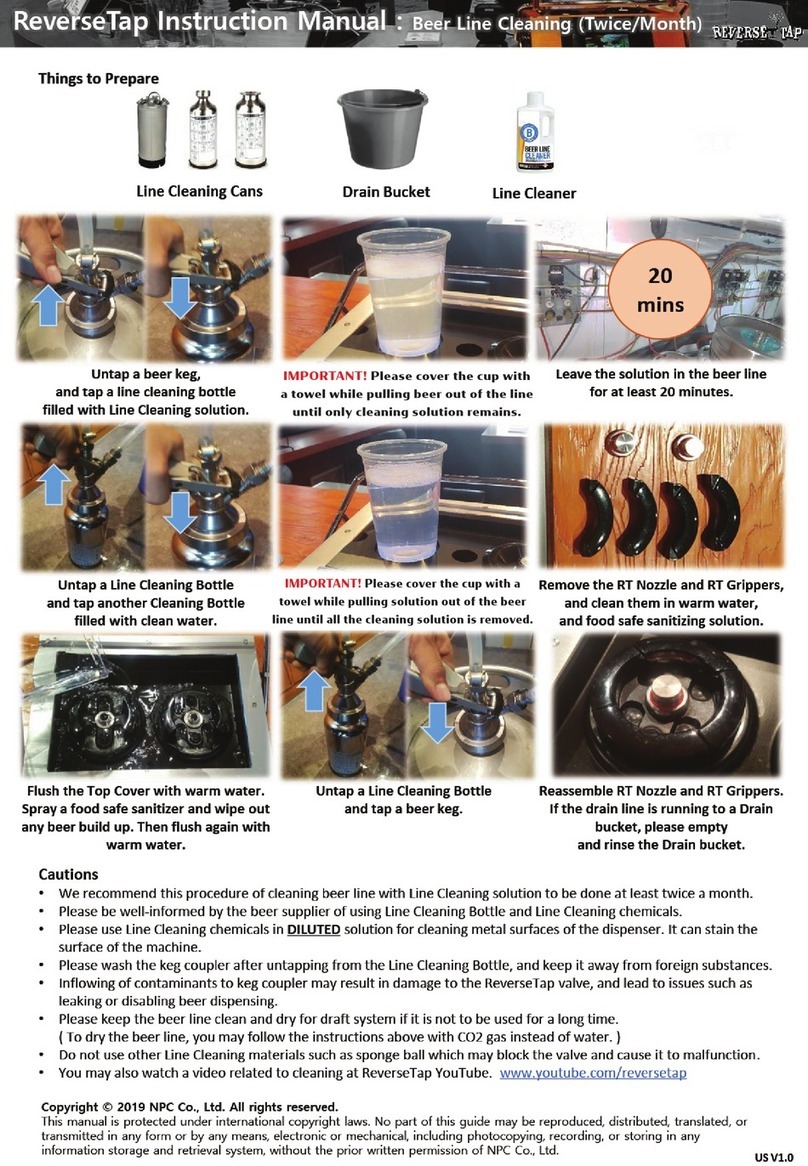

NPC

NPC ReverseTap instruction manual

AMD DIrect

AMD DIrect SSRFR-24DK user manual

KegLand

KegLand Fermzilla instruction manual

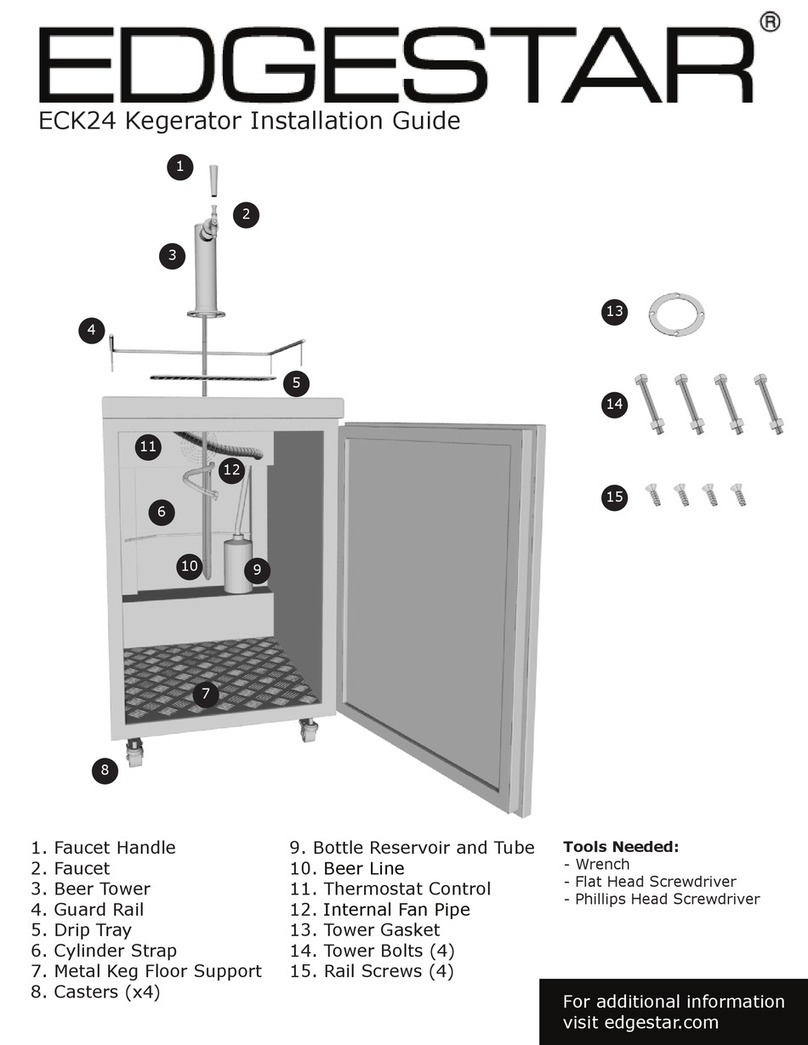

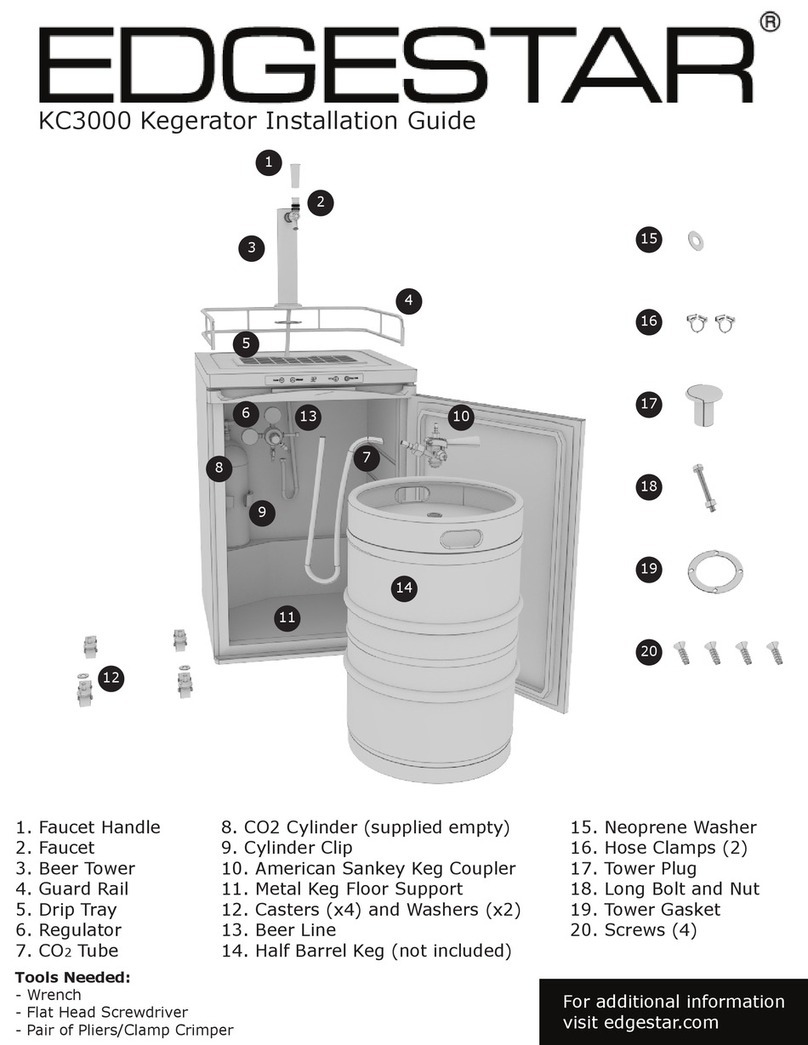

EdgeStar

EdgeStar KC3000 installation guide

Nostalgia Electrics

Nostalgia Electrics Kegorator KRS-2150 instruction manual

Nostalgia Electrics

Nostalgia Electrics KEGORATOR KRS-2000 SERIES instruction manual

NPC

NPC ReverseTap RD-B1 installation guide

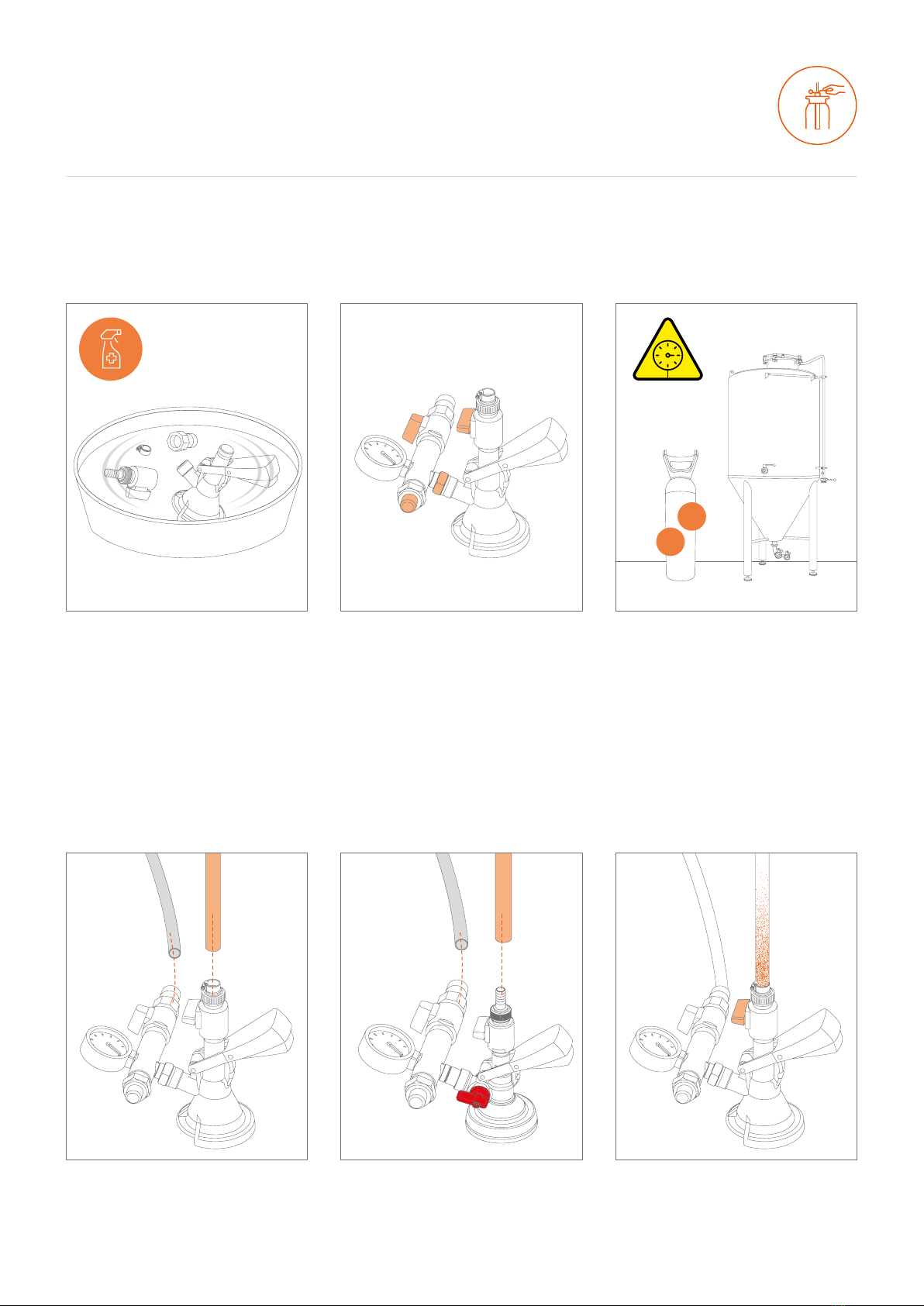

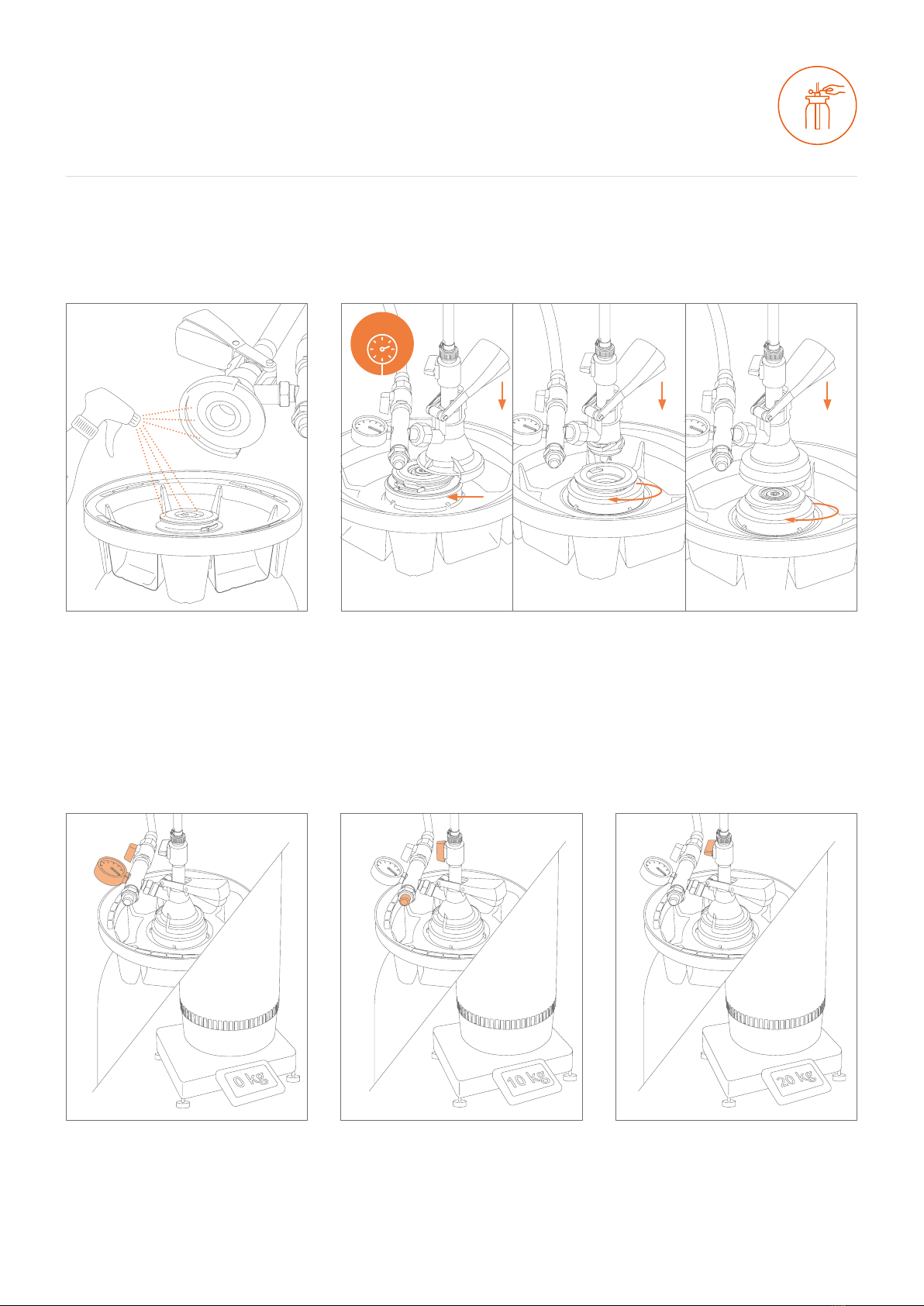

KegLand

KegLand Benchy Carbon KL18210 instruction manual

KegLand

KegLand Benchy - Glycol instruction manual

Kegco

Kegco Hot Draft KC HDT301 user manual