* If the boiler is cold, cold water is going out by the steam outlet:

Check

- the heating element ref. PN0771

- the thermofuses ref. PN1970 or PN1971

- the thermostat 150°C ref. PN0880

* If when heating the milk the foam is not taking form:

- Check the little hole at the top of the teflon steam outlet ref. PN1110

TEMPERATURE ADJUSTMENT OF THE COFFEE HEAT EXCHANGER

−Switch off the machine before introducing the adjusting key in the potentiometer located on the temperature

control card ref. PN0490

−The temperature is increased by turning anti-clockwise, it is decreased by turning clockwise (Be careful that

the potentiometer is very sensitive).

−During the first heating of a machine, an important thermic impulse is producing. The heat exchanger can

reach 120°C. Before adjusting temperature, let the machine become stable and make water go through to

start heating again.

−Directions for operating:

•The thermometer must be placed directly at the outlet of the coffee spout ref. PY7066.

•As the filter-holder is closed and without coffee, make flow around 5 cl of water by turning the selecting

button to the right.

•The maximum temperature pointed during flowing must be 87° C ± 3°C.

•If it is not the case, adjust the potentiometer and repeat the operation.

−NOTA :

When exchanging an electronic probe, put always some special white paste between this and the heat

exchanger.

ADJUSTMENT OF PULSES FOR STEAM

−Switch off the machine before introducing the adjusting key in the potentiometer located on the electronic

card ref. PN0510.

−The number of pulses is increased by turning clockwise, it is decreased by turning anti-clockwise.

−More the number of pulses is increased, less the steam is dry and less the foam will be fine, but the time

taken to get cream will be shorter.

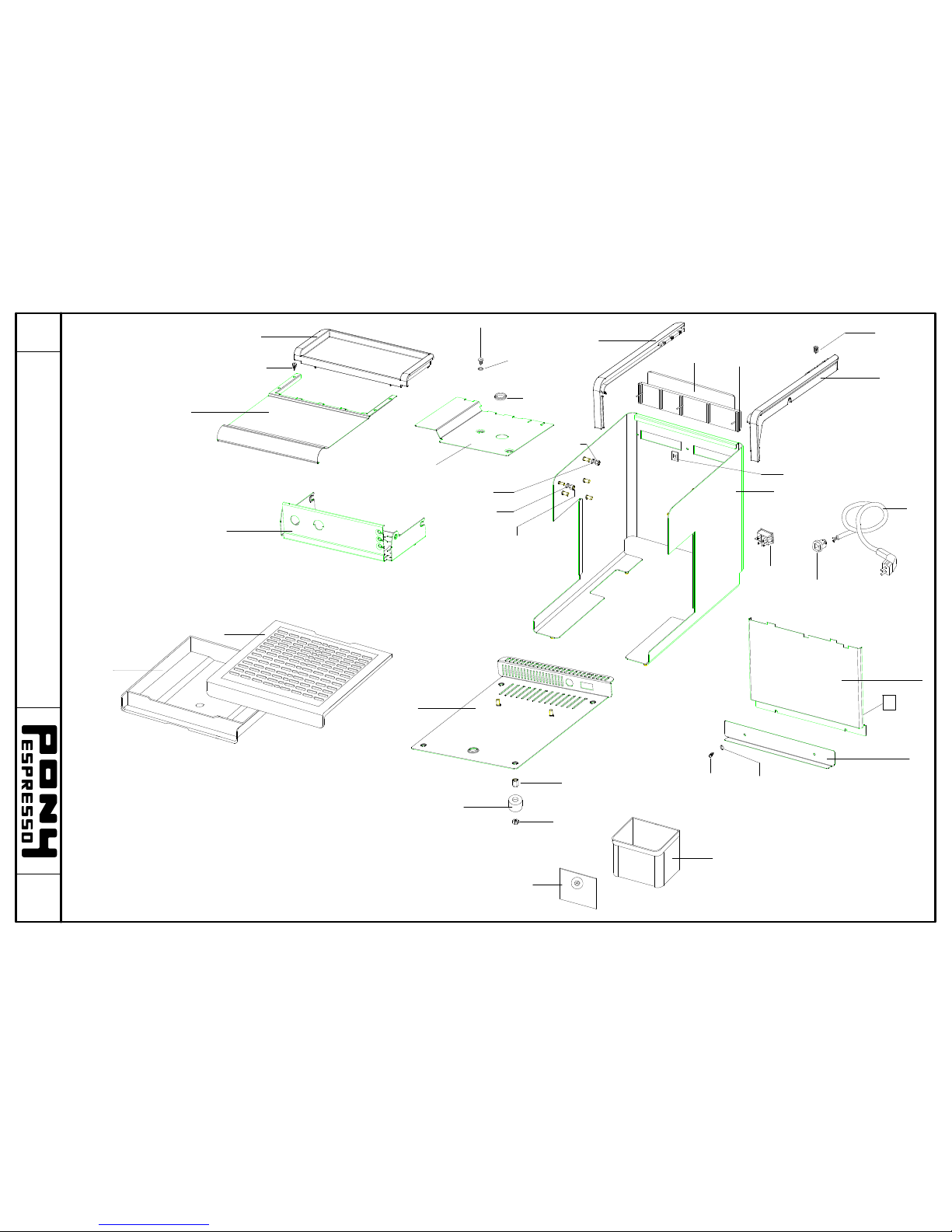

DIS-ASSEMBLING OF THE COFFEE HEAT EXCHANGER

−The heat exchanger can be completely taken off by unscrewing under the screws located under the "nose" of

the machine, beside the infusion head which maintain it at the frame. This operation is necessary when dis-

assembling the 3-way electrovalve.

−When operating on the heat exchanger to change the heating lement, some gaskets, or dis-assemble the

mobile piston, the unit can remain on the frame. So only the upper part is dis-assembled by unscrewing the 5

screws which join the 3 elements of the heat exchanger together – base, heating element, cover

−Note that the mobile piston is composed of a piece in aluminium ref. PY4090 and a stainless steel axle ref.

PY4093. The two pieces must be stuck together with Loctite 601 glue and well tight.

−When re-assembling the piston closing screw ref. 53310, use Loctite 243 glue.