MPK with CommandPak™Control System BACnet /IP User’s Guide

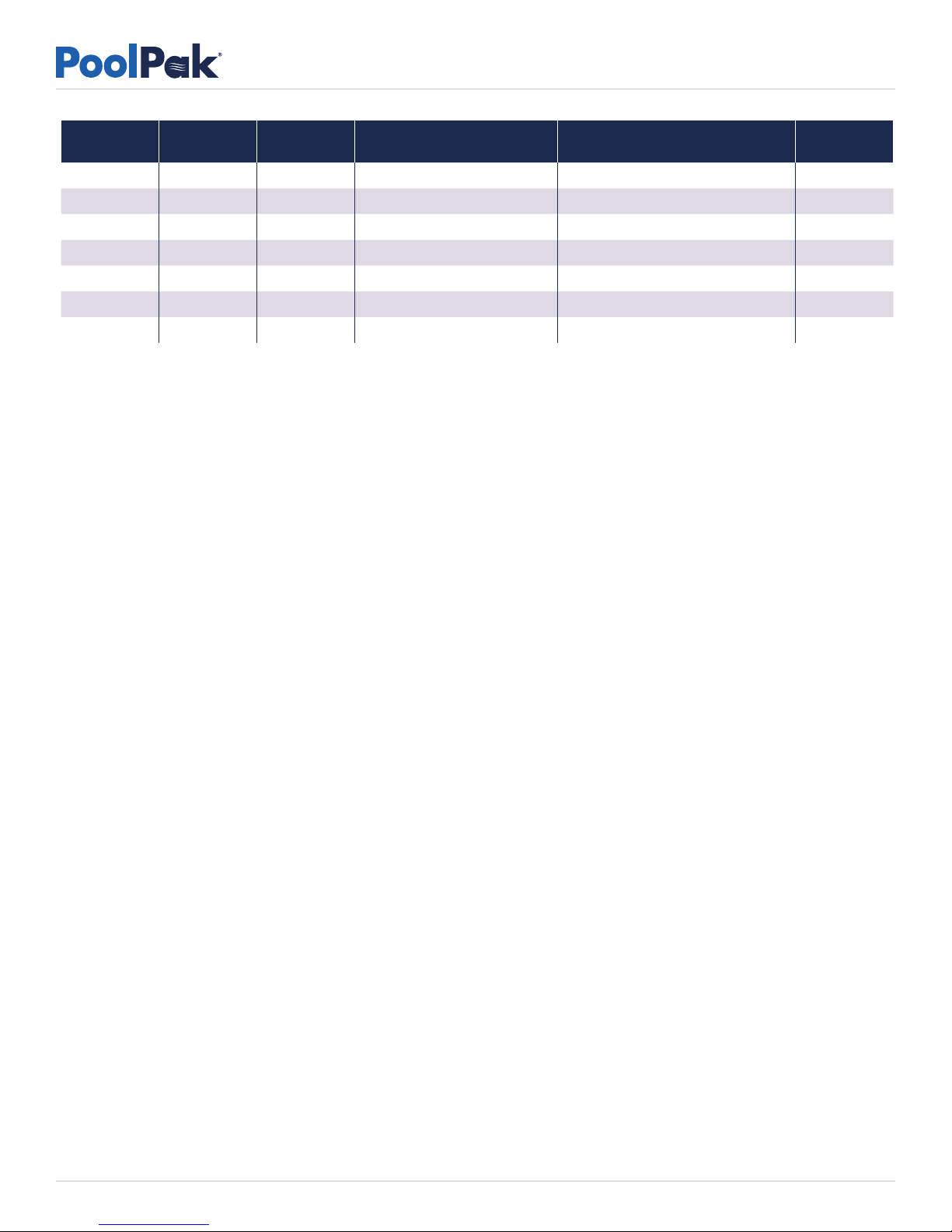

SYMPTOM POSSIBLE CAUSE SOLUTION

The dehumidifier cannot be seen

on the BACnet network.

The interface card is not properly

connected to the network. Correct network wiring.

Power to the controller is off.

If safe to do so, turn on the main

disconnect and the control power

switch(CPS) in the control

compartment of the dehumidifier.

The BAS is trying to access the interface

with the wrong device instance number.

Follow the instructions in this

document to set the instance number

to a value appropriate for the BAS.

The variable values sent by the

controller are different than

those shown on the RIU.

Incorrect setting of the

BAS configuration parameters

in the service menu.

Correct the parameter values to match

the settings shown in this document.

Set point changes are different

than requested by the BAS.

Requested set point change is

outside of the acceptable range.

Select set points based

on the acceptable range.

3491 Industrial Drive

York, Pennsylvania 17402 USA

800-959-7725 Fax 717-757-5085

© 2017 PoolPak LLC. All rights reserved. SVW07-MPKBACNIP-20171020

With more than 45 years of experience in indoor pool dehumidification equipment manufacturing, PoolPak®LLC is the most well-known brand

in the industry. Our people and products work daily to improve the quality and comfort of indoor pool environments. PoolPak®dehumidification

solutions include a variety of heating, ventilation, and air conditioning systems, in addition to an industry-leading PoolPak®support network. For more

information, please visit www.PoolPak.com.

For questions about the interface that are not answered in this document,

please contact the PoolPak Service department at 800-959-7725.

BACnet®is a registered trademark

of American Society of Heating,

Refrigerating and Air-Conditioning

Engineers (ASHRAE). This

trademark is used in the text, but

for the sake of readability, it is not

individually marked.