MDT-4000 User Manual (Original Instructions)

Ver: 1.0

1. PRODUCT OVERVIEW ..................................................................................................................................... 4

2. SAFETY CONSIDERATIONS .............................................................................................................................. 5

2.1. SAFETY STANDARD COMPLIANCE STATEMENT..................................................................................................... 5

2.2. SAFETY SYMBOLS ........................................................................................................................................ 5

2.3. EXPLOSION HAZARD .................................................................................................................................... 5

2.4. DESCRIPTION OF INTENDED USE...................................................................................................................... 5

2.5. LIST OF PROHIBITED USES.............................................................................................................................. 6

2.6. WARNINGS ............................................................................................................................................... 6

2.7. PERSONAL PROTECTIVE EQUIPMENT................................................................................................................ 6

3. REGULATORY MARKINGS ............................................................................................................................... 7

4. SYSTEM SPECIFICATIONS ................................................................................................................................ 8

4.1. MECHANICAL SPECS .................................................................................................................................... 8

4.2. MOTION................................................................................................................................................... 8

4.3. ELECTRICAL SPECS....................................................................................................................................... 8

4.4. ENVIRONMENTAL SPECS ............................................................................................................................... 9

4.5. EMC EMISSION.......................................................................................................................................... 9

4.6. EMC IMMUNITY......................................................................................................................................... 9

4.7. ELECTROSTATIC DISCHARGE (ESD).................................................................................................................. 9

4.8. EXPECTED SERVICE LIFE ................................................................................................................................ 9

5. INSTALLATION .............................................................................................................................................. 10

5.1. UNPACKING AND INITIAL SETUP INSTRUCTIONS................................................................................................. 10

5.2. AC MAINS DISCONNECT.............................................................................................................................. 12

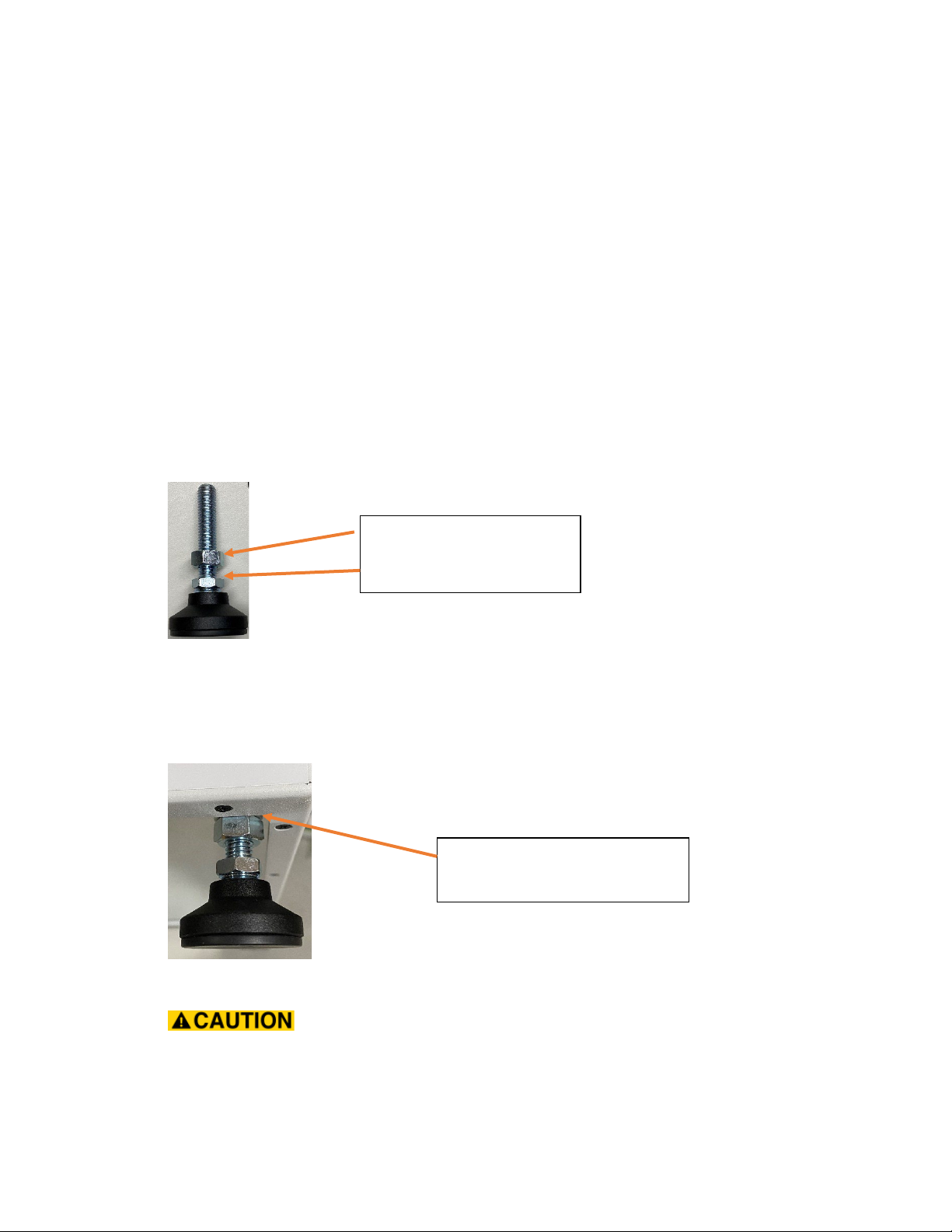

5.3. INSTALLATION CONFIGURATION:FREESTANDING USING LEVELING LEGS .................................................................. 12

5.4. INSTALLATION CONFIGURATION:BOLTED TO FLOOR .......................................................................................... 12

5.5. INSTALLATION CONFIGURATION:INVERTED ON CEILING...................................................................................... 12

5.6. ADDITIONAL INSTALLATION WARNINGS.......................................................................................................... 13

5.7. CABLE ROUTING GUIDELINES........................................................................................................................ 16

5.8. SAFETY GUIDELINES FOR FIXTURING ATTACHED TO THE TURNTABLE ....................................................................... 16

6. SYSTEM OPERATION..................................................................................................................................... 17

6.1. FRONT PANEL ELEMENTS............................................................................................................................ 17

6.2. REAR PANEL ELEMENTS.............................................................................................................................. 18

6.3. EMERGENCY STOP SYSTEM.......................................................................................................................... 18

6.4. CURRENT ANGLE READOUT.......................................................................................................................... 19

6.5. DIRECTION OF ROTATION ............................................................................................................................ 20

6.6. DESCRIPTION OF CONTROL INTERFACES .......................................................................................................... 21

6.7. SETTING THE SYSTEM ZERO POSITION............................................................................................................. 22

6.8. USE OF THE MAXIMUM TORQUE SETTING........................................................................................................ 23

6.9. REMOTE CONTROL INTERFACES .................................................................................................................... 23

7. FACTORY DEFAULT CONFIGURATION ........................................................................................................... 24

8. MECHANICAL DRAWINGS AND DIMENSIONS............................................................................................... 25

8.1. PLATTER DETAILS ...................................................................................................................................... 25

8.2. TOP OUTLINE ........................................................................................................................................... 26

8.3. FRONT OUTLINE........................................................................................................................................ 27