degree of protecon against an electric shock.

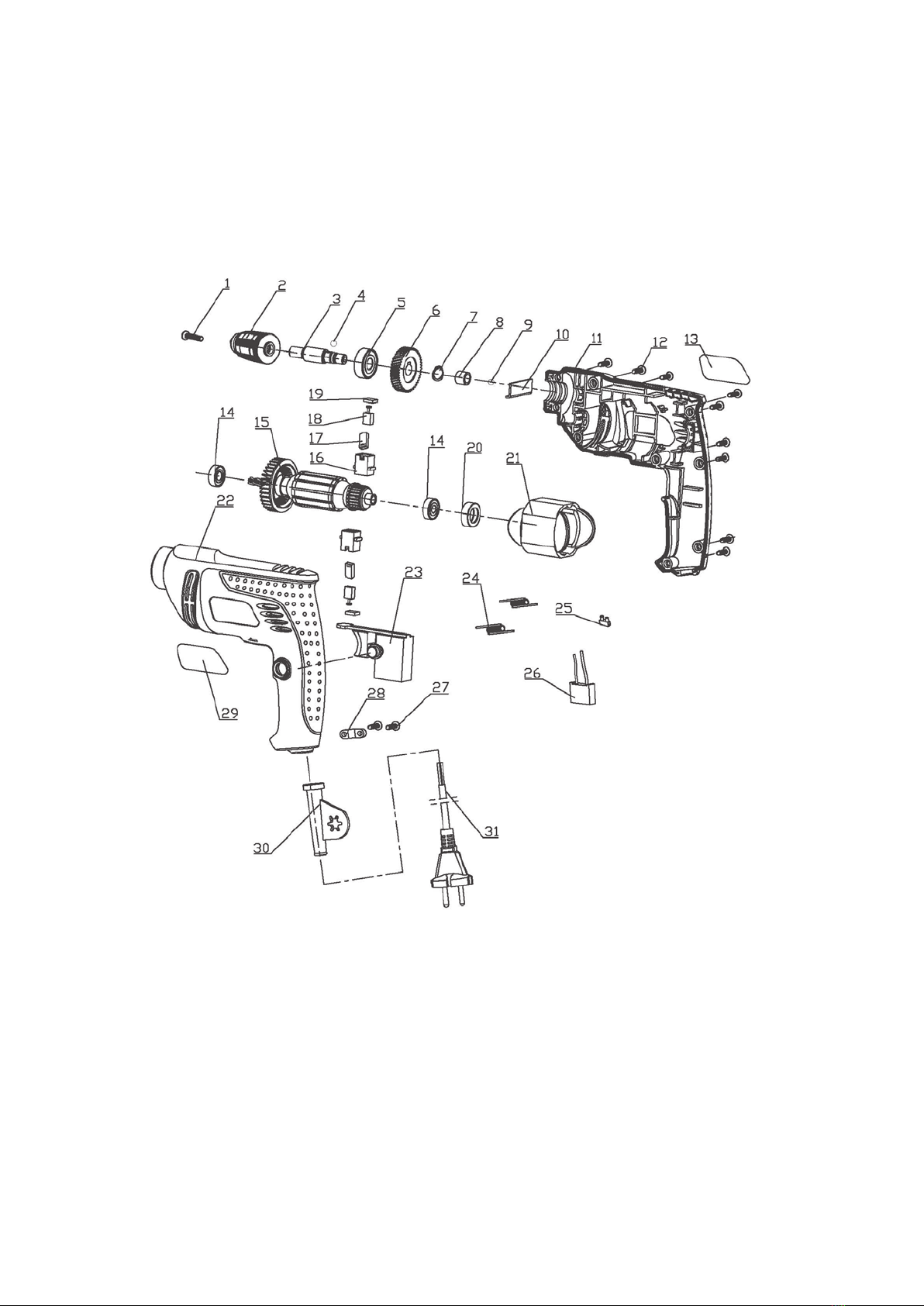

Your Drill has the following Funcons:

The operang switch (3) is used for all work carried out with the drill machine

The machine can be set to connuous operaon with the locking buon (4)

The direcon switch (2) controls the direcon of moon when the machine is used as a

screwdriver or if you would like to remove a drilling bit that has become jammed.

Preparing the Drilling Machine

Warning! When performing the following work. Always ensure that the machine is not connected

to the mains power supply.

Inserting the Drill

For key chuck

First remove the mains supply from the socket. Turn the ring of the drill chuck (1) unl the

clamping jaws are open wide enough. Insert the drill into the clamping jaws of the drill chuck (1).

Insert the end of the drill chuck key into one of the three holes on the body of the drill chuck (1)

and let the head of the key lock into place in the ring of the drill chuck (1). In order to ghten

the clamping jaws and fix the drill in place, turn the drill chuck key in a clockwise direcon.

Important: Then remove the key from the chuck (1)!

Working with the Drilling Machine

Ensure that the mains power supply voltage is the same as the operang voltage of your machine.

For details, please see the type plate.

Insert the correct drill for the type of job to be performed. If necessary, adjust the bit stop. Adjust

the speed of the machine using the regulang wheel on the operang switch (4). The more the

operang switch (4) is pressed in. the faster the drill rotates. Set the direcon switch (2) to the

desired direcon of moon. Never alter the posion of the direcon switch (2) when the

machine is switched on by pressing the operang switch (4). When operang switch (4) is

released, the machine stops. If you would like to use connuous operaon press the locking

buon (3) while the operang switch (4) is press. In order to switch offthe machine during

connuous operaon, press the operang switch (4) again and then let it go. Do not touch the

drill chuck (1) while the machine is switched on.

Drilling Tips

Always insert the correct size and type of drill or screwdriver.