Transtecno TT100 series User manual

TT100

·A·

CONTENTS

I. Product ………………………………………………………………..

1.1 Product model naming rule….………………………………

1.2 Optional function naming rule………………………………

1.3 Nameplate……..……………………………………………

1.4 Appearance…………….……………………………………

1.5 Technical Specifications ……………………………………

1.6 Designed Standards for Implementation……………………

1.7 Safe Instructions………………………………………………

1.8 Precautions……………………………………………………

1.9 Examination and Maintenance…………………………..……

II. Keypad panel……………………………………………………..…

2.1 Panel Illustrations……………………………………………

2.2 Panel Structure………………………………………………

2.3 Panel Operating ……………………………………………

2.4 Parameters Setting …………………………………………

2.5 Function Codes Switchover In/Between Code-Groups…..…

2.6 Panel Display ………………………………………………

III. Installation & Connection ………………………………………………

3.1 Installation……………………………………………………

3.2 Connection ……………………………………………………

3.3 Function of Control Terminals……………………………………

3.4 Wiring Recommended…………………………………………

3.5 Lead Section Area of Protect Conductor(grounding wire) ……

3.6 Overall Connection………………………………………………

IV. Operation and Simple Running ………………………………………

V. Function Parameters ……………………………………………………

5.1 Basic Parameters………………………………………………

5.2 Operation Control ……………………………………………..

1

1

1

2

2

4

5

5

6

7

8

8

9

9

10

10

11

12

12

12

14

17

17

18

19

26

26

34

TT100

·B·

5.3 Multifunctional Input and Output Terminals……………………

5.4 Analog Input and Output………………………………….…

5.5 Pusle input and output………………………………….……

5.6 Multi-stage Speed Control…………………….………………

5.7 Auxiliary Functions………………………………..…….……

5.8 Malfunction and Protection……………………………………

5.9 Parameters of the motor………………………………………

5.10 Communication parameters……………………………………

5.11 PID parameters…………………………………………….

Appendix 1 Trouble Shooting…………………………………..…….

Appendix 2 Products and Structure List…………………..…………..

Appendix 3 Selection of Braking Resistance ………………………….….

Appendix 4 Communication Manual………………………………….

Appendix 5 Zoom Table of Function Code ……………………….………

41

45

50

52

54

56

58

58

59

60

61

65

66

75

TT100

·1·

I. Product

This manual offers a brief introduction of the installation connection for TT100 series

inverters, parameters setting and operations, and should therefore be properly kept. Please

contact manufacturer or dealer in case of any malfunction during application.

1.1 Product model naming rule

TT100 –0007 S2

1.2 Optional function naming rule

D F1 Y K B R

Mark

0002

0004

0007

……

Motor power(kw)

0.2

0.4

0.75

……

Mark

Built-in EMIfilter

None

None

R

Including built-in EMI filter

Mark

Built-in braking unit

None

None

B

Including built-in braking unit

Mark

Operation panel with potentiometer

None

Localoperationpanelwithoutpotentiometer

K

Localoperationpanelwithpotentiometer

Mark

Operation panel type

None

Operation panel is not removable.

Y

Operation panel is removable, to be controlled remotely.

Mark

Scene bus type

None

No communication function

F1

With MODBUS communication function

Mark

Structure code

None

Hanging type

D

Cabinet type

Relation

Input power type:

S2 means single-phase 230VAC

T3 means three-phase 400VAC

Motor power

Product series

TT100

·2·

1.3 Nameplate

Taking for instance the TT100 series

0.75KW inverter with 1-phase input, its

nameplate is illustrated as Fig 1-1.

1Ph: single-phase input; 230V, 50/60Hz:

input voltage range and rated frequency.

3Ph: 3-phase output; 4.5A, 0.75KW:

rated output current and power;

0.50~650.0Hz: output frequency range.

1.4 Appearance

The external structure of TT100 series inverter is classified into plastic and metal housings.

And wall hanging type is adopted. Good poly-carbon materials are adopted through

die-stamping for plastic housing with nice form, good strength and toughness.

Taking TT100-0007S2 for instance, the external appearance and structure are shown as in

below Fig.

Vent Hole

Control Terminal

Keypad Controller

Power Terminal

Mounting Hole

Heatsink

Fig 1-1 Nameplate

MODEL

TT100-0007S2

Function

Symbol

F1KBR

INPUT

AC 1PH 230V 50/60Hz

OUTPUT

3PH 0.75KW 4.5A 0~230V

0.50~650.0Hz

条形码

TT100

·3·

1.5 Technical Specifications

Table1-1 Technical Specifications for TT100 Series Inverters

Items

Contents

Input

Rated Voltage Range

3-phase 400V±15%; single-phase 230V±15%

Rated Frequency

50/60Hz

Output

Rated Voltage Range

3-phase 0~400V;3-phase 0~230V

Frequency Range

0.50~650.0Hz

Control

Mode

Carrier Frequency

2000~10000Hz; Fixed carrier-wave and random carrier-wave

can be selected byF159.

Input Frequency Resolution

Digitalsetting:0.01Hz,analogsetting:max frequency

0.1%

Control Mode

VVVF control

Overload Capacity

150% rated current, 60 seconds.

Torque Elevating

Auto torque promotion, Manual Torque Promotion

0.1%~30.0% (VVVF)

V/F Curve

3 kinds of modes: beeline type, square type and

under-defined V/F curve.

DC Braking

DCbraking frequency: 1.0~5.0 Hz,brakingtime:0.0~10.0s

Jogging Control

Jogging frequency range: min frequency~ max frequency,

jogging acceleration/deceleration time: 0.1~3000.0s

Auto Circulating Running and

multi-stage speed running

Auto circulating running or terminals control can realize

15-stage speed running.

Built-in PID adjusting

Easy to realize a system for process closed-loop control

Operation

Function

Frequency Setting

Potentiometer or external analog signal (0~5V, 0~10V,

0~20mA); keypad (terminal)▲/▼ keys, external

control logic and automatic circulation setting.

Start/Stop Control

Terminal control, keypad control or communication control.

Running Command Channels

3 kinds of channels from keypad panel, control terminal and

series communication port.

Frequency Source

Frequency sources: given digit, given analog voltage, given

analog current and given series communication port.

Accessorial frequency Source

Flexible implementation of 5 kinds of accessorial frequency

fine adjustments and frequency compound.

Optional

Built-in EMI filter, built-in braking unit, Modbus communication, telecontrol panel

Protection

Function

Input out-phase, Output out-phase, input under-voltage, DC over-voltage, over-current,

over-load, current stall, over-heat, external disturbance

Display

LED nixie tube showing present output frequency, present rotate-speed (rpm), present output

current, present output voltage, present linear-velocity, types of faults, and parameters for the

system and operation; LED indicators showing the current working status of inverter.

Environment

Conditions

Equipment Location

In an indoor location, Prevent exposure from direct

sunlight, Free from dust, tangy caustic gases, flammable

gases, steam or the salt-contented, etc.

Environment Temperature

-10℃~+50℃

Environment Humidity

Below 90% (no water-bead coagulation)

Vibration Strength

Below 0.5g (acceleration)

Height above sea level

1000m or below

TT100

·4·

Protection

level

IP20

Applicable

Motor

0.2~15KW

1.6 Designed Standards for Implementation

IEC/EN 61800-5-1: 2003 Adjustable speed electrical power drive systems

safety requirements.

IEC/EN 61800-3: 2004 Adjustable speed electrical power drive systems-Part

3: EMC product standard including specific test methods.

1.7 Safe instructions

Please check the model in the nameplate of the inverter and the rated value of

the inverter. Please do not use the damaged inverter in transit.

Installation and application environment should be free of rain, drips, steam,

dust and oily dirt; without corrosive or flammable gases or liquids, metal

particles or metal powder. Environment temperature within the scope of -10℃~

+50℃.

Please install inverter away from combustibles.

Do not drop anything into the inverter.

The reliability of inverters relies heavily on the temperature. The around

temperature increases by 10℃, inverter life will be halved. Because of the wrong

installation or fixing, the temperature of inverter will increase and inverter will

be damaged.

If inverter is installed in a control cabinet, smooth ventilation should be ensured

and inverter should be installed vertically. If there are several inverters in one

cabinet, in order to ensure ventilation, please install inverters side by side. If it is

necessary to install several inverters up and down, please add heat-insulation

plate.

TT100

·5·

1.8 Precautions

1.8.1 Instructions for use

Never touch the internal elements within 15 minutes after power off. Wait till it

is completely discharged.

Input terminals R, S and T are connected to power supply of 400V while output

terminals U, V and W are connected to motor.

Proper grounding should be ensured with grounding resistance not exceeding

4Ω; separate grounding is required for motor and inverter. Grounding with

series connection is forbidden.

Load switch is forbidden at output while inverter is in operation.

AC reactor or/and DC reactor is recommended when your inverter is above 37KW.

There should be separate wiring between control loop and power loop to avoid

any possible interference.

Signal line should not be too long to avoid any increase with common mode

interference.

It shall comply with the requirements for surrounding environment as stipulated

in Table 1-1 “Technical Specifications for TT100 Series Inverter”.

1.8.2 Special Warning!!

Never touch high-voltage terminals inside the inverter to avoid any electric shock.

Before inverter is powered on, please be sure that input voltage is correct.

Please do not connect input power supplyonto U,V,Wor terminals.

Please do not install inverter directly under sunshine, do not block up the cooling hole.

TT100

·6·

All safety covers should be well fixed before inverter is power connected, to

avoid any electric shock.

Only professional personnel are allowed for any maintenance, checking or

replacement of parts.

No live-line work is allowed.

1.9 Maintenance

1.9.1 Periodic Checking

Cooling fan and wind channel should be cleaned regularly to check whether it is

normal; remove the dust accumulated in the inverter on a regular basis.

Check inverter‟s input and output wiring and wiring terminals regularly and

check if wirings are ageing.

Check whether screws on each terminals are fastened.

Check whether inverter is corrosive.

1.9.2 Replacement of wearing parts

The wearing parts include cooling fan and electrolytic capacitors.

The life of the fan usually is 2~3 years. Users should change the cooling fan

according to all running time of inverter. Cooling fan could be damaged

because bearing is damaged and fan blades are aging. Users could check fan

blades for cracks or check the abnormal vibration noise when starting. Users

could change fan according to abnormal phenomena.

The useful life of electrolytic capacitors is 4~5 years. Users should change the

electrolytic capacitors according to all running time of inverter. Capacitors

could be damaged because the power supply is unstable, the environment

temperature is high, frequent over-load occurs and electrolyte is ageing. By

checking whether there is leakage of liquid, or the safety valve bulges out, or

the static electricity and insulated resistor is ok, users could change the

capacitor according to these phenomena.

1.9.3 Storage

Please put the inverter in the packing case of manufacture.

If inverter is stored for long time, please charge the inverter within half a year

to prevent the electrolytic capacitors damaged. The charging time should be

longer than 5 hours.

1.9.4 Daily Maintenance

Environment temperature, humidity, dust and vibration would decrease the life of

inverter. So daily maintenance is necessary to inverter.

Daily inspecting:

Inspecting for noise of motor when it is working.

Inspecting for abnormal vibration of motor when it is working.

Inspecting for the installing environment of inverter.

Inspecting for the fan and inverter temperature.

Daily cleaning:

Keep the inverter clean. Clean surface dust of inverter to prevent dust, metal

powder, oily dirt and water from dropping into the inverter.Inspecting for the fan

and inverter temperature.

Daily cleaning:

Keep the inverter clean. Clean surface dust of inverter to prevent dust, metal

powder, oily dirt and water from dropping into the inverter.

TT100

·7·

II. Keypad panel

Keypad panel and monitor screen are both fixed on keypad controller. Two kinds of controllers (with and

without potentiometer) are available for TT100 series inverters. Refer to note for Fig2-1.

2.1 Panel Illustration

The panel covers three sections: data display section, status indicating section and keypad operating section,

as shown in Fig. 2-1.

Instructions for operation panel:

Operation panels of below 15KW can not be pulled out. Please select AA or A6 control panel to realize

remote control, which is connected by 4 core telephone wire.

.

Operation panel

RUN FWD DGT FRQ

Min Max

Fun

Set

▲

▼

Run

stop

reset

4LEDsindicateworkingstatus.RUNis lightingwhilerunning.FWDislighting

whenworkingforwardandFRQislightingwhenshowingfrequency.

4个发光二极管指示工作状态。运行时 RUN亮,正转时 FWD亮,功能

码区间内切换 DGT 亮,FRQ亮表示显示频率。

LED shows running frequency, flashing target frequency, function code,

parameter value or fault code.

Press “Fun”for function code, and “set”for original parameters.▲

and▼keys can be used to select function codes and parameters.

Press “set”again to confirm. In the mode of keypad control, ▲and

▼keys can also be used for dynamic speed control. “Run”and

“Stop/Reset”keys control start and stop. Press “Stop/Reset”key to

reset inverter in fault status.

Potentiometer can be used for manual speed control in mode of

analog signals control. External potentiometer or external analog

signal can also be used.

Fun

Set

▲

▼

Run

Stop

reset

RUN FWD DGT FRQ

LED shows running frequency, flashing target frequency, function code,

parameter value or fault code.

4LEDsindicateworkingstatus.RUNislightingwhilerunning.FWDislighting

whenworkingforwardandFRQislightingwhenshowingfrequency.

Press “Fun”for function code, and “set”for original parameters.▲

and▼keys can be used to select function codes and parameters.

Press “set”again to confirm. In the mode of keypad control, ▲and

▼keys can also be used for dynamic speed control. “Run”and

“Stop/Reset”keys control start and stop. Press “Stop/Reset”key to

reset inverter in fault status.

Operation panel

Fig.2-1 Operation Panels in Two Kinds

TT100

·8·

2.2 Panel structure

1. structure diagram

2. Structure size (Unit: mm)

Code

A

B

C

D

H

Opening size

AA

76

52

72

48

24

73*49

A6

124

74

120

70

26

121*71

2.3 Panel Operating

All keys on the panel are available for user. Refer to Table 2-1 for their functions.

Table 2-1 Uses of Keys

Keys

按键

Names

Remarks

Fun

To call function code and switch over display mode.

Set

To call and save data.

Up

To increase data (speed control or setting parameters)

Down

To decrease data (speed control or setting parameters)

Run

To start inverter;

Stop or reset

To stop inverter; to reset in fault status; to change function codes in a code

group or between two code groups.

Fun

Set

Run

Stop/reset

▲

▼

TT100

·9·

2.4 Parameters Setting

This inverter has numerous function parameters, which the user can modify to effect different modes of

operation control. User needs to realize that if user sets password valid (F107=1), user‟s password must be

entered first if parameters are to be set after power off or protection is effected, i.e., to call F100 as per the

mode in Table 2-2 and enter the correct code. User‟s password is invalid before delivery, and user could set

corresponding parameters without entering password.

Table 2-2 Steps for Parameters Setting

Steps

Keys

Operation

Display

1

Press “Fun” key to display function code

2

Press “Up” or “Down” to select requiredfunctioncode

3

To read data set in the function code

4

To modify data

5

To show corresponding target frequency by flashing

after saving the set data

To display the current function code

The above-mentioned step should be operated when inverter is in stop status.

2.5 Function Codes Switchover in/between Code-Groups

It has more than 300 parameters (function codes) available to user, divided into 10 sections as indicated in Table 2-3.

Table 2-3 Function Code Partition

Group Name

Function

Code Range

Group

No.

Group Name

Function

Code Range

Group

No.

Basic Parameters

F100~F160

1

Subsidiary function

F600~F630

6

Run Control Mode

F200~F230

2

Timing control and

protection function

F700~F740

7

Multi-functional

input/output terminal

F300~F330

3

Parameters of the motor

F800~F830

8

Analogsignals of

input/output

F400~F439

4

Communication

function

F900~F930

9

Pulse of input/output

F440~F460

4

PID parameter setting

FA00~FA30

10

Multi-stage speed

parameters

F500~F580

5

As parameters setting costs time due to numerous function codes, such function is specially designed as

“Function Code Switchover in a Code Group or between Two Code-Groups” so that parameters setting

become convenient and simple.

Press “Fun” key so that the keypad controller will display function code. If press “▲” or “▼” key then,

Fun

▲

▼

or

Set

Set

Fun

▲

▼

or

F

1

1

4

F

1

1

4

TT100

·10·

function code will circularly keep increasing or decreasing by degrees within the group; if press the

“stop/reset” key again, function code will change circularly between two code groups when operating the

“▲” or “▼” key.

e.g. when function code shows F111 and DGT indicatoris on, press “▲”/ “▼” key, function code will keep

increasing or decreasing by degrees within F100~F160; press “stop/reset” key again, DGT indicator will be

off. When pressing “▲”/ “▼” key, function codes will change circularly among the 10 code-groups, like

F211, F311…FA11, F111…, Refer to Fig 2-2 (The sparkling “ is indicated the corresponding target

frequency values).

2.6 Panel Display

Table 2-4 Items and Remarks Displayed on the Panel

Items

Remarks

HF-0

This Item will be displayed when you press “Fun” in stopping status, which indicates jogging

operation is valid. But HF-0 will bedisplayedonlyafter you changethe valueof F132.

-HF-

It stands for resetting process and will display target frequency after reset.

OC,OC1,OE,

OL1,OL2,OH,

LU,PF0,PF1

Fault code, indicating “hardware over-current”, “software over-current”,

“over-voltage”, “inverter over-load”, “motor over-load”“over-heat”, “under-voltage

for input”, “out-phase for input” ,” and “out-phase for output”respectively.

ESP

During two-line/three line running mode, “stop/reset”key is pressed or external emergency stop

terminalisclosed,ESPwillbedisplayed.

F152

Function code (parameter code).

10.00

Indicating inverter‟s current running frequency (or rotatespeed)andparametersettingvalues,etc.

Sparklinginstoppingstatustodisplaytarget frequency.

0.

Holdingtimewhenchangingtherunningdirection. When “Stop” or “Free Stop” command is executed,

theholdingtimecanbecanceled

A100、U100

Output current (100A) and output voltage (100V). Keep one digit of decimal when current is below

100A.

Enter correct user‟s

password (currently

showing )

Fun

Display

Display

DGT

Stop/Reset

Display

DGT

▲

Display

▲

Display

▲

Display

DGT Off

DGT On

Fig2-2 SwtichoverinaCodeGrouporbetweenDifferentCode-Groups

TT100

·11·

III. Installation & Connection

3.1 Installation

Inverter should be installed vertically, as shown in Fig 3-1. Sufficient ventilation space should be ensured in

its surrounding. Clearance dimensions (recommended) are available from Table 3-1 for installing the

inverter.

Table 3-1 Clearance Dimensions

Inverter Model

Clearance Dimensions

Hanging (≤ 15 kw)

A≥150mm

B≥50mm

3.2 Connection

In case of 3-phase input, connect R/L1,

S/L2 and T/L3 terminals (L1/R and

L2/S terminals for single-phase) with

power source from network and

/PE/E to earthing, U, V and W terminals to motor.

Motor shall have to be ground connected. Orelse electrified motor causes interference.

For inverter power lower than 15kw, braking cell is also built-in. If the load inertia is moderate,

it is Ok to only connect braking resistance.

Power terminals sketch of inverter with single-phase 230V 0.2~0.75KW.

L1

L2

P

B

U

V

W

Power terminals sketch of inverter with single-phase 230V 1.5~2.2KW and three-phase

400V 0.75KW~15KW.

L1/R

L2/S

L3/T

P

-

B

U

V

W

Note: power terminals L1/R, L2/S of single-phase 230V 1.5KW and 2.2KW are connected

to 230V of power grid; L3/T is not connected.

The inverters below 11kw have no the terminal “-”.

Grounding

Input ~400V

For braking resistor

Output

Grounding

Input ~230V

For braking resistor

Output

A

B B

A

Inverter

C

D D

Inverter

Trench

Hanging

Cabinet

Fig 3-1 Installation Sketch

TT100

·12·

(The figure is only sketch, terminals order of practical products may be different from the above-mentioned

figure.) Introduction of terminals of power loop

Terminals

Terminal

Marking

Terminal Function Description

Power Input

Terminal

R/L1, S/L2,

T/L3

Input terminals of three-phase 400V AC voltage (R/L1 and S/L2

terminals for single-phase)

Output Terminal

U, V, W

Inverter power output terminal, connected to motor.

Grounding

Terminal

/PE/E

Inverter grounding terminal.

Rest Terminal

P, B

External braking resistor (Note: no Terminals P or B for inverter

without built-in braking unit).

P+、-(N)

DC bus-line output

P、-(N)

Externally connected to braking unit

P connected to input terminal “P” or “DC+”of braking unit, -(N)

connected to input terminal of braking unit “N” or “DC-”.

P, P+

Externally connected to DC reactor

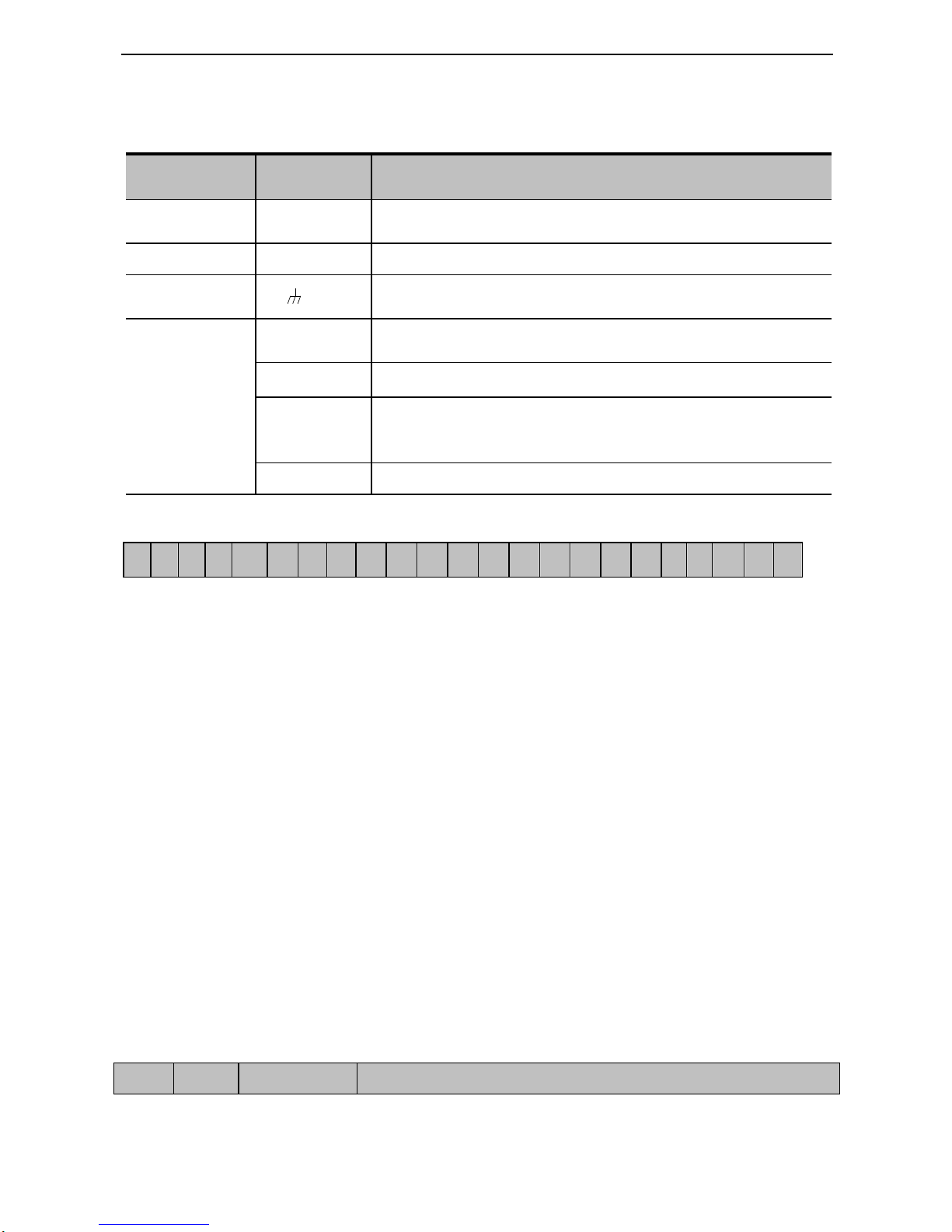

Wiring for control loop as follows:

A+

B-

TA

TB

TC

DO1

DO2

24V

CM

OP1

OP2

OP3

OP4

OP5

OP6

OP7

OP8

10V

AI1

AI2

GND

AO1

AO2

Note: 15KW inverters and below 15KW have no A+、B- , DO2 and OP7, OP8 control terminal.

3.3 Functions of control terminals

The key to operate the inverter is to operate the control terminals correctly and flexibly. Certainly, the control

terminals are not operated separately, and they should match corresponding settings of parameters. This

chapter describes basic functions of the control terminals. The users may operate the control terminals by

combining relevant contents hereafter about “Defined Functions of the Terminals”.

Table 4-3 Functions of Control Terminals

Terminal

Type

Description

Function

TT100

·13·

DO1

Output

signal

Multifunctional

output terminal 1

When the token function is valid, the value

between this terminal and CM is 0V; when the

inverter is stopped, the value is 24V.

The functions of output

terminals shall be defined

per manufacturer‟s value.

Their initial state may be

changed through

changing function codes.

DO2Note

Multifunctional

output terminal 2

When the token function is valid, the value

between this terminal and CM is 0V; when the

inverter is stopped, the value is 24V.

TA

Relay contact

TC is a common point, TB-TC are normally

closed contacts, TA-TC are normallyopen

contacts. The contact capacity of 15kw and below

15kw inverter is 10A/125VAC、5A/250VAC、

5A/30VDC, contact capacity of bove 15kw is

12A/125VAC、7A/250VAC、7A/30VDC.

TB

TC

AO1

Running

frequency

It is connected with frequency meter or speedometer externally, and its

minus pole is connected with GND. See F423~F426 for details,.

AO2

Current display

It is connected with ammeter externally, and its minus pole is connected

with GND. See F427~F430 for details

10V

Analog

power

supply

Self contained

power supply

Internal 10V self-contained power supply of the inverter provides power

to the inverter. When used externally, it can only be used as the power

supply for voltage control signal, with current restricted below 20mA.

AI1

Input

Signal

Voltage analog

input port

When analog speed control is adopted, the voltage signal is input through

this terminal. The range of voltage input is 0~10V, grounding: GND.

When potentiometer speed control is adopted, this terminal is connected

with center tap, earth wire to be connected to GND.

AI2

Voltage / Current

analog input port

When analog speed control is adopted, the voltage or current signal is

input through this terminal. The range of voltage input is 0~5V or 0~10V

and the current input is 0~20mA, input resistor is 500Ω, grounding:

GND. If the input is 4~20mA, it can be realized through adjusting

parameter F406=2. The voltage or current signal can be chosen by coding

switch. See table 4-2 and 4-3 for details, the current channel (0-20mA) is

chosen before delivery.

GND

Self-contained

Power

supplyGround

Ground terminal of external control signal (voltage control signal or

current source control signal) is also the ground of 10V power supply of

this inverter.

24V

Power

supply

Control power

supply

Power: 24±1.5V, grounding: CM; current is restricted below 50mA for

external use.

OP1

Digital

input

control

terminal

Jogging terminal

When this terminal is in the valid state, the

inverter will have jogging running. The

jogging function of this terminal is valid

under both at stopped and running status. This

terminal can also be used as high-speed pulse

input port. The max frequency is 50K.

The functions of input

terminals shall be defined

per manufacturer‟s value.

Other functions can also

be defined by changing

function codes.

OP2

External

Emergency Stop

When this terminal is in the valid state, “ESP”

malfunction signal will be displayed.

OP3

“FWD”Terminal

When this terminal is in the valid state,

inverter will run forward.

OP4

“REV”Terminal

When this terminal is in the valid state,

inverter will run reversely.

OP5

Reset terminal

Make this terminal valid under fault status to

reset the inverter.

OP6

Free-stop

Make this terminal valid during running can

TT100

·14·

realize free stop.

OP7

Running terminal

When this terminal is in the valid state,

inverter will run by the acceleration time.

OP8

Stop terminal

Make this terminal valid during running can

realize stop by the deceleration time.

CM

Common

port

Groundingof

controlpower

supply

The grounding of 24V power supply and other control signals.

A+note

485

communic

ation

terminals

Positivepolarityof

differentialsignal

Standard: TIA/EIA-485(RS-485)

Communication protocol: Modbus

Communication rate: 1200/2400/4800/9600/19200/38400/57600bps

B-note

Negativepolarityof

Differentialsignal

Note : 15KW inverters and below 15KW have noA+, B- , DO2 and OP7, OP8 control terminal.

Wiring for digital input terminals:

Generally, shield cable is adopted and wiring distance should be as short as possible. When active

signal is adopted, it is necessary to take filter measures to prevent power supply interference. Mode of

contact control is recommended.

Digital input terminals are only connected by source electrode (NPN mode) or by drain electrode (PNP

mode). If NPN mode is adopted, please turn the toggle switch to the end of “NPN”.

Wiring for control terminals as follows:

1. Wiring for positive source electrode (NPN mode).

2. Wiring for active source electrode (NPN

mode)

TT100

·15·

NPN

PNP

Fig3-2 ToggleSwitch J7

If digital input control terminals are connected by drain electrode, please turn the toggle switch to the

end of “PNP”. Wiring for control terminals as follows:

3. Wiring for positive drain electrode (PNP mode)

4. Wiring for active drain electrode (PNP mode)

Wiring by source electrode is a mode most

in use at present. Wiring for control terminal is connected by source electrode before delivery, user

should choose wiring mode according to requirement.

Instructions of choosing NPN mode or PNPmode:

1. There is a toggle switch J7 near to control terminals. Please refer to

Fig 3-2.

2. When turning J7 to “NPN”, OP terminal is connected to CM.

When turning J7 to “PNP”, OP terminal is connected to 24V.

TT100

·16·

3. J7 is on the back of control PCB of single-phase 0.2KW-0.75KW.

3.4 Wiring Recommended

Inverter Model

LeadSectionArea(mm2)

TT100-0002S2

1.0

TT100-0004S2

1.5

TT100-0007S2

2.5

TT100-0015S2

2.5

TT100-0022S2

4.0

TT100-0007T3

1.5

TT100-0015T3

2.5

TT100-0022T3

2.5

TT100-0037T3

2.5

TT100-0040T3

2.5

TT100-0055T3

4.0

TT100-0075T3

4.0

TT100-0110T3

6.0

TT100-0150T3

10

3.5 Lead section area of protect conductor (grounding wire)

Lead section area S of U,V,W (mm2)

Minimum lead section area S of /PE/E (mm2)

S

16

16<S

35

35<S

S

16

S/2

3.6 Overall Connection and “Three- Line” Connection

*Refer to next figure for overall connection sketch for TT100 series inverters. Wiringmodeis available for various

terminalswhereasnoteveryterminalneedsconnection whenapplied.

TT100

·17·

Note:

1.Pleaseonlyconnectpowerterminals L1/RandL2/Swithpowergridforsingle-phaseinverters.

2. Remote-control panels and 485 communication port should be connected with 4 core telephone wire. They must not

beused atthesametime.

3. 485 communication port has built-in standard MODBUS communication protocol. Communication port is on the left

sideofinverter.Thesequence fromtoptodownis5Vpower,B-terminal,A+terminalandGNDterminal.

4. Inverter above 15kw has 8 multifunctional input terminals OP1~OP8, 15kw inverter and below 15kw has 6

multifunctionalinput terminals OP1~OP6.

5. The contact capacity of 15kw and below 15kw inverter is 10A/125VAC、5A/250VAC、5A/30VDC.

IV. Operation and Simple Running

TT100

·18·

This chapter defines and interprets the terms and nouns describing the control, running and status of the

inverter. Please read it carefully. It will be helpful to your correct operation.

4.1 Control mode

Control mode of TT100 inverter is V/F control.

4.2 Mode of torque compensation

Linear compensation (F137=0); Square compensation (F137=1); User-defined multipoint compensation

(F137=2); Auto torque compensation (F137=3)

4.3 Mode of frequency setting

Please refer to F203~F207 for the method for setting the running frequency of the TT100 inverter.

4.4 Mode of controlling for running command

The channel for inverter to receive control commands (including start, stop and jogging, etc) contains three

modes: 1. Keypad (keypad panel) control; 2. External terminal control; 3. Modbus control.

The modes of control command can be selected through the function codes F200 and F201.

4.5 Operating status of inverter

When the inverter is powered on, it may have four kinds of operating status: stopped status, programming

status, running status, and fault alarm status. They are described in the following:

4.5.1 Stopped status

If re-energize the inverter (if “self-startup after being powered on”is not set) or decelerate the inverter to

stop, the inverter is at the stopping status until receiving control command. At this moment, the running

status indicator on the keypad goes off, and the display shows the display status before power down.

4.5.2 Programming status

Through keypad panel, the inverter can be switched to the status that can read or change the function

code parameters. Such a status is the programming status.

There are numbers of function parameters in the inverter. By changing these parameters, the user can

realize different control modes.

4.5.3 Running status

The inverter at the stopped status or fault-free status will enter running status after having received

operation command.

The running indicator on keypad panel lights up under normal running status.

4.5.4 Fault alarm status

The status under which the inverter has a fault and the fault code is displayed.

Fault codes mainly include: OC, OE, OL1, OL2, OH, LU, PF1, representing “over current”, “over

voltage”, “inverter overload”, “motor overload”, “overheat”, “input undervoltage”, “input out-phase”, and

respectively.

For trouble shooting, please refer to Appendix I to this manual, “Trouble Shooting”.

4.6 Keypad panel and operation method

Keypad panel (keypad) is a standard part for configuration of TT100 inverter. Through keypad panel, the

user may carry out parameter setting, status monitoring and operation control over the inverter. Both keypad

panel and display screen are arranged on the keypad controller, which mainly consists of three sections: data

display section, status indicating section, and keypad operating section. There are two types of keypad

controller (with potentiometer or without potentiometer) for inverter. For details, please refer to Chapter II of

this manual, “Keypad panel”.

It is necessary to know the functions and how to use the keypad panel. Please read this manual carefully

Table of contents

Popular Inverter manuals by other brands

Go Power

Go Power PureSine 150 user manual

Delta

Delta RPI M50A Installation and operation manual

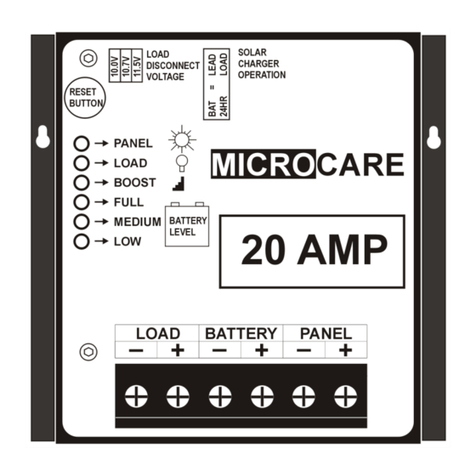

Microcare

Microcare 10 Amp user manual

DualLite

DualLite SYNCHRON Installation instructions and user manual

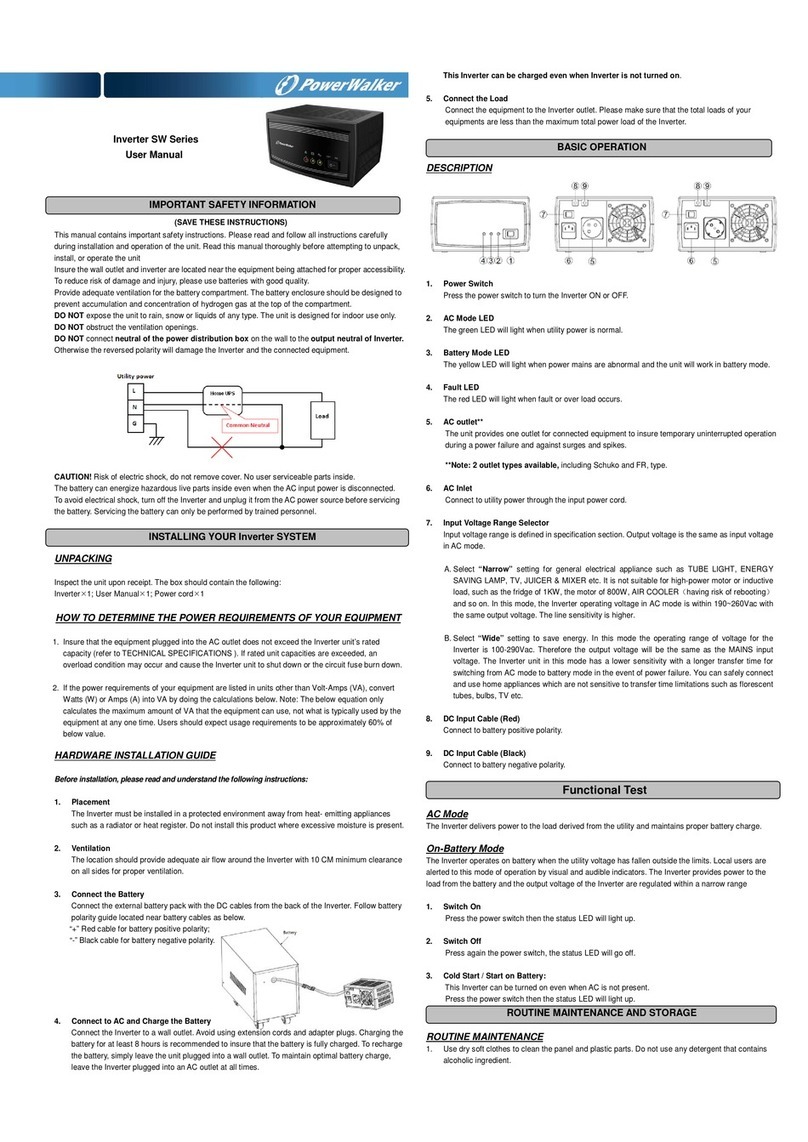

PowerWalker

PowerWalker 650 SW user manual

LIVARNO LUX

LIVARNO LUX 311196 Assembly, operating and safety instructions

FRONIUS

FRONIUS Symo GEN24 quick start guide

CanadianSolar

CanadianSolar CSI-125KTL-GS-E Installation and operation manual

Atronix

Atronix PPS Solar bag user manuel

Qcells

Qcells Q.HOME CORE H4 installation manual

Tripp Lite

Tripp Lite PowerVerter owner's manual

FRONIUS

FRONIUS Symo Hybrid Installation instruction