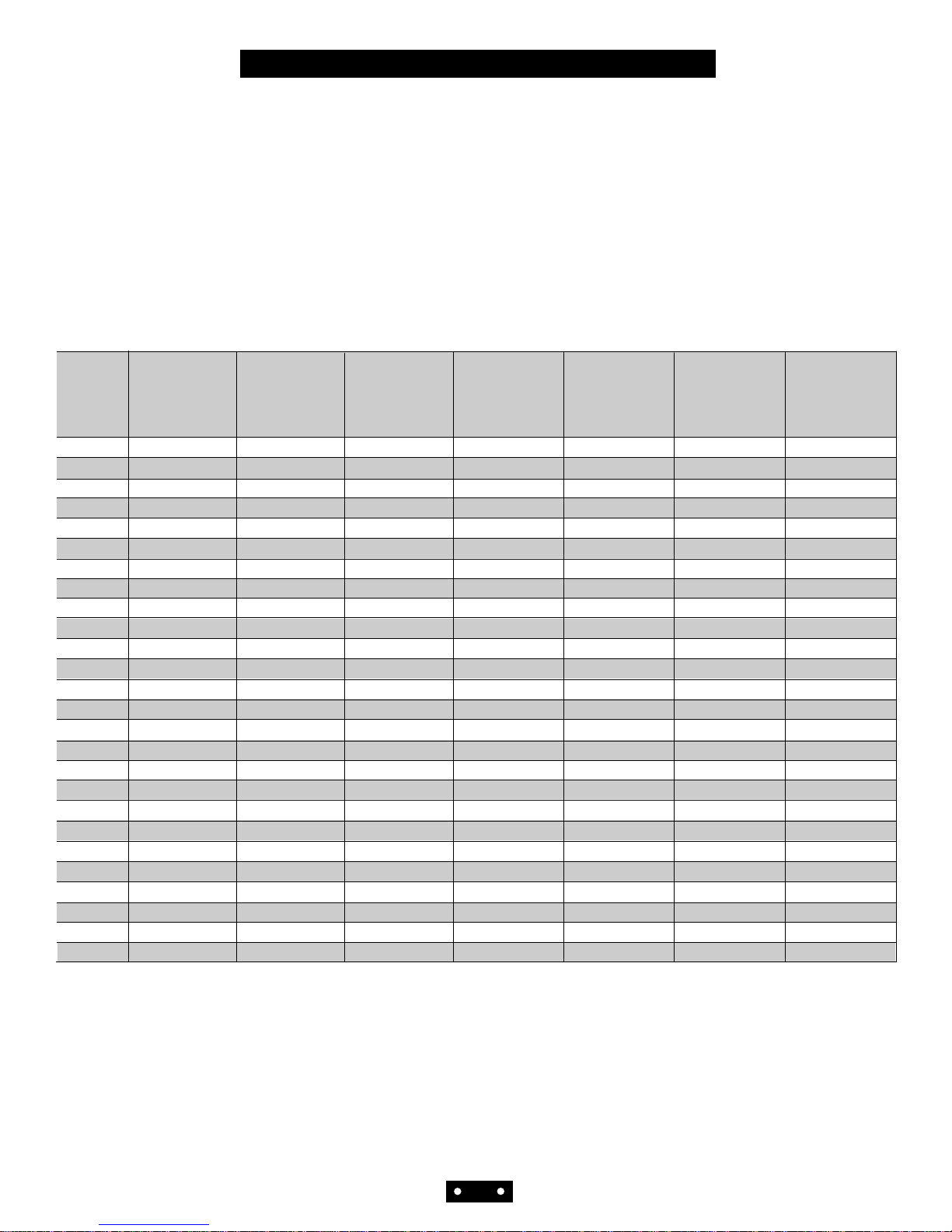

@ 0.05C rate @0.1C rate @0.2C rate @0.5C rate @1C rate @2C rate @3C rate

Rated (20 Hr. Rate.) (9 Hr. Rate) (4 Hr. Rate) (1.3 Hr. Rate) (33 Min. Rate) (12 Min. Rate) (7.2 Min. Rate)

Capacity Current Capacity Current Capacity Current Capacity Current Capacity Current Capacity Current Capacity Current Capacity

Amps. Amp. Hrs Amps. Amp. hrs. Amps. Amp.Hrs Amps. Amp. Hrs. Amps. Amp. hrs. Amps. Amp. Hrs. Amps. Amp. Hrs.

0.5AH 0.025 0.50 0.05 0.45 0.10 0.40 0.25 0.325 0.50 0.28 1.00 0.20 1.50 0.18

0.8AH 0.04 0.80 0.08 0.72 0.16 0.64 0.40 0.52 0.80 0.44 1.60 0.32 2.40 0.29

1.0AH 0.05 1.00 0.10 0.90 0.20 0.80 0.50 0.65 1.00 0.56 2.00 0.40 3.00 0.36

1.3AH 0.065 1.30 0.13 1.17 0.26 1.04 0.65 0.845 1.30 0.715 2.60 0.52 3.90 0.47

2.3AH 0.115 2.30 0.23 2.07 0.46 1.84 1.15 1.495 2.30 1.288 4.60 0.92 6.90 0.83

3.0AH 0.15 3.00 0.30 2.70 0.60 2.40 1.50 1.95 3.00 1.65 6.00 1.20 9.00 1.08

3.2AH 0.16 3.20 0.32 2.88 0.64 2.56 1.60 2.08 3.20 1.76 6.40 1.28 9.60 1.15

4.5AH 0.22 4.40 0.45 4.05 0.90 3.60 2.25 2.92 4.5 2.47 9.00 1.80 13.50 1.62

5.0AH 0.25 5.00 0.50 4.50 1.00 4.00 2.50 3.25 5.00 2.80 10.00 2.00 15.00 1.80

6.5AH 0.325 6.50 0.65 5.85 1.30 5.20 3.25 4.23 6.50 3.64 13.00 2.60 19.50 2.34

7.0AH 0.35 7.00 0.70 6.30 1.40 5.60 3.50 4.55 7.00 3.85 14.00 2.80 21.00 2.52

8.0AH 0.40 8.00 0.80 7.20 1.60 6.40 4.00 5.20 8.00 4.48 16.00 3.20 24.00 2.88

9.0AH 0.45 9.00 0.90 8.10 1.80 7.20 4.50 5.85 9.00 5.04 18.00 3.60 27.00 3.24

10.0AH 0.50 10.00 1.00 9.00 2.00 8.00 5.00 6.50 10.00 5.60 20.00 4.00 30.00 3.60

12.0AH 0.60 12.00 1.20 10.80 2.40 9.60 6.00 7.80 12.00 6.72 24.00 4.80 36.00 4.32

18.0AH 0.90 18.00 1.80 16.20 3.06 14.40 9.00 11.70 18.00 9.90 36.00 7.20 54.00 6.48

20.0AH 1.00 20.00 2.00 18.00 4.00 16.00 10.00 13.00 20.00 11.20 40.00 8.00 60.00 7.20

26.0AH 1.30 26.00 2.60 23.40 5.20 20.80 13.00 16.90 26.00 14.30 52.00 10.40 78.00 9.36

28.0AH 1.40 28.00 2.80 25.20 5.40 21.60 14.00 18.20 28.00 15.40 54.00 10.88 84.00 10.08

33.0AH 1.65 33.00 3.30 29.70 6.60 26.40 16.50 21.45 33.00 18.15 66.00 13.20 99.00 11.88

40.0AH 2.00 40.00 4.00 36.00 8.00 32.00 20.00 26.00 40.00 22.40 80.00 16.00 120.00 14.40

55.0AH 2.75 55.00 5.50 49.50 11.00 44.00 27.50 35.75 55.00 30.25 110.00 22.00 165.00 19.80

60.0AH 3.00 60.00 6.00 54.00 12.00 48.00 30.00 39.00 60.00 33.60 120.00 24.00 180.00 21.60

75.0AH 3.75 75.00 7.50 67.50 15.00 60.00 37.50 48.75 75.00 41.25 150.00 30.00 225.00 27.00

80.0AH 4.00 80.00 8.00 72.00 16.00 64.00 40.00 52.00 80.00 44.80 160.00 32.00 240.00 28.80

100.0 AH 5.00 100.00 10.00 90.00 20.00 80.00 50.00 65.00 100.00 55.00 200.00 40.00 300.00 36.00

The capacity of a battery is the total amount of electrical

energy available from a fully charged cell or cells. Its

value depends on the discharge current, the temperature

during discharge, the final (cut-off) voltage and the gen-

eral history of the battery.

Capacity, expressed in ampere-hours (AH) is the product

of the current discharged and the length of discharge

time. The rated capacity (C) of a Power-Sonic battery is

measured by its performance over 20 hours of constant

current discharge at a temperature of 68°F (20°C) to a

cutoff voltage of 1.75 volts.

As an example, Model PS-610, with a rated capacity of

1AH will deliver 50 mA (1/20 of 1AH, or 0.05C ) for 20

hours before the voltage drops from 6.45 to 5.25 volts.

By cycling the battery a few times or float charging it for

a month or two, the highest level of capacity develop-

ment is achieved. Power-Sonic batteries are fully charged

before leaving the factory, but full capacity is realized

only after the battery has been cycled a few times or been

on float charge for some time.

The table in Figure 2 shows capacities for various multi-

ples of the 20-hour discharge current.

CAPACITY

Figure 2

When a battery discharges at a constant rate, its capacity

changes according to the amperage load. Capacity

increases when the discharge current is less than the 20-

hour rate and decreases when the current is higher.

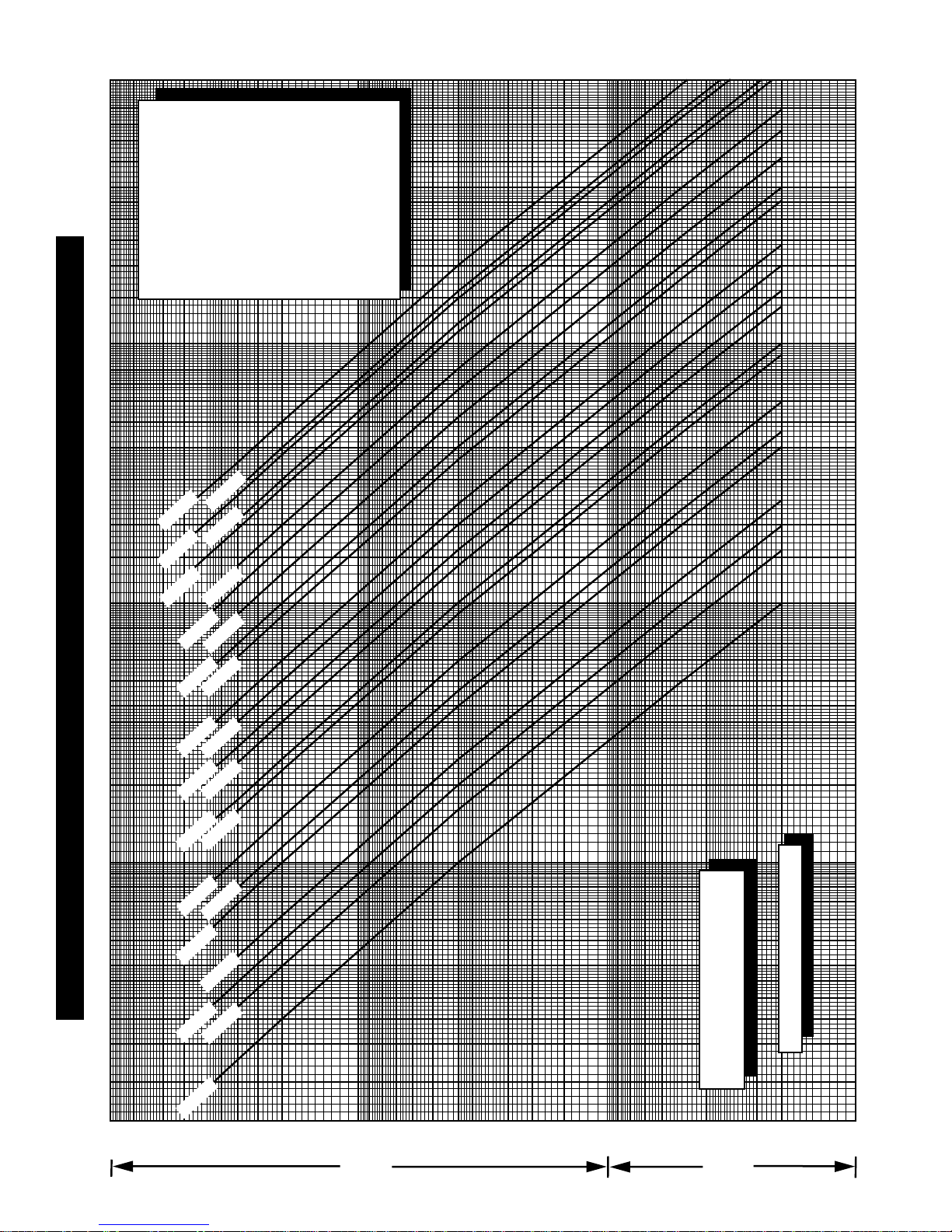

Figure 3 shows capacity curves for major Power-Sonic battery

models with different ampere-hour ratings. Amperage is on the

horizontal scale and the time elapsed is on the vertical scale; the

product of these values is the capacity.

Proper battery selection for a specific application can be

made from this graph if the required time and current are

known. For example, to determine the proper capacity of

a battery providing 3 amps for 20 minutes, locate the

intersection of these values on the graph. The curve

immediately above that point represents the battery

which will meet the requirement.

3