Power Tec 71703 User manual

Model No. 71703INSTRUCTION SHEET

Table Saw Sled Kit

QUESTION...

1•847•780•6120

WARNING

To reduce the risk of injury, turn table saw off and disconnect it

from power source before installing and removing accessories.

An accidental start-up can cause injury.

WARNING

Some dust created by operation of power tool contains

chemicals known to the State of California to cause cancer, birth

defects or other reproductive harm. To reduce your exposure

to these chemicals, work in a well ventilated area and work

with approved safety equipment. Always wear OSHA/NIOSH

approved, properly fitting face mask or respirator when using

such tools.

WARNING

For your own safety, read and follow all safety procedures listed

in the table saw instruction manual.

WARNING

Do not use the table saw sled kit until it is completely assembled

and you have read and understood this entire operating manual

and the operating manual of the table saw being used with this

table saw sled kit.

NOTE: These instructions are only a general guide for building

your own table saw sled. The dimensions and materials used

in these instructions reflect the design we chose. They can be

changed or altered to meet your design or requirements.

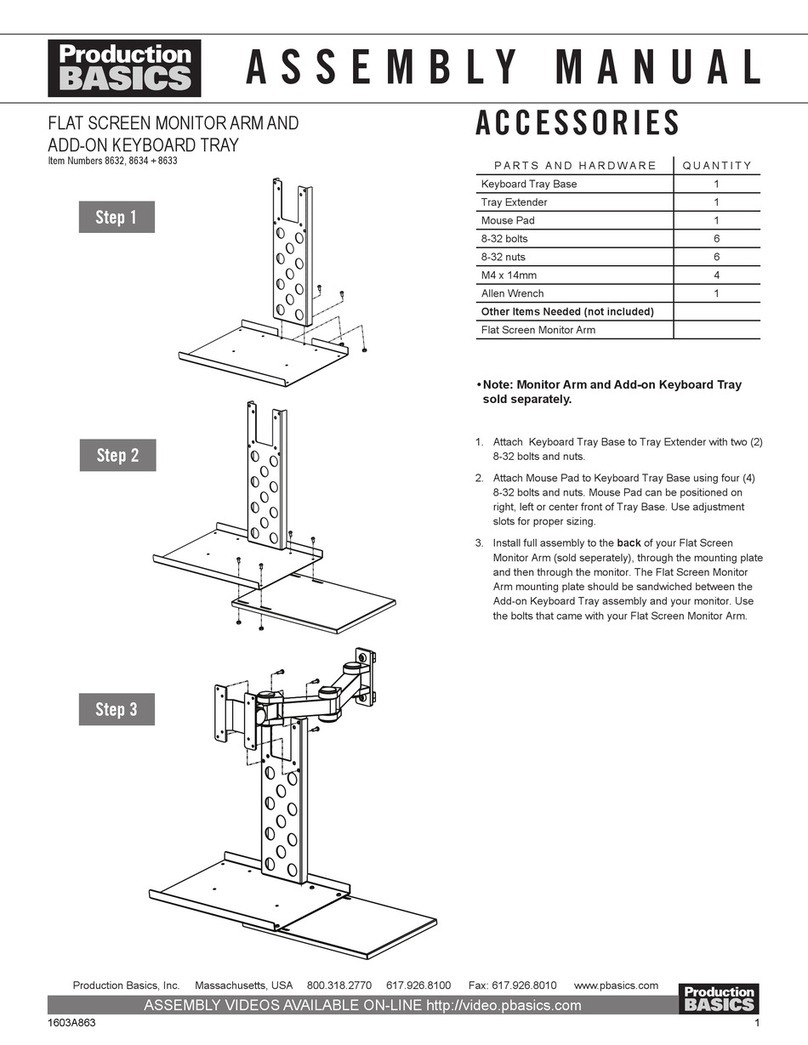

PACKAGING CONTENTS

ITEM DESCRIPTION QTY

AUniversal T-Track (24" long) 1

BHDPE (High Density Polyethylene) bars, 19"

long x 3/4" x 3/8" 2

C 3" Flip stop 1

DFlat Head Wood Screws, #6 x 1/2" 6

E Blade guard 1

F 1/4"-20 x 1/2" hex bolts 2

G1/4"-20 acorn hex nuts 2

Instruction Sheet (not shown) 1

B A

C

DE

G

F

Figure 1

Additional materials will be needed to build the table saw sled.

The things listed under Tools Needed and Other Materials

Needed are NOT included in the kit. Gather all tools and

materials before starting.

NOTE: Because your sled may vary in size and appearance

depending on your needs, an exact cut list can not be provided.

The example in these instructions will be for 18" x 24" base.

TOOLS NEEDED

• Drill

• Square

• Clamps

• Countersink

bit, forstner bit

(depends on the

screws used)

• Router table

OTHER MATERIALS NEEDED

• CA Glue (Cyanoacrylate Adhesives)

• #8 x 3/4" flat head wood screws (quantity depends on

your design)

• Flat head wood screws (size and quantity depends on

your design)

• 1/2" Baltic Birch for the base (our example will cut the base

to 18" x 24", purchase the size needed for your needs).

NOTE: Other stock may be used, using the 1/2" Baltic Birch

will make the sled lighter and easier to handle.

• Stock for Front and Back Fence, needs to be 24" long and

2-5/8" tall. This will allow the flip stop to work, without a gap

between the end of the fence, the sled and the blade when it

is fully raised. (In our example we used the stock size shown

in Figure 2.) NOTE: The use of 3/4" wide stock will make

mounting the T-Track to the front fence easier.

Mark

3/4"

24"

18"

Back Fence

24" x 2-5/8" x 1-1/2"

Front Fence

24" x 2-5/8" x 3/4"

Figure 2

CROSSCUT SLED-BASE

1. Cut the 1/2" Baltic Birch to 18" by 24" for the base. The

short side (18") should be going with the grain of the stock.

2. Mark the center point on the 24" side of the base.

3. With the saw turned off and disconnect from the power

source, raise the saw blade until it is visible.

4. Place the base onto the saw table with the 18" side against

the fence and align the center mark on the 24" side to the

saw blade. With the base firmly against the fence and the

center mark aligned with the saw blade, lock the fence

into place.

IMPORTANT: Once the center point has been marked and the

fence has been set and LOCKED it is important that the fence

stays in this position for the next steps.

Figure 3

INSTALL HDPE BARS

IMPORTANT: Before installing the HDPE bars, make sure the

holes for #8 x 3/4" flat head wood screws (not supplied) have

been drilled and countersunk.

1. Place dimes into the table saw tracks, the dimes act as

spacers and raise the bars so they contact the base.

2. Place the HDPE bars on top of the dimes in the saw tracks.

Figure 4

3. Dab the CA glue every few inches along the length of each

bar. DO NOT apply the glue heavily, too much glue can

cause it to drip into the table saw.

Figure 5

4. Place the short side (18") of the base up against the locked

table saw fence and make sure both of the HDPE bars are

even with one side of the board. Use the locked fence as a

guide and carefully place the base onto the HDPE bars.

5. Place steady, downward pressure onto the base for

a few minutes so the HDPE bars adhere to the base.

NOTE: A heavy object placed onto the base will work to

apply pressure.

Figure 6

6. When the CA glue is dry, remove the base and dimes

(spacers) from the table saw tracks.

7. Flip the base over and use a screwdriver to secure the

HDPE bars to the base with #8 x 3/4" flat head wood screws

(not supplied). Make sure the head of each screw is far

enough in and is below the HDPE surface.

IMPORTANT: DO NOT over tighten the screws. DO NOT

tighten the screws with a drill.

Figure 7

8. After the screws are all tight, make sure the bars will slide

freely in the saw table tracks. Adjust the screws until the

bars slide freely.

INSTALL THE BACK FENCE

In the example used, the back fence is cut to 24" long, 2-5/8" tall

and 1-1/2" wide.

IMPORTANT: THE FRONT AND BACK FENCE MUST BE

2-5/8" TALL IN ORDER FOR THESE INSTRUCTIONS TO

WORK PROPERLY. Measure 3/4" down from the top of the

fence and draw a line. NEVER raise the blade above this mark.

When the blade is fully raised it should be about 1-7/8" from the

top of the sled base.

1. Place the base (sled) with the extended HDPE bars onto the

back fence, make sure it is flush.

2. Clamp the back fence to the back of the base (sled). Make

sure the back fence is flush with the back of the sled.

Pre-drill counter sink holes across the back edge of the

base into the back fence. MAKE SURE THE HOLES DO

NOT ALIGN WITH THE BLADE CUT (CENTER MARK

ON BASE).

3. Secure the back fence to the base with the appropriate

length flat head wood screws (not supplied).

Figure 8

4. Unlock the saw fence and move it out of the way.

5. With the back fence facing the saw blade, place the base

onto the saw with the HDPE guide bars in the tracks.

6. Raise the saw blade to the 3/4" mark made earlier. DO NOT

CUT ABOVE THIS MARK. Turn on the table saw and push

the base (sled) through the saw blade, cutting through the

back fence and base, STOP SHORT before cutting all the

way through the base.

Figure 9

DO NOT CUT

ABOVE THIS MARK

INSTALL THE FRONT FENCE

In the example used, the front fence is cut to 24" long, 2-5/8" tall

and 3/4" wide.

The front fence needs to be square to the saw blade.

1. Clamp one end of the front fence to the base.

2. Use a square to adjust the front fence to be square to the

kerf line (cut earlier) in the base. When square, clamp the

other end of the front fence to the base.

3. Pre-drill counter sink holes from the underside of the

base into the front fence. MAKE SURE THE HOLES DO

NOT ALIGN WITH THE BLADE CUT (CENTER MARK

ON BASE).

4. Secure the front fence to the base with the appropriate

length flat head wood screws.

Figure 10

INSTALL THE T-TRACK

The T-Track allows the blade guard and flip stop to

be assembled to the front fence.

1. Place the T-Track onto the top of the front fence and clamp

it in place.

2. There are countersunk holes on the top of the T-Track,

drive the #6 flat head wood screws (suppled) through the

countersunk holes and into the fence.

Figure 11

T-Track

#6 flat

head wood

screws

Front

Fence

21-0901

Southern Technologies, LLC

Waukegan, IL 60087

Put these instructions and the original sales invoice in a safe,

dry place for future reference.

Visit us on the web at powertecproducts.com

INSTALL GUARD

1. Slide the 1/4"-20 x 1/2" hex bolts into the T-Slot in the top of

the front fence.

2. Place the blade guard onto the 1/4"-20 x 1/2" hex bolts and

secure with the 1/4"-20 acorn hex nuts. DO NOT tighten.

Figure 12

Blade

Guard

1/4"-20 x 1/2" Hex Bolts

1/4"-20 x 1/2"

Hex Bolts

T-Slot in

T-Track

on Front

Fence

1/4"-20 Acorn

Hex Nut

3. Position the blade guard with the rear channel centered over

the blades path. Use the slot in the table saw's throat plate

as a guide.

4. Tighten the 1/4"-20 acorn hex nuts to lock the blade guard

in place.

CAUTION When cutting do not push the sled too

far. Make sure the blade stays inside the guard.

Blade's Path

Figure 13

1/4"-20

Acorn Hex

Nuts

Throat

Plate

Blade Guard

INSTALL THE FLIP STOP

Slide the T-Bolt on the flip stop into the T-Slot in the top of the

front fence, tighten the knob. The arm on the flip stop functions

as an easily adjustable stop and can be flipped up when

not needed.

Figure 14

Knob

Flip Stop

The 3" fence flip stop is extremely versatile and quickly converts

from inboard to outboard position for a variety of applications.

In addition, the flip arm can be moved from right to left to match

your feed direction requirements.

• Slide the T-Bolt on the bottom of the flip stop into the T-Slot on

the top of the front fence. See Figure 14.

• In the inboard position, the stop works with the T-Track fence

and functions as an easily adjustable stop.

• In the outboard position, the body rotates and the flip arm

moves out. In this position the stop can work with the T-Track

fence and a 3/4" sacrificial wood board.

To Convert from Inboard to Outboard Position

Remove the knob and T-Bolt and rotate the stop body 180°.

Replace the knob and T-bolt. See Figure 15.

inboard outboardtransition

Figure 15 Knob

Stop Body

T-Bolt

THE SLED IS READY TO USE

Figure 16

DO NOT CUT ABOVE

THIS MARK

Other Power Tec Rack & Stand manuals