16

Chapter 6 Protection and description

PR5300 series soft starter with complete protection to protect the safety of soft starter and

motor. During the application, appropriate protection parameters and level should be set based on

different situation.

6-1.Protection functions and their parameters

6-1-1.Soft starter over-temperature protection: The temperature rose to 80 ℃±5 ℃over-

temperature protection, when the temperature dropped to 55 ℃(the lowest), no over-temperature

protection.

6-1-2.Input phase lose protection delay time : <3 seconds.

6-1-3.Input phase lose protection delay time: <3 seconds.

6-1-4.Three-phase unbalance protection delay time: <3 seconds. It is based on the deviation of

all phase current greater than 50% ±10% . When the load current is lower than 30% of the nominal

rating of soft starter, the deviation will increase.

6-1-5.Over-current protection time during soft starting: Continuous 5 times greater than the

maximum operating current of the protection time set byp6 in Table 6.1.

6-1-6.Time of running overload protection: Continues 5 times greater than the load regulation

of the protection time setted by P6 in Table 6.1 .

6-1-7.The protection lag time of much too low supply voltage, when the power supply voltage

is lower than the 40% of limit, the protection time <0.5 seconds, or the protection time <3 seconds

if it is lower than the setting value.

6-1-8.The protection lag time of much too high supply voltage : When the power supply

voltage is lower than the 140% of limit, the protection time <0.5 seconds, or the protection time <3

seconds if it is higher than the setting value.

6-1-9.The protection delay time of load short-circuit : <0.1 seconds, the current is 10 times

more than soft starter nominal rated current. This protection can not replace fuse short-circuit

protection device.

6-1-10.Motor under load protection, the current range is 10% to 90% of motor rated current,

the protection action delay from 5 to 90 seconds.

These time parameters are from tested effective signal to a tripping protection instructions,

and the parameters just for reference. All the protection functions of PR5300 series soft starter can

be verified through the actual or simulation method. If it can't meet the user's requirements, special

protection device should be added to ensure safety.

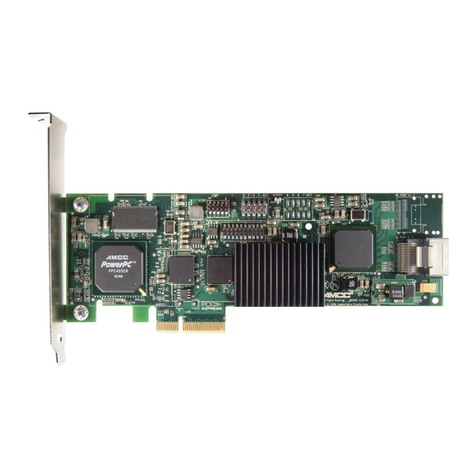

6-2.Protection level setting description

6-2-1. In order to adapt to different applications, PR5300 series soft starter has five protection

level, there are 0: Primary, 1: Light load, 2: Standard load, 3:Heavy load, 4: Advanced, it set by PA

parameter. Among them:

1) Primary protection is against to the function of external terminal instantaneous stop,

meanwhile only remains the overheating, short circuit and main circuit fault protection, it can

be applied to needed emergency start in unconditional occasion, such as fire systems, etc.

2) The three protection level of light load, standard load and overload have the complete

protection function. The difference is the time curves of motor overloaded thermal protection

are not the same. The time parameters of motor thermal protection are as Table 6.1 and Figure

6.1. 3) High level of protection standards is stringent at start. Other protection features

parameters keep the same with standard protection set.

6-2-2. Protection level and thermal protection time according to PA setting is as the diagram

below: