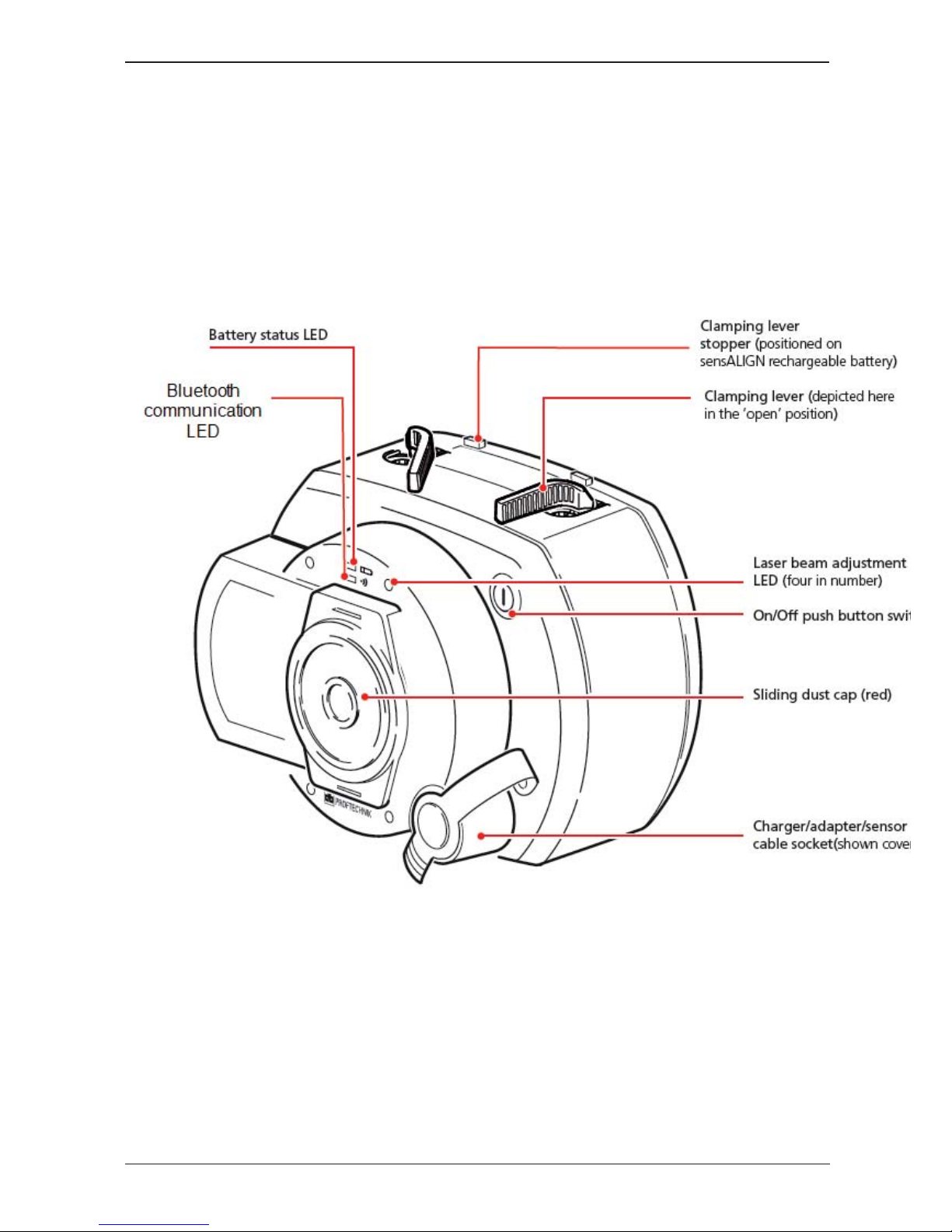

The four beam adjustment LEDs provide additional help when adjusting the laser beam position on

sensALIGN sensor position detectors. The LEDs indicate the angle and position at which the laser

beam enters the sensor. The LEDs blink either red or green depending on the angle at which the laser

beam strikes the sensor. Green indicates a small angle while red indicates a large angle that must be

corrected before beginning measurement.

Activity Laser beam adjustment LEDs

SwitchonsensALIGNsensor All four LEDs light up red then continue to blink

every two seconds

Laser beam striking dust cap [laser off] All four LEDs blink red every second

Laser beam entering sensor with a large angular

deviation One or more LEDs blinks red every second

Laser beam entering sensor with little or neg-

ligible angular deviation but with an offset All four LEDs blink green twice every second

Laser beam entering sensor with neither appre-

ciable angular deviation nor offset All four LEDs blink green every second

Adjusting the laser beam

1. With the lens covered, let the laser beam strike the centre of the sensALIGN sensor dust cap.

2. Slide the dust cap to open the lens. Observe the four laser beam adjustment LEDs while adjusting

the laser beam using the vertical and horizontal beam positioning thumbwheels. The thumbwheels are

used to adjust both the horizontal and vertical laser beam angles.

3. Carry out this adjustment until all four LEDs are blinking green once every second.

4. If the LEDs are blinking green twice every second, the angle at which the laser beam enters the

sensor is correct, but an offset is present. Eliminate the offset by sliding back the sensALIGN sensor

dust cap to cover the lens, then loosen the chain type bracket supporting sensALIGN sensor and

move the sensor sideways. At the same time, release the sensALIGN sensor clamping levers and

move the sensor upwards and downwards until the laser beam is centred on the dust cap. During this

adjustment, DO NOT touch sensALIGN laser.

5. Open the lens by sliding the dust cap and check the blinking of the four LEDS. If all four are blink-

ing green once every second, then the laser beam has been correctly centred.

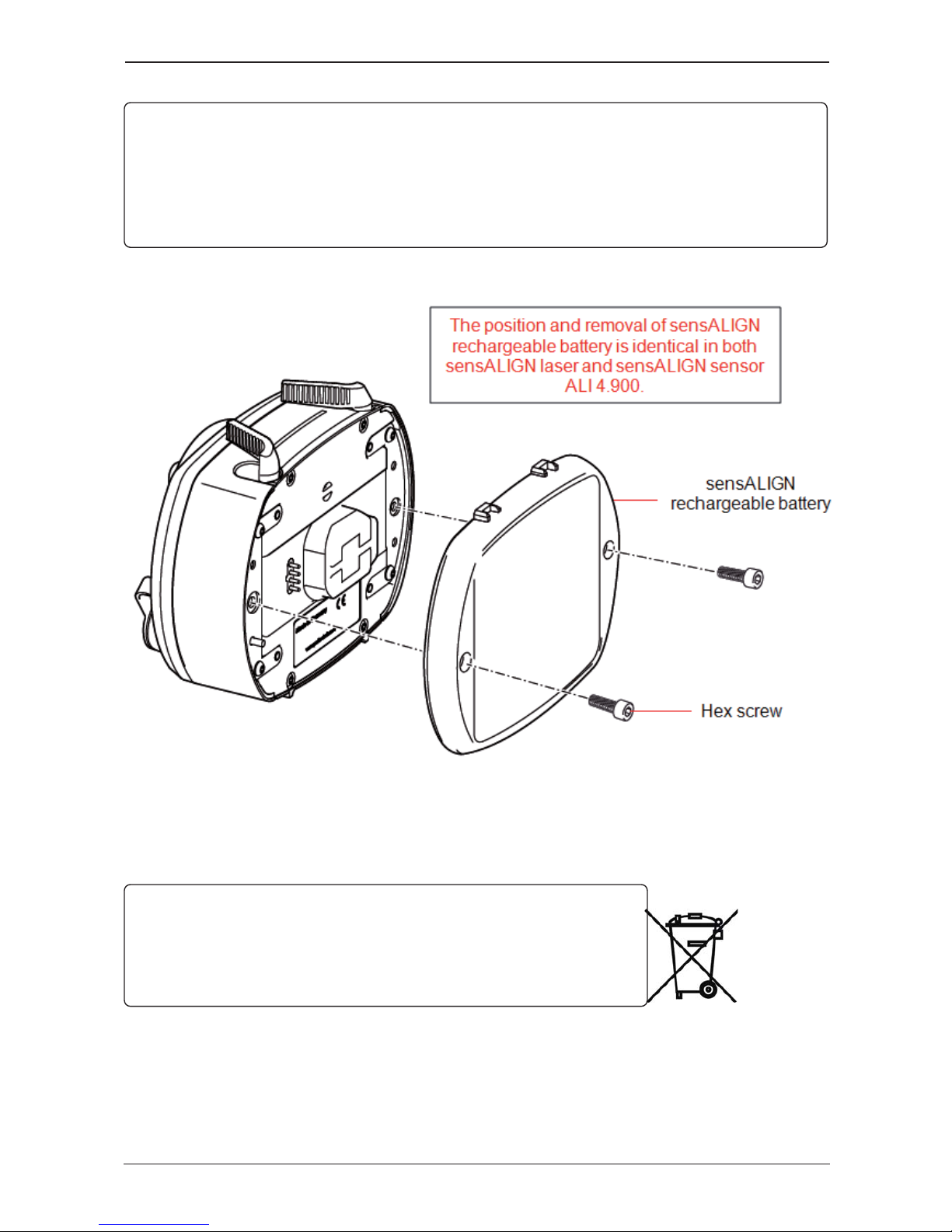

sensALIGN laser and sensor labelling

The labelling diagram represents both sensALIGN sensor and sensALIGN laser. It shows the

engraved symbols, markings and labels as they appear on the respective measurement head. The laser

safety labels are affixed on the housing of sensALIGN laser at the positions shown in the diagram.

The rechargeable battery label is located on the rear of sensALIGN rechargeable battery.

FictionSoft 7

(Undefined variable: General.UserGuideTitle)