prana 340S User guide

OPTIONS AND

DIMENSIONS

INDUSTRIAL RANGE

PRANA 340S

Use the QR code or visit the website:

http://prana.help/p023 to overview useful infor-mation such as

ventilation system information, owner's manual and other.

• Read all safety information carefully to ensure safe and proper use of the device.

MODEL RANGE: PRANA 2022®

PL

CONTENTS

WARNING AND SAFETY MEASURES ........................................ 4

SYSTEM CONDITIONAL ASSIGNMENT STRUCTURE ............ 8

DESIGN VARIANTS AND DIMENSIONS ................................. 10

PRANA-340S TYPE1 ................................................................... 10

PRANA-340S TYPE2 .................................................................... 16

PRANA-340S TYPE3 .................................................................... 21

PRANA-340S TYPE4 ............................................................. 27

PRANA-340S TYPE5 ............................................................. 31

PRANA-340S TYPE6 ............................................................. 37

PRANA-340S TYPE7 ............................................................ 43

4

WARNING AND SAFETY MEASURES

• The ventilating system can be used by children aged 8

years and older and by people with physical, sensory, mental

disabilities or lack of experience and knowledge if they are

supervised or instructed to operate the unit in a safe manner

and understand the hazards involved in its use. Do not allow

children to play with the ventilation system.

Installation, cleaning, and maintenance should not be

performed by children.

• The fan inside the device rotates during operation. Avoid

putting foreign objects inside the device during operation.

Doing so may result in personal injury.

• The unqualified user must not install, move, dismantle,

modify or repair the ventilation system himself.

• Begore the use make sure that the installation complies

with the mechanical and electrical regulations which are in

force in the country where the installation was carried out.

• Do not install heating equipment for air intake by a

ventilation system.

Incomplete combustion products can cause an accident.

• Installation by unqualified people can result in poor

performance, damage to the ventilation system, and

accidents.

• If the ventilation system is used in the same room as

other ventilation systems in operation, the performance of

the unit may differ from the stated performance.

5

• The presence of excessive wind pickup can affect the

performance of the ventilation system.

• Avoid damaging of the ventilation system.

• Warnings and precautions when installing the PRANA

ventilation system are described in the installation manual.

• If the heating elements from a third party supplier

are connected to the PRANA system control unit, the

manufacturer is not responsible for the proper operation of

both devices.

The heating elements, which may (optionally) be supplied

by the manufacturer, undergo a technical preparation stage

for proper operation.

• The air conveyed must not contain combustible or

explosive mixtures, chemically active vapors, sticky

substances, fibrous materials, coarse dust, soot, grease or

media that promote the formation of harmful substances

(poison, dust, pathogens).

• The unqualified user must not install, move, dismantle,

modify or repair the ventilation system himself.

• Before installation, make sure that there is no mechanical

damage to the structure and fasteners.

• If damage occurs, immediately de-energize the system

with a circuit breaker.Continued use may cause smoke, fire,

electric shock or injury.

6

Contact the manufacturer's service center or dealer in

your area for repair.

• It is not allowed to mount the connection heater with

the box downwards (danger of condensation and short-

circuiting of the wiring).

• Do not twist, damage or change the power cord. Do not

expose it to heat or place heavy objects on it. Doing so may

cause a fire or an electric shock.

• Do not block the intake or exhaust air passages as this

will reduce the performance of the system and could result

in stopping and/or smoke, fire, electric shock or injury.

• The recuperator is connected by means of insulated

strong conductors (cables, wires) with a cross-section of

0.5-0.75mm2. All wiring must be installed by a qualified

electrician in accordance with the Electrical Installations

Code.

• Heaters must be installed in a duct of similar diameter

(size). The minimum allowable distance between heater and

recuperator is at least 0.5 m of metal duct.

• The duct heaters are designed for a minimum airflow

rate of 1.5 m/s and a maximum exhaust air operating

temperature of 40 °C.

• Before performing any maintenance operations, de-

energize the unit (turn off the main power switch and wait

for the fans to of the fans to stop completely).

• Heaters cannot be insulated with thermal insulation

materials.

7

• The manufacturer is not responsible for the installation

that is carried out by an unqualified specialist (or group of

specialists) and all subsequent consequences connected

with it.

Incorrect installation will invalidate the warranty.

• The air ducts must be equipped with grills or other device

preventing free access to the fans.

• To avoid reverse draught in rooms where fireplaces,

gas heaters and other equipment producing or different

gas mixtures are in operation, the "Separate control" mode

must not be used.

8

SYSTEM CONDITIONAL ASSIGNMENT STRUCTURE

• PRANA-340S TYPE1 - Indoor module with using 200 mm

side spigots for circular duct connection. The front center

spigot of the system with 200 mm diameter is used to

connect the supply air duct in the room, and the rear center

spigot with 200 mm diameter to connect the exhaust air

duct from the room;

• PRANA-340S TYPE2 - Indoor module with the use of side

spigots with a diameter of 200 mm to connect the circular

duct. The front center spigot of the system with a diameter

of 200 mm is used to connect the exhaust duct in the room,

and the rear center spigot with a diameter of 200 mm to

connect the air intake duct from the street;

• PRANA-340S TYPE3 - Wall module with side spigots of

200 mm diameter to connect the circular duct. The system's

front 200 mm center spigot is used to connect the room

supply air duct, and the rear 200 mm center spigot is used

to connect the exhaust air duct from the room;

• PRANA-340S TYPE4 - Indoor module with side spigots

use 204x60 mm for the connection of a rectangular duct.

The front center spigot of the system with a 204x60 mm is

used to connect the supply duct to the room, and the rear

center spigot with a diameter of 200 mm is used to connect

the exhaust duct from the room;

• PRANA-340S TYPE5 - Indoor module using side spigots

204x60 mm diameter used to connect the rectangular duct.

9

The front center spigot of the system with a 204x60 mm is

used to connect the exhaust duct in the room, and the rear

center spigot with a diameter of 200 mm is used to connect

the air intake duct from the street;

• PRANA-340S TYPE6 - Wall module PRANA-340S with the

use of side spigots 204x60 mm for connecting a rectangular

duct. The front center spigot of the system with a 204x60

mm is used to connect the supply duct in the room, while the

rear center spigot, 200 mm in diameter, is used to connect

the exhaust air duct from the room;

• PRANA-340S TYPE7 - Wall module PRANA - 340S without

using side spigots for duct connection, air intake is made

through a 40 mm wide slot, along the outside diameter of

the casing.

10

DESIGN VARIANTS AND DIMENSIONS

PRANA-340S TYPE1 - Indoor module with using 200 mm

side spigots for circular duct connection. The front center

spigot of the system with 200 mm diameter is used to

connect the supply air duct in the room, and the rear center

spigot with 200 mm diameter to connect the exhaust air

duct from the room;

Main dimensions. Top view.

1210

200

340

200

350

200

200

230 230

550

11

1210

210

200

200

340

350

550

L/2 L/2

ø200

250

50

85

ø200

The main dimensions. Side view.

The main dimensions. Side view.

H

B

A

CD

E

F

G

A-Inflow of air into the

room

B-Terminal box

C-Room air intake

Ø200 mm

D-Energy intake Ø200 mm

Ø200 mm

E-Building ceiling

F-Condensate drain

pipe Ø10 mm

G-System brackets

H-Exhaust air outlet to

the outside Ø200 mm

12

Assignment of system connections. Top view.

A

C

B

D

A-Inflow of air into the room.

B-Room air intake. Use the necessary (and) or install

a blanking plug. Use one/two Ø200 mm required

connections.

C-External air intake Ø200 mm. Use the required (and)

or install a blanking plug. Use one/two Ø200 mm

connection(s).

D-Exhaust air discharge to the outside.

13

A

B

D

E

I

J

C

H

G

F

E

D

BF

G

D

C

B

A

Exterior placement. Isometric scheme.

Assignment of system connections. Isometric diagram.

A-P2 Ø250 mm

B-Installation of flexible

insertion Ø200 mm

C-B4 Ø250 mm

D-Muffler

Ø200/250 mm

A-Room air inflow Ø200mm.

B-Air intake from room

Ø200 mm.

C-Control box.

E-PRANA -340S

F-P1 Ø200/250 mm

G-Filter box Ø200/250 mm

H-Outer grille P1

I-В3 Ø200/250 mm

J-External grille B3

D-External air intake

Ø200 mm.

E-System fixing.

F-Covering of the building.

G-Exhaust air outlet to the

outside Ø200 mm.

14

Min 2000

E

H

G

F

L

B

I

A

C

J

K

M

D

Min 1000

Recommended connection diagram for ducts.

1 connection.

A-P2 Ø250 mm

B-B4 Ø250 mm

C-Electric duct heater

Ø200/250 mm

D-Install flexible insertion

Ø200 mm

E-PRANA -340S

F-Muffler Ø200/250 mm

G-Install flexible plug

Ø200 mm

H-Insert plugs

Ø200 mm

I-P1 Ø200/250 mm

J-Interior grid P1

K-Filter box

Ø200/250 mm

L-В3 Ø200/250 mm

M-External grille B3

15

F

G

J

D

B

B

H

A

C

K

I

L

E

Min 2000

Min 1000

Recommended connection diagram of the air ducts.

2 connections.

L-External grille B3

D-Install flexible connector

Ø200 mm

G-Insert blanking plug

Ø200 mm

I-Filter box Ø200/250 mm.

F-PRANA-340S mm

E-Muffler Ø200/250

J-B4 Ø200 mm

C-Electric duct heater

Ø200/250 mm

A-P2 Ø250 mm

H-P1 Ø200/250 mm

K-External grille P1

16

1130

200

340

200

350

200

200

190 190

550

PRANA-340S TYPE2 - Indoor module with the use of side

spigots with a diameter of 200 mm to connect the circular

duct. The front center spigot of the system with a diameter

of 200 mm is used to connect the exhaust duct in the room,

and the rear center spigot with a diameter of 200 mm to

connect the air intake duct from the street;

Main dimensions. Top view.

17

1130

170

200

200

340

350

550

L/2 L/2

ø200 ø200

250

50

85

475

190190

170

Assignment of connections of the system. Side view.

The main dimensions. Side view.

H

C

A

DE

B

F

G

A-Fence from room Ø200 mm

B-Building ceiling

C-Terminal box

D-Enhalation of air into Ø200 mm

E-Exhaust air outlet to the outside

Ø200 mm

F-Condensate drain

pipe Ø10 mm

G-System brackets

H-Box for outside air

Ø200 mm

18

A

C

B

D

Assignment of system connections. Top view.

A-Extract air from Ø200 mm

B-Room air inlet Ø200 mm

C-Exhaust air outlet to the outside Ø200 mm

D-Exhaust air intake Ø200 mm

19

Assignment of system connections. Isometric diagram.

External positioning. Isometric scheme.

B

F

E

C

G

E

D

C

A

C

H

E

G

F

A

D

B

I

K

J

A-Extract air from

Ø200 mm

B-System bracket

C-Room air inlet Ø200 mm

D-Terminal box

E-Exhaust air outlet to the

outside Ø200 mm

F-Building ceiling

G-Exhaust air intake

Ø200 mm

A-P2 Ø250 mm

B-Electric duct heater

Ø200/250 mm

C-B4 Ø250 mm

D-Muffler Ø200/250 mm

E-PRANA -340S

F-Filter box Ø200/250 mm

G-P1 Ø200/250 mm

H-Install flexible insert

Ø200 mm

I-External grid P1

J-B3 Ø200/250 mm

K-External grille B3

20

F

D

G

B

C

I

A

J

H

K

E

Min1500

Duct connection diagram. 1 connection.

A-B4 Ø250 mm

B-P2 Ø250 mm

C-Electric heater

Ø200/250 mm

D-Muffler Ø200/250 mm

E-Install flexible insert

Ø200 mm

F-PRANA -340S

G-Filter box

Ø200/250 mm

H-P1 Ø200/250 mm

I-B3 Ø200/250 mm

J-External grille B3

K-External grille P1

Other manuals for 340S

2

Table of contents

Other prana Fan manuals

Popular Fan manuals by other brands

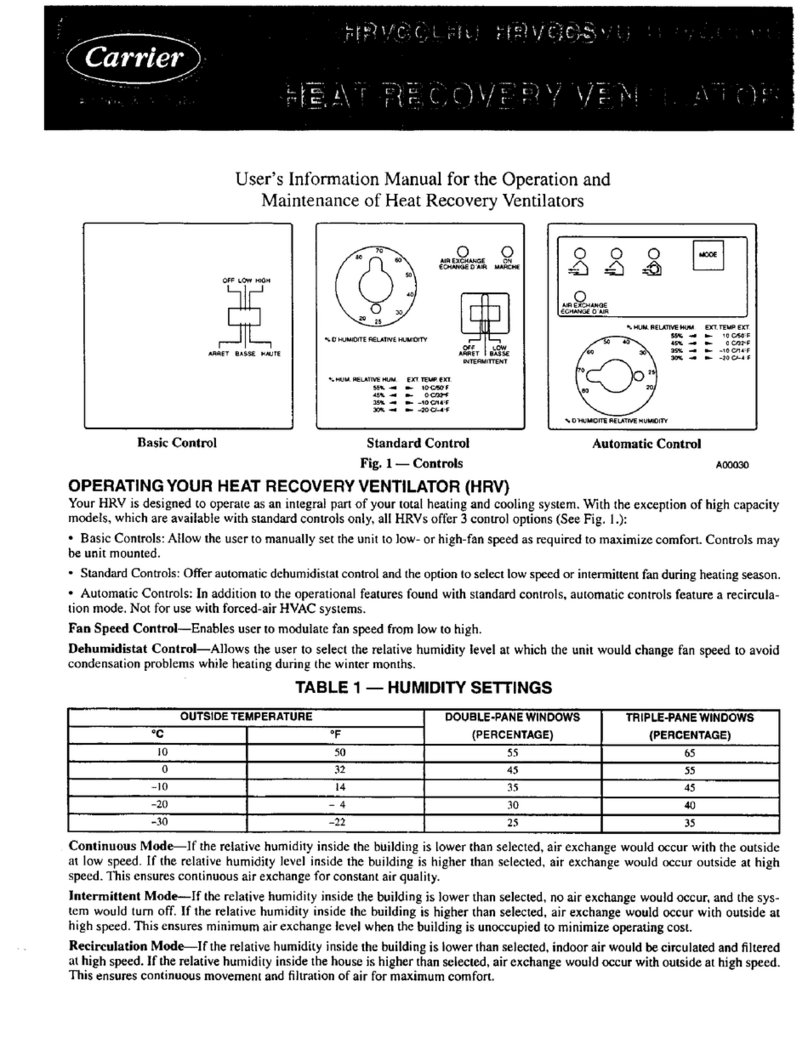

Carrier

Carrier HRVCCSVU User's information manual

Harbor Breeze

Harbor Breeze TEX52MBK5C1L user manual

VENTOMAXX

VENTOMAXX Z-WRG RONDO-Plus Assembly and operating instructions

Faro Barcelona

Faro Barcelona Lantau installation guide

Sulion

Sulion MARINA 2172200 instructions

Sinbo

Sinbo SF 6710 instruction manual