prana 150 Operator's manual

1

TECHNICAL-OPERATING

DOCUMENTATION

Infl ow and exhaust ventilation system

with heat recovery

PRANA-150

PRANA-200C

PRANA-200G

8

2

INTENDED USE

PRINCIPLE OF WORK

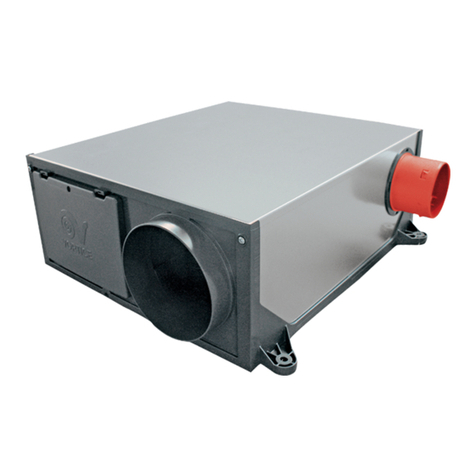

The basis of the technical solution for recuperation ventilation is the countercurrent, with a

continuous thermal cycle, a copper heat exchanger, which makes it possible to form two

different-directed airfl ows in the volume of one cylinder (Fig. 1).

Warm exhaust air that is removed from the room, passing through a copper heat exchanger

transmits its warmth to the counter stream of fresh air from the outside.

The system allows recover heat, which contributes to increasing the overall recuprration rate

and allows maintain the optimum humidity mode in the room. Taking into account that air

streams are separated and regulated at levels “infl ow” – “exhaust”», there is no mixing of

different-directional air fl ows.

High velocity of the fl ow with suffi cient heat transfer effi ciency ensures removal of up to

90% moisture in a dispersed state, preventing its condensation and freezing of the heat

exchanger at low ambient temperatures.

DESCRIPTION OF THE SYSTEM

Ventilation systems “PRANA-150”, “PRANA-200C”, “PRANA-200G” are intended for creation

and maintenance of healthy microclimate in premises.

These systems are recommended for use in residential and public facilities (apartments,

houses, offi ce premises, educational establishments, kindergartens, etc.).

Monoblocks of the centralized anti-current infl ow-exhaust ventilation.

PRANA-150 and PRANA-200 belong to the category of innovative and reliable products

aimed at creating and maintaining a healthy microclimate in premises of various functional

purposes.

High energy effi ciency and signifi cant air exchange capabilities make it possible to apply

these ventilation systems for organizing domestic ventilation.

Technologically, the system is a monoblock with high-effi ciency counter-current

copperrecuperator ready to use in accordance with the design and assembly tasks and

conditions.

Fig.1. The principle of operation of recuperator PRANA-150, PRANA-200C, PRANA-200G

Cold fresh air

from outside

100-150 mm

from the ceiling

Removal of warm return

air from the premises

Supply & exhaust are

operating simultaneously

copper

heat exchanger

Preheated fresh air

from outside

Unit slope

3-5 degrees

Removal of the air

from the premises

3

ADDITIONAL FUNCTIONS

The function of “heating with minimally-raised temperature”

For additional comfort in equipping residential premises with ventilation systems PRANA of

residential-and-public and semi-industrial series, the function of air “heating with minimally-

raised temperature” is provided for. It can be switched on by pressing the “On heating with

minimally-raised temperature” button on the remote control or in a mobile application (see

the remote control manual included in the list of standard equipment).

After having activated the function of “heating with minimally-raised temperature”, the

temperature of the infl ow air increases by 3-5 ºC.

When the motors are switched off and the cover of the recuperator is open, this function

additionally plays the role of an air heat curtain.

WARNING! DO NOT SWITCH ON «heating with minimally-raised temperature» , if the outside

air temperature is +20 ºС and above!

Function “Winter Mode”

Function “Winter Mode” is intended to prevent the icing of condensate drainage during the

cold season or to freeze it if icing has occurred.

WARNING! To avoid icing and to ensure the system operates correctly at the minus

temperature from the outside - the use of the Winter Mode is mandatory.

MAIN TECHNICAL CHARACTERISTICS

PRANA 150 PRANA 200G PRANA 200C

Diameter of the working module, mm

with thermal insulation, mm 150

160 200

210 200

210

Diameter of the mounting hole, mm

Length of the working module, mm

≥162

≥475

≥215

≥440

≥215

≥500

Recommended area of the premises, m 2 <60 <60 <120

Amounts of air exchange during recovery, m3/h;

(the infl ow and exhaust work simultaneously):

- i n fl o w

-exhaust

-night / minimal

- passive mode

115

105

25

6

135

125

25

10

235

220

40

10

Energy consumption, W * h:

recuperator

“mini-after-heating” 7-32

55 7-32

55 12-54

55

Recovery effi ciency, % 91 92 93

Acoustic pressure from the product at a distance,

dB (A):

3m

1m 13/24

21/36 13/24

21/36 13/24

22/38

Weight of the system in individual packing ≥ 4,4 ≥ 5,8 ≥ 6,0

The size of the packing box, mm (LxHxW) ≥750х210х210 ≥750х260х260 ≥750х260х260

Power supply: AC: 230 ± 10% V. Class of insulation: II. Degree of protection: IP 24.

Control: remote control, mobile application.

The body of the system is thermally insulated. Double protection against frontal blasting.

The function of “heating with minimally-raised temperature” and “freezing”.

The established service life of the system: 10 years. The warranty period: 2 years.

The use of the system is designed for long-term operation at air temperature in the range

from -30 ºС to +50 ºС.

4

In mode «AUTO» after engine shutdown, «Winter mode» will work for 30 minutes to prevent

icing in the system, which may result in reduced effi ciency or condensate drainage

complications.

Preheating element (additional option)

Recuperators that will be used in rooms with excessive humidity in the cold climate are

recommended to be equipped with an additional heating element.

Passive mode

The operating mode of the ventilation system with the open lid of the recuperator and

switched off motors. It lies in the movement of uncontrolled airfl ows through the recuperator

due to the difference in pressure and temperature inside and outside the premises. It is

allowed to use, when the difference between outside and inside temperatures is no more

than 5 o C.

Defrosting

WARNING! In the cold season, the improper operation of the recuperator is likely to freeze it!

When freezing, it is necessary to activate function «mini-heating» with engine switched off

for at least 60 minutes, and let it freeze, then turn on the recuperator to the required mode.

switched off motors

+

the “heating with

minimally-raised

temperature” switched on

turn on

the desired mode

1.

2.

2.

9

switched off motors

switched off motors

Fig. 2. Defrosting

5

OVERALL DIMENSIONS

Fig. 3. The overall dimensions and the dimensions of ventilation system “PRANA-150”, “PRANA-200G”,

“PRANA-200C”:

a) the ventilation grid and air intake in the premises;

b) monoblock, side view;

c) the ventilation grid and air intake from the outside.

535

475

35

mm

500mm

475

a)

a)

a)

a)

b)

b)

b)

b)

c)

c)

c)

c)

6

The infl ow and exhaust ventilation system with heat recovery “PRANA” is a monoblock ready

for use in accordance with design and assembly tasks and conditions.

The system is mounted in a hole of the appropriate diameter in the upper part of the wall

adjoining the outside, at a distance of no less than 100-150 mm from the ceiling or walls. The

through hole should be a slope of 3-5 degrees towards the outside. The operating module of

the ventilation system is mounted in the hole using a seal (Fig. 4).

The length of the working module should correspond to the thickness of the wall in which

the installation will be carried out. In order to ensure the normal operation of the system, it

is necessary that its body facing the the outside extends beyond the wall by 1-2 cm to the

beginning of the air intake (Fig. 4).

INSTALATION

Fig. 4. The diagram of installing the recuperator in the wall.

airborne

airborne

grille

grille

airborne

grille

airborne

airborne

grille

airborne

> 50 mm

> 50 mm

unit slope

unit slope

3-5 degrees

3-5 degrees

unit slope

3-5 degrees

unit slope

unit slope

3-5 degrees

unit slope

100-150 mm

from the ceiling

sealant

sealant

sealant

air intake

Fig. 5. An example of mounting of the recuperator “PRANA-150”, “PRANA-200G”, “PRANA-200C”.

Other preparatory works:

- preparation of the hole for installing the switch and preparation of the grooves for the

installation of the electrical supply network between the system, the switch and the place of

connection of the system to the power supply source.

7

CONNECTING TO THE ELECTRICAL SUPPLY NETWORK

Connecting the recuperator to the electrical supply network, controlling the system from the

remote control.

Disconnect the power supply to the electrical system to which the ventilation system will be

connected.

WARNING! Ensure that the electric power supply is really switched off!

The connection of the ventilation system to the electrical supply network is done using an

electric cable, which is laid from the working module (standard equipment).

In the event that the electrical system is not laid to the mounting hole, the electric cable

from the recuperator should be connected to the electrical supply network in the distribution

box according to the diagram in Fig. 6: You must connect the contact terminals 1 and 2 in

parallel, or install in the cable an electrical connector that meets the above parameters for

quick connecting and disconnecting electrical appliances. Electrical connectors are not

included in the list of the standard equipment.

If the cable of the electrical supply network of the building has been laid to the mounting

hole, then the power supply to the working module cable is carried out in the immediate

vicinity of the body of the recuperator. Shorten the electric cable from the recuperator to a

length that is convenient for electrical connection.

All electrical cables used in the installation should have the cross-section of 0.5-0.75 mm².

The operation of the system is controlled using a remote control or mobile application that

controls the operation of the fans installed in the body of the ventilation system (it turns on,

regulates and turns off).

The PRANA 150 / 200G / 200C recuperators are adapted to an existing electrical network in

an automatic mode, without the use of software. This signifi cantly reduces the noise indicators

of the equipment and allows ensure the the noise characteristics of the ventilation system

declared in the technical passport.

WARNING! After having connected the ventilation system to the electricity supply network,

it is necessary:

1. to supply electrical power to the system.

2. to check the operation of the fans in different operating modes, using control units.

1

2

Fig. 6. Connection of the recuperator to the electrical supply network in the case of controlling the

system from the remote control or using a mobile application.

8

START-UP

The fi rst start-up of the system should be carried out by a specialist who has theoretical

knowledge and haspractical skills in the electrical installation of this ventilation system.

Before starting-up, it is necessary to check:

- if the connection to the electrical supply network has been performed correctly (according

to the mark in Fig. 6);

- if the air in is open;

- if the ventilation system is functioning properly.

WARNING!Before switching on the system, open the air intake as indicated in the photo

below:

OPERATION

During operation, it is necessary to periodically check:

- the quality of function of the fans;

- the correspondence of the graphic symbols of the indication;

- correct operation of the device in accordance with the control devices.

The device must be switched off in case of:

- excessive oscillations and noise;

- damage to the elements of the device body;

- damage to the insulation of the electric cable;

- damage to the elements of automation;

- the temperature of the outside air is below -30 ºС.

1. The lid is closed. Do not switch on the system,

when the lid is closed.

2. Smoothly pull the cover. The system is ready

for starting-up.

The PRANA 150 / 200G / 200C recuperators are adapted to an existing electrical supply net

work automatically, without the use of software. It signifi cantly reduces the noise indicators

of the equipment and allows ensure the noise characteristics of the ventilation system

declared in the technical passport.

ADAPTATION TO THE ELECTRICAL SUPPLY NETWORK

9

1. Press the “Switch off” button on the remote

control. Switch off the ventilation system. 2. De-energize the ventilation system.

7. Extract the heat exchanger and fans

from the body.

6. Unscrew the self-tapping screws through

special openings. Remove the fl ange.

MAINTENANCE

The maintenance consists in periodic (recommended 1-2 times a year) and preventive

inspection of surfaces of the fans and the heat exchanger and, if necessary, in cleaning

them. The procedure for disassembling / assembling the device for / after cleaning:

6. Unscrew the self-tapping screws through

special openings. Remove the fl ange.

7. Extract the heat exchanger and fans

from the body.

3. Open the lid of the recuperator. 4. Turn the fasteners of the lid and remove it.

5. Disconnect the cable and remove the power wires by

pressing the terminals. Remove the lid.

10

ASSEMBLY IN THE REVERSE ORDER

The technological process provides for 100% inbound quality control for all components,

as well as double 100% inbound control after their manufacture and 24-hour run in the

maximum power mode.

Transportation and storage of the products in individual packing boxes is ensured in a

horizontal position.

Keep the recuperator in the factory packaging under the cover or (in enclosed space) with

relative humidity of air of no more than 70% and air temperature from -20˚С to + 40˚С.

TRANSPORTATION AND STORAGE RULES

12. The drain in the heat exchanger and

the body must coincide and be below

during the installation.

14. The fl ange must be installed correctly;

the larger protrusion of the should be below.

11. Clean the heat exchanger in adry or, if

necessary, in a wet manner.

WARNING!

Before rinsing or wet cleaning of the

heat exchanger, make sure that all

the electrical components and parts

are removed from the heat exchanger

(except for the components of “heating

with minimally-raised temperature”and

“heating the condensate drainage with

raised temperature”.

QUALITY

9. Unscrew the self-tapping screws.

Remove the fans on both sides.

10. Remove the blades from the fan

housings and clean them in a dry manner.

12. The drain in the heat exchanger and

>

9. Unscrew the self-tapping screws.

Remove the fans on both sides.

10. Remove the blades from the fan

housings and clean them in a dry manner.

11

- Ventilation system.

- Technical passport for the system.

- Technical (warranty) card.

- Remote control.

- Manual for the remote control.

- Packing box

SCOPE OF DELIVERY

SAFETY REQUIREMENT

All electrical installation works (maintenance) must be carried out only by a qualifi ed

specialist with a category of admission to such works.

Ensure that during installation, the provisions, mechanical and electrical installation rules

and norms valid in the country, in which the installation is carried out, are observed.

WARNING! All installation and electrical works relating to the connection (maintenance) are

carried out only after the device is disconnected from the electrical supply network.

WARNING! Do not operate the ventilation system, if there is a threat that foreign objects may

enter the infl ow part of the body, which objects may jam or damage the impeller of any of

the two fans.

WARNING! Do not operate the ventilation system in premises, where the air contains

aggressive substances and does not correspond to the working temperature regime.

After commissioning, the ventilation system must comply with the provisions of the following

directives:

- Directive 2014/35 / EU. Low Voltage Directive (LVD);

- Directive 2006/42 / EU. Safety of Machinery mechanisms;

- Directive 2004/108 / EU. Electromagnetic Compatibility (EMC);

- Directive 2011/65 / EU. Restriction of Hazardous Substances (RoHS).

12

Other manuals for 150

1

This manual suits for next models

2

Table of contents

Other prana Fan manuals

Popular Fan manuals by other brands

The Modern Fan Company

The Modern Fan Company Lapa Flush Installation instructions and owner's manual

Myson

Myson X 100 TH user manual

HealthyAir

HealthyAir Source Capture HA-SCV-G1-WS owner's manual

NuTone

NuTone QTRE090FL Specification sheet

Fanimation

Fanimation Air Shadow FP810 Series owner's manual

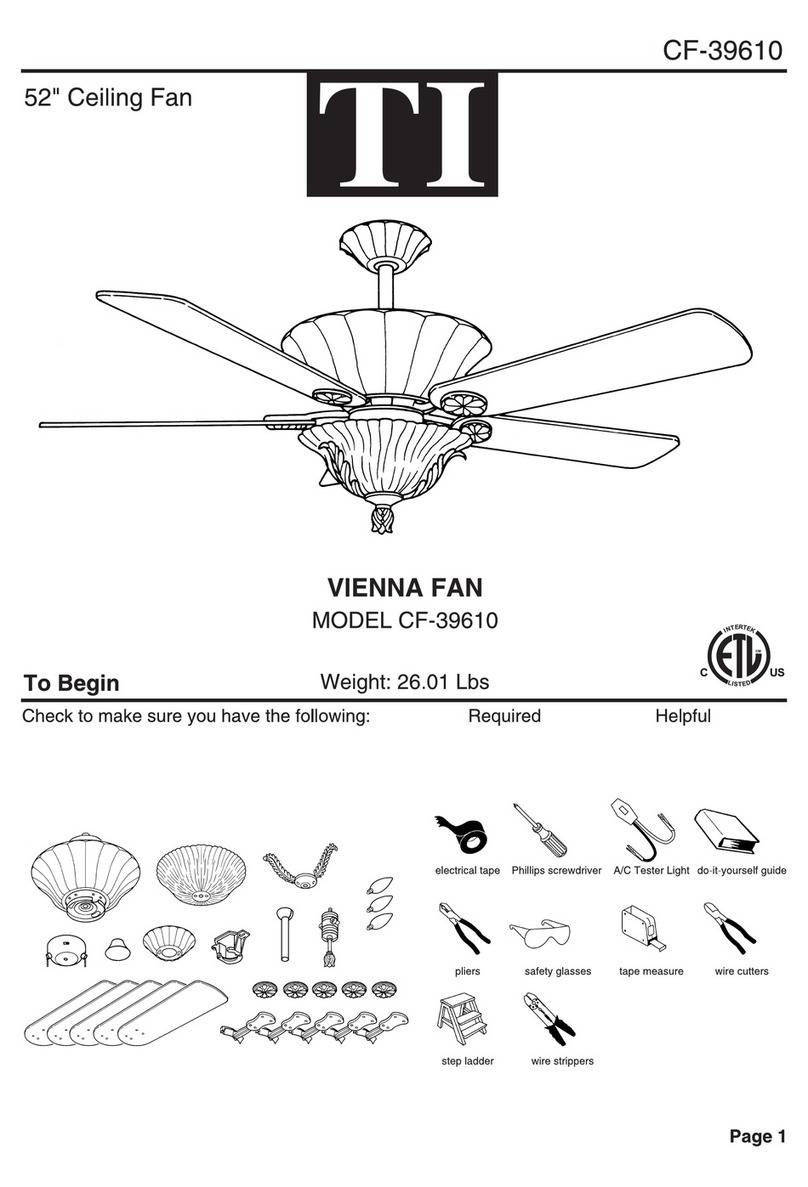

TI

TI CF-39610 installation instructions