Prebena KT-1000 User manual

Introduction

Introduction

These operating instructions will help you with the

intended,

safe and

cost-effective

use of the KT-1000 cartridge, referred to as the "cartridge" below.

We assume that each user of the cartridge knows how to deal with

compressed air containers and compressed air-driven devices.

People who do not know how to do this must be instructed by an

experienced user in the use of the cartridge.

Everyone who

uses,

fills,

cleans or

disposes of this cartridge

must have read and understood these operating instructions.

These operating instructions are considered a part of the product.

Always keep these operating instructions with the cartridge. Pass the

operating instructions along if you sell the cartridge or pass it on in

another way.

Table of contents

3

Table of contents

Layout characteristics.................................................................. 4

General layout characteristics.................................................... 4

Safety instruction attributes........................................................ 4

Basic safety instructions.............................................................. 5

Intended use.............................................................................. 5

To avoid explosion hazards........................................................ 6

To avoid damage to the cartridge............................................... 6

Description .................................................................................... 7

Scope of supply ......................................................................... 7

Information on the KT-1000 cartridge......................................... 7

To use the cartridge...................................................................... 9

Check the condition.................................................................... 9

To connect the cartridge............................................................. 9

To disconnect the cartridge from the device..............................10

Transporting and storing the cartridge ......................................11

Servicing the cartridge ................................................................11

Cleaning the cartridge...............................................................11

Filling the cartridge....................................................................12

Having the cartridge tested .......................................................13

Repairing faults............................................................................14

Cartridge disposal........................................................................15

Technical specifications..............................................................15

KT-1000....................................................................................15

Manufacturer's address...............................................................16

Warranty .......................................................................................17

Manufacturer's address

4

Layout characteristics

General layout characteristics

Various elements in the operating instructions are marked with

specific layout characteristics. This allows you to easily distinguish

whether the elements are

normal text,

lists or

handling steps

that you are reading about.

These notes provide additional information, such as specific

information on the cost-effective use of the cartridge.

Safety instruction attributes

All the safety instructions in these operating instructions are based

on the same pattern. On the left, you will find a hazard symbol. To

the right of it, you will see a signal word which indicates the severity

of the danger. Under the signal word, you will find a description of

the source of danger and instructions on how to avoid this danger.

WARNING

Instructions with the word WARNING warn of

hazards that can lead to potentially serious or

even fatal injuries.

CAUTION

Instructions with the word CAUTION warn of

hazards that can potentially lead to slight to

moderate injuries, or to property or

environmental damage.

Warranty

5

Basic safety instructions

When using the cartridge, observe and follow all the warnings and

instructions in these operating instructions and those on the

cartridge. The included Declaration of Conformity is an element of

these operating instructions.

Intended use

The cartridges are to be used exclusively to supply compressed air

to those PREBENA devices in whose operating instructions this type

of cartridge is expressly specified. Use with other devices is

permitted only after consultation with the manufacturer. Intended use

also includes compliance with the accident prevention regulations

and the statutory regulations and standards in force at the site of

use. Any other use is not considered intended use and can result in

material damage or even personal injury.

In particular, unintended use constitutes operation

with non-approved devices,

with oxygen or other flammable gases or gas mixtures or

by people with no knowledge of the use of compressed air tanks

and compressed air-driven devices.

PREBENA WILFRIED BORNEMANN GMBH & CO. KG accepts no

liability for any damage or injuries resulting from any such improper

or unintended use.

Manufacturer's address

6

To avoid explosion hazards

Only fill the cartridge using PREBENA compressors of the

PKT-FILLMASTER series.

Only fill the cartridge with compressed air.

Only fill the cartridge up to the maximum filling pressure of

300 bar.

Do not fill any damaged cartridges.

Do not expose the cartridge to any temperature above 60 °C or to

direct sunlight.

Only use the cartridge up to the date of the maximum service life

specified on the rating plate.

Each time before transporting, disconnect the cartridge from the

tacker and the controller.

Keep the cartridge out of reach of children and other unauthorized

persons.

Do not use a cartridge whose last periodic inspection was more

than 10 years ago.

To avoid damage to the cartridge

Never open the cartridge. Always leave repairs to qualified

specialists.

Do not use the cartridge if it has been dropped or is damaged.

Have the cartridge inspected by qualified specialists before

putting it into use again.

Prevent contact of the cartridge with the following substances:

-aggressive solvents

-fuels and lubricants

-acids

-cleaning agents

-chemicals of all types.

Warranty

7

Description

Scope of supply

The cartridge is delivered in a Systainer plastic case for five

cartridges (KT-1000-SY), or with the device. Included in the scope of

supply are protective caps for the valves of the cartridges, the

operating instructions, and the Declaration of Conformity.

Information on the KT-1000 cartridge

The following important information is provided on the cartridge:

No.

Explanation

1

Company name

2

Serial number

3

Pi marking

4

Acceptance date

5

Factory Acceptance Test

6

UN No.

7

Volume

8

Gas type

Manufacturer's address

8

9

Test pressure

10

Filling pressure

11

EN standard

12

Recurring test date

13

Registration office

14

Logo

15

Empty weight

16

Hazardous goods label

17

Air cartridge label

Do not remove or cover the information on the cartridge.

Warranty

9

To use the cartridge

Check the condition

WARNING

There is a risk of explosion when operating a

damaged cartridge.

Check the condition of the cartridge before

each connection.

Connect the cartridge only if it is in good

condition.

Check the following points in particular:

-The valve must not be damaged or dirty or loose fitting.

-The cartridge must not show any external damage, such as

scratches or dents.

-The last periodic inspection of the cartridge must not have

been more than ten years ago.

-The useful service life of the cartridge must not be exceeded.

Do not connect a damaged cartridge to a device.

Have a damaged cartridge repaired by PREBENA qualified

personnel before connecting it.

To connect the cartridge

Take the cartridge out of the transport case.

Keep the transport case for transporting the cartridge.

The transport of the cartridge is only permitted in the transport

case.

Manufacturer's address

10

WARNING

There is a risk of an explosion if the maximum

operating pressure is exceeded (see operating

instructions for the tacker).

If this case, immediately disconnect the

cartridge from the device.

Unscrew the cap from the valve.

Check the valve for debris and dirt.

Clean the valve if necessary (see Page 12).

Check the condition of the cartridge (see Page 9).

WARNING

Operating the cartridge with unsuitable devices

can cause damage to the cartridge and the

devices.

Only connect the cartridge to

manufacturer-approved devices.

Slide the cartridge forward with the valve in front into the holders

for the device.

Screw the cartridge hand tight into the connector thread of the

device.

To disconnect the cartridge from the device

After operation or after extended downtime periods, carry out the

steps described below:

Unscrew the cartridge from the connecting thread.

Pull the cartridge towards the back out of the holders for the

device.

Screw the cap on the valve of the cartridge.

Keep the cartridge protected against impacts and shocks in the

included transport case.

Warranty

11

Transporting and storing the cartridge

CAUTION

Damage possible by chemicals or impacts.

Transport and store the cartridge so that it

is protected against impacts.

Transport and store the cartridge so that it

is protected from chemicals.

Leave some pressure in the cartridge (2-3 bar).

Before storing or transporting, pack the cartridge in the transport

case or a sturdy shipping carton.

Transport the cartridge to the desired location.

Store the cartridge at room temperature at a location that is dry

and protected against dust.

Servicing the cartridge

The cartridge must be serviced only by persons who have the

knowledge, skills and experience necessary to do so. All work not

described here must be carried out by the manufacturer's aftersales

service department or by the manufacturer.

Cleaning the cartridge

Clean the valve and the outside of the cartridge and after every

use.

CAUTION

The cartridge may be damaged by improper

cleaning agents.

For cleaning, only use a cloth that is dry,

slightly moistened or moistened with mild

soap suds.

Manufacturer's address

12

To remove light dirt from the cartridge housing, proceed as follows:

Wipe off the cartridge with a cloth that is slightly moistened with

mild soap suds.

Then wipe off the cartridge with cloth that is slightly moistened

with tap water.

Finally wipe the housing dry with a soft, dry cloth.

To clean the valve, proceed as follows:

WARNING

There is a risk of an explosion if the valve is

damaged.

Do not clean the valve with hard or sharp

objects.

Wipe off the outside of the valve with a cloth that is slightly

moistened with mild soap suds.

Then wipe off the outside of the valve with a cloth that is slightly

moistened with tap water.

Finally wipe the outside dry with a soft, dry cloth.

The cartridge is only to be cleaned with the described means.

If you can not clean the cartridge as described, please send it to

the manufacturer.

Filling the cartridge

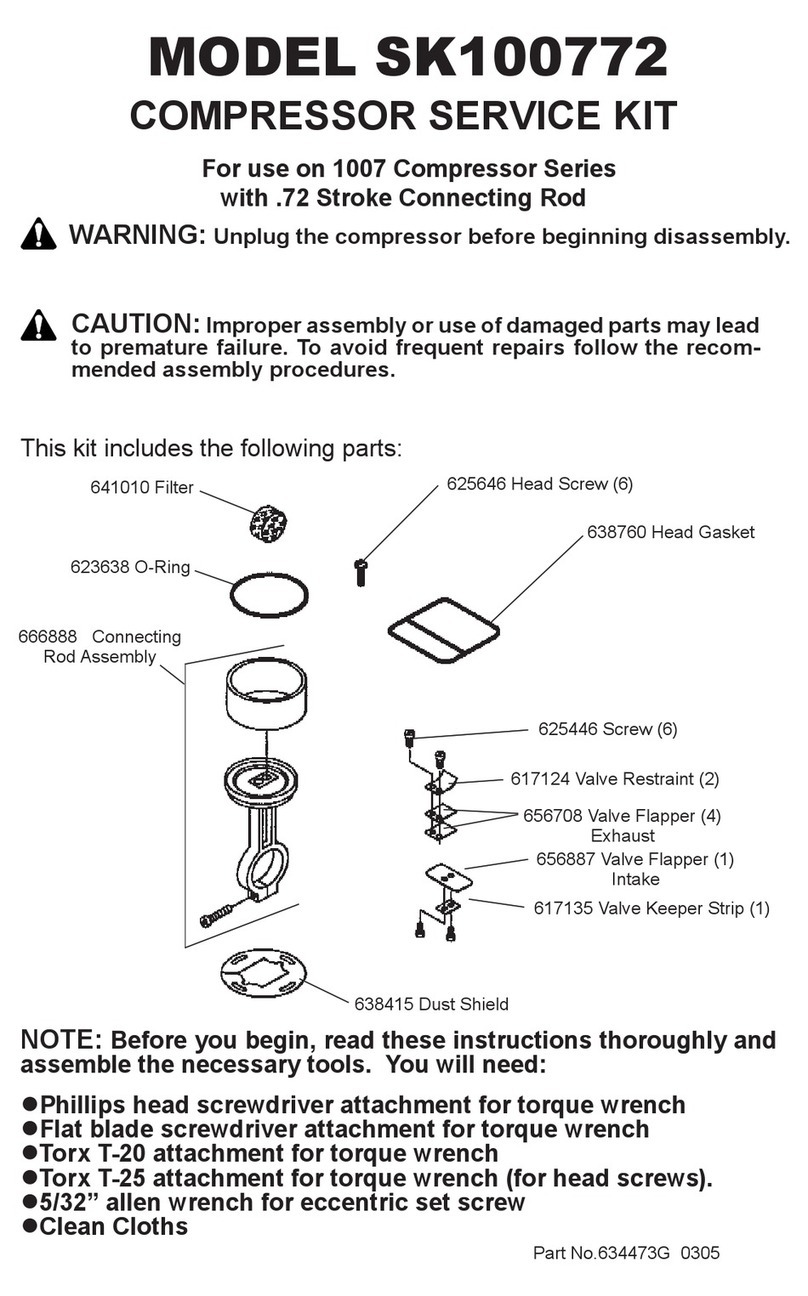

The cartridge can be filled by using compressors of the

PKT-FILLMASTER series, available as accessories, and adapter

ET No. 00205801.

During this process, follow the operating instructions for the

compressor.

You can also buy a full cartridge with the exchange of an empty

cartridge from your dealer.

Warranty

13

Having the cartridge tested

WARNING

There is a risk of an explosion with untested

cartridges.

Only use properly tested cartridges.

The cartridge must be inspected at the intervals specified in the

national regulations and every ten years by Prebena. This inspection

must be documented on the label of the cartridge.

Check the date of the last periodic test on the rating plate.

If the date is a decade or more ago, then proceed as follows:

Pack the cartridge in a sturdy shipping carton (see Page 11).

Send the cartridge to PREBENA for testing.

Manufacturer's address

14

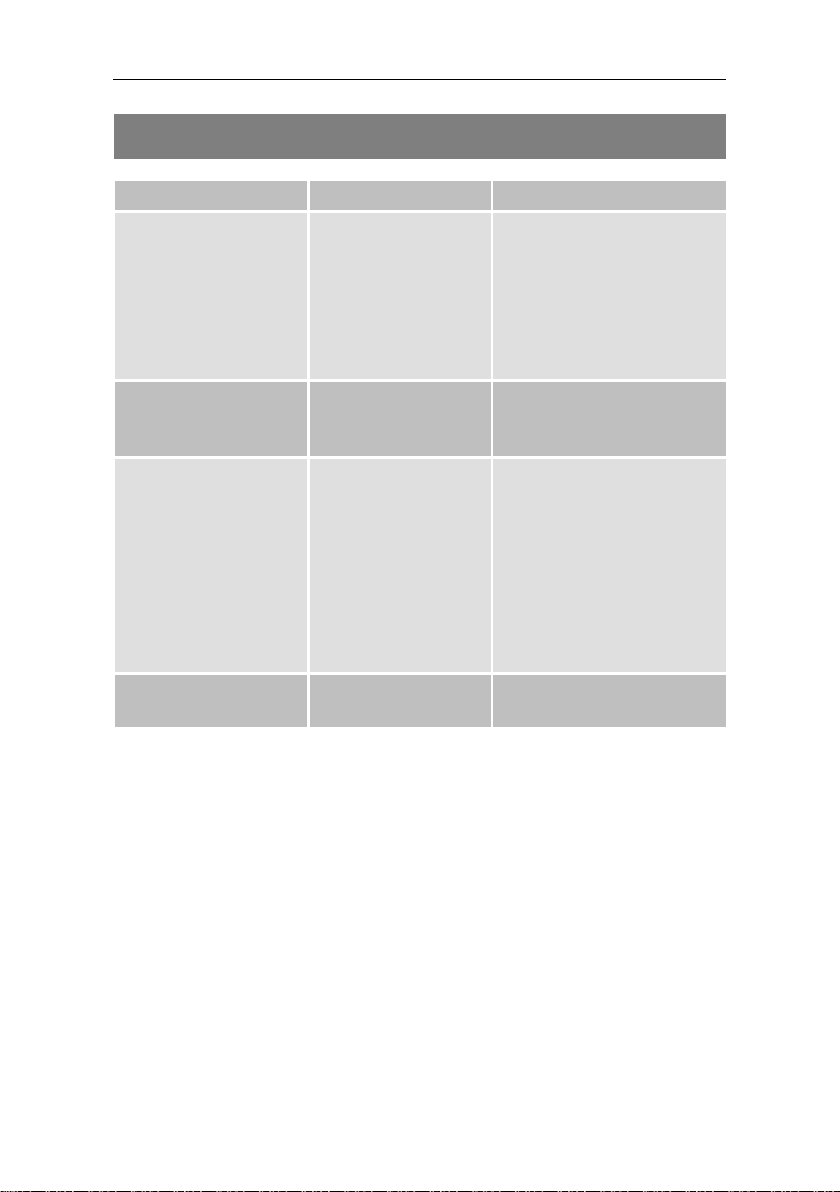

Repairing faults

Symptom

Possible cause

Corrective measure

Air escapes audibly from

the tacker safety valve.

The operating

pressure is too high,

the tacker is damaged.

Disconnect the cartridge

from the tacker

(see Page 10).

Send the cartridge and

the device via the dealer

to PREBENA

(see Page 16).

Air escapes audibly at

the connection for the

cartridge.

The cartridge has

become loose because

of vibrations.

Screw in the cartridge

hand tight into the

connector (see Page 9).

The seals at the

connections for the

cartridge are defective.

Connect a new cartridge

(see Page 9).

Send the cartridge via

the dealer to PREBENA

(see Page 16).

If the problem persists,

send the tacker via the

dealer to PREBENA

(see Page 16).

Triggering is not

possible.

The operating

pressure is too low.

Connect a new cartridge

(see Page 9).

If the malfunction continues to persist, contact your dealer or the

manufacturer (see Page 16).

Warranty

15

Cartridge disposal

CAUTION

Environmental damage if disposed of

incorrectly.

Clean the cartridge before disposal.

Comply with the applicable regulations for

oil disposal.

Do not, under any circumstances, dispose of the

cartridge along with normal household waste.

Send the cartridge to the manufacturer for

disposal (see Page 16).

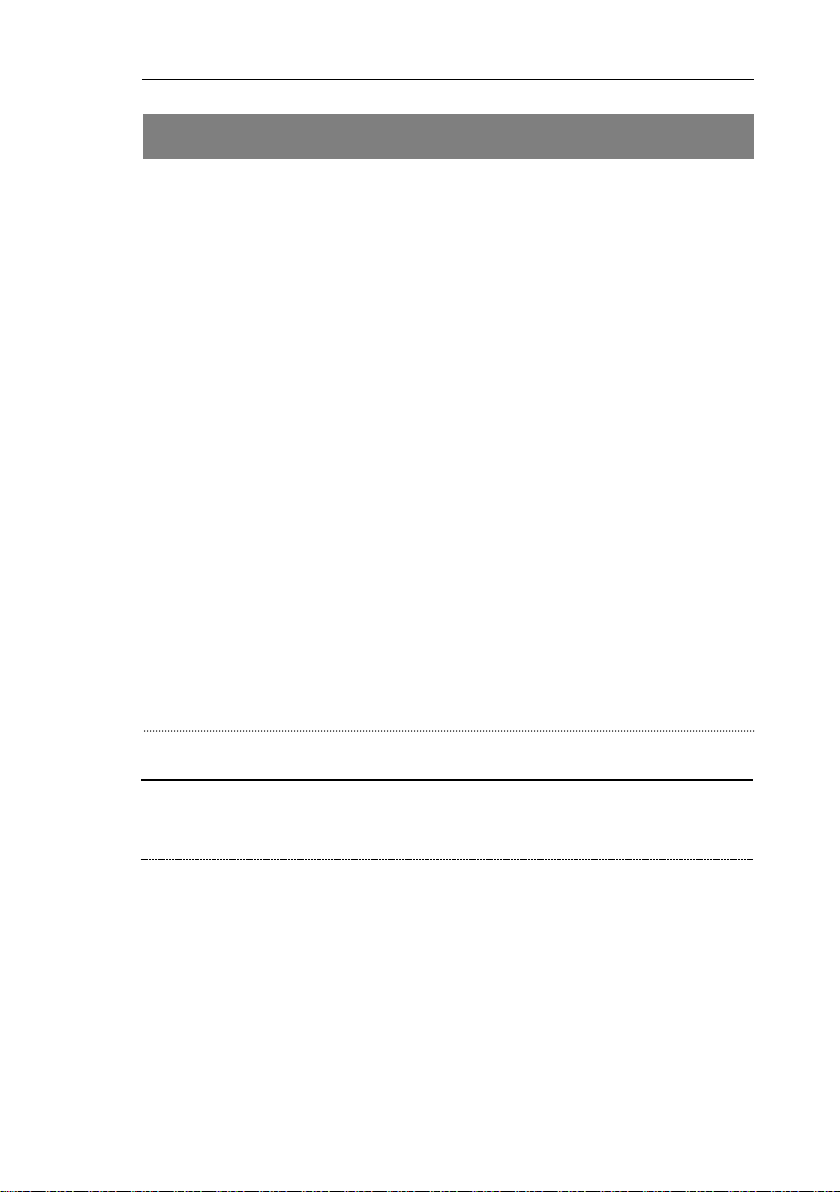

Technical specifications

KT-1000

Length:

277.2 mm

Diameter:

50.8 mm

Packaging dimensions (L × W × H):

KT-1000-SY: 395 x 295 x 112 mm

Weight, empty cartridge:

0.91 kg

Weight, filled cartridge:

0.94 kg

KT-3500-S weight,

with transport case:

6.26 kg

Contents:

0.36 l compressed air

Maximum container air pressure:

300 bar

Operating temperature:

–5 to +45 °C

Storage/transport temperature:

Room temperature, maximum 60 °C

Maximum service life:

Unlimited, if regular 10-year

inspections are carried out

Warranty

17

Warranty

Starting from the date of the sale, PREBENA provides a 1 year

warranty on the stated product under the following warranty terms.

According to the PREBENA warranty, faults attributable to material

or manufacturing faults will be repaired free of charge. Malfunctions

or damage caused by improper use are not covered by the free of

charge warranty.

Furthermore, only original PREBENA fasteners must be used; in

case of non-observance, the product liability and thus warranty

claims become void. The warranty does not cover wearing parts

such as O-rings, etc. It shall be at the discretion of PREBENA to fulfil

the warranty by replacement of the faulty part or by the supply of a

new product. No further claims will be accepted.

In order to file a claim under the warranty, the completed warranty

form with dealer's stamp and date of sale, or an invoice containing

the dates and information required on the warranty form, must be

enclosed with the product.

Shipping: The faulty device must be carefully packed so that it is

resistant to breakage, the postage must be paid and the package

sent to PREBENA.

Warranty form

Model name:

Date of purchase:

Dealer:

(Stamp)

Table of contents

Other Prebena Air Compressor manuals

Popular Air Compressor manuals by other brands

GÜDE

GÜDE AIRPOWER 200/08/6 Translation of the original instructions

Craftsman

Craftsman 919.167462 owner's manual

Campbell Hausfeld

Campbell Hausfeld Vertical Operating instrctions

Electric Signal

Electric Signal MMXV AD user manual

Hanshin Machinery

Hanshin Machinery GRH 3 series user manual

Sears

Sears 919.184191 owner's manual