PREFORMED LINE PRODUCTS COYOTE 80805258 User manual

1

COYOTE® CLOSURE

FOR UNDERGROUND, AERIAL, AND BURIED SPLICES

6.0" x 22" • 8.5" x 22"

(15.24 cm x 55.88 cm • 21.59 cm x 55.88 cm)

OCTOBER 2004

Be sure to read and completely understand this procedure before applying product. Be sure to select

the proper PREFORMED™ product before application.

PLEASE NOTE: For OPGW application, see procedure entitled, “OPGW Cable and End Plate Prepara-

tion for COYOTE® Closure” (SP2849).

CONTENTS PAGE

1. NOMENCLATURE ................................2,3,4

2. DESCRIPTION AND CLOSURE

CAPACITIES ...............................................5

3. END PLATE CONFIGURATIONS ...............5

4. CABLE PREPARATION–LOCK-TAPE

SEALANT APPLICATION ........................6,7

5. INTERNAL BOND PROCEDURE ...............7

6. END PLATE PREPARATION ......................8

7. END PLATE ASSEMBLY .........................8,9

8. UNITUBE PREPARATION ........................10

9. INSTALLING TRANSITION

COMPARTMENT FOR SINGLE

TUBE CABLE ......................................10,11

10. SECURING UNITUBE CABLE

IN THE TRANSITION

COMPARTMENT ..................................11,12

11. ROUTING AND STORING FIBER

IN THE STORAGE

COMPARTMENT .......................................12

CONTENTS PAGE

12. INSTALLING FIBERS INTO

TRANSPORT TUBES AND SECURING

TO STORAGE COMPARTMENT ........12,13

13. SECURING TRANSPORT TUBES

AND ROUTING FIBERS IN

SPLICE TRAYS ................................... 14-17

14. ROUTING LOOSE BUFFER TUBE

CABLE .................................................17,18

15. INSTALLING COYOTE CLOSURE

SHELLS ................................................... 19

16. EXTERNAL BOND PROCEDURE ............20

17. STRAND MOUNT PROCEDURE .............21

18. MANHOLE SUPPORT BRACKET

KIT INSTALLATION .............................21,22

19. BURIED INSTALLATION ..........................22

20. MAINTENANCE PROCEDURES ..............22

21. SAFETY CONSIDERATIONS ...................22

2

©2004 Preformed Line Products Company. All rights reserved.

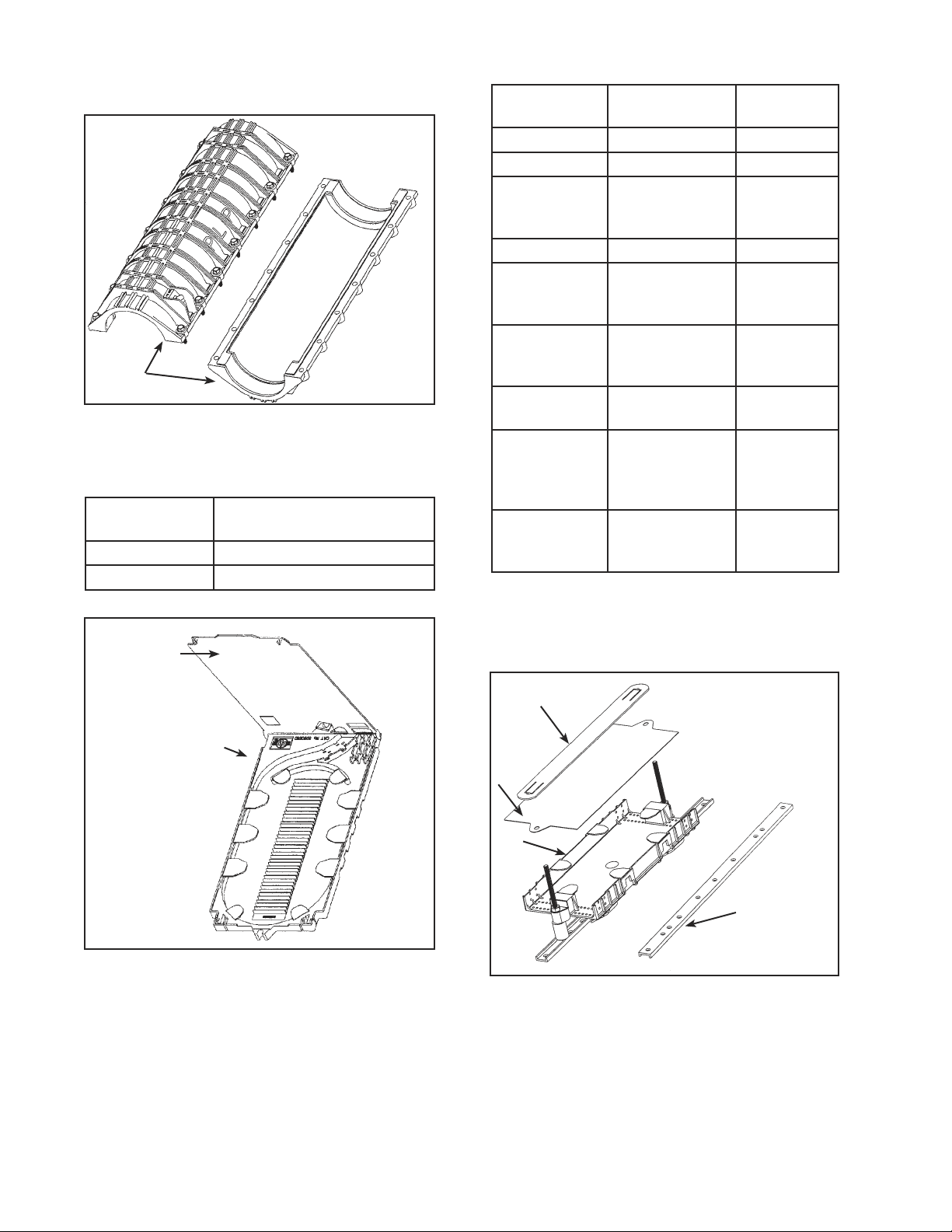

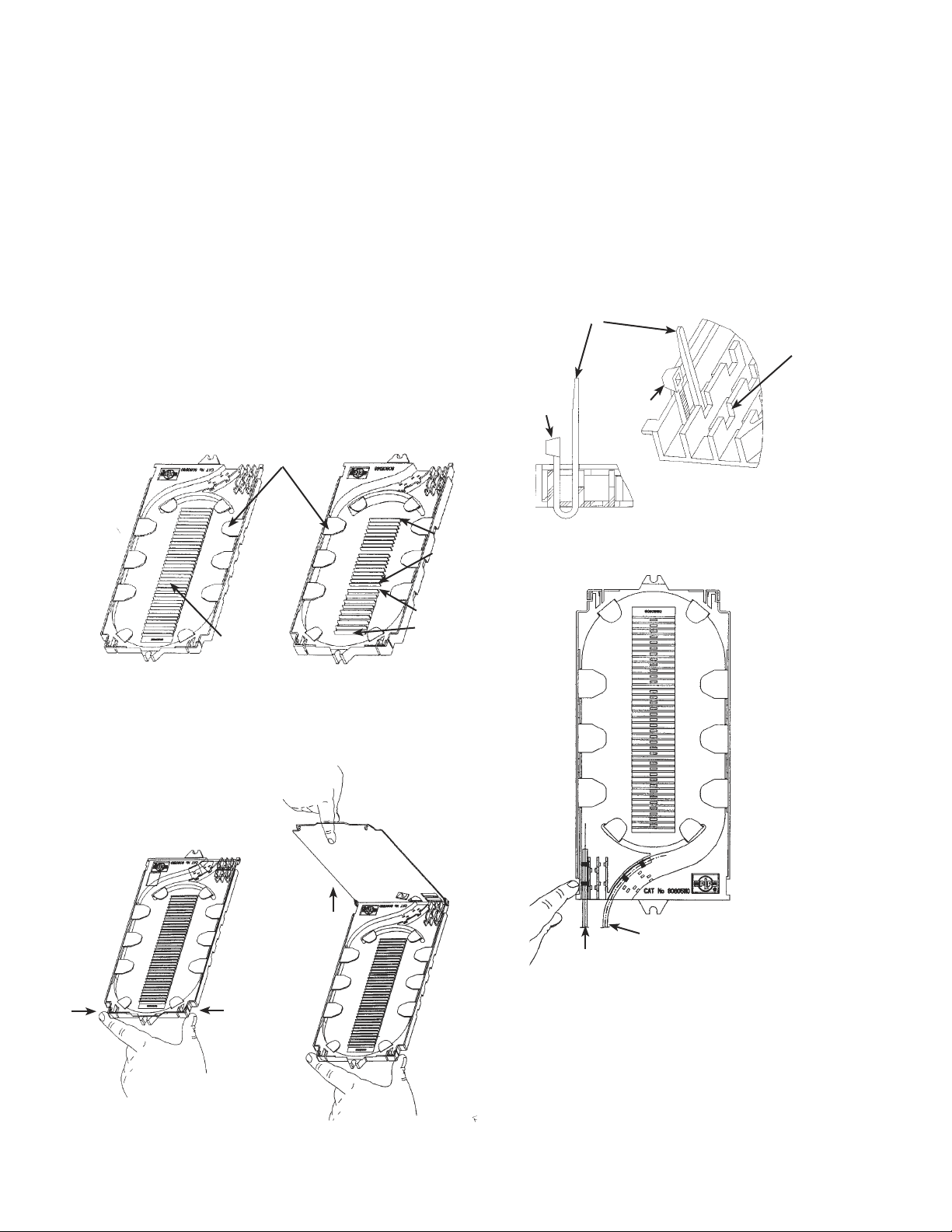

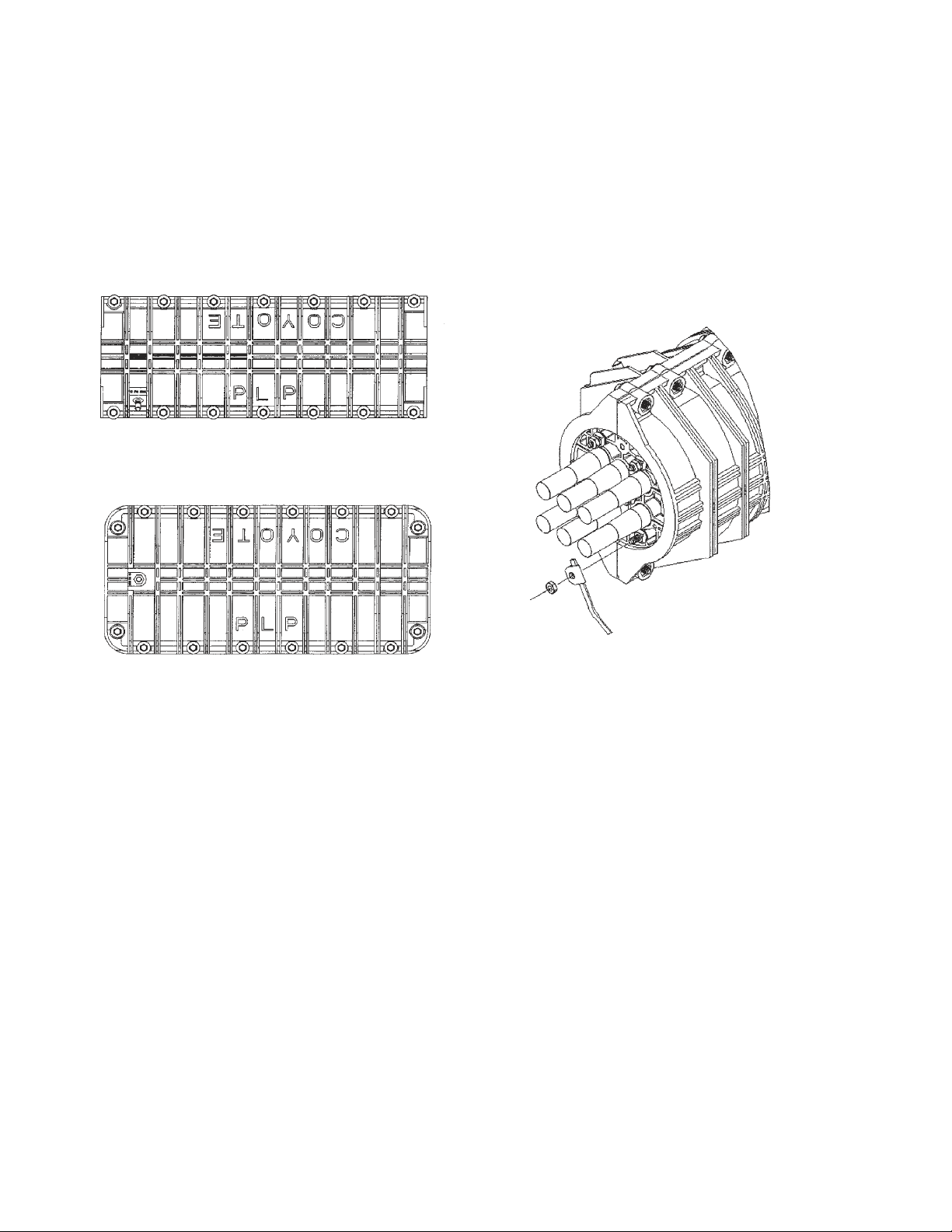

FIGURE 1 - SHELL KIT

1. Two COYOTE® Closure shell halves,

neoprene gasket is applied at factory.

1.00 NOMENCLATURE

1.

FIGURE 3 - UNITUBE TRANSITION

COMPARTMENT KIT

1.

2.

FIGURE 2 - SPLICE TRAY KIT

1. Cover

2. Tray

3. Splice Count Label (not shown)

4. Tie Wraps (not shown)

5. Felt Strips (not shown)

*Based on mass fusion splices; 96 for mass

mechanical.

PLP CATALOG

NUMBER

COYOTE CLOSURE

DIMENSIONS (CM)

80805258 6.0" x 22" (15.24 X 55.88)

80805259 8.5" x 22" (21.59 X 55.8)

1.

2.

3.

4.

PLP Catalog

Number

Splice

Tray

Splice

Capacity

80805110 Single Fiber Tray 36

80805509 Blank Tray 36

80805514 Blank Tray with

Three Elastomer

Splice Blocks

36

8001127 Low Profile Tray 12 per block

8001130 Low Profile

COYOTE Blank

Splice Tray

blank

80805146 Ribbon Fiber

Mechanical/

Fusion Tray

144*

80805510 Blank Ribbon

Tray

144*

80805515 Blank Ribbon

Tray with Two

Elastomer

Splice Blocks

144*

8003381 Elastomer

Splice Block Kit

- 3 per kit

12 per block

1. Splice Tray Hold 3. Transition Compartment

Down Strap 4. Torque Bar

2. Cover

3

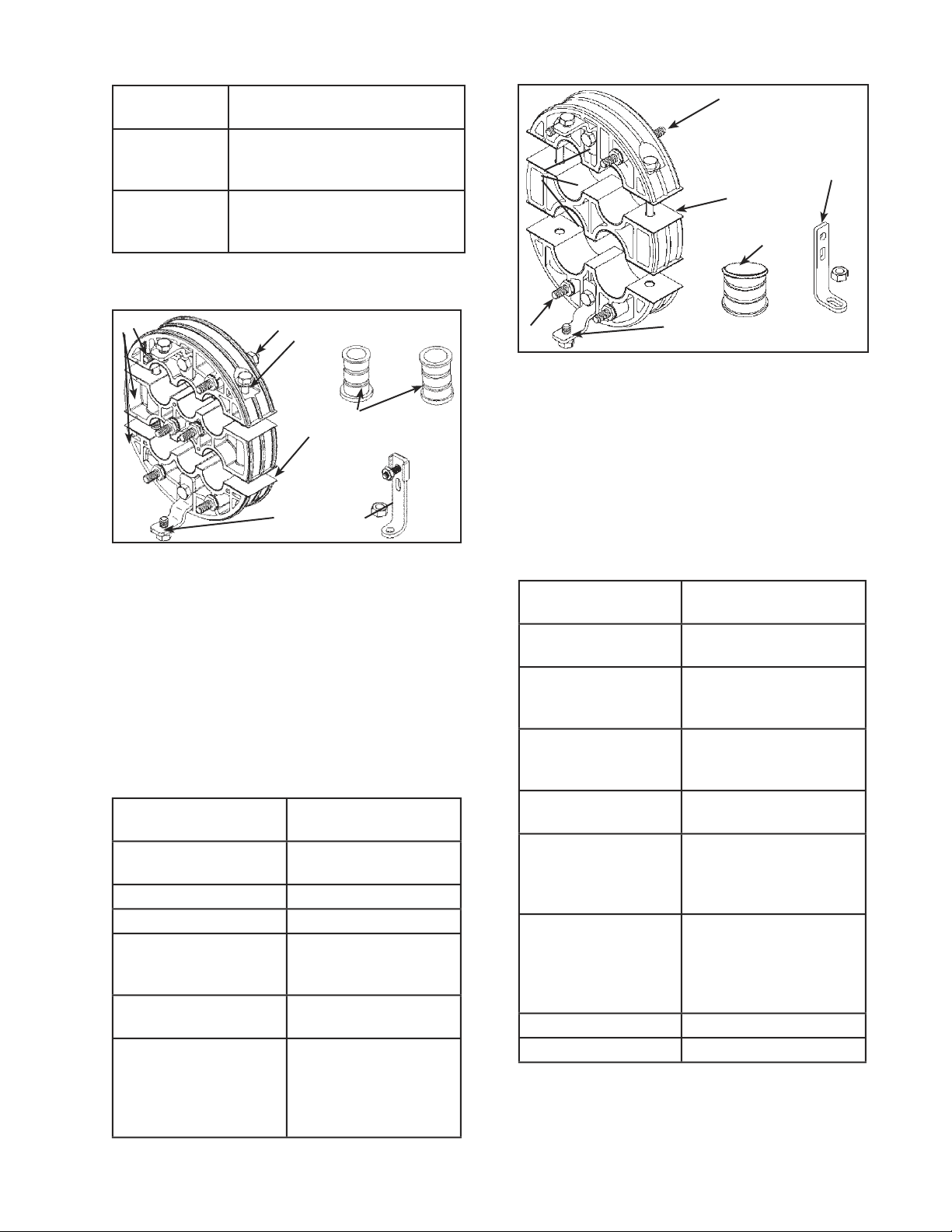

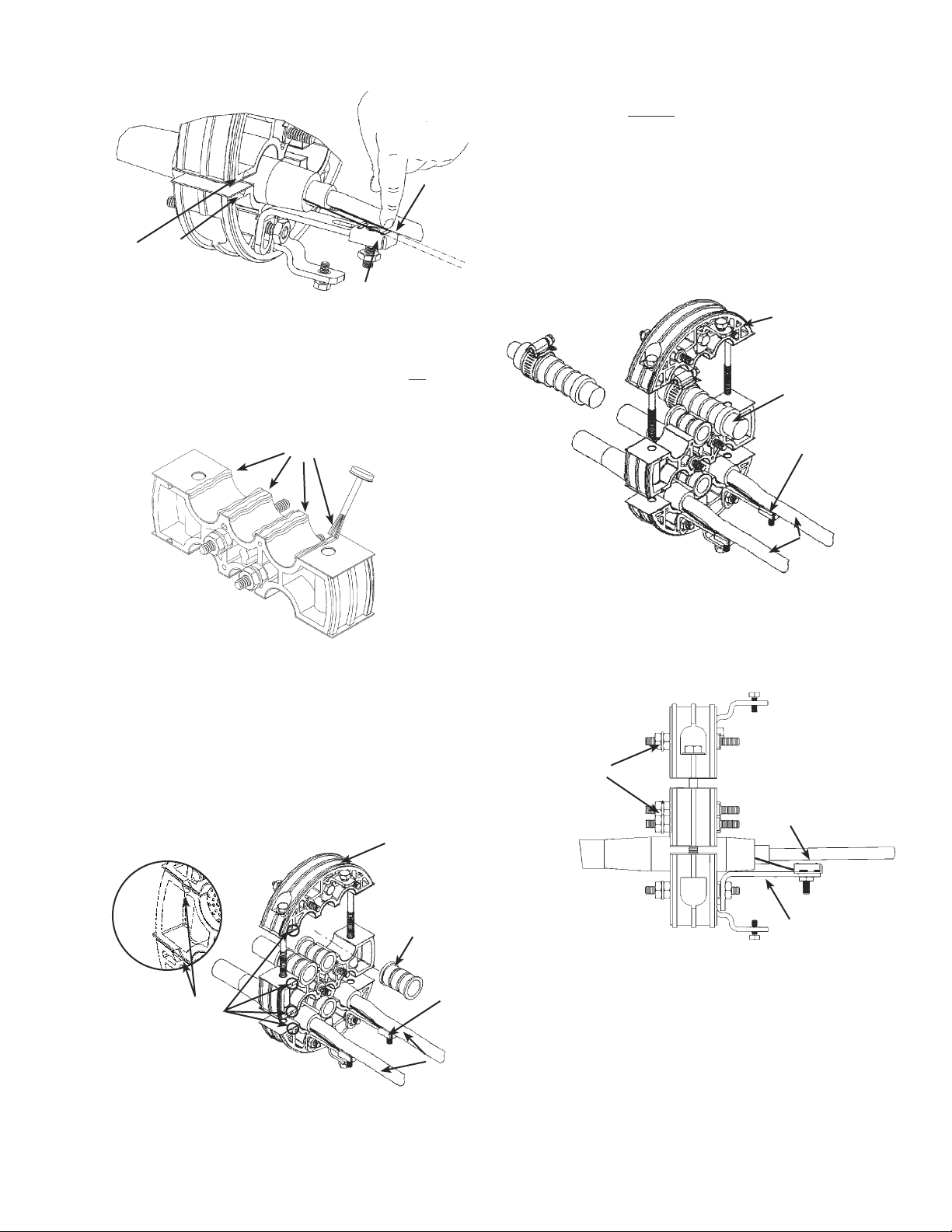

1. End Plate Sections

2. Torque Bar Brackets (2)

3. Plugs (5)

4. "L" Brackets (2)

5. LOCK-TAPE™ Sealant (factory-applied)

6. Internal Ground Inserts (6; factory-installed)

7. COYOTE Cable Mea-SURE™ Tape

(not shown)

PLP Catalog

Number

Description

80805112 6.0" x 22" (15.24 CM x 55.88

CM) Unitube Transition

Compartment Kit

80805113 8.5" x 22" (21.59.24 cm x 55.88

cm) Unitube Transition Compart-

ment Kit

FIGURE 4A - THREE-SECTION

SIX PORT END PLATE KIT

FIGURE 4B - THREE-SECTION

FOUR PORT END PLATE KIT

3.

1. End Plate Sections

2. Torque Bar Brackets (2)

3. Plugs (5)

4. "L" Brackets (2)

5. LOCK-TAPE™ Sealant (factory-applied)

6. Internal Ground Inserts (4; factory-installed)

7. COYOTE Cable Mea-SURE™ Tape (not

4.

1.

2.

2.

5.

6.

1. 2.

2.

3.

5.

6.

4.

PLP Catalog

Number

Description

80805105 Three-Section Six Port

End Plate Kit

80806037 3/4" plugs (2)

80806180 7/8" plugs (2)

8003371 Future Cable Port Kit

for 7/8” port (.56 max

cable diameter)

8003291 Future Cable

Installation Kit

8003289 Future Cable Port/

Installation Kit

(includes cat. no.

8003371 and cat. no.

8003291 for 7/8" port)

PLP Catalog

Number

Description

80805739 Three-Section Four Port

End Plate Kit

8003407 Future Cable Port Kit for

1" port (.81 max. cable

diameter)

8003409 Future Cable Port Kit

for 1-1/4" port (1" max.

cable diameter)

8003291 Future Cable Installation

Kit, only

8003408 Future Cable Port/

Installation Kit (includes

cat. no. 8003407 and cat.

no. 8003291 for 1" port)

8003410 Future Cable Port/

Installation Kit (includes

cat. no. 8003409 and

cat. no. 8003291 for

1-1/4" port)

80806038 1" plug (2)

80806181 1-1/4" plugs (2)

4

ACCESSORY KITS

1. End Plate

2. Torque Bar Brackets (2)

FIGURE 5 - BLANK END PLATE KIT

2.

1.

2.

1.

2.

3.

1. Torque Bar 3. Splice Tray Hold

2. Retainer Brackets Down Strap

FIGURE 6 - LOOSE BUFFER TUBE

STORAGE KIT

PLP Catalog Number Description

80805260 Blank End Plate Kit

PLP Catalog

Number

Description (cm)

80805262 6.0" x 22" (15.24 x 55.88) Loose

Buffer Tube Storage Kit

80805263 8.5"x 22" (21.59 x 55.88) Loose

Buffer Tube Storage Kit

80805419 6.0" x 22" (15.24 x 55.88)

COYOTE Express Organizer (for

loose buffer tube applications)

80805420 8.5" x 22" (21.59 x 55.88)

COYOTE Express Organizer (for

loose buffer tube applications)

PLP Catalog

Number

Description [cm]

8003285 Color-Coded Transport

Tube Kit (6 per kit)

80805293 Transport Tube Kit

(6 per kit)

80805107 Strength Member Bracket

Kit (2 per kit)

80805431 Long Strength Member

Bracket Kit (2 per kit)

8003280 Transition Tube Kit

8003281 External Bond Clip Kit

(2 per kit)

80805286 Bracket Adaptor Kit for

AT&T Bond Connector

(4 per kit)

8003325 Adjustable Aerial Hanger

Bracket Kit

80803448 Moisture Blocking Sealant

Kit (3 oz. tube)

80805238 C-Cement (1 oz tube)

8003279 Manhole Support

Bracket Kit

8003372 Vertical Mount Bracket Kit

(for 6.0" or 8.5" [15.24 x

21.59] COYOTE Closures)

8003322 Internal Ground Kit

(0.27" - 0.31" [.69 x .79]

ground wire)

8003360 Exterior Bond Braid kit

8003386 Heat Shield Kit for

6.0" x 22" [15.24 x 55.88]

COYOTE Closure

8003387 Heat Shield Kit for

8.5" x 22" [21.59 x 55.88]

COYOTE Closure

8003385 Flame-Retardant Blanket

for 6.0" x 22" [15.24 x

15.88] COYOTE Closure

8003388 Flame-Retardant Blanket

for 8.5" x 22" [21.59 x

55.88] COYOTE Closure

5

1.01 The COYOTE Closure contains every-

thing needed for installation except hand

tools, vinyl tape, filled cable cleaning fluid, and

C-Cement.

1.02 Tools Needed:

• 1/2" socket*

• 7/16" socket*

• 3/8" socket/Can wrench

• Snips

• Ratchet Wrench*

• Torque Wrench (capable of reading

50 inch lbs.)*

• Fiber optic cable opening tools

*Available from Preformed Line Products

2.00 DESCRIPTION AND CLOSURE

CAPACITIES

2.01 For Safety Considerations, refer to Section

21.00 of this procedure.

2.02 The COYOTE Closure series organizes,

distributes and protects all types of fiber

optic cable with a water and air tight seal.

2.03 The COYOTE Closure series accommo-

dates the following splice trays and splice

connectors (Table 1):

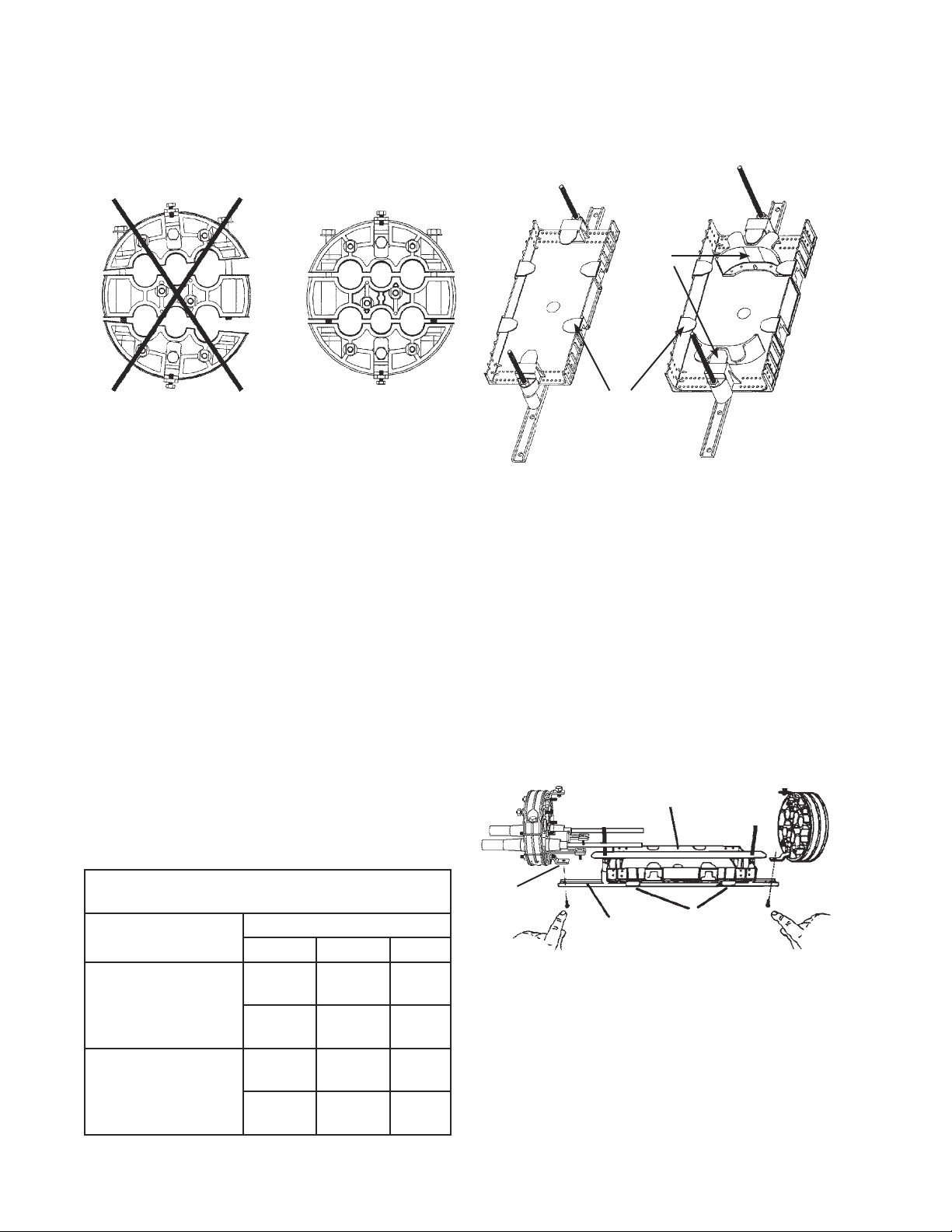

TABLE 1

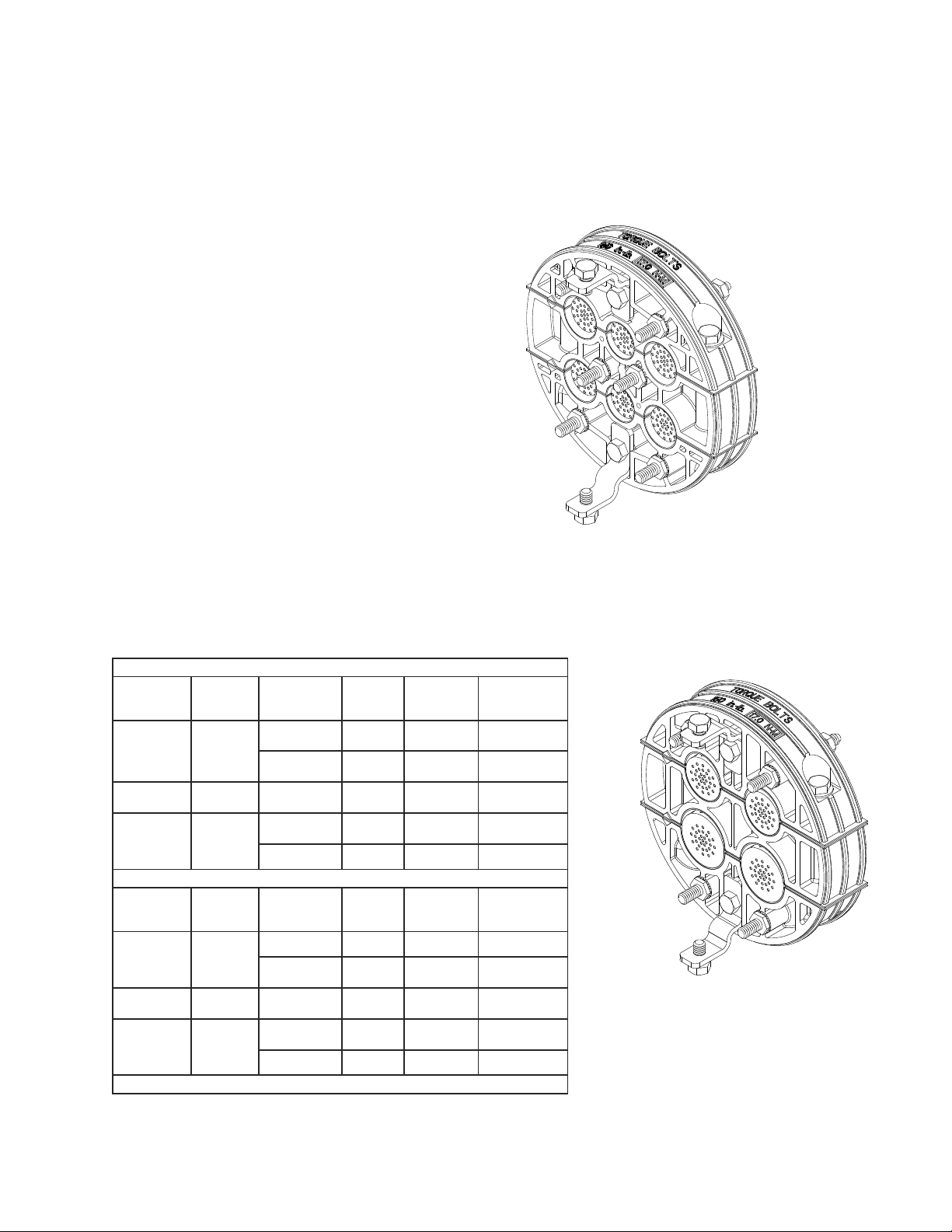

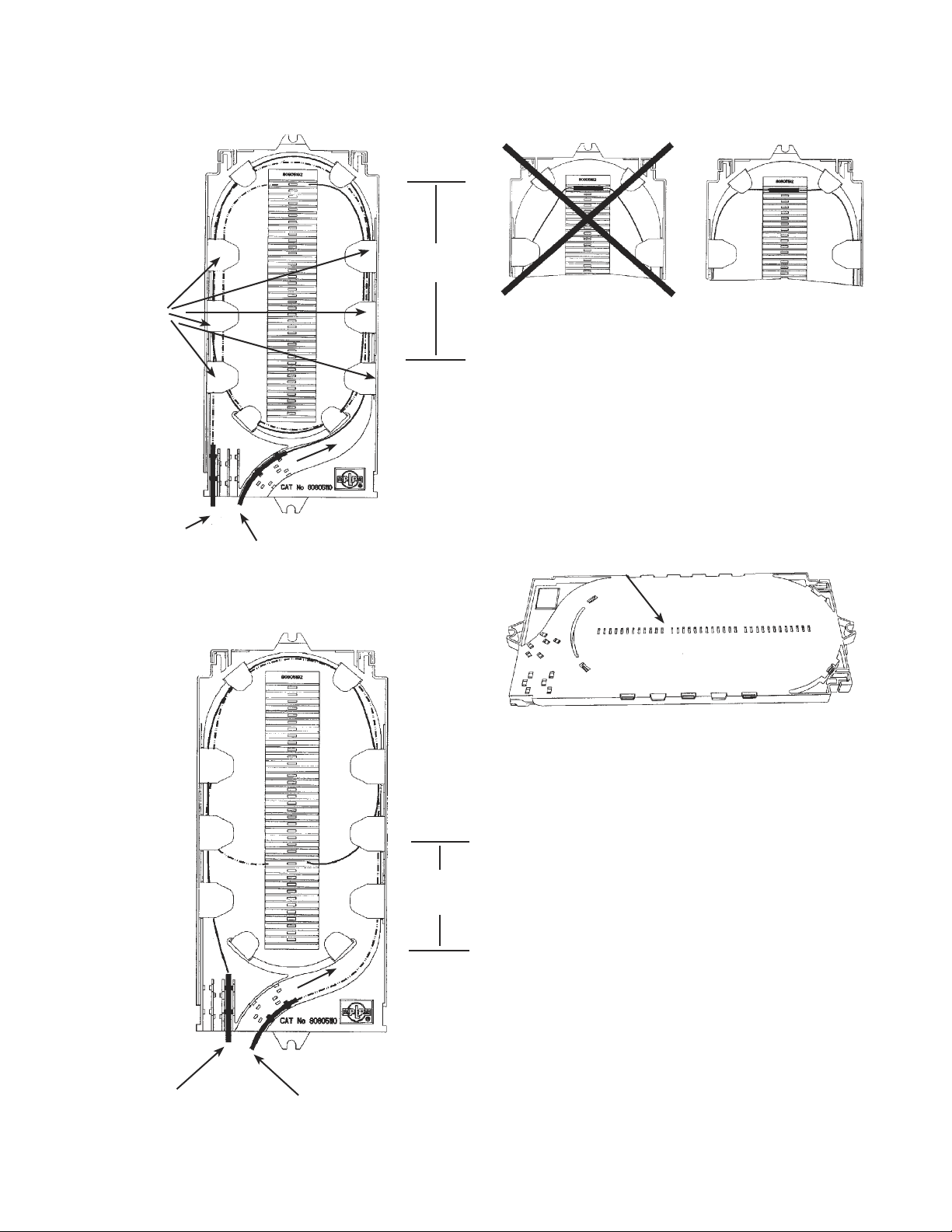

3.00 END PLATE CONFIGURATIONS

3.01 Two versions of the Three-Section End

Plate are available for the COYOTE Clo-

sure; one which accepts up to six cables, and one

which accepts up to four larger cables. (Figures 7A

and 7B)

A = 7/8" (2.22 cm)

diameter

B = 3/4" (1.90 cm)

diameter

FIGURE 7A - DIAGRAM OF SIX PORT

END PLATE

A = 1" (2.54 cm)

diameter

B = 1-1/4" (3.18 cm)

diameter

FIGURE 7B - DIAGRAM OF

FOUR PORT END PLATE

A

A

B

B

A

A

B

6.0" X 22" (15.24 cm x 55.88 cm) COYOTE Closure

Splice Tray

Catalog

Number

Description Usable

Connectors

Splice

Capacity

Per Tray

Maximum No.

of Trays Per

Closure

Maximum

Closure Splice

Capacity

80805110 or

80805514

36 Count

Single Fiber

Tray

Single Fusion 36 4 144

Single

Mechanical

36 4 144

8001127 Low Profile

Tray

Single Fusion 36 6 216

80805146 96 Count

Mass

Ribbon

Fiber Tray

Mass

Mechanical*

96 2 192*

Mass Fusion* 144 2 288*

8.5" X 22"(21.59 cm x 55.88 cm) COYOTE Closure

Splice Tray

Catalog

Number

Description Usable

Connectors

Splice

Capacity

Per Tray

Maximum No.

of Trays Per

Closure

Maximum

Closure Splice

Capacity

80805110 or

80805514

36 Count

Single Fiber

Tray

Single Fusion 36 8 288

Single

Mechanical

36 8 288

8001127 Low Profile

Tray

Single Fusion 36 11 396

80805146 96 Count

Mass

Ribbon

Fiber Tray

Mass

Mechanical*

96 4 384*

Mass Fusion* 144 4 576*

* Assumes 12 fiber ribbon is utilized. Also holds 16 single count splices.

A

A

B

6

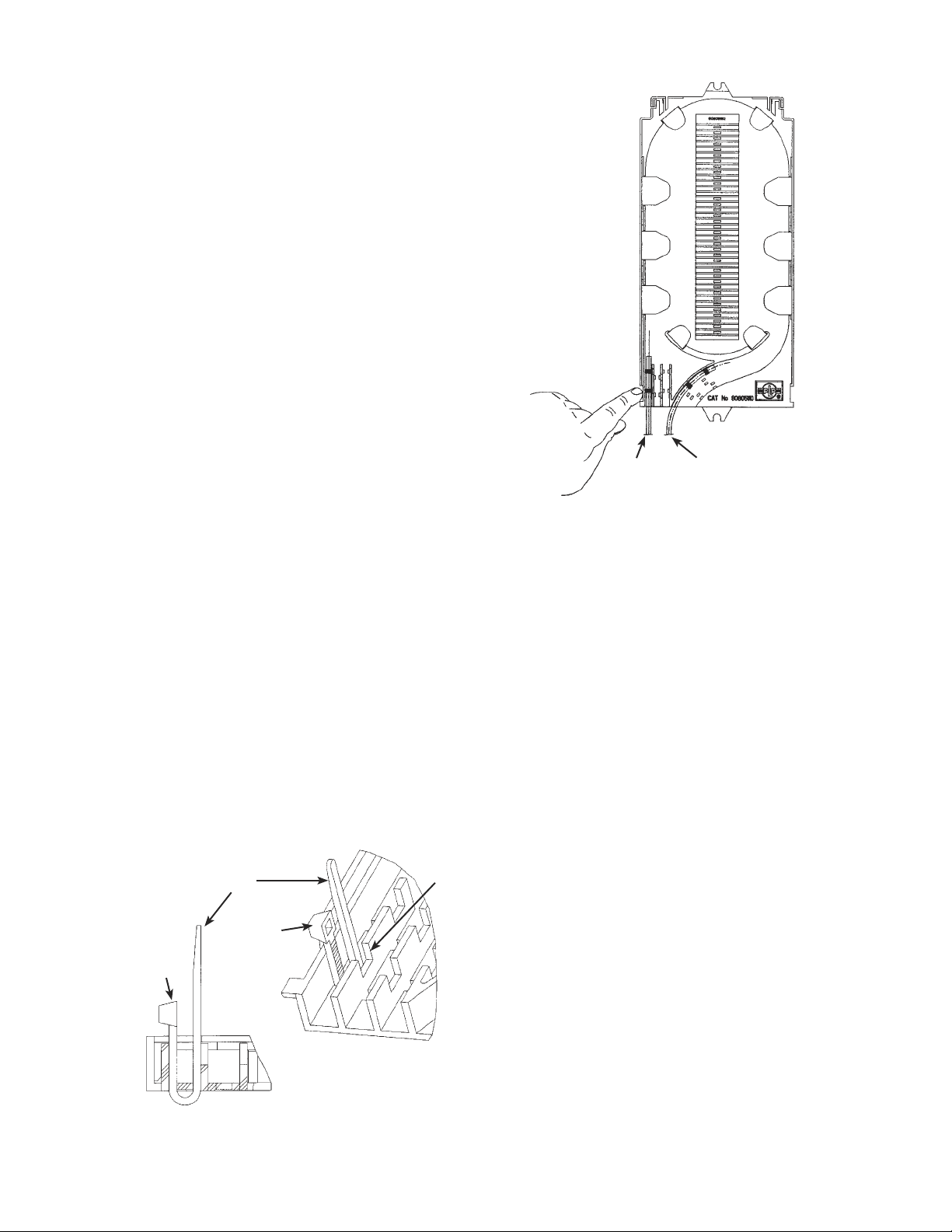

3.02 See Figure 8 for hardware that can be used

with the Three-Section End Plate.

4.00 CABLE PREPARATION–LOCK-

TAPE SEALANT APPLICATION

NOTE: For OPGW application, see procedure en-

titled, “OPGW Cable and End Plate Preparation

for COYOTE® Closure” (SP2849).

4.01 Cable sheath opening measurements, for

both size closures, whether using unitube or

buffer tube, are 152" (386.10 cm) for continuous

loop/express applications, and 76" (193.04 cm)

for cut cable.

NOTE: The COYOTE Closure is designed for main

cables to enter the bottom outside cable ports

and for branch cables to enter the bottom middle

and upper cable ports in the End Plate.

PLP TIP: Where irregular cable ends exist, measure

from the shortest cable to establish End Plate

location.

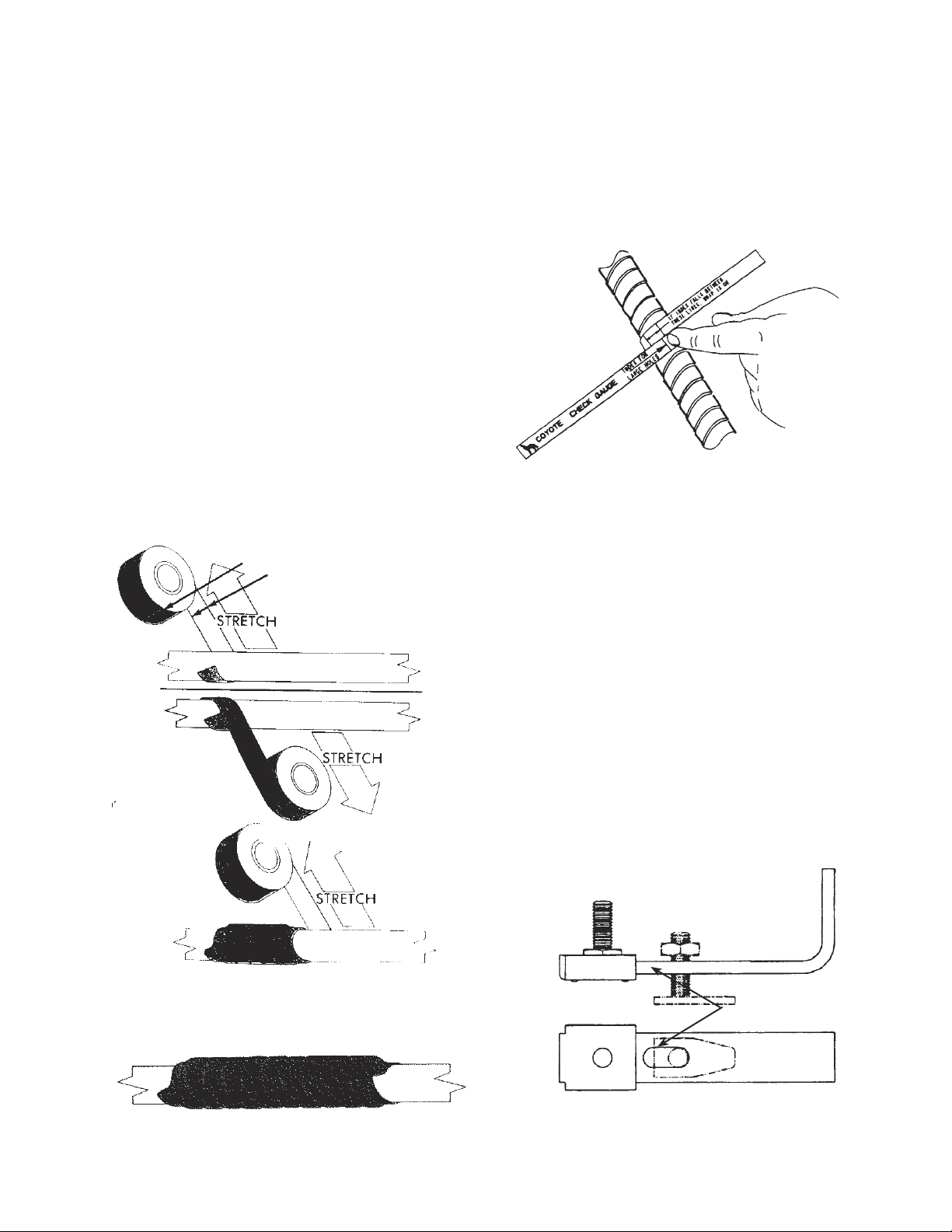

4.02 The color-coded COYOTE Cable Measure

Tapes are used to determine the number of

half-lapped layers of LOCK-TAPE Sealant required

to seal the cable in the End Plate. The back of the

Measure Tape is used to check whether the LOCK-

TAPE Sealant wrap is the proper diameter to ensure

a water and air tight seal. (Figure 9)

For the Six Port End Plate, the orange-colored end is

used to measure cables entering the 7/8" (2.22 cm)

FIGURE 8 - END PLATE HARDWARE

diameter ports while the blue-colored end measures

cables entering the 3/4" (1.90 cm) diameter ports.

For the Four Port End Plate, the COYOTE Cable

Measure Tape has a green-colored end for the 1"

diameter port and a red-colored end for the 1-1/4"

diameter port.

FIGURE 9 - COYOTE CABLE MEASURE TAPE

(TAPE FOR SIX PORT END PLATE SHOWN)

4.03 TO USE COYOTE CABLE MEASURE

TAPE:

• Wrap the correct end of COYOTE Cable

Measure Tape around cable where it will

enter the End Plate.

• If the index line falls directly between two

numbers use the higher number.

• The number on the COYOTE Cable Mea-

sure Tape indicates the number of half-

lapped layers of LOCK-TAPE Sealant to be

applied around the cable. (Figure 10)

FIGURE 10 - MEASURING CABLE --

BE SURE TO USE CORRECT END OF CABLE

MEASURE TAPE

"L" BRACKET

BOLT

HEAD-

TOP

BOLT-

BOTTOM

INTERNAL

GROUND

INSERTS

FOR EACH

PORT

STRENGTH

MEMBER

CAP

TORQUE BAR

BRACKET

BLUE

BLUE

ORANGE

ORANGE

7

FIGURE 13 - CHECK GAUGE

4.08 To protect LOCK-TAPE Sealant from cable

grease, cover the LOCK-TAPE Sealant with

vinyl tape.

NOTE: If strength members are to be secured, leave

4-5" (10.16-12.70 cm) of metallic or non-metal-

lic strength members exposed from the sheath

opening.

4.09 Open and clean cable according to accepted

company practices.

5.00 INTERNAL BOND PROCEDURE

5.01 Bond cable according to accepted company

practices. Use the slot on the "L" bracket to

attach most bond connectors, as outlined in Section

8.00. (Figure 14)

FIGURE 14A - SLOT IN "L" BRACKET

4.07 To check LOCK-TAPE Sealant application,

wrap the proper end of the COYOTE Cable

Measure Tape check gauge around the applied

LOCK-TAPE Sealant. If the measurement line falls

outside of the index lines of the check gauge, LOCK-

TAPE Sealant must be reapplied. It is acceptable to

reapply the original LOCK-TAPE Sealant. (Figure 13)

SLOT

4.04 Using the provided Emery Cloth, thoroughly

scuff the cable sheath for 5" (12.70 cm) from

measured opening. Always scuff around the cable,

never lengthwise.

4.05 Coat the scuffed area with C-Cement and

allow to dry. It is important that the C-Cement

dries to a tacky base before LOCK-TAPE Sealant is

applied.

PLP TIP: Use removed LOCK-TAPE Sealant backing

from Step 4.06 to dry and remove excess C-Ce-

ment applied to cable.

4.06 Remove backing from LOCK-TAPE Sealant

and wrap LOCK-TAPE Sealant onto the

cable with the black side up. Stretch the 1" (2.54 cm)

LOCK-TAPE Sealant to a width of 7/8" (2.22 cm).

(Figure 11) Apply the required numbers of half-

lapped layers of LOCK-TAPE Sealant, as indicated

on the Cable Measure Tape, to the area coated with

C-Cement. (Figure 12)

FIGURE 11 - STRETCH LOCK-TAPE

FIGURE 12 - APPLIED LOCK-TAPE

1" (2.54 cm)

7/8" (2.22 cm)

8

FIGURE 15A - ATTACH "L" BRACKET–

FRONTAL VIEW

FIGURE 15B - ATTACH "L" BRACKET–SIDE VIEW

7.02 Remove the protective vinyl tape applied to

LOCK-TAPE Sealant in Paragraph 4.08.

7.03 Place the cable into the End Plate as close to

the assembly location as possible. Mark it

1/4-1/2" (.64-1.27 cm) from the outside surface of the

End Plate. Apply vinyl tape over the remaining LOCK-

TAPE Sealant. Do not apply vinyl tape in the seal

area.

7.04 Use the strength member cap on the "L"

bracket as a guide for trimming the strength

member. (Figure 16)

PLP TIP: A long "L" bracket is available (Catalog

#80805431) for bonded loose buffer tube cable

with a dielectric central strength member.

FIGURE 14B - LONG "L" BRACKET

6.00 END PLATE PREPARATION

6.01 Disassemble the End Plate by removing the

two long bolts holding the three End Plate

sections together. Remove the packaging plugs.

6.02 Refer to Table 2 for the measurement of

sheath to extend beyond the inside of the

End Plate for the type of cable and bond connector

being used. For all non-metallic cables the sheath will

extend 3/4" (1.90 cm) inside the End Plate.

Cable Positions In COYOTE Closure End Plate

Cable Type If using

Bond

Connectors

Length of Sheath

Inside End Plate (cm)

Dielectric 3/4" (1.90)

Metallic RAYCHEM* 1-1/4" (3.18)

AT&T* Total 1-3/8" (3.47) =

5/8" (1.57) shield +

3/4" (1.90) sheath

*See Accessory Kits for additional bond hardware

TABLE 2

7.00 END PLATE ASSEMBLY

7.01 Loosely attach "L" brackets to the ground

insert on the inside of the End Plate adjacent

to the cable ports being used with the nut provided.

(Figure 15 A & B)

INTERNAL

GROUND

INSERT

BOLT

HEAD-

TOP

EXTERNAL

GROUND

INSERT--

DOUBLE-NUTTED

"L" BRACKET

BOLT-

BOTTOM

STRENGTH

MEMBER

CAP

"L" BRACKET

BOLT

HEAD-

TOP

BOLT-

BOTTOM

INTERNAL

GROUND

INSERTS

FOR EACH

PORT

STRENGTH

MEMBER

CAP

MAIN

CABLE

PORT

ENTRY

9

FIGURE 16 - CAP AS TRIMMING GAUGE

7.05 Remove cable from the End Plate port(s) and

apply C-Cement along the edge of all End

Plate ports. Make sure C-Cement is dry before con-

tinuing. The End Plate center section is illustrated in

Figure 17.

FIGURE 17 - APPLY C-CEMENT

7.06 Lay prepared cable and correct end of

appropriate plugs into ports and loosely

tighten all three sections of End Plate. Use care that

no grease from the cable contacts the LOCK-TAPE

Sealant on the End Plate ports. (Figure 18)

PLP TIP: Use orientation marks on End Plate as

alignment guide. (See Figures 18 & 19)

7.07 Future cable entry ports and End Plate

grommets cannot be added once End Plate

assembly is complete. Therefore, when using future

cable entry ports, insert ports at this time. Future

cable entry ports will fit in only the 7/8" ports of the

Six Port End Plate, and different future cable entry

ports are available for both the 1" ports and the 1-1/4"

ports in the Four Port End Plate (see page 3 for de-

tails). Also see the Application Procedure accompa-

nying the Future Cable Entry Port Kits and End Plate

Grommet Kits. (Figure 19)

FIGURE 19 - INSTALLED FUTURE CABLE

ENTRY PORTS (SIX PORT END PLATE)

7.08 Slide strength members under cap and

tighten. Tighten "L" bracket. (Figure 20)

FIGURE 20 - INSTALLING STRENGTH MEMBER

A = 7/8" (2.22 CM) B = 3/4" (1.90 CM)

A

A

B

C-Cement

FIGURE 18 - INSTALLED CABLE AND PLUGS

(SIX PORT END PLATE)

INSIDE SURFACE

OF END PLATE

DOUBLE

NUTTED

CAP

"L" BRACKET

OUTSIDE SURFACE

OF END PLATE

PREPARED

CABLE

CAP

INSIDE

SURFACE

OF END PLATE

FUTURE

CABLE ENTRY

PORT

INSIDE SURFACE

OF END PLATE

PLUG

PREPARED

CABLE

CAP

ORIENTATON

MARKS

CUT

STRENGTH

MEMBER

HERE

CAP

ORIENTATION

MARKS

10

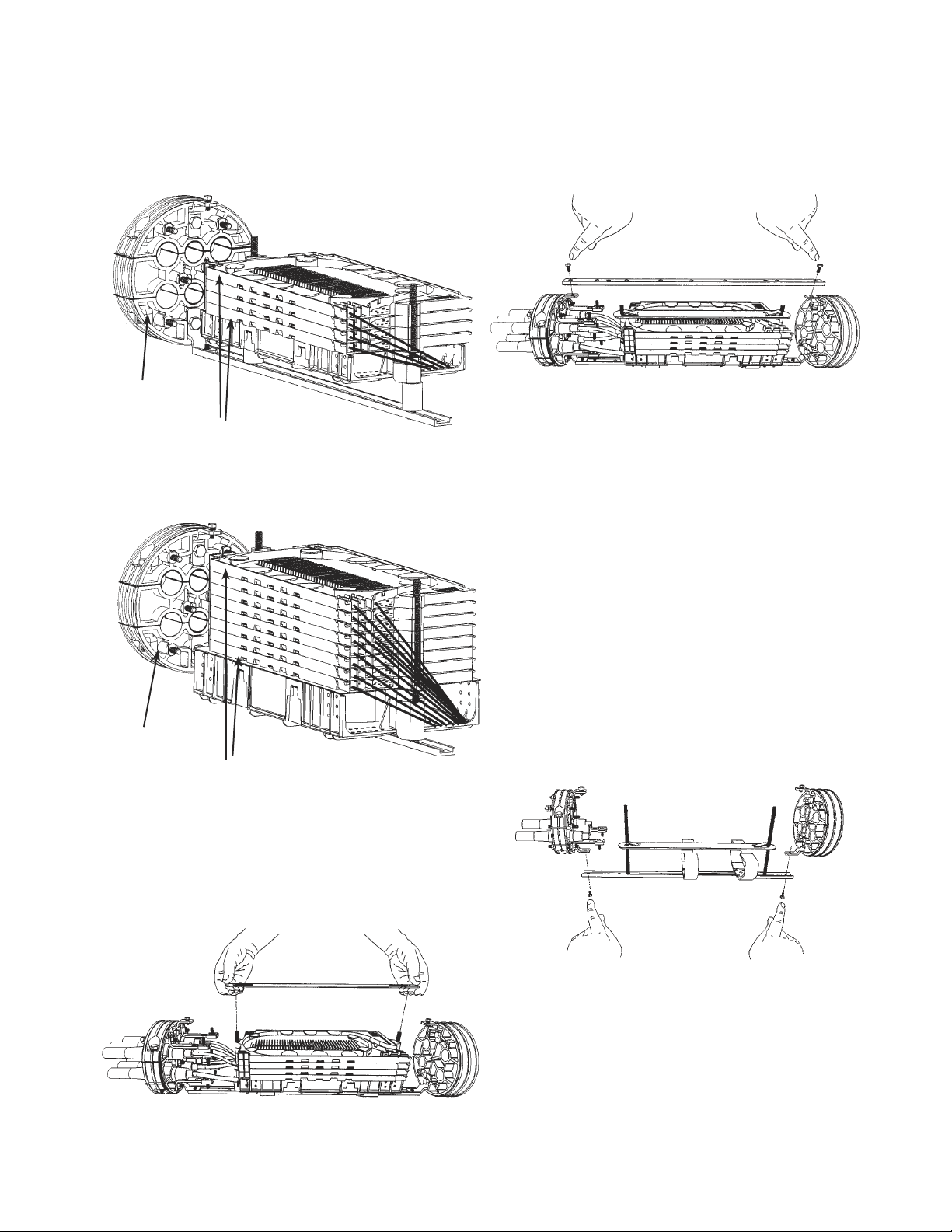

9.00 INSTALLING TRANSITION COM-

PARTMENT FOR UNITUBE CABLE

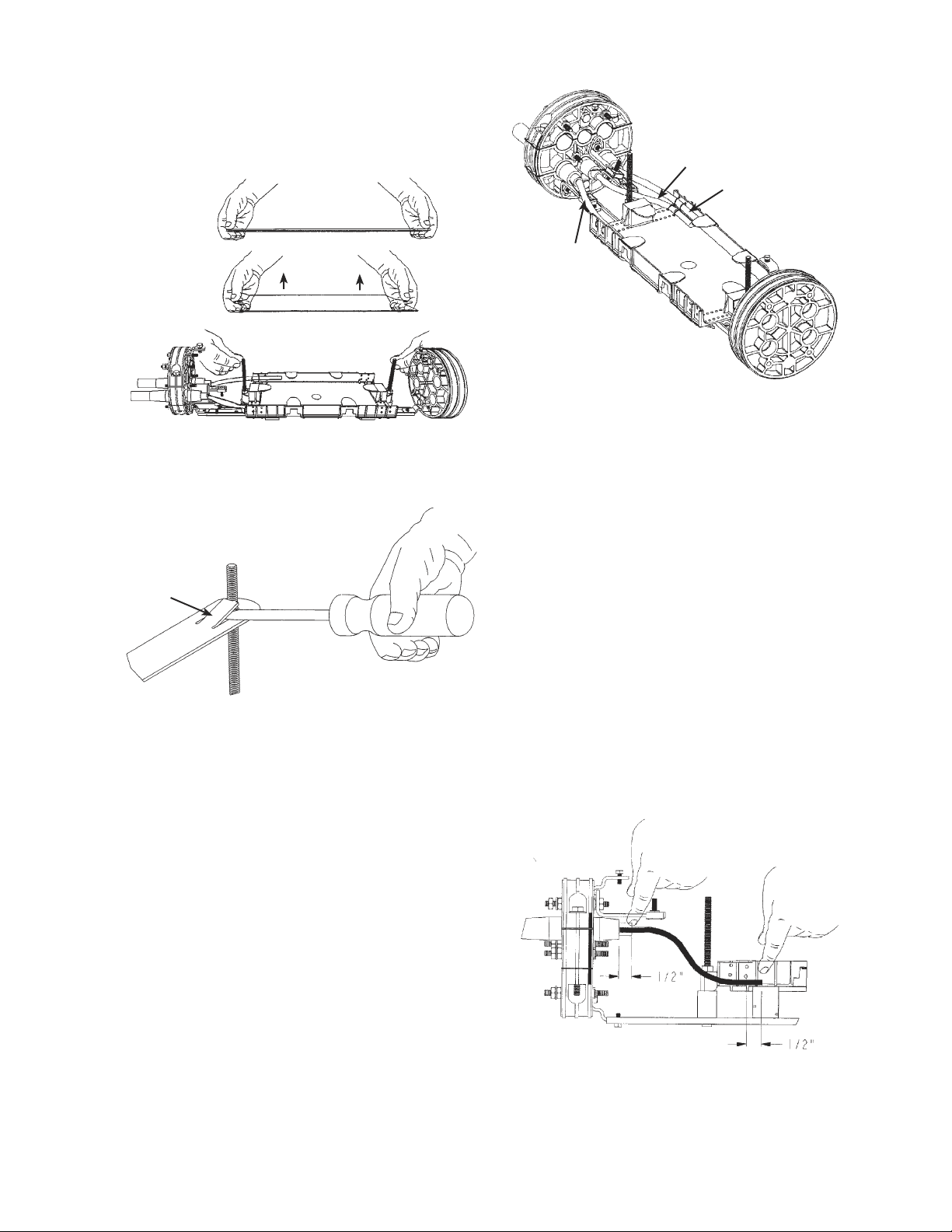

9.01 See Figure 22 for the features of the transi-

tion compartments.

6.0" x 22" 8.5" x 22"

(15.24 cm x 55.88 cm) (15.24 cm x 55.88 cm)

TRANSITION COMPARTMENT TRANSITION COMPARTMENT

--SINGLE FIBER --SINGLE OR RIBBON FIBER

FIGURE 22 - TRANSITION COMPARTMENTS

9.02 The transition compartment assembly

attaches to the torque bar bracket on the bot-

tom of the end plates with the bolts provided. (Figure

23) Make sure the side of the torque bar labelled "3

Section End" is nearest the Three-section End Plate.

The torque bars are labelled for in-line as well as butt

installation.

FIGURE 23 - INSTALL TRANSITION

COMPARTMENT

9.03 Remove splice tray hold down strap and

transition compartment cover. (Figure 24A)

7.09 When all cables and/or plugs have been

installed, tighten End Plate bolts by rotating

2 or 3 turns on each bolt so the End Plates come

together evenly. Tighten bolts with torque wrench to

150 inch pounds. (Figure 21)

FIGURE 21 - CORRECT END PLATE ALIGNMENT

7.10 Apply vinyl tape to the remaining 1/4–1/2"

(.64-1.27 cm) (Paragraph 7.03) of exposed

LOCK-TAPE Sealant on the cable outside the End

Plate.

8.00 UNITUBE PREPARATION

8.01 For unitube cable refer to Table 3 to

determine the correct length of core tube

necessary to enter the transition compartment when

using the lower cable ports in the End Plate. Cables

entering the upper ports will be transitioned into the

compartment using a transition tube. Refer to Para-

graph 10.02 for core tube lengths. See Section 14.00

for routing loose buffer tube cable into the storage

compartment. When routing both unitube and buf-

fer tube in the same closure, follow instructions for

unitube application.

Unitube Lengths (cm) From Sheath

to Transition Compartment

COYOTE Closure

Dimensions

Splice Configurations

In-Line Butt

6.0" x 22"

(15.24 x 55.88)

Top 3/4"

(1.91)

3/4"

(1.91)

Bottom 5-3/4"

(13.97)

6"

(15.24)

8.5" x 22"

(21.59 x 55.88)

Top 3/4"

(1.91)

3/4"

(1.91)

Bottom 6"

(15.24)

6-3/4"

(16.51)

TABLE 3

INCORRECT CORRECT

TORQUE BAR

BRACKET

TORQUE BAR

TRANSITION

COMPARTMENT

ASSEMBLY

CLIPS FOR

ROUTING

LOOSE BUFFER

TUBES

REMOVE

TABS WHEN

STORING

FIBERS

REMOVABLE

RETAINING

TABS

11

FIGURE 25 - SECURING CABLE TUBE

10.02 Unitube cables entering through the top

ports of the End Plate will require a transition

kit (Catalog # 8003280). The kit includes two lengths

of tube approximately 24" (60.96 cm) long which can

be field cut 7"-8". The smaller transition tube (.240"

[.610 cm] diam.) is for unitube cables ranging from 4-

48 fiber count. The larger transition tube (.311" [.790

cm] diam.) is for unitube cables ranging from 50-96

fiber count.

10.03 Leave approximately 3/4" (1.90 cm) of cable

tube for all cables entering the top ports of

the End Plate. Determine which diameter transition

tube is to be used. To measure the correct amount of

transition tube necessary, hold it 1/2-3/4" (1.27-1.90

cm) past the unitube, make an "S" bend into the tran-

sition compartment 1/2" (1.27 cm) past the tie down

ports in the bottom of the tray. Cut the transition tube

at this mark and apply. (Figure 26)

FIGURE 26 - MEASURING TRANSITION TUBE

PLP TIP: Install fibers in transition tube, then apply

moisture blocking compound.

PLP TIP: If the hold down strap is snug against the

studs, lift the tab using a screwdriver as demon-

strated in Figure 24B.

FIGURE 24A - REMOVE SPLICE TRAY HOLD

DOWN STRAP AND COVER

FIGURE 24B - HOLD DOWN STRAP REMOVAL

10.00 SECURING UNITUBE IN THE

TRANSITION COMPARTMENT

NOTE: Prior to installing unitube cable, apply mois-

ture blocking sealant (Catalog #80803448) into

the end of the tube according to your company or

cable manufacturer's practices.

10.01 Secure unitube to the transition compartment

as shown in Figure 25.

NOTE: It is important that all single cable tubes are

secured in the correct position on the transition

compartment.

MAIN

CABLE

BOTTOM

MIDDLE

CABLE

MAIN CABLE

TAB

LIFT

12

10.04 Wrap the end of the transition tube with one

layer of the felt tape provided and secure to

the bottom of the transition compartment with two of

the tie wraps provided. (Figure 27)

FIGURE 27 - SECURING TRANSITION TUBE FOR

CABLES ENTERING TOP END PLATE PORTS

11.00 ROUTING AND STORING FIBER IN

THE TRANSITION COMPARTMENT

11.01 When routing fiber in the transition compart-

ment of either size closure for continuous

loop applications, cut the fibers to be spliced at the

midpoint of the loop. This allows for splicing in either

direction. Lay the fibers to be spliced directly through

the transition compartment exiting the opposite end.

These fibers will be routed to splice trays 1-4 of the

6.0" x 22" (15.24 cm x 55.88 cm) and trays 1-8 of

the 8.5" x 22" (21.59 cm x 55.88 cm) via transport

tubes. Wrap the continuous loop, and the fibers not

being spliced, until all fibers are stored in the transi-

tion compartment. For cut cables bring all fibers to be

spliced directly through the transition compartment

exiting the opposite end of the same corner

(Figure 28).

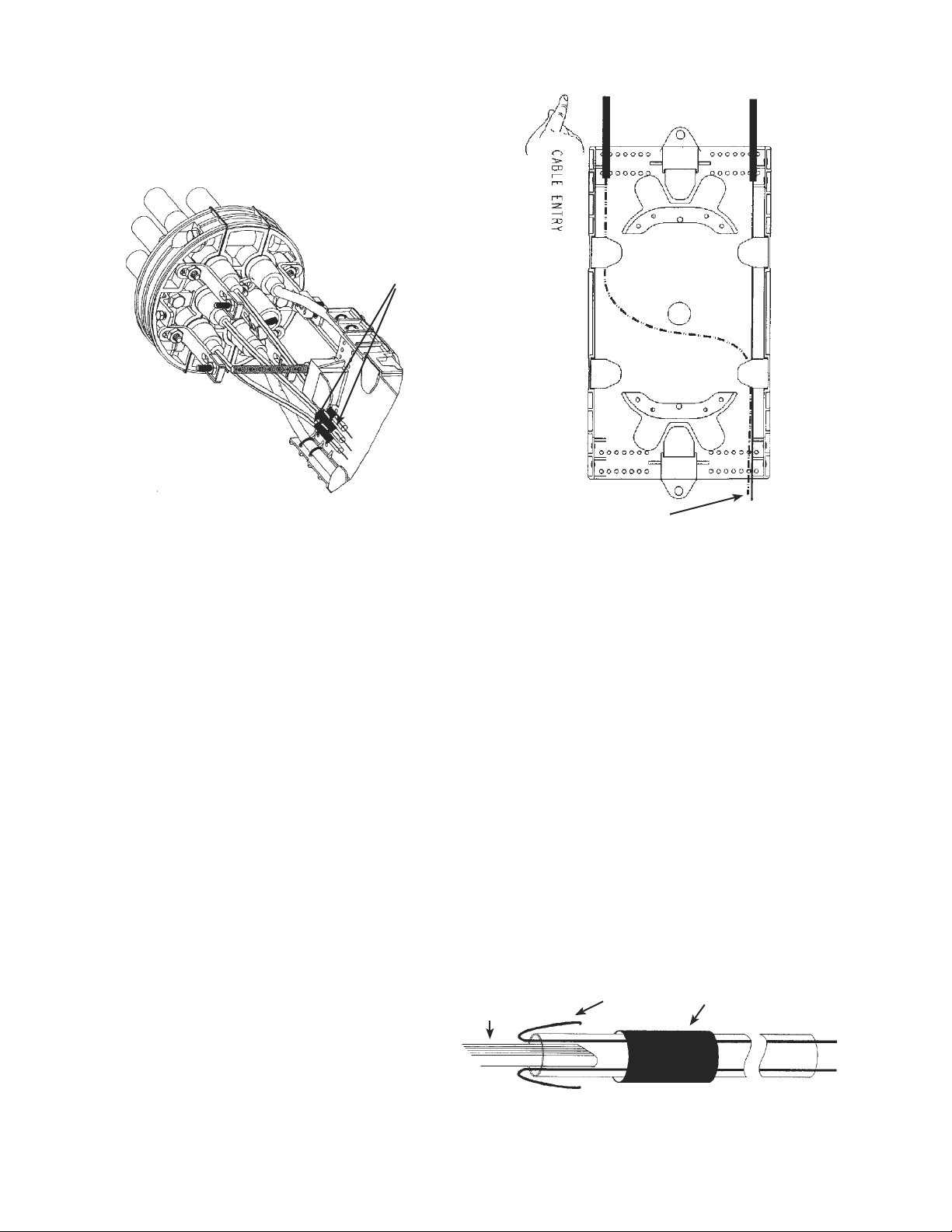

FIGURE 28 - ROUTE FIBERS IN TRANSITION

COMPARTMENT – 6.0" X 22" AND 8.5" X 22"

12.00 INSTALLING FIBERS INTO

TRANSPORT TUBES AND

SECURING TO TRANSITION

COMPARTMENT

12.01 Group fibers into bundles determined by how

many fibers will be inserted into each trans-

port tube. A maximum of six transport tubes can be

terminated per splice tray.

12.02 Push fibers through the transport tubes.

NOTE: For ribbon fiber application, fiber guide wires

are provided. Suggested use is four ribbons per

tube. (Figure 29)

FIGURE 29 - GUIDE WIRES IN USE

RIBBON

FIBER

FELT

FIBER

GUIDE

WIRE

FELT

EXIT POINT FOR FIBERS

TO BE SPLICED

13

12.03 Select the required number of transport

tubes and wrap one layer of felt tape 1/2"

(1.27 cm) from one end of all transport tubes.

(Figure 30)

FIGURE 30 - WRAP FELT TAPE

NOTE: Fiber from transition compartment enters at

felt tape end of transport tube.

12.04 Repeat steps 12.01 through 12.03 for re-

maining transport tubes.

PLP TIP: To differentiate between the office and field

side, place vinyl tape at the end of one set of

transport tubes.

12.05 Secure all transport tubes with the felt tape

applied to the inside tie down holes in the

transition compartment with two of the tie wraps pro-

vided. (Figure 31)

FIGURE 31 - SECURE TRANSPORT TUBES

PLP TIP: For ease of handling, group the transport

tubes in multiples of six. This simplifies the ar-

rangement of the final group of transport tubes in

the transition compartment. (Figure 32 A & B)

FIGURE 32A - GROUP TRANSPORT

TUBES-SINGLE CLUSTER

FIGURE 32B - GROUP TRANSPORT TUBES-

MULTIPLE CLUSTERS

12.06 Replace protective cover on transition

compartment as in Figure 33.

FIGURE 33 - REPLACE COVER

1/2"

FELT

FIBER ENTRY POINT

EXIT POINT

FOR FIBERS

TO BE

SPLICED

14

13.03 Position the transport tubes onto the splice

tray so they extend 1/4" (.64 cm) past the tie

down holes and apply provided tie wraps as shown in

Figures 36 A & B.

PLP TIP: For easy tie wrap installation, insert the

tie wrap with the ridges on the inside of the loop,

with the head opposite the notch in the splice

tray. Insert the tail into the head. Press head

down to the tray and hold in place while pulling

the tail to tighten the tie wrap.

FIGURE 36A - SECURE TIE WRAPS

FIGURE 36B - POSITION AND SECURE

TRANSPORT TUBES

13.04 When routing the fiber in the SINGLE

COUNT SPLICE TRAY, route fibers 1-24

1-1/2 times around the splice tray and lay into

the top of the splice block (see Figure 37A). Route fi-

bers 25-36 1-3/4 times around the splice tray, and lay

into the bottom of the splice block (see Figure 37B).

13.00 SECURING TRANSPORT TUBES

AND ROUTING FIBER IN SPLICE

TRAYS

13.01 There are six types of splice trays available

for the COYOTE Closure. The single fiber

trays are designed for single fusion or single me-

chanical splice applications. The single fiber trays can

accommodate up to 36 single fiber splices. The mass

fiber trays are designed for 12 mass fusion or 8 mass

mechanical splices. (Figure 34) Refer to Table 1 for

COYOTE Splice Tray capacities.

Single fiber Splice Tray (Cat. No. 80805514) consists

of a bare splice tray and three self-stick elastomer

(12-count) splice blocks. Follow the procedures

included with this splice tray to position the splice

blocks on the tray.

SINGLE FIBER TRAY MASS FIBER TRAY

FIGURE 34 - SPLICE TRAYS

13.02 Remove cover of splice tray. (Figure 35)

FIGURE 35 - REMOVE SPLICE TRAY COVER

NOTCH

TAIL

HEAD HEAD

FIELD

OFFICE

REMOVABLE

RETAINING TABS

36

SINGLE

FIBER

SPLICES

12

MASS

FUSION

SPLICES

8

MASS

MECHANICAL

SPLICES

PRESS

LIFT

15

13.05 Splice the fibers according to your accepted

company practices. (Figure 38)

FIGURE 38 - BEND RADIUS - IMPORTANT

PLP TIP: If splice protectors loosely fit in the slots

of the splice block, wrap each protector with felt

tape to provide the desired fit or use a bead of

silicone caulk to secure the connectors and place

a strip of felt tape over the connectors and sili-

cone caulk. Place Splice Count Label on cover to

identify fibers spliced. On the back of both trays,

slots are provided to aid in the removal of splice

protectors or connectors. (Figure 39)

FIGURE 39 - SPLICE BLOCK SLOTS

NOTE: There should be a minimum of 50" (127 cm)

of exposed fiber for splicing.

FIGURE 37A - ROUTING FIBERS IN THE

SINGLE FIBER SPLICE TRAY–FIBERS 1-24

FIGURE 37B - ROUTING FIBERS IN THE

SINGLE FIBER SPLICE TRAY–FIBERS 25-36

SLOTS

OFFICE

FIELD

SLOTS

1-24

FOR

EASE OF

ACCESS

DURING

SPLICING,

TABS

MAY BE

REMOVED

SLOTS

25-36

OFFICE FIELD

16

FIGURE 41 - ROUTING FIBERS IN THE

MASS FIBER SPLICE TRAY FOR MASS FUSION

13.08 Splice fibers according to accepted company

practices. (Refer back to Figure 38)

PLP TIP: If splice protectors loosely fit in the slots

of the splice block, wrap each protector with felt

tape to provide the desired fit or use a bead

of silicone caulk to secure the connectors and

place a strip of felt tape over the connectors and

silicone caulk.

13.09 Replace all tray retaining tabs.

13.10 To replace tray cover, position pivotal arm on

plastic cover underneath the hinges on the

splice tray and snap into place. (Figure 42)

FIGURE 42 - REPLACE SPLICE TRAY COVER

13.06 When routing the fiber in the MASS FIBER

SPLICE TRAY for MASS MECHANICAL,

route fibers 1-1/2 times around the splice tray and lay

into the top of the splice block. (Figure 40)

NOTE: There should be a minimum of 50" (127 cm)

of exposed fiber for splicing.

FIGURE 40 - ROUTING FIBERS IN THE MASS

FIBER SPLICE TRAY FOR MASS MECHANICAL

13.07 When routing fibers in the MASS FIBER

SPLICE TRAY for MASS FUSION, route

fiber 1-3/4 times around the splice tray and lay into

the splice block. (Figure 41)

HINGE

MASS

MECHANICAL

SPLICE BLOCK–

8 POSITIONS

FIELDOFFICE

FIELD

OFFICE

MASS

FUSION

SPLICE BLOCKS–

16 POSITIONS

(USE 12

POSITIONS

MAXIMUM FOR

MASS FUSION

SPLICES)

17

13.13 Install the top torque bar to the upper torque

bar brackets on the end plates with the

bolts provided. (Figure 45) Make sure the side of the

torque bar labelled "3 Section End" is nearest the

Three-section End Plate. The torque bars are labelled

for in-line as well as butt installation.

FIGURE 45 - INSTALL TOP TORQUE BAR

13.14 See Section 15.00 for installing COYOTE

Closure Shells.

14.00 ROUTING LOOSE BUFFER TUBE

CABLE

14.01 When routing both unitube and buffer tube in

the same closure, follow instructions for

unitube application beginning in Paragraph 8.00. For

buffer tube alone, install the loose buffer tube storage

compartment (Figure 46A) or express loose buffer

tube storage compartment (Figure 46B) to the torque

bar bracket on the bottom of the End Plates with the

bolts provided. Make sure the side of the torque bar

labelled "3 Section End" is nearest the Three-section

End Plate. The torque bars are labelled for in-line as

well as butt installation.

FIGURE 46A - INSTALL LOOSE BUFFER TUBE

STORAGE COMPARTMENT

13.11 Slide all splice trays onto the threaded studs.

See Figures 43 A & B for proper splice tray

alignment for the 6.0" x 22" (15.24 cm x 55.88 cm)

closure and the 8.5" x 22" (21.59 cm x 55.88 cm)

closure.

FIGURE 43A - PROPER SPLICE TRAY

ALIGNMENT 6.0" X 22" (15.24 CM X 55.88 CM)

FIGURE 43B - PROPER SPLICE TRAY ALIGNMENT

8.5" X 22" (21.59 CM X 55.88 CM)--TRAYS 1-8

13.12 After all splices are completed, secure all

splice trays onto the threaded studs by reap-

plying the splice tray hold down strap. (Figure 44)

FIGURE 44 - REPLACE SPLICE TRAY HOLD

DOWN STRAP

3-SECTION

END PLATE

TRAYS 1-8

3-SECTION

END PLATE

TRAYS 1-4

18

ROUTING STORING

FIGURE 48 - LOOSE BUFFER TUBE ROUTING

AND STORAGE

14.04 Position the trays on the threaded studs.

There should be a minimum of 50" (127 cm) of

exposed fiber for splicing in the tray. Lay the loose

buffer tubes in the tray and make a mark on the tube

1/4" (.64 cm) past the tie down holes. See Figure 49.

Remove the loose buffer tube from this point outward.

Clean exposed fibers according to accepted com-

pany practices.

FIGURE 49 - LAY TUBES IN TRAY AND MARK

STUDS

FIGURE 46B - INSTALL EXPRESS LOOSE BUF-

FER TUBE STORAGE COMPARTMENT

14.02 Remove splice tray hold down strap.

(Figure 47A)

PLP TIP: If the hold down strap is snug against the

studs, lift the tab using a screwdriver as demon-

strated in Figure 47B.

FIGURE 47A - REMOVE SPLICE TRAY HOLD

DOWN STRAP

FIGURE 47B - HOLD DOWN STRAP REMOVAL

NOTE: See Table 1 for COYOTE Splice Tray capaci-

ties.

14.03 When routing loose buffer tubes in the 6.0" x

22" (15.24 cm x 55.88 cm) and 8.5" x 22"

(21.59 cm x 55.88 cm) COYOTE Closure. Route the

loose buffer tubes to be spliced through the storage

compartment, exiting them both at the opposite end

on the same side. Store any unspliced loose buffer

tubes or continuous loop loose buffer tubes by routing

them inside the storage brackets. (Figure 48)

MARK

➔

THREE-SECTION

END PLATE

SIDE

FIBERS FROM

STORAGE

COMPARTMENT

MINIMUM

50" (127 CM)

EXPOSED

FIBER

TAB

EXIT POINT

FOR FIBERS

TO BE

SPLICED

19

FIGURE 50B - POSITION AND SECURE

TRANSPORT TUBES

14.11 For routing the fiber in the SINGLE FIBER

SPLICE TRAY, see Paragraph 13.04.

14.12 For routing fibers in the MASS FIBER

SPLICE TRAY, see Paragraphs 13.07 and

13.08.

14.13 To replace splice tray cover, splice tray hold

down strap and torque bar see Paragraphs

13.10-13.13.

15.00 INSTALLING THE COYOTE

CLOSURE SHELLS

15.01 The neoprene in the shells must be pliable

when installed. In cold weather (below 32˚ F),

for new installation, or re-entry, warm shells prior to

installation.

15.02 Remove protective paper liners from shells.

Take care to keep gasket area clean.

15.03 The top and bottom shells are mated to-

gether around the End Plates. The top shell

is identified by an air valve and bolts. Position the

top and bottom shells around the End Plates in the

grooves located in each shell half.

14.05 COYOTE Express Closure Application:

The COYOTE Express Closure is designed

for loop or ring application where a high count fiber

is used and a continuous loop or express splice is

made and a low count branch cable is being spliced.

More room in the storage compartment is required

for the storage of slack buffer tube.

14.06 Follow Paragraph 4.01 for cable opening

measurements.

14.07 Separate the buffer tubes to be spliced from

the rest of the express buffer tubes and cut

them at the center points.

14.08 From the left entrance, start wrapping the

express fiber to be stored in a clockwise

rotation until all express buffer tubes are stored in the

express storage compartment.

14.09 Route buffer tubes to be spliced to the splice

trays.

NOTE: The express storage compartments accept

two single splice trays in the 6.0" COYOTE

Express Closure and four single trays in the 8.5"

closure.

14.10 Place one wrap of felt tape at the end of

each loose buffer tube. Position the buffer

tubes onto the splice tray so they extend 1/4" (.64)

past the tie down holes and apply provided tie wraps

as shown in Figures 50 A & B.

PLP TIP: For easy tie wrap installation, insert the

tie wrap with the ridges on the inside of the loop,

with the head opposite the notch in the splice

tray. Insert the tail into the head. Press head

down to the tray and hold in place while pulling

the tail to tighten the tie wrap.

FIGURE 50A - SECURE TIE WRAPS

NOTCH

TAIL

HEAD

HEAD

FIELD

OFFICE

20

16.00 EXTERNAL BOND PROCEDURE

16.01 For all ground inserts with cables attached,

loosely attach a bond clamp (2 per kit) (Cata-

log #8003281) outside the End Plate. The clamp

attaches between the two nuts on the stud on the

outside of the End Plate. NOTE: DO NOT REMOVE

THE NUT ON THE GROUND INSERT CLOSEST TO

THE END PLATE. When reattaching hex nut, secure

using a can wrench, or torque wrench set no higher

than 40 inch/pounds. Route bond ribbon (not sup-

plied) through the clamps and to the ground source.

Tighten all clamps. (Figure 52)

FIGURE 52 - BOND CABLES

16.02 For bonding all isolated grounds together

on the exterior of the COYOTE Closure, use

Exterior Bond Braid Kit (Catalog #8003360).

16.03 The eyelets of the Exterior Bond Braid Kit are

placed at intervals to align with isolated

ground studs on the exterior of the COYOTE End

Plate.

16.04 Remove one hex nut from each of the ground

studs.

16.05 Apply the Exterior Bond Braid and re-apply

hex nuts and tighten. When reattaching hex

nuts, secure using a can wrench, or torque wrench

set no higher than 40 inch/pounds.

16.06 Attach tail of the Exterior Bond Braid via the

remaining eyelet to the ground source as per

company practice.

8.5" X 22" (21.59 CM X 55.88 CM)

123

4

65

7

8

9

10 11 12

13 14

6.0" X 22" (15.24 CM X 55.88 CM)

15.04 Align the closing hardware and first HAND-

TIGHTEN in the torque sequence shown in

Figure 51. Once all closing hardware is hand-tight-

ened, repeat the torque sequence using a torque

wrench set at 55 inch pounds. After completing

torque sequence, re-torque the two outside corner

bolts on all four corners (in bold).

NOTE: SET TORQUE TO 55 INCH POUNDS.

FIGURE 51 - TORQUE SEQUENCE

15.05 Flash test and soap COYOTE Closure

according to accepted company practices, to

a maximum of 10 psi.

15.06 Release pressure from closure and replace

cap on air valve.

14

3

2

5

6

7

8

9

10

11

12

13

14

15

16

This manual suits for next models

3

Table of contents

Other PREFORMED LINE PRODUCTS Industrial Electrical manuals

Popular Industrial Electrical manuals by other brands

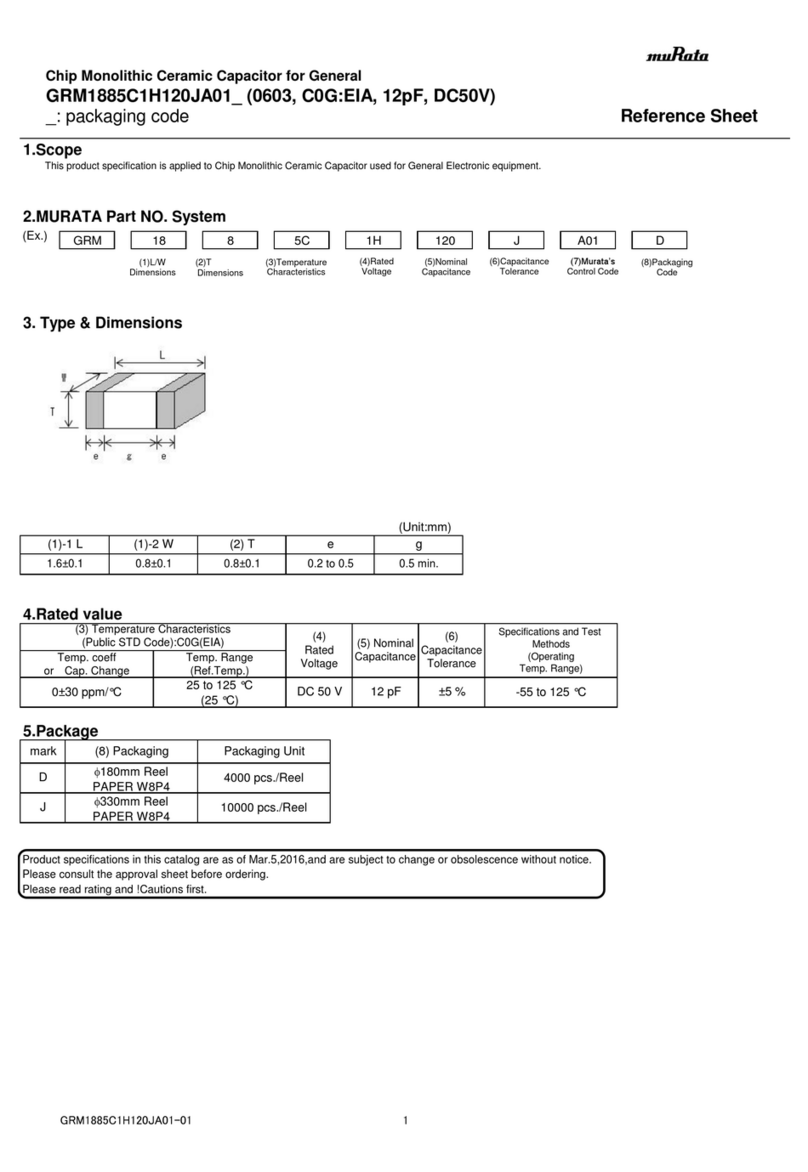

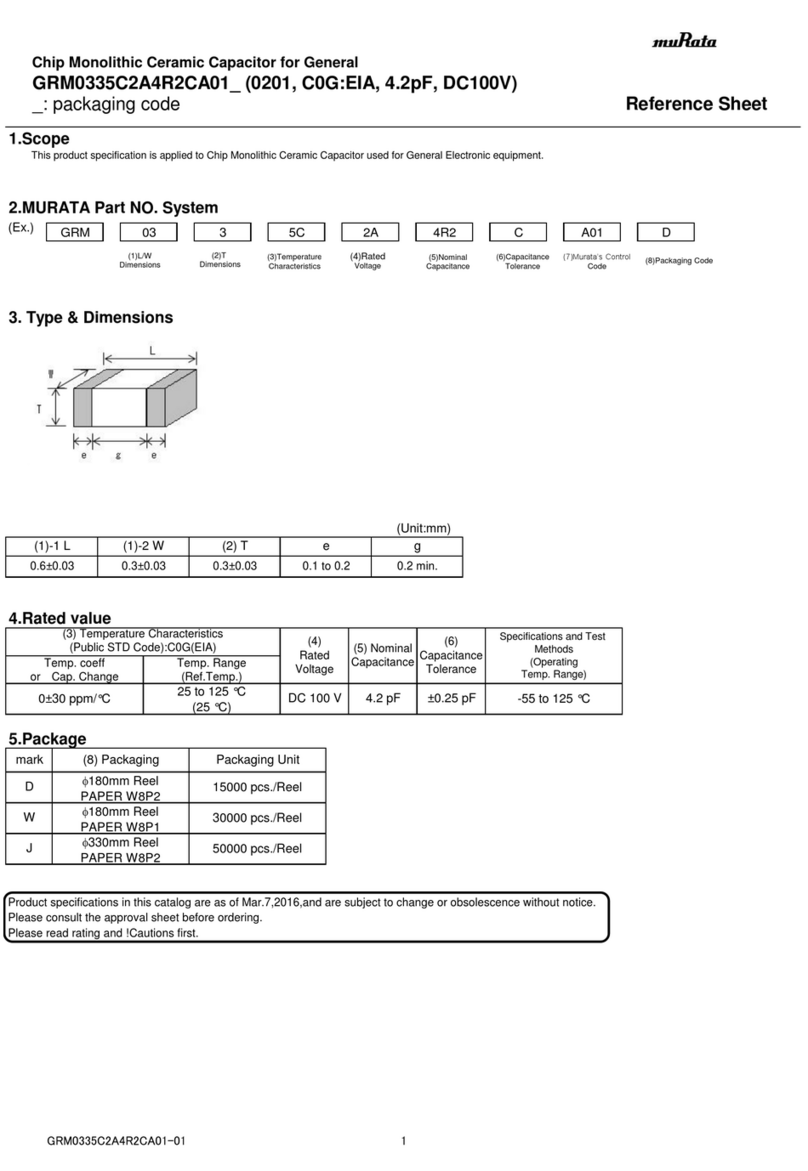

Murata

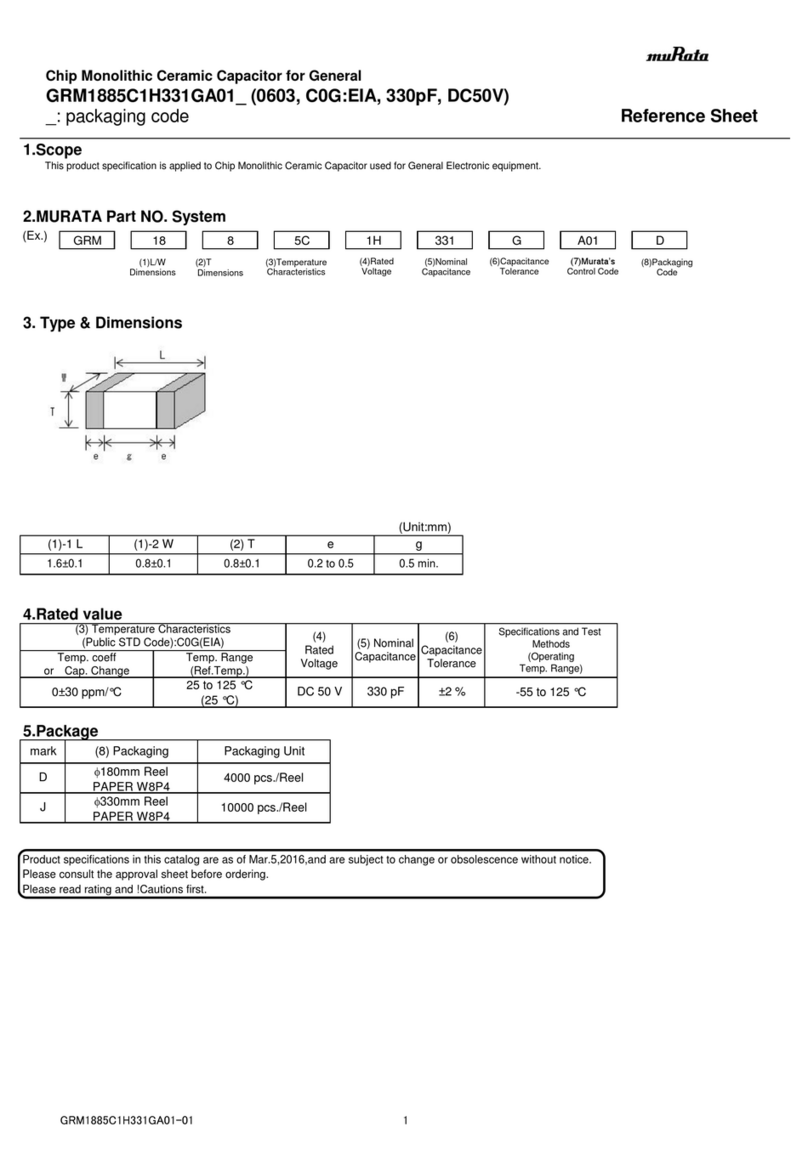

Murata GRM1885C1H331GA01 Series Reference sheet

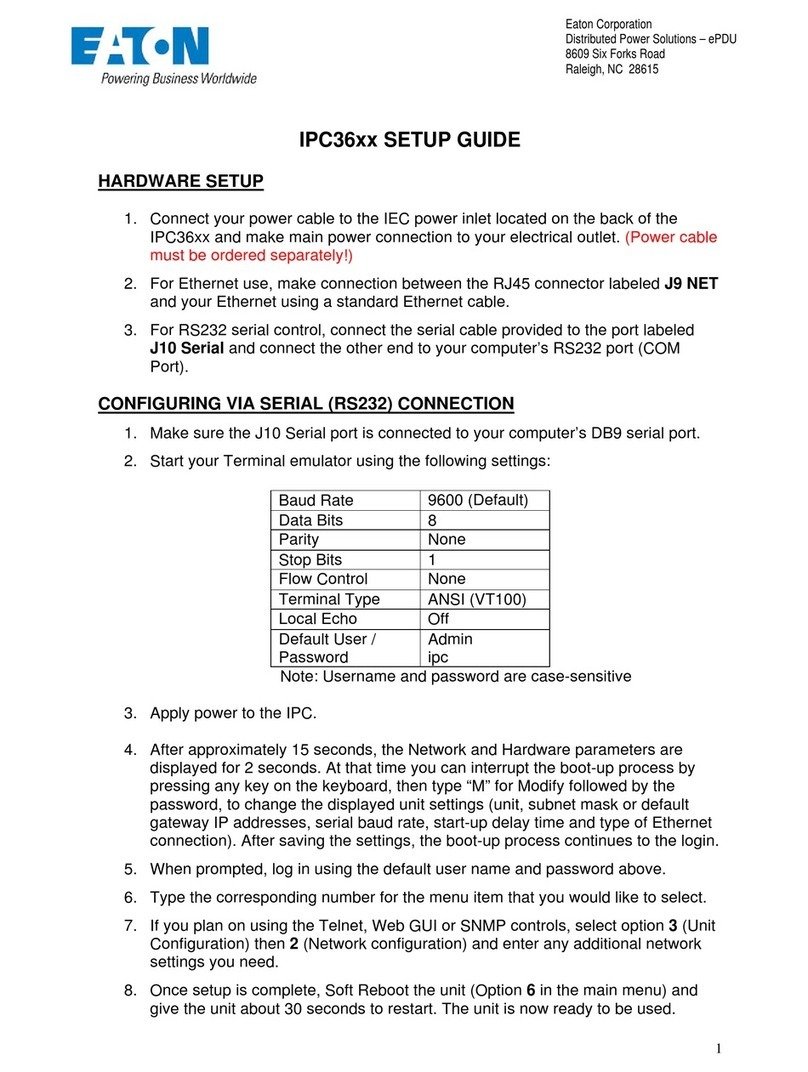

Eaton

Eaton DILM7-21 Instruction leaflet

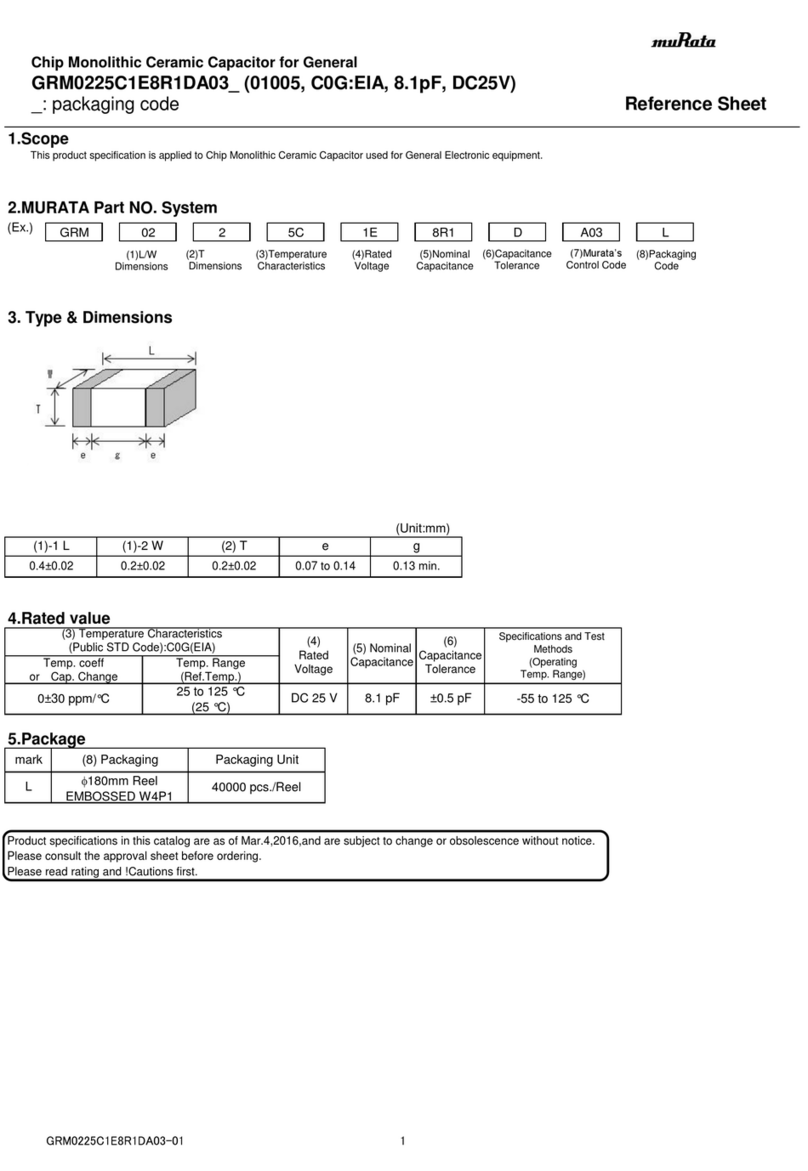

Murata

Murata GRT31CR61C335ME01 Series Reference sheet

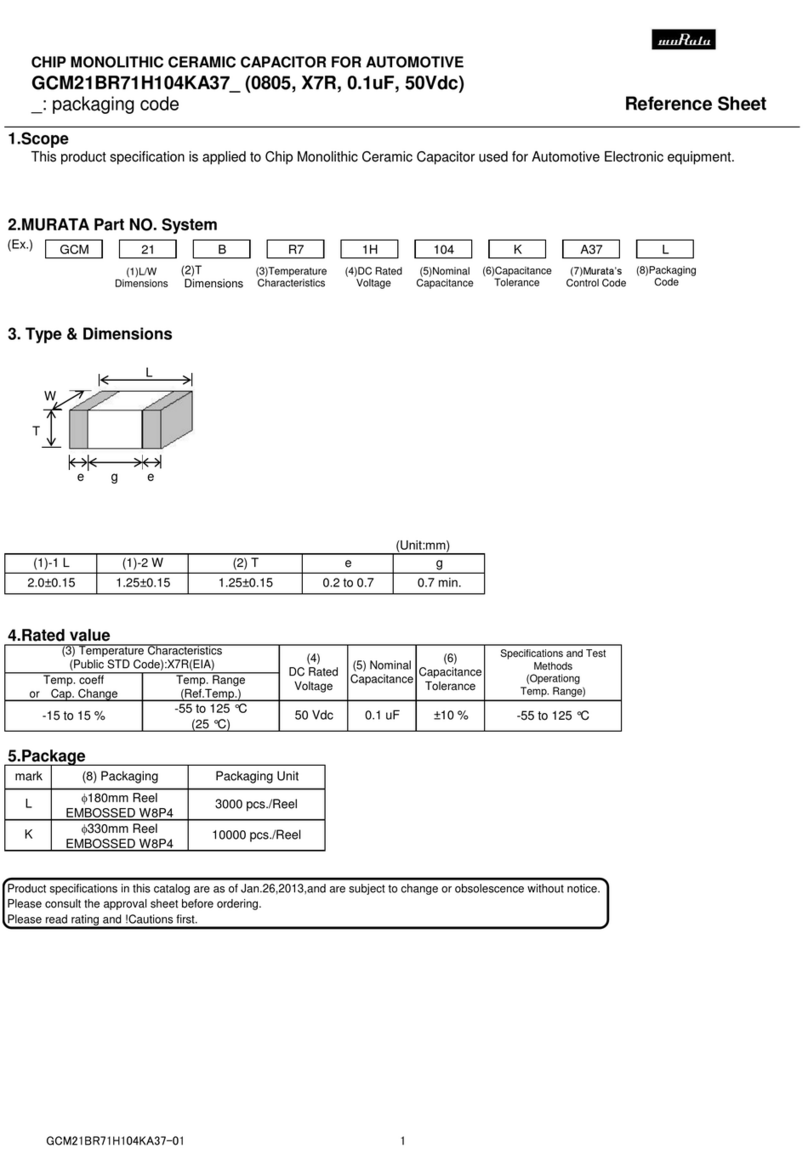

Murata

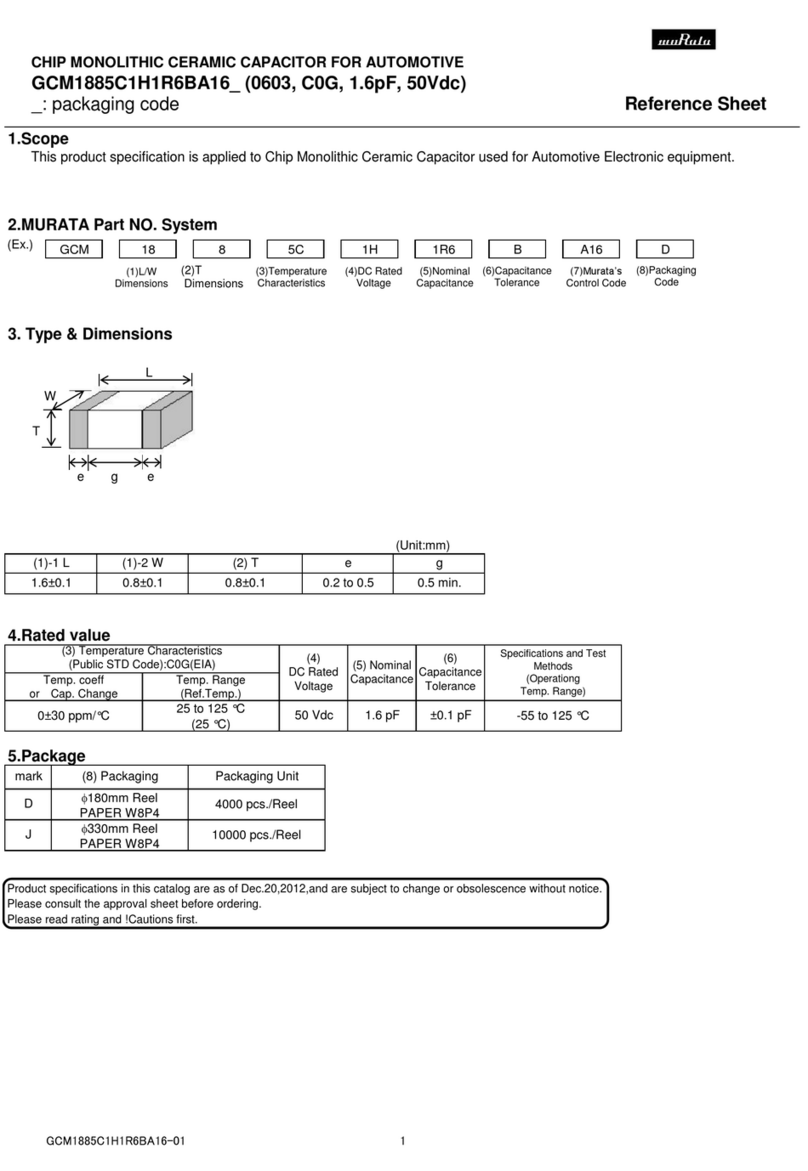

Murata GCM1885C1H1R6BA16 Series Reference sheet

Murata

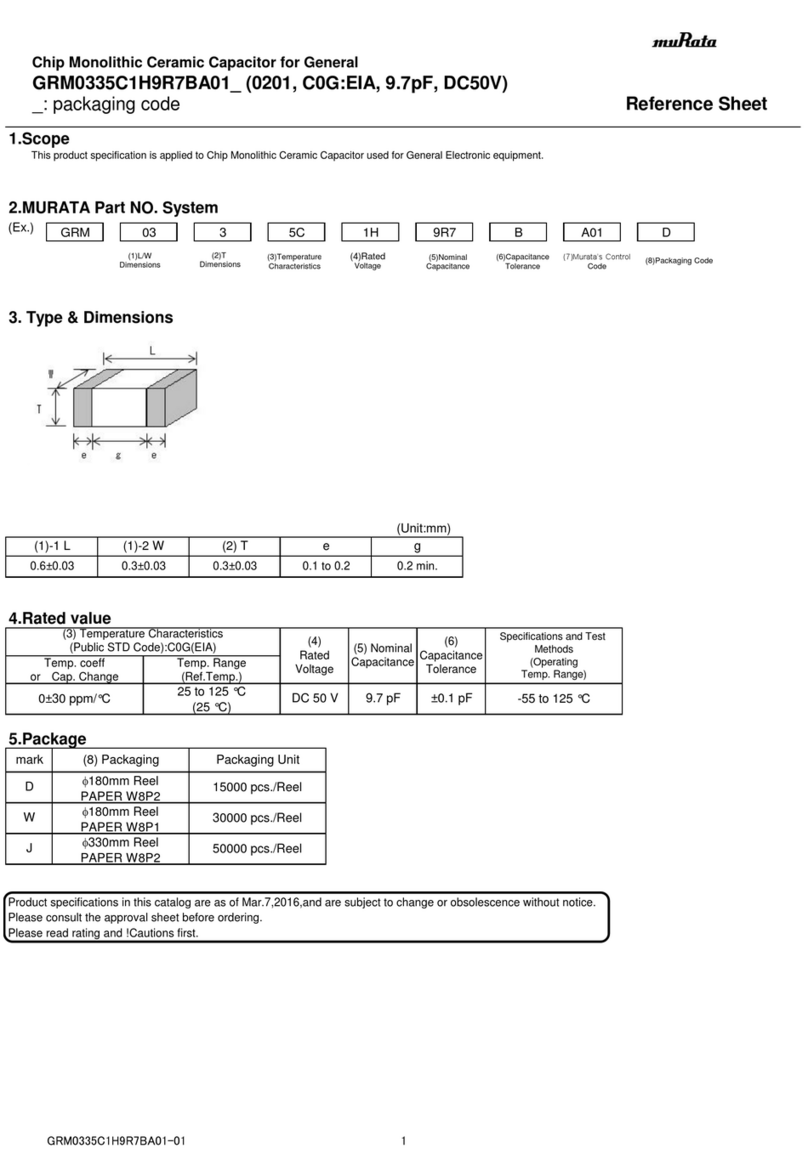

Murata GRM0335C1H9R7BA01 Series Reference sheet

Murata

Murata GRM0335C2A4R2CA01 Series Reference sheet