Preiffer PKR 251 User manual

OPERATING INSTRUCTIONS

EN

Translation of the Original

PKR 251

Pirani/Cold cathode gauge

Dear Customer,

Thank you for choosing a Pfeiffer Vacuum product. Your new gauge is designed to support

you in your individual application with maximum performance and without malfunctions. The

name Pfeiffer Vacuum stands for high-quality vacuum technology, a comprehensive and

complete range of top-quality products and first-class service. From this extensive, practical

experience we have gained a large volume of information that can contribute to efficient

deployment and to your personal safety.

In the knowledge that our product must avoid consuming work output, we trust that our

product can offer you a solution that supports you in the effective and trouble-free

implementation of your individual application.

Please read these operating instructions before putting your product into operation for the

first time. If you have any questions or suggestions, please feel free to contact info@pfeiffer-

vacuum.de.

Further operating instructions from Pfeiffer Vacuum can be found in the Download Center on

our website.

Disclaimer of liability

These operating instructions describe all models and variants of your product. Note that your

product may not be equipped with all features described in this document. Pfeiffer Vacuum

constantly adapts its products to the latest state of the art without prior notice. Please take

into account that online operating instructions can deviate from the printed operating

instructions supplied with your product.

Furthermore, Pfeiffer Vacuum assumes no responsibility or liability for damage resulting from

the use of the product that contradicts its proper use or is explicitly defined as foreseeable

misuse.

Copyright

This document is the intellectual property of Pfeiffer Vacuum and all contents of this

document are protected by copyright. They may not be copied, altered, reproduced or

published without the prior written permission of Pfeiffer Vacuum.

We reserve the right to make changes to the technical data and information in this document.

2/50

Table of contents

1 About this manual 7

1.1 Validity 7

1.1.1 Applicable documents 7

1.1.2 Variants 7

1.2 Target group 7

1.3 Conventions 8

1.3.1 Instructions in the text 8

1.3.2 Pictographs 8

1.3.3 Stickers on the product 8

1.3.4 Abbreviations 9

1.4 Trademark proof 9

2 Safety 10

2.1 General safety information 10

2.2 Safety instructions 10

2.3 Safety precautions 12

2.4 Limits of use of the product 13

2.5 Proper use 13

2.6 Foreseeable improper use 13

3 Product description 14

3.1 Function 14

3.2 Status display 14

3.3 Identifying the product 14

3.4 Scope of delivery 14

4 Transport and storage 16

4.1 Transporting the product 16

4.2 Storing the product 16

5 Installation 17

5.1 Establishing vacuum connection 17

5.2 Removing/installing magnetic unit 18

5.3 Establishing electric connection 20

6 Operation 22

6.1 Operating modes 22

6.2 Converting measuring signal and pressure 22

6.3 Determining effective pressure with calibration factors 23

6.4 Observing ignition delay 25

6.5 Protecting gauge from contamination 26

7 Removal 27

8 Maintenance 29

8.1 Calibrating gauge 29

8.2 Disassembling gauge 31

8.3 Cleaning components 32

8.4 Gauge assembling 33

9 Malfunctions 36

10 Shipping 37

11 Recycling and disposal 38

11.1 General disposal information 38

11.2 Dispose of gauges 38

Table of contents

3/50

List of tables

Tbl. 1: Applicable documents 7

Tbl. 2: Variants 7

Tbl. 3: Abbreviations used 9

Tbl. 4: Limits of use of the product 13

Tbl. 5: Operating modes 22

Tbl. 6: Constants for converting measuring signal and pressure 23

Tbl. 7: Conversion table 23

Tbl. 8: Calibration factors for the pressure range < 10 hPa 25

Tbl. 9: Malfunctions 36

Tbl. 10: Conversion table: Pressure units 44

Tbl. 11: Conversion table: Units for gas throughput 44

Tbl. 12: Measured and pressure values 44

Tbl. 13: Electrical data 45

Tbl. 14: Internal volume and weight 45

Tbl. 15: Ambient conditions 45

Tbl. 16: Temperatures 46

Tbl. 17: Substances in contact with the media 46

List of tables

5/50

List of figures

Fig. 1: Measuring configuration 14

Fig. 2: Light emitting diode 14

Fig. 3: Establishing vacuum connection 18

Fig. 4: Removing/installing magnetic unit 19

Fig. 5: Connection diagram 20

Fig. 6: Measurement cable and Hirschmann cable socket 21

Fig. 7: Relation between measuring signal and pressure 22

Fig. 8: Pressure range > 10 hPa, Pirani operation only 24

Fig. 9: Pressure range from 10 to 0.1 hPa 24

Fig. 10: Removing gauge 28

Fig. 11: Calibrating gauge (HV) 30

Fig. 12: Calibrating gauge (ATM) 30

Fig. 13: Individual parts 31

Fig. 14: Mounting tool for the ignition aid 34

Fig. 15: Spare parts 41

Fig. 16: Filter disk 43

Fig. 17: Dimensions 46

List of figures

6/50

1 About this manual

IMPORTANT

Read carefully before use.

Keep the manual for future consultation.

1.1 Validity

This document describes the function of the products listed in the following and provides the most im-

portant information for safe use. The description is written in accordance with the valid directives. The

information in this document refers to the current development status of the products. The document

retains its validity assuming that the customer does not make any changes to the product.

1.1.1 Applicable documents

Designation Document

Brief instruction for "Pirani/cold cathode gauge"

PKR 251

BG 5119

"Total Pressure Measuring and Control Unit" operating instructions

TPG 361 | TPG 362

BG 5500

"Total Pressure Measuring and Control Unit" operating instructions

TPG 366

BG 5501

Declaration of conformity A component of these instruc-

tions

Tbl. 1: Applicable documents

You can find these documents in the Pfeiffer Vacuum Download Center.

1.1.2 Variants

This document applies to products with the following article numbers:

Article number Designation

PT R26 000 PKR 251, DN 25 ISO-KF

PT R26 001 PKR 251, DN 40 ISO-KF

PT R26 002 PKR 251, DN 40 CF-F

Tbl. 2: Variants

You can find the part number on the rating plate of the product.

Pfeiffer Vacuum reserves the right to make technical changes without prior notification.

Information that relates to only one of the products is indicated accordingly.

The figures in this document are not to scale.

Graphics without a caption reflect the product featuring a DN 25 ISO-KF vacuum connection, however,

they also apply for the other vacuum connections accordingly.

Dimensions are in mm unless stated otherwise.

1.2 Target group

These operating instructions are aimed at all persons performing the following activities on the product:

●Transportation

●Setup (Installation)

●Usage and operation

●Decommissioning

About this manual

7/50

●Maintenance and cleaning

●Storage or disposal

The work described in this document is only permitted to be performed by persons with the appropriate

technical qualifications (expert personnel) or who have received the relevant training from Pfeiffer Vac-

uum.

1.3 Conventions

1.3.1 Instructions in the text

Usage instructions in the document follow a general structure that is complete in itself. The required ac-

tion is indicated by an individual step or multi-part action steps.

Individual action step

A horizontal, solid triangle indicates the only step in an action.

►This is an individual action step.

Sequence of multi-part action steps

The numerical list indicates an action with multiple necessary steps.

1. Step 1

2. Step 2

3. ...

1.3.2 Pictographs

The pictographs used in the document indicate useful information.

Note

Tip

Wear laboratory gloves

Perform a visual inspection

1.3.3 Stickers on the product

This section describes all the stickers on the product along with their meaning.

D-35614 Asslar

Mod.

P/N

S/N

Input

PKR 251

PT R26 xxx

xxxxxxxxx

15...30 V DC 2 W

Made in Liechtenstein 2019/04

3103457

Rating plate

The rating plate is located on the top of

the device.

10 cm

4”

Warning against magnetic fields

The sticker displays a warning that the

magnetic field of the gauge can interfere

with the functioning of pacemakers, and

specifies the minimum distance to the

gauge which must be maintained by per-

sons with pacemaker implants.

About this manual

8/50

1.3.4 Abbreviations

Abbreviation Explanation

ATM Atmosphere

c Constant for converting measuring signal and pressure

C Calibration factor for calculating the pressure for gases other than air

d Constant for converting measuring signal and pressure

GND Ground

HV High vacuum

cpl. Complete unit

LED Light emitting diode

LPS Limited power source

MSL Mean sea level

p Pressure

PELV Protective extra low voltage

s seconds

WAF Width Across Flats

U Measuring signal [V] (output voltage)

VCR Trademark of the Swagelok Company

Tbl. 3: Abbreviations used

1.4 Trademark proof

●FullRange® is a trademark of Pfeiffer Vacuum GmbH.

●Hirschmann® is a trademark of Hirschmann Electronics GmbH.

●Scotch-Brite® is a registered trade name of 3M Company.

About this manual

9/50

2 Safety

2.1 General safety information

The following 4 risk levels and 1 information level are taken into account in this document.

DANGER

Immediately pending danger

Indicates an immediately pending danger that will result in death or serious injury if not observed.

►Instructions to avoid the danger situation

WARNING

Potential pending danger

Indicates a pending danger that could result in death or serious injury if not observed.

►Instructions to avoid the danger situation

CAUTION

Potential pending danger

Indicates a pending danger that could result in minor injuries if not observed.

►Instructions to avoid the danger situation

NOTICE

Danger of damage to property

Is used to highlight actions that are not associated with personal injury.

►Instructions to avoid damage to property

Notes, tips or examples indicate important information about the product or about this docu-

ment.

2.2 Safety instructions

Safety instructions according to product life stages

All safety instructions in this document are based on the results of a risk assessment.

Pfeiffer Vacuum has taken into account all the relevant life stages of the product.

Risks during installation

DANGER

Danger to life due to dangerous contact voltage

Voltages above 30 V (AC) or 60 V (DC) are considered dangerous in accordance with EN 61010. If

you come into contact with dangerous contact voltage, this can result in injury through electric shocks

or even death.

►Only connect the product to devices which meet the following criteria:

●Requirements of the earthed protective extra-low voltage (PELV)

●Limited power source (LPS) Class 2

►Secure the line to the product.

–Pfeiffer Vacuum measuring and control equipment complies with this requirement.

Safety

10/50

DANGER

Risk to life due to electric shock

An improperly earthed product is potentially fatal in the event of a fault.

►Connect the product galvanically with the earthed vacuum chamber.

►Ensure that the connection complies with the requirements of a protective bonding according to

EN 61010. (CF and VCR connections comply with this requirement.)

►Use electrically conductive centering rings and circlips for KF connections.

WARNING

Danger from magnetic fields

The product has a magnetic field that disturbs or impairs the function of electronic devices (e.g. pace-

makers).

►Maintain the distances specified by the manufacturer of the pacemakers.

–Pfeiffer Vacuum recommends a safety distance of at least 130 mm between the pacemaker

and the product.

►Avoid the influence of strong magnetic fields by means of magnetic field shielding.

Risks during operation

WARNING

Risk of injury resulting from overpressure in the vacuum system

Opening tensioning pieces with an overpressure > 1000 hPa in the vacuum system can lead to inju-

ries as a result of flying parts, and escaping process medium could prove harmful to health.

Elastomer seals in KF connections (e.g. O-rings) are not resistant to pressures > 2500 hPa. This

could prove harmful to health due to escaping process medium.

►Do not open any tensioning pieces when overpressure is prevalent in the vacuum system.

►Use suitable tensioning pieces for overpressure.

►Use tensioning pieces which can only be opened and closed using a tool (e.g. tightening strap-

circlip).

►Use sealing rings with an outer centering ring.

Risks during maintenance

DANGER

Risk to life due to electric shock

If no earth connection is established, voltage flows become hazardous to the touch and could lead to

electronic components sustaining damage.

►Always tighten the electronic unit with the grub screw.

►Ensure that the grub screw of the electronic unit has been tightened correctly.

DANGER

Electric shock due to moisture entering the unit

Water that has entered the unit will result in personal injury through electric shocks.

►Only operate the unit in a dry environment.

►Operate the unit away from fluids and sources of moisture.

►Do not switch on the unit if fluid has entered it. Instead contact Pfeiffer Vacuum Service.

►Always disconnect the power supply before cleaning the unit.

Safety

11/50

WARNING

Health hazard through poisoning from toxic contaminated components or devices

Toxic process media result in contamination of devices or parts of them. During maintenance work,

there is a risk to health from contact with these poisonous substances. Illegal disposal of toxic sub-

stances causes environmental damage.

►Take suitable safety precautions and prevent health hazards or environmental pollution by toxic

process media.

►Decontaminate affected parts before carrying out maintenance work.

►Wear protective equipment.

WARNING

Health hazards due to cleaning agent

The cleaning agent being used causes health hazards which could include, for example, poisoning,

allergies, skin irritations, chemical burns or damage to the airways.

►When handling cleaning agents, observe the applicable regulations.

►Adhere to safety measures regarding handling and disposal of cleaning agents.

►Be aware of potential reactions with product materials.

Risks when shipping

WARNING

Risk of poisoning from contaminated products

Where products that contain harmful substances are shipped for maintenance or repair purposes, the

health and safety of service personnel is at risk.

►Comply with the instructions for safe distribution.

Risks during disposal

WARNING

Health hazard through poisoning from toxic contaminated components or devices

Toxic process media result in contamination of devices or parts of them. During maintenance work,

there is a risk to health from contact with these poisonous substances. Illegal disposal of toxic sub-

stances causes environmental damage.

►Take suitable safety precautions and prevent health hazards or environmental pollution by toxic

process media.

►Decontaminate affected parts before carrying out maintenance work.

►Wear protective equipment.

2.3 Safety precautions

The product is designed according to the latest technology and recognized safety engineering rules.

Nevertheless, improper use can result in danger to operator all third party life and limb, and product

damage and additional property damage.

Duty to provide information on potential dangers

The product holder or user is obliged to make all operating personnel aware of dangers

posed by this product.

Every person who is involved in the installation, operation or maintenance of the product

must read, understand and adhere to the safety-related parts of this document.

Safety

12/50

Infringement of conformity due to modifications to the product

The Declaration of Conformity from the manufacturer is no longer valid if the operator

changes the original product or installs additional equipment.

●Following the installation into a system, the operator is required to check and re-evalu-

ate the conformity of the overall system in the context of the relevant European Direc-

tives, before commissioning that system.

General safety precautions when handling the product

►Observe all applicable safety and accident prevention regulations.

►Check that all safety measures are observed at regular intervals.

►Pass on safety instructions to all other users.

►Do not expose body parts to the vacuum.

►Always ensure a secure connection to the earthed conductor (PE).

►Never disconnect plug connections during operation.

►Observe the above shutdown procedures.

►Keep lines and cables away from hot surfaces (> 70 °C).

►Do not carry out your own conversions or modifications on the device.

►Observe the unit protection degree prior to installation or operation in other environments.

►Provide suitable touch protection, if the surface temperature exceeds 70 °C.

►Inform yourself about any contamination before starting work.

2.4 Limits of use of the product

Parameter Value

Relative humidity of air At temperatures up to +31°C max. 80 %

At temperatures up to +40°C max. 50%

Mounting orientation Arbitrary

Usage Only in indoor areas

Installation altitude max. 2000 m MSL

Protection degree IP40

Tbl. 4: Limits of use of the product

2.5 Proper use

The FullRange gauge provides vacuum measurement of gases within the range of 5 × 10-9 to

1000 hPa.

Use the product according to its intended purpose

►Operate the gauge with a Pfeiffer Vacuum total pressure measuring and control unit or with an

evaluation unit provided by the customer.

►Install, operate and maintain the gauge exclusively as prescribed in these operating instructions.

►Observe the application limits prescribed in the technical data.

►Observe the technical data.

2.6 Foreseeable improper use

Improper use of the product invalidates all warranty and liability claims. Any use that is counter to the

purpose of the product, whether intentional or unintentional, is regarded as improper use; in particular:

●Use outside the mechanical and electrical limits of use

●Use with corrosive or explosive media, if this is not explicitly permitted

●Use for the measurement of highly flammable or combustible gases mixed with an oxidizing agent

(e.g. atmospheric oxygen) within the explosion limits

●Use outdoors

●Use after technical changes (inside or outside on the product)

●Use with replacement or accessory parts that are not suitable or not approved

Safety

13/50

3 Product description

3.1 Function

The gauge has two measurement systems:

●Pirani measurement system

●Cold cathode measurement system according to the inverted magnetron principle

The Pirani measurement system is always switched on. The gauge only activates the cold cathode

measurement system controlled by the Pirani measurement system at pressures p < 1 × 10-2 hPa. Spe-

cific linking of both measuring systems ensures that the measuring systems generally behave as one

standardized measuring system for the user. The measuring signal is logarithmically dependent on the

pressure across the entire measuring range. The gauge applies the optimum measuring configuration to

the respective pressure range.

10-4 hPa

10-2 hPa

1000 hPa

5×

10-9 hPa

Cold Cathode Pirani

Fig. 1: Measuring configuration

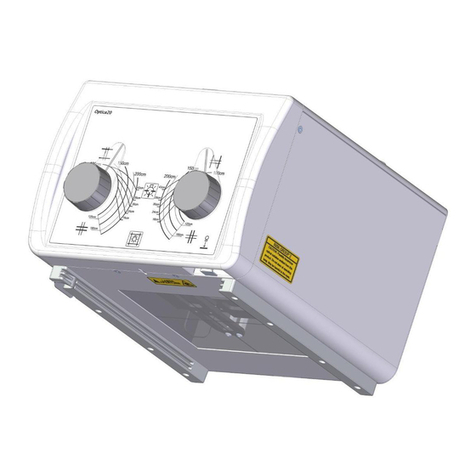

3.2 Status display

The LED on the top of the gauge indicates the operating status of the gauge (see chapter “Operating

modes”, page 22).

1

Fig. 2: Light emitting diode

1 Green LED

3.3 Identifying the product

You will need all the data from the rating plate to safely identify the product when communicating with

Pfeiffer Vacuum.

1. Read the data on the product rating plate.

2. Record this data.

3. Always have all rating plate specifications to hand.

3.4 Scope of delivery

The shipment includes the following parts:

●Gauge

●Short instructions

Product description

14/50

Unpacking the product and checking completeness of the shipment

1. Unpack the product.

2. Remove the transport fasteners, transport protection etc.

3. Store the transport fasteners, transport protection etc. in a safe place.

4. Check that the shipment is complete.

5. Ensure that no parts are damaged.

Product description

15/50

4 Transport and storage

4.1 Transporting the product

NOTICE

Damage caused by incorrect transport

Transport in unsuitable packaging or failure to install all transport locks can result in damage to the

product.

►Comply with the instructions for safe transport.

Packing

We recommend keeping the transport packaging and original protective cover.

Transport product safely

►Observe the weight specified on the transport packaging.

►Where possible, always transport or ship the product in the original transport packaging.

►Always use dense and impact-proof transport packaging for the product.

►Remove the existing protective cover and transport protections only immediately prior to installa-

tion.

►Reattach transport locks and transport protections prior to each transport.

4.2 Storing the product

NOTICE

Damage caused by improper storage

Improper storage will lead to damage to the product.

Static charging, moisture, etc. will lead to defects on the electronic components.

►Comply with the instructions for safe storage.

Packing

We recommend storing the product in its original packaging.

Store product safely

►Store the product in a cool, dry, dust-free place, where it is protected against impacts and me-

chanical vibration.

►Always use dense and impact-proof packaging for the product.

►Where possible, store the product in its original packaging.

►Store electronic components in antistatic packaging.

►Maintain the permissible storage temperature.

►Avoid extreme fluctuations of the ambient temperature.

►Avoid high air humidity.

►Seal connections with the original protective caps.

►Protect the product with the original transport protection (where available).

Transport and storage

16/50

5 Installation

5.1 Establishing vacuum connection

DANGER

Risk to life due to electric shock

An improperly earthed product is potentially fatal in the event of a fault.

►Connect the product galvanically with the earthed vacuum chamber.

►Ensure that the connection complies with the requirements of a protective bonding according to

EN 61010. (CF and VCR connections comply with this requirement.)

►Use electrically conductive centering rings and circlips for KF connections.

DANGER

Risk to life due to electric shock

If no earth connection is established, voltage flows become hazardous to the touch and could lead to

electronic components sustaining damage.

►Always tighten the electronic unit with the grub screw.

►Ensure that the grub screw of the electronic unit has been tightened correctly.

WARNING

Risk of injury resulting from overpressure in the vacuum system

Opening tensioning pieces with an overpressure > 1000 hPa in the vacuum system can lead to inju-

ries as a result of flying parts, and escaping process medium could prove harmful to health.

Elastomer seals in KF connections (e.g. O-rings) are not resistant to pressures > 2500 hPa. This

could prove harmful to health due to escaping process medium.

►Do not open any tensioning pieces when overpressure is prevalent in the vacuum system.

►Use suitable tensioning pieces for overpressure.

►Use tensioning pieces which can only be opened and closed using a tool (e.g. tightening strap-

circlip).

►Use sealing rings with an outer centering ring.

WARNING

Danger from magnetic fields

The product has a magnetic field that disturbs or impairs the function of electronic devices (e.g. pace-

makers).

►Maintain the distances specified by the manufacturer of the pacemakers.

–Pfeiffer Vacuum recommends a safety distance of at least 130 mm between the pacemaker

and the product.

►Avoid the influence of strong magnetic fields by means of magnetic field shielding.

NOTICE

Impairment from contamination and damage

Touching the devices or components with bare hands increases the desorption rate and leads to in-

correct measurements. Dirt (e.g. dust, fingerprints, etc.) and damage impair the function.

►When working on high or ultra high vacuum systems, always wear clean, lint-free and powder-

free laboratory gloves.

►Only use clean tools.

►Make sure that the connection flanges are free of grease.

►Remove protective caps and protective covers from flanges and connections only when necessa-

ry.

►Carry out all work in a well lit area.

Installation

17/50

NOTICE

Electric flashover from helium

Helium can cause electric flashovers in the unit’s electronics which will destroy the electronics.

►Switch off the unit before carrying out a leak test.

►Remove the electronic unit before carrying out a leak test.

Prerequisites

●Appropriate ambient conditions

●Operating temperature within permissible range

●Adequate room available for electrical connection (e.g. permissible bending radii for cables)

42

1

3

Fig. 3: Establishing vacuum connection

1 Magnetic unit 3 Small flange components

2 Tensioning piece 4 Protective cap

Recommendations

►Ensure where possible that the gauge is not exposed to any vibrations during operation, as vibra-

tions in general will lead to deviations in the measured values.

►Mount the gauge in a horizontal to upright mounting orientation (flange facing downwards).

–This prevents condensate and particles from accumulating in the measurement chamber.

►Fit a seal with centering ring and filter for applications susceptible to pollution and to protect the

measuring system against contamination.

►Ensure that both trimming potentiometers of the gauge can be easily accessed with a screwdriver

once fitted.

►Remove the magnetic unit of the gauge temporarily wherever installation is only possible with the

magnetic unit removed.

–This will facilitate assembly of the CF flange connection.

Procedure

1. Remove the protective cap and store in a safe place.

2. Assemble the gauge with vacuum components from the Pfeiffer Vacuum Components Shop on

the vacuum system.

5.2 Removing/installing magnetic unit

WARNING

Danger from magnetic fields

The product has a magnetic field that disturbs or impairs the function of electronic devices (e.g. pace-

makers).

►Maintain the distances specified by the manufacturer of the pacemakers.

–Pfeiffer Vacuum recommends a safety distance of at least 130 mm between the pacemaker

and the product.

►Avoid the influence of strong magnetic fields by means of magnetic field shielding.

Installation

18/50

NOTICE

Impairment from contamination and damage

Touching the devices or components with bare hands increases the desorption rate and leads to in-

correct measurements. Dirt (e.g. dust, fingerprints, etc.) and damage impair the function.

►When working on high or ultra high vacuum systems, always wear clean, lint-free and powder-

free laboratory gloves.

►Only use clean tools.

►Make sure that the connection flanges are free of grease.

►Remove protective caps and protective covers from flanges and connections only when necessa-

ry.

►Carry out all work in a well lit area.

Remove the magnetic unit to facilitate installation of the gauge.

Required tools

●Allen key, WAF 1.5

●Open-end wrench, WAF 7

5

1

4

2

3

Fig. 4: Removing/installing magnetic unit

1 Measurement chamber 4 Electronic unit

2 Hexagon head set screw 5 Grub screw

3 Magnetic unit

Removing the magnetic unit

1. Loosen the grub screw on the side of the electronic unit.

2. Remove the electronic unit without exerting any rotary movement.

3. Loosen the hexagon head screw on the magnetic unit.

4. Remove the magnetic unit.

–Separation of the magnetic unit and measurement chamber is made more difficult due to the

effect of magnetic force and the tendency for them to tilt easily.

Installing magnetic unit

1. Fit the magnetic unit.

–Fitting of the magnetic unit is made more difficult due to the effect of magnetic force and the

tendency for it to tilt easily.

2. Fasten the hexagon head set screw on the magnetic unit.

3. Carefully fit the electronic unit.

–The male connector of the Pirani element must engage in the corresponding opening of the

electronic unit.

4. Push the electronic unit as far as the limit stop.

5. Secure the grub screw on the side of the electronic unit.

Installation

19/50

5.3 Establishing electric connection

DANGER

Danger to life due to dangerous contact voltage

Voltages above 30 V (AC) or 60 V (DC) are considered dangerous in accordance with EN 61010. If

you come into contact with dangerous contact voltage, this can result in injury through electric shocks

or even death.

►Only connect the product to devices which meet the following criteria:

●Requirements of the earthed protective extra-low voltage (PELV)

●Limited power source (LPS) Class 2

►Secure the line to the product.

–Pfeiffer Vacuum measuring and control equipment complies with this requirement.

NOTICE

Damage sustained as a result of improper connection

Improper connection, incorrect polarity or impermissible supply voltage will damage the gauge.

►Always connect the supply earth (Pin 5) with the earth for the supply unit.

►Always connect the shielding (Pin 6) with the earth for the supply unit.

Required tools

●Crosshead screwdriver

●Torque wrench (≤ 0.2 Nm)

Required materials

●Measurement cable for a Pfeiffer vacuum total pressure measuring and control unit from the Ac-

tiveLine accessories

●Self-fabricated measurement cable for an evaluation unit provided by the customer

●Hirschmann cable socket

Establishing the electric connection

1. Connect the measurement cable to the gauge.

2. Tighten the locking screw on the Hirschmann cable socket.

–Tightening torque: ≤ 0.2 Nm

3. Connect the gauge to a Pfeiffer Vacuum total pressure measuring and control unit, or to an evalu-

ation unit provided by the customer.

10

Ω

Ident

2

3

1

4

5

6

V–

+

–

+

10

Ω

10k

Ω

Fig. 5: Connection diagram

1 Identification 4 Supply

2 Measuring signal 5 Supply ground (GND)

3 Signal ground 6 Screening

Installation

20/50

Table of contents

Other Preiffer Industrial Equipment manuals