Pressura RPM10 Operation manual

PRESSURA™

ROOM PRESSURE MONITOR

MODEL RPM10 AND RPM20

OPERATION AND SERVICE MANUAL

P/N 6006644, REVISION C

JANUARY 2015

PRESSURA™

ROOM PRESSURE CONTROLLER

MODEL RPM10 AND RPM20

OPERATION AND SERVICE MANUAL

P/N 6006644, REVISION C

JANUARY 2015

U.S. AND CANADA OTHER COUNTRIES

Sales & Customer Service: Sales & Customer Service:

(800) 874-2811/(651) 490-2811 (001 651) 490-2811

Fax: Fax:

(651) 490-3824 (001 651) 490-3824

SHIP/MAIL TO: E-MAIL

ATTN: Customer Service

500 Cardigan Road WEB SITE

Shoreview, MN 55126 www.tsi.com

USA

i

Copyright TSI Incorporated / 2013-2015 / All rights reserved.

Part number 6006644 / January 2015

Limitation of Warranty and Liability (effective April 2014)

(For country-specific terms and conditions outside of the USA, please visit www.tsi.com.)

Seller warrants the goods, excluding software, sold hereunder, under normal use and service as described in

the operator's manual, to be free from defects in workmanship and material for 24 months, or if less, the

length of time specified in the operator's manual, from the date of shipment to the customer. This warranty

period is inclusive of any statutory warranty. This limited warranty is subject to the following exclusions and

exceptions:

a. Hot-wire or hot-film sensors used with research anemometers, and certain other components when

indicated in specifications, are warranted for 90 days from the date of shipment;

b. Pumps are warranted for hours of operation as set forth in product or operator’s manuals;

c. Parts repaired or replaced as a result of repair services are warranted to be free from defects in

workmanship and material, under normal use, for 90 days from the date of shipment;

d. Seller does not provide any warranty on finished goods manufactured by others or on any fuses, batteries or

other consumable materials. Only the original manufacturer's warranty applies;

e. This warranty does not cover calibration requirements, and seller warrants only that the instrument or

product is properly calibrated at the time of its manufacture. Instruments returned for calibration are not

covered by this warranty;

f. This warranty is VOID if the instrument is opened by anyone other than a factory authorized service center

with the one exception where requirements set forth in the manual allow an operator to replace

consumables or perform recommended cleaning;

g. This warranty is VOID if the product has been misused, neglected, subjected to accidental or intentional

damage, or is not properly installed, maintained, or cleaned according to the requirements of the manual.

Unless specifically authorized in a separate writing by Seller, Seller makes no warranty with respect to, and

shall have no liability in connection with, goods which are incorporated into other products or equipment, or

which are modified by any person other than Seller.

The foregoing is IN LIEU OF all other warranties and is subject to the LIMITATIONS stated herein. NO OTHER

EXPRESS OR IMPLIED WARRANTY OF FITNESS FOR PARTICULAR PURPOSE OR MERCHANTABILITY

IS MADE. WITH RESPECT TO SELLER’S BREACH OF THE IMPLIED WARRANTY AGAINST

INFRINGEMENT, SAID WARRANTY IS LIMITED TO CLAIMS OF DIRECT INFRINGEMENT AND

EXCLUDES CLAIMS OF CONTRIBUTORY OR INDUCED INFRINGEMENTS. BUYER’S EXCLUSIVE

REMEDY SHALL BE THE RETURN OF THE PURCHASE PRICE DISCOUNTED FOR REASONABLE WEAR

AND TEAR OR AT SELLER’S OPTION REPLACEMENT OF THE GOODS WITH NON-INFRINGING

GOODS.

TO THE EXTENT PERMITTED BY LAW, THE EXCLUSIVE REMEDY OF THE USER OR BUYER, AND

THE LIMIT OF SELLER'S LIABILITY FOR ANY AND ALL LOSSES, INJURIES, OR DAMAGES

CONCERNING THE GOODS (INCLUDING CLAIMS BASED ON CONTRACT, NEGLIGENCE, TORT,

STRICT LIABILITY OR OTHERWISE) SHALL BE THE RETURN OF GOODS TO SELLER AND THE

REFUND OF THE PURCHASE PRICE, OR, AT THE OPTION OF SELLER, THE REPAIR OR

REPLACEMENT OF THE GOODS. IN THE CASE OF SOFTWARE, SELLER WILL REPAIR OR REPLACE

DEFECTIVE SOFTWARE OR IF UNABLE TO DO SO, WILL REFUND THE PURCHASE PRICE OF THE

SOFTWARE. IN NO EVENT SHALL SELLER BE LIABLE FOR LOST PROFITS, BUSINESS

INTERRUPTION, OR ANY SPECIAL, INDIRECT, CONSEQUENTIAL OR INCIDENTAL DAMAGES.

SELLER SHALL NOT BE RESPONSIBLE FOR INSTALLATION, DISMANTLING OR REINSTALLATION

COSTS OR CHARGES. No Action, regardless of form, may be brought against Seller more than 12 months

after a cause of action has accrued. The goods returned under warranty to Seller's factory shall be at Buyer's

risk of loss, and will be returned, if at all, at Seller's risk of loss.

Buyer and all users are deemed to have accepted this LIMITATION OF WARRANTY AND LIABILITY, which

contains the complete and exclusive limited warranty of Seller. This LIMITATION OF WARRANTY AND

LIABILITY may not be amended, modified or its terms waived, except by writing signed by an Officer of Seller.

ii

Service Policy

Knowing that inoperative or defective instruments are as detrimental to TSI as they are to our customers, our

service policy is designed to give prompt attention to any problems. If any malfunction is discovered, please

contact your nearest sales office or representative, or call TSI's Customer Service department at (800) 874-

2811 or (651) 490-2811.

Trademarks

TSI and TSI logo are registered trademarks of TSI Incorporated. PresSura is a trademark of TSI

Incorporated. BACnet is a trademark of ASHRAE. Modbus is a registered trademark of Modicon, Inc.

LonWorks is a registered trademark of Echelon®Corporation.

iii

CONTENTS

HOW TO USE THIS MANUAL ......................................................................................................1

Safety Information ................................................................................................1

Description of Caution Symbol..........................................................................1

Access Code / Passcode..................................................................................1

PART ONE.....................................................................................................................................3

User Basics ..........................................................................................................3

The Instrument .....................................................................................................3

Useful User Information ....................................................................................3

Operator Panel.....................................................................................................3

Display Screen..................................................................................................4

Room Indicator Colors ......................................................................................4

Operator Keys...................................................................................................4

USB Port ...........................................................................................................5

Alarms...................................................................................................................5

Visual Alarm......................................................................................................5

Audible Alarms..................................................................................................5

Alarm Relays.....................................................................................................6

Before Calling TSI ................................................................................................6

PART TWO.....................................................................................................................................7

Technical Section.................................................................................................7

Software Programming.........................................................................................8

Changing Room Mode......................................................................................8

Entering Menus.................................................................................................9

Menus and Menu Items.....................................................................................9

Entering Data ....................................................................................................9

Programming Example....................................................................................11

Menu and Menu Items........................................................................................12

Configure Menu...............................................................................................15

ALARM CONSTRAINTS.................................................................................25

Alarm Config Menu .........................................................................................27

Interface Menu ................................................................................................28

Diagnostics Menu............................................................................................33

Calibration ..........................................................................................................59

Room Pressure Calibration.............................................................................59

Flow Calibration...............................................................................................60

Maintenance and Repair Parts...........................................................................63

System Component Inspection.......................................................................63

Pressure Sensor Cleaning..............................................................................64

Display Screen Cleaning.................................................................................64

Replacement Parts..........................................................................................64

Troubleshooting Section.....................................................................................64

Hardware Test.................................................................................................65

Troubleshooting Chart.....................................................................................67

iv

APPENDIX A................................................................................................................................71

Specifications*....................................................................................................71

APPENDIX B................................................................................................................................73

Network Communications ..................................................................................73

Modbus®Communications.................................................................................73

Unique to TSI ..................................................................................................73

Network Points RAM Variables.......................................................................74

XRAM Variables..............................................................................................75

RPM10 Variable List .......................................................................................75

RPM20 Variable List .......................................................................................77

RPM20 Variable List .......................................................................................80

RPM20 Variable List .......................................................................................81

LonWorks®Object..............................................................................................83

Node Object Network Variables......................................................................83

Room Pressure Monitor Object Network Variables........................................83

Description of LON SNVTs .............................................................................84

Model RPM10 and RPM20 BACnet®MS/TP Protocol Implementation

Conformance Statement ....................................................................................85

BACnet®MS/TP Object Set................................................................................88

RPM10 PresSura Monitor...............................................................................88

RPM20 PresSura Monitor...............................................................................90

APPENDIX C................................................................................................................................95

Wiring Information ..............................................................................................95

Back Panel Wiring...........................................................................................95

APPENDIX D..............................................................................................................................107

Access Codes / Passcode................................................................................107

1

How to Use This Manual

The Operation and Service Manual describes how to operate, configure, calibrate, maintain and

troubleshoot the Model RPM10 and RPM20 Room Monitors. The manual is divided into two

parts. Part one describes the unit and how to interface with the device. This section should be

read by users, facilities staff, and anyone who requires a basic understanding of how the device

operates.

Part two describes the technical aspects of the product which include operation, configuration,

calibration, maintenance and troubleshooting. Part two should be read by personnel

programming or maintaining the unit. TSI recommends thoroughly reading this manual

before changing any software items.

NOTE: This operation and service manual assumes that the monitor has been properly installed.

Refer to the Installation Instructions if there is any question as to whether the monitor has

been installed properly.

Safety Information

This section gives instructions to promote safe and proper handling of Model RPM10 and RPM20

Room Monitors.

There are no user-serviceable parts inside the instrument. Opening the instrument case will void

the warranty. Refer all service of the unit to a qualified technician.

Description of Caution Symbol

C a u t i o n

Caution indicates:

Equipment may be damaged if procedures are not followed.

Improper settings may result in loss of containment.

Important information about unit operation.

Access Code / Passcode

Model RPM10 and RPM20 Room Monitors have access codes to limit unauthorized access to

the room mode or complete menu system. The access codes can be turned on or off through the

Passcode menu item. When the units ship from TSI, they are configured with the access code

off. Refer to Appendix D, Passcode, for instructions on entering the access code.

2

(This page intentionally left blank)

User Basics 3

Part One

User Basics

This section is designed to provide a brief but thorough overview of the product installed. These

few pages explain the purpose (The Instrument) and the operation (Useful user information,

Operator panel, Alarms) of the product. Technical product information is available in Part Two of

the manual.

The Instrument

The Model RPM10 and RPM20 Monitors are designed to measure and report room pressure

differential in health-care facilities and other critical environments. They also can measure other

parameters, such as supply flow, exhaust flow, relative humidity, and room temperature.

Useful User Information

The display of the monitor is colored gray, green, or red. Green indicates the room pressure

differential and other configured measurements are adequate. The display turns red to indicate

alarm status when the room pressure differential or another configured measurement has risen

above or dropped below a safe level. The display provides additional information depending on

the configuration of the unit. Gray indicates that the room is in no isolation mode and will not

alarm if room pressure differential is not maintained.

Operator Panel

The Model RPM10 and RPM20 Room Monitors are easy to use. Normal vs. alarm condition and

room modes are always shown on the display. In addition, the displayed can be configured to

show the room pressure differential or all measurements. Specific details about the front panel

display and controls are described on the following pages. The front panel, shown in Figure 1 and

Figure 2 identifies the important features on the display:

Figure 1. Single Room Screen

4 Part One

Figure 2. Two Room Screen

Display Screen

The LCD display is highly configurable and can display various critical information including

pressure differential, flow rate, alarm status, menu options, and error messages. In addition, the

LCD display is used for programming the unit. When programming the unit, the display will show

menus, menu items, and current value of the menu item, depending on the specific programming

function being performed.

Room Indicator Colors

Green

The screen icon is colored green (NORMAL) when the room pressure and/or other

configured measurements are adequate. This light indicates the room is operating

safely. If a set point cannot be maintained or an alarm limit has been reached, the

green light turns off and the red alarm light turns on.

Red

The room icon is colored red (ALARM) when the room pressure and/or other

configured measurements are not within alarm limits. This light indicates the room is

not operating safely. The display screen will also indicate the type of alarm or an

emergency message.

Gray

The room icon is colored gray to indicate No Isolation mode. In No Isolation mode

the Model RPM10 and RPM20 will not alarm.

Operator Keys

The following keys appear on the display of the Model RPM10 and RPM20 room monitor:

MUTE key

The MUTE key silences an audible alarm. The alarm remains silent until the

MUTE TIME value has been reached or the unit returns to control set point.

ACKNOWLEDGE key

The ACKNOWLEDGE key clears alarms when the Model RPM10 and RPM20

have been set latched alarms under the ALARM RESET item.

User Basics 5

USB Port

There is a USB port on the case. This USB port can be used with TSI’s Configuration Software.

Figure 3. USB Port Location

Alarms

The Model RPM10 and RPM20 monitors have visual (red light) and audible alarms to inform you

of changing room conditions. The alarm levels (set points) are determined by facilities staff, which

could be Engineering, Industrial Hygiene, or a facilities group depending on how the safety staff

is organized.

The audible and visual alarms will activate whenever the field configured alarm level is reached.

The alarms will activate if the room pressure differential is low or inadequate, high or too great, or

when the airflow is too low or too high (need optional flow device installed). When the room is

operating safely, no alarms will sound.

Example: The low alarm is preset to activate when the room pressure differential falls below -

0.01 in H2O (closer to neutral). When the room pressure drops to -0.005 in H2O, for

example, the audible and visual alarms activate. The alarms turn off (when set to

unlatched) when the unit returns to the safe range, which is defined as 0.001 in H2O

greater than alarm set point (-0.01 in H2O).

Visual Alarm

The display of the monitor turns red to indicate an alarm condition. The icon turns continuously

red for all alarm conditions.

Audible Alarms

The audible alarm is continuously on in all low and high alarm conditions. The audible alarm can

be silenced by pressing the key.

If the audible alarm has been muted, the alarm is silenced for a configurable period of time (see

menu item MUTE TIME) or the measurement returns to the safe range. The safe range is

0.001 in H2O (50 cfm) above the low alarm set point and 0.001 in H2O (50 cfm) below the high

alarm set point.

6 Part One

The audible and visual alarms can be programmed to either automatically turn off when the unit

returns to the safe range or to stay in alarm until the key is pressed (See menu item

ALARM RESET).

Alarm Relays

The PresSura monitors feature 2 alarm relays. The alarm relays can be field configured to either

open or close to indicate an alarm condition, although they will close on loss of power.

Relay 1 functions as the low alarm relay, and will activate after the alarm delay for low pressure,

low flow, low temperature and low RH alarms. Relay 1 will trigger without waiting for the alarm

delay to indicate a LOM alarm, or low pressure drop across a venturi valve, if a flow input is

configured for venturi valves.

Relay 2 is field-configurable to function as a high alarm relay or to indicate the room status. Refer

to the Relay 2 Out item in the Alarm Config menu for details on this operation.

Before Calling TSI

This manual should answer most questions and resolve most problems you may encounter. If

you need assistance or further explanation, contact your local TSI representative or TSI. TSI is

committed to providing high quality products backed by outstanding service.

Please have the following information available prior to contacting your authorized TSI

Manufacturer’s Representative or TSI:

- Model number of unit* RPM10 and RPM20

- Type of room pressure sensor (TSI Through-the-wall sensor or pressure transducer)

- Software revision level*

- Facility where unit is installed

* Can be determined by entering the Diagnostics menu.

Due to the different configurations of the Model RPM10 and RPM20 monitor available, the above

information is needed to accurately answer your questions.

For the name of your local TSI representative or to talk to TSI service personnel, please call TSI

at (800) 874-2811 (U.S. and Canada) or (001 651) 490-2811 (other countries).

Prior to shipping any components to TSI for service or repair, please utilize our convenient

Return Material Authorization (RMA) Form, which is available online at

https://secure.tsi.com/rma/intro.aspx.

Technical Section 7

Part Two

Technical Section

The PresSura™Room Pressure Monitor is

ready to use after being properly installed and

configured. The TSI through-the-wall sensor is

factory calibrated, as are most pressure

transducers. Figure 4 shows the Digital Interface

Module (DIM) which is programmed with a

default configuration that can be easily modified

to fit your application.

The technical section is separated into five parts

that cover all aspects of the unit. Each section is

written as independently as possible to minimize

flipping back and forth through the manual for

an answer.

Figure 4. PresSura Room Pressure Monitor

The Software Programming section explains the programming keys on the DIM. In addition, the

programming sequence is described, which is the same regardless of the menu item being

changed. At the end of this section is an example of how to program the DIM.

The Menu and Menu Items section lists all of the software items available to program and

change. The items are grouped by menu which means all set points are in one menu, control

signal items in another, etc. The menu items and all related information is provided including;

programming name, description of menu item, range of programmable values, and how the unit

shipped from the factory (default value).

The Calibration section describes the required procedure to calibrate the controller. This section

explains how to compare the controller’s reading to a portable thermal anemometer and then

adjust the span to establish an accurate calibration. This section also describes how to zero a

TSI flow station transducer (if installed).

The Maintenance and Repair Parts section covers all routine maintenance of equipment, along

with a list of repair parts.

The Troubleshooting section is split into two areas: mechanical operation of the unit and system

performance. Many external variables will affect how the unit functions so it is critical to first

determine if the system is having mechanical problems—i.e., no display on unit, alarms do not

function, , etc. If no mechanical problems exist, look for performance problems (i.e., does not

seem to read correctly, display fluctuates, etc.). The first step is to determine that the system is

mechanically operating correctly, followed by modifying the configuration to eliminate the

performance problems.

8 Part Two

Software Programming

Programming the PresSura Model RPM10/RPM20 monitor is quick and easy if the proper

keystroke procedure is followed. The programming keys are defined first, followed by the

required keystroke procedure. At the end of this section is a programming example.

NOTE: It is important to note that the unit is always operating when programming. When a menu

item value is changed, the new value takes effect immediately after saving the change,

not when the unit returns to normal operating mode.

This section covers programming the instrument through the keypad and display. If

programming through network communications (see Appendix B), use the host

computer’s procedure. The changes take place immediately upon saving data in the

instrument.

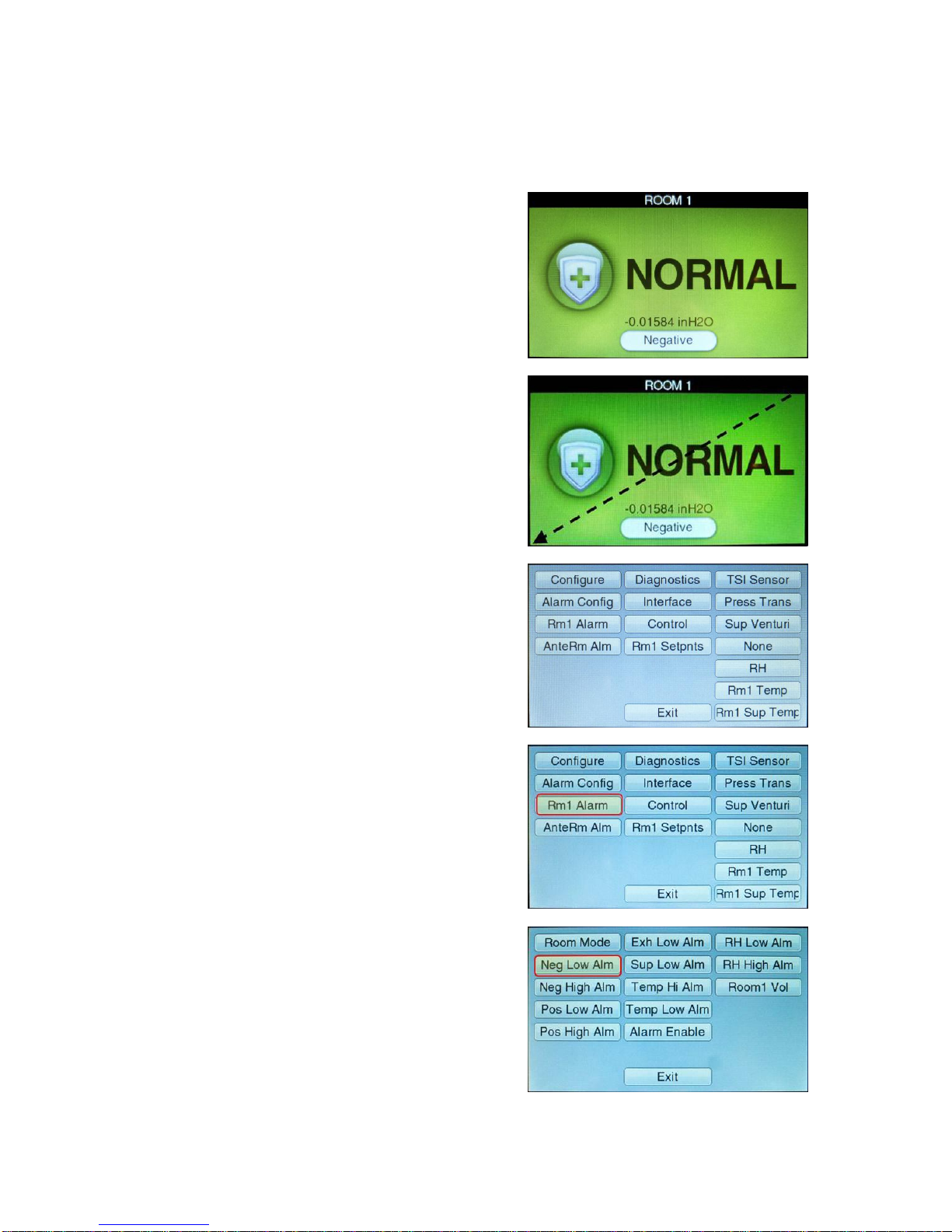

Changing Room Mode

1. Press the Room Mode button for the room on the touchscreen.

Figure 5. Main Running Screen

2. Select the desired room mode by pressing on the desired room mode button at the bottom of

the screen.

NOTE: If a room mode is not selected, the PresSura monitor will return to the main running

screen after a short delay,

Figure 6. Room Mode Selection Screen

Technical Section 9

Entering Menus

Swipe across the display, from the top right corner to the bottom left corner, to access the

menu system.

Figure 7. Swipe to access menu system

Menus and Menu Items

After accessing a menu, the screen will change to show the items associated with that menu.

Refer to the Menu and Menu Items section for a list of the menus and their associated items.

Entering Data

After entering a menu item, the Model RPM10/RPM20 monitor display will change to select items.

Some items have pre-defined choices selected through a drop-down menu; others allow numeric

setpoints. Not all menus will be available on all models.

Figure 8. Menu System

10 Part Two

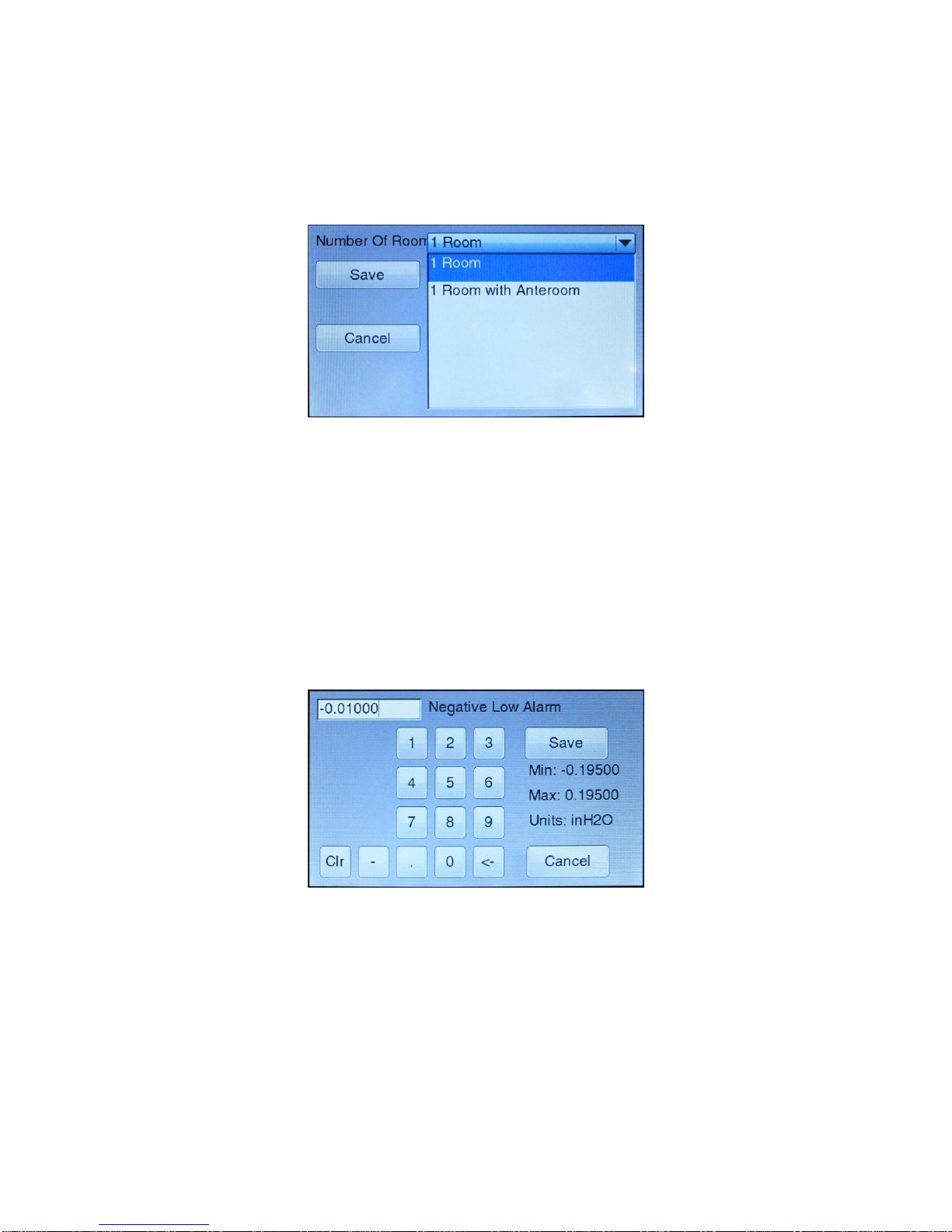

Drop-Down Selection

It is easy to view available choices and make a selection from drop-down items. Touch the item

displayed in the drop-down box to view all available options. Then, touch the item desired. Touch

the Save button to save your selection and exit the item or touch the Cancel button to exit the

item without saving.

Figure 9. Using a Drop-Down Selection

Numeric Setpoints

It is easy to enter new numeric setpoints on the PresSura Model RPM10/RPM20 monitor. On a

numeric setpoint screen, the current setpoint is displayed in a box at the top left of the screen.

Use the numeric keypad to enter a new setpoint.

The value entered must be between the min and max listed on-screen.

The measurement units are displayed as units. The <- button deletes the last digit.

The Clr button clears the entire setpoint.

The Save button saves your selection and exits the item.

The Cancel button exits the item without saving changes.

Figure 10. Entering Numeric Setpoints

Technical Section 11

Programming Example

The following example demonstrates the keystroke sequence. In this example the negative low

alarm set point for Room 1 will be changed from -0.01000 in H2O to -0.01300 in H2O.

Unit is in normal operation.

Swipe from the top right corner to the

bottom left corner to access the menu

system.

The menu screen is displayed.

Select the Rm1 Alarm menu.

Select the Neg Low Alm item.

12 Part Two

Enter the new setpoint of -

0.01300 in H2O. Save the new setting.

Touch the Exit button in the Rm1 Alarm menu and again in the main menu to

return to the main running screen.

Menu and Menu Items

The PresSura Model RPM10 and RPM20 monitors are very versatile devices which can be

configured to meet your specific application. This section lists all of the menu items available to

program and change (except diagnostics menu). Changing items is accomplished by using the

touchscreen or through communications with the Building Automation System. If you are

unfamiliar with the keystroke procedure please see Software Programming section for a detailed

explanation. This section provides the following information:

Complete list of menus and all menu items.

Gives the menu or programming name.

Defines each menu item’s function; what it does, how it does it, etc.

Gives the range of values that can be programmed.

Gives default item value (how it shipped from factory).

The menus covered in this section are divided into groups of related items to ease programming.

As an example all set points are in one menu, alarm information in another, etc. The manual

follows the menus as programmed in the controller. The menu items are always grouped by

menu and then listed in menu item order, not alphabetical order.

Figure 11 and Figure 12 show the PresSura Model RPM10 and RPM20 monitor menu items.

Other manuals for RPM10

1

This manual suits for next models

1

Table of contents