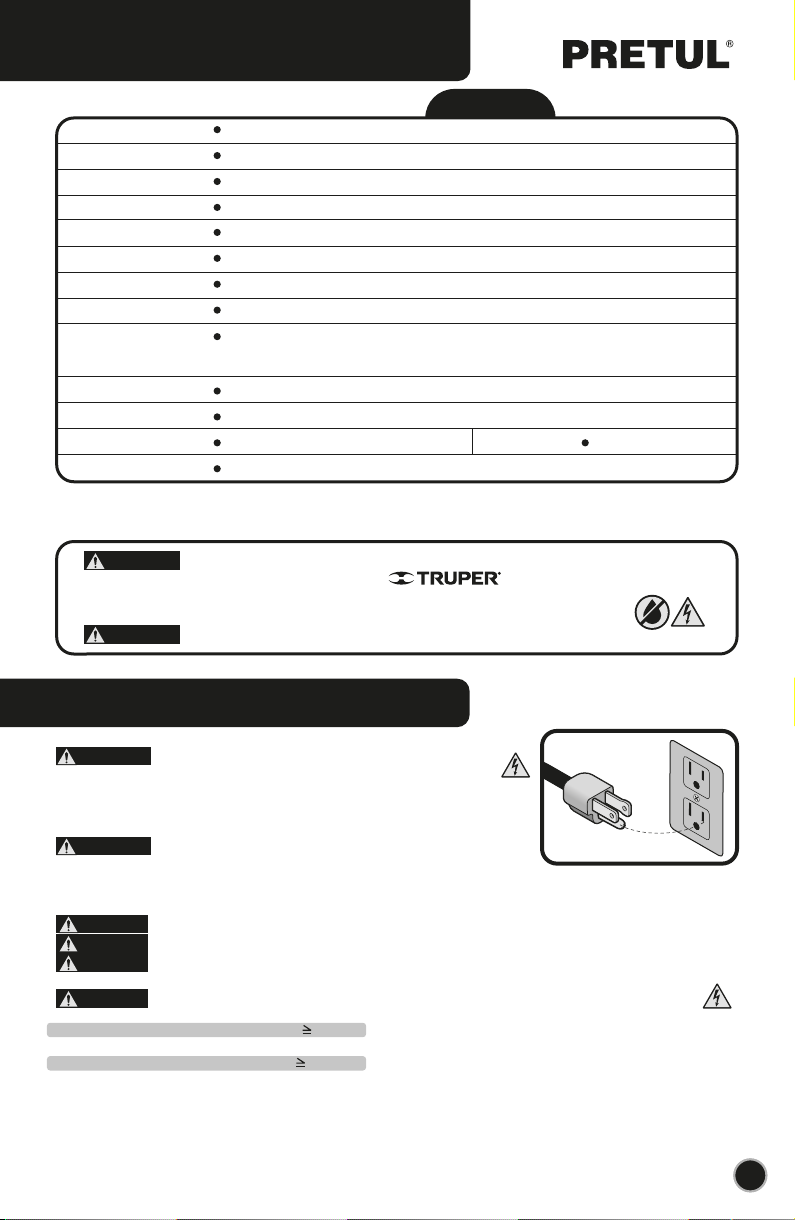

PRETUL SOIN-130P User manual

ModelCode

SOIN-130P

Applies for:

27225

40%

Manual

Inverter Welder Work Cycle

CAUTION Read this manual thoroughly

before using the tool.

INGLÉS

ESPAÑOL

Use and care recommendations

Perform periodic MAINTENANCE to your machine. (Page 11)

The tool has a THERMAL PROTECTOR that in case of overheating

turns the welder off and a LED light turns on. If this happens, let the

welder cool for 15 minutes and turn it back on.

It is recommended to use a 10 AWG (5.26 mm2)extension cord and connect it to an

INDEPENDENT CHARGING CENTER.

2ENGLISH

Contents

CAUTION

Keep this manual for future references.

The illustrations in this manual are for reference

only. They might be different from the real tool.

To gain the best performance of

the tool, prolong the duty life,

make the Warranty valid if

necessary, and to avoid hazards

of fatal injuries please read and

understand this Manual before

using the tool.

Technical specifications

Power Requirements

General Power Tools Safety Warnings

Safety Warnings for Inverter Welders

Parts

Installation (SMAW)

Installation (TIG)

Start Up

Maintenance

Troubleshooting

Notes

Authorized Service Centers

Warranty Policy

3

3

4

5

6

7

8

9

11

11

12

13

14

33

Technical specifications

ENGLISH

Power Requirements

Power cord grips: Type “Y”.

Build quality: Basic insulation.

Thermal insulation on motor winding: Class H

27225

Código

Descripción

SOIN-130P

Rated Input Capacity

Input Voltage

Current Range 20 A - 130 A

Max No Load Voltage 69 V~

Power Factor Cos 0.73

Inverter Welder

127 V~/ 50 Hz / 60 Hz

3/32” - 1/8” - 5/32” - 3/32”

Electrode

IP21S

IP Grade

11.4” x 4.3” x 9”

Dimension

40%

4 minutes’ work per 6 minutes’ rest.

This duty cycle is for use at a temperature of 20 ºC (68 °F), for higher temperatures the working time must be reduced

Rated Duty Cycle

Insulation Class I

12 AWG x 3C with 221 °F insulation temperature

Conductors

WARNING

WARNING Avoid the risk of electric shock or severe injury. When the power cable gets damaged

it should only be replaced by the manufacturer or at a Authorized Service Center.

The build quality of the electric insulation is altered if spills or liquid gets into the tool while in use.

Do not expose to rain, liquids and/or dampness.

Before gaining access to the terminals all power sources should be disconnected.

4.7 kVA

Current 37 A

If faults or breakdowns happen. Ground connection offers a

trajectory with minimum resistance for electric power. It reduces the risk of electric

shock. This tool is built with a power cable with an earth conductor and a plug with

ground connection. The plug shall be connected into a power outlet installed and

grounded according to all local codes.

Do not modify the plug supplied. If the plug cannot be fitted

to the socket, have a qualified electrician to install the suitable socket.

• When using the welder together with more tools using the same ground connect those in parallel, never connect a

series.

• The gauge of the ground conductor cable shall not be of a smaller gauge than the power supply cable.

• Connection to the power supply shall only be carried out by a professional electrician.

• Double check the input connection voltage stipulated in the welder nameplate matches the power

supply voltage.

• The power supply cord shall meet the following requisites:

CAUTION

CAUTION

CAUTION

* The current for fuse fusion is double of its rated current.

Switch

Fuse (Work Rated Current)

Electric Wire

30 A

30 A (*)

2.5 mm2

• If extensions between the welder and the work piece

are needed, the soldering cable gauge shall be increased

to keep the welder energy output with a potential drop

not higher than 4 V

CAUTION

WARNING

WARNING

4

General Power Tools

Safety Warnings

ENGLISH

Work area

Keep your work area clean, and well lit.

Cluttered and dark areas may cause accidents.

Never use the tool in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust.

Sparks generated by power tools may ignite the flammable material.

Keep children and bystanders at a safe distance while operating

the tool.

Distractions may cause loosing control.

Electrical Safety

The tool plug must match the power outlet. Never modify

the plug in any way. Do not use any adapter plugs with

grounded power tools.

Modified plugs and different power outlets increase the risk of electric shock.

Avoid body contact with grounded surfaces, such as pipes,

radiators, electric ranges and refrigerators.

The risk of electric shock increases if your body is grounded.

Do not expose the tool to rain or wet conditions.

Water entering into the tool increases the risk of electric shock.

Do not force the cord. Never use the cord to carry, lift or unplug

the tool. Keep the cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase the risk of electric shock.

When operating a tool outdoors, use an extension cord suitable

for outdoor use.

Using an adequate outdoor extension cord reduces the risk of electric shock.

If operating the tool in a damp location cannot be avoided, use

a ground fault circuit interrupter (GFCI) protected supply.

Using a GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common sense

when operating a tool. Do not use a power tool while you are

tired or under the influence of drugs, alcohol or medication.

A moment of distraction while operating the tool may result in personal injury.

Use personal protective equipment. Always wear eye

protection.

Protective equipment such as safety glasses, anti-dust mask, non-skid shoes,

hard hats and hearing protection used in the right conditions significantly

reduce personal injury.

Prevent unintentional starting up. Ensure the switch is in the

“OFF” position before connecting into the power source and /

or battery as well as when carrying the tool.

Transporting power tools with the finger on the switch or connecting power

tools with the switch in the “ON” position may cause accidents.

Remove any wrench or vice before turning the power tool on.

Wrenches or vices left attached to rotating parts of the tool may result in personal

injury.

Do not overreach. Keep proper footing and balance at all times.

This enables a better control on the tool during unexpected situations.

Dress properly. Do not wear loose clothing or jewelry. Keep

hair, clothes and gloves away from the moving parts.

Loose clothes or long hair may get caught in moving parts.

If you have dust extraction and recollection devices connected

onto the tool, inspect their connections and use them correctly.

Using these devices reduce dust-related risks.

Power Tools Use and Care

Do not force the tool. Use the adequate tool for your

application.

The correct tool delivers a better and safer job at the rate for which it was designed.

Do not use the tool if the switch is not working properly.

Any power tool that cannot be turned ON or OFF is dangerous and should be

repaired before operating.

Disconnect the tool from the power source and / or battery

before making any adjustments, changing accessories or

storing.

These measures reduce the risk of accidentally starting the tool.

Store tools out of the reach of children. Do not allow persons

that are not familiar with the tool or its instructions to

operate the tool.

Power tools are dangerous in the hands of untrained users.

Service the tool. Check the mobile parts are not misaligned or

stuck. There should not be broken parts or other conditions that

may affect its operation. Repair any damage before using the

tool.

Most accidents are caused due to poor maintenance to the tools.

Keep the cutting accessories sharp and clean.

Cutting accessories in good working conditions are less likely to bind and are

easier to control.

Use the tool, components and accessories in accordance with

these instructions and the projected way to use it for the type of

tool when in adequate working conditions.

Using the tool for applications different from those it was designed for, could

result in a hazardous situation.

Service

Repair the tool in a Authorized Service Center

using only identical spare parts.

This will ensure that the safety of the power tool is maintained.

WARNING! Read carefully all safety warnings and instructions listed below. Failure to comply with any of

these warnings may result in electric shock, fire and / or severe damage. Save all warnings and instructions for

future references.

This tool is in compliance with

the Official Mexican Standard

(NOM - Norma Oficial Mexicana).

5

• Wear a welding mask to protect eyes

and face when soldering. Assure the mask protective glass

shade is adequate for the soldering process to carry out.

• Wear leather gloves specially made for

welding as well as leather dungarees and gaiter.

• Wear robust clothing and long sleeves made of fire-resistant

materials such as wool or leather.

• Use special screens or curtains to insulate the work place from

passersby, to protect them from sparks, flares and slag originated by

the soldering process.

• Benches and work tables where work pieces shall rest, must have

orifices or slots that can easily let through residues originated by the

soldering process.

• Vapor and gases produced while soldering is

dangerous to your health. Work in well ventilated areas or with

adequate ventilation systems.

• Do not breath in smokes and gasses

emanated from the soldering process. Keep your head away

from vapors.

• If ventilation is poor use an adequate

autonomous breathing device because the gases generated

when soldering may displace air and cause a fatal accident.

• Do not operate the welder near de-greasing

agents, cleaning products or aerosol containers. Heat and

radiation from the welding process may react to those vapors

forming toxic gases.

• Avoid soldering metals covered in lead, zinc or

cadmium. Those materials generate toxic gases. Otherwise,

remove the covering from the welding area. Make sure the work

area is well ventilated or wear an adequate autonomous

breathing device.

Protection Equipment for Welding

CAUTION

CAUTION

CAUTION

WARNING

DANGER

ENGLISH

• Verify there is a safe connection for the input and

output cables. They shall be correctly insulated and the connections in

good repair (check and eliminate any possibility of electric shock).

• Double check the welder is plugged to a

reliable ground connection.

• Do not expose the welder to rain or humidity.

• The user shall be insulated from the work piece and

ground connection stepping onto insulating and dry mats.

• For any reason touch the two poles in the welder

circuit (welding stick and work piece).

• Do not try to adjust the welder current when

carrying out a soldering job.

• Connect the ground clamp to the work piece as

close as possible to the welding zone. This prevents the current to flow

long distances and eliminate the possibility of short circuit.

• The work piece shall make contact with the ground

connection clamp before operating the welder. Do not disconnect

until finishing welding because it can lead to an electric discharge and

severe injury.

• Disconnect the welder from the power supply

before carrying any maintenance jobs.

Prevent Electric Shock

• Have always handy a fire extinguisher in

good conditions.

• There shall not be flammable or explosive

materials in the work area (no less than 36’). Do not carry out

soldering jobs where the sparks can reach or fall onto

flammable or explosive materials.

Fire Prevention

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

DANGER

WARNING

WARNING

WARNING

WARNING

Prevent Health Risks

WARNING

WARNING

• Risks of electric shock:

An electric shock coming from the soldering electrode may

cause death. Do not weld under rain or snow. Do not touch the

electrode with your bare hands. Do not wear damp or damaged

gloves. Personal protection against electric shock: insulation from the

work piece. Do not open the equipment enclosure. Do not weld on

top of drums or any closed container.

• Soldering sparks may cause explosion

or fire.

• Risks generated by the welding arc:

Radiation coming out from the arc my burn eyes and damage skin.

Wear face mask and protection glasses. Wear hearing

protection and protective clothes that protect skin up to

the neck. Wear full-body protective clothes.

• Risk induced by electro-magnetic fields:

Welding current produces electro-magnetic fields. Do not

use this power source if having a medical implant. Never roll up the

welding cable around your body. Set together and parallel both

welding cables so the fields of each cable counteract.

• Do not use the welder power source to de-ice pipes.

• Never allow unexperienced people to dismount or

regulate the welder.

• Double check that the operator and the welder

are away from the sparks and residues trajectory originated by the

soldering process.

• The welder shall be operated in a place protected from sun and

rain. Away from places where violent vibrations are present.

• Store the welder in a place free of humidity with a range of

temperature from -13 °F to 131 °F

• There shall be a 11.8” space around the welding machine to allow

good ventilation.

• Double check no foreign metal piece is inside the

welder.

• Any problem with the welder that cannot be fixed

by the operator making the adjustments needed for a good welding

job shall be carry out in a Authorized Service

Center. For any reason try to open the welder housing to carry out

any type of maintenance.

• Compressed gas cylinders are widely used in

many welding processes. If not stored, handled, inspected and used

adequately compressed gas cylinders may be fatal. Can explode or

turn into missiles, drawing such force they can even break brick walls.

• Inspect the cylinders. Look for external corrosion,

indentation, lumps, holes of wells. If in doubt about any imperfection

observed is acceptable for those guidelines, stop using the cylinder.

Consult the gas safety page before using it.

• Many compressed gases not only represent a

physical hazard but also dangerous to your health. Be sure you learn

the danger to your health and how to be protected. Always follow the

use and handling caution measures provided in the safety page.

• Never set the cylinders next to heat or flame or

where they can be part of an electric circuit. Do not use them as a

source of ground during the electric welding process.

• Wear safety glasses and a protective mask when

connecting and disconnecting regulators and lines to the cylinder.

• Close the cylinder valve to release pressure before

removing the regulator and when not in use. Cylinders shall be

stored with a visible identification and with the protection valve cap

fitted.

Prevent Injuries and Accidents

Use of Compressed Gas Cylinders

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

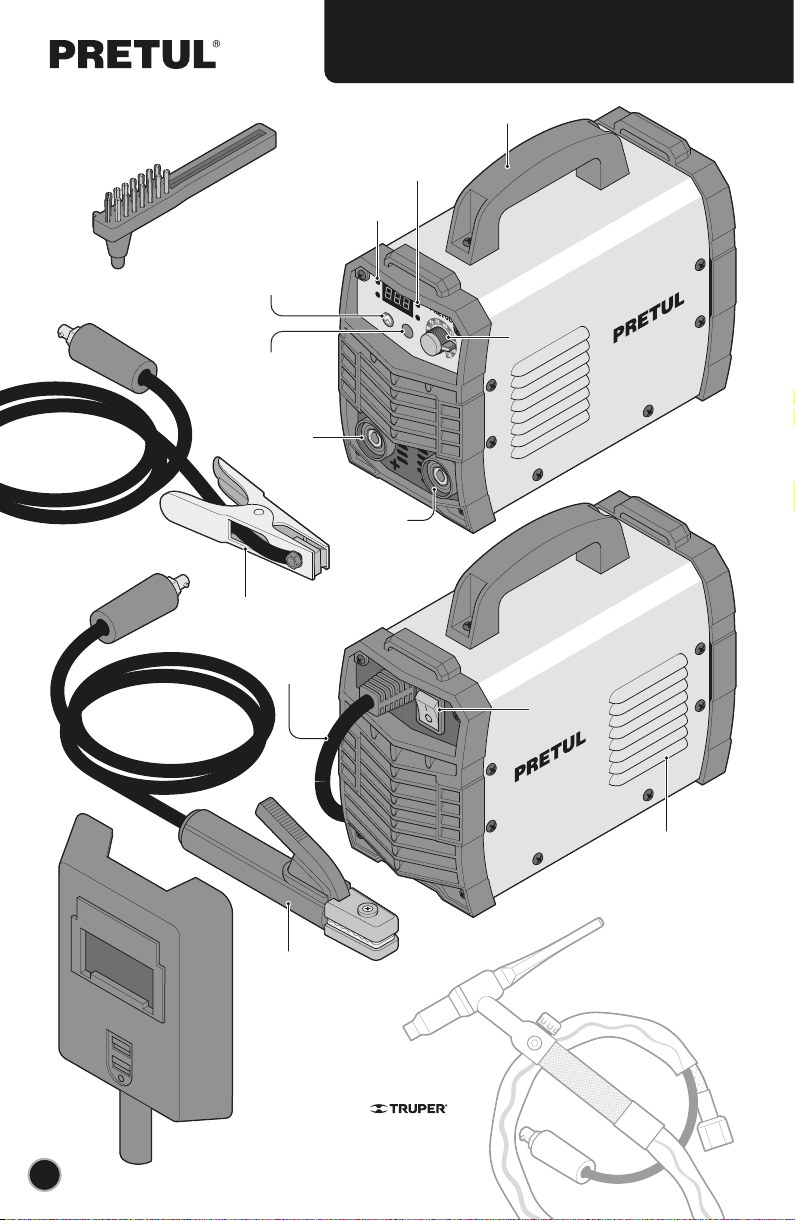

Safety Warnings for

Inverter Welders

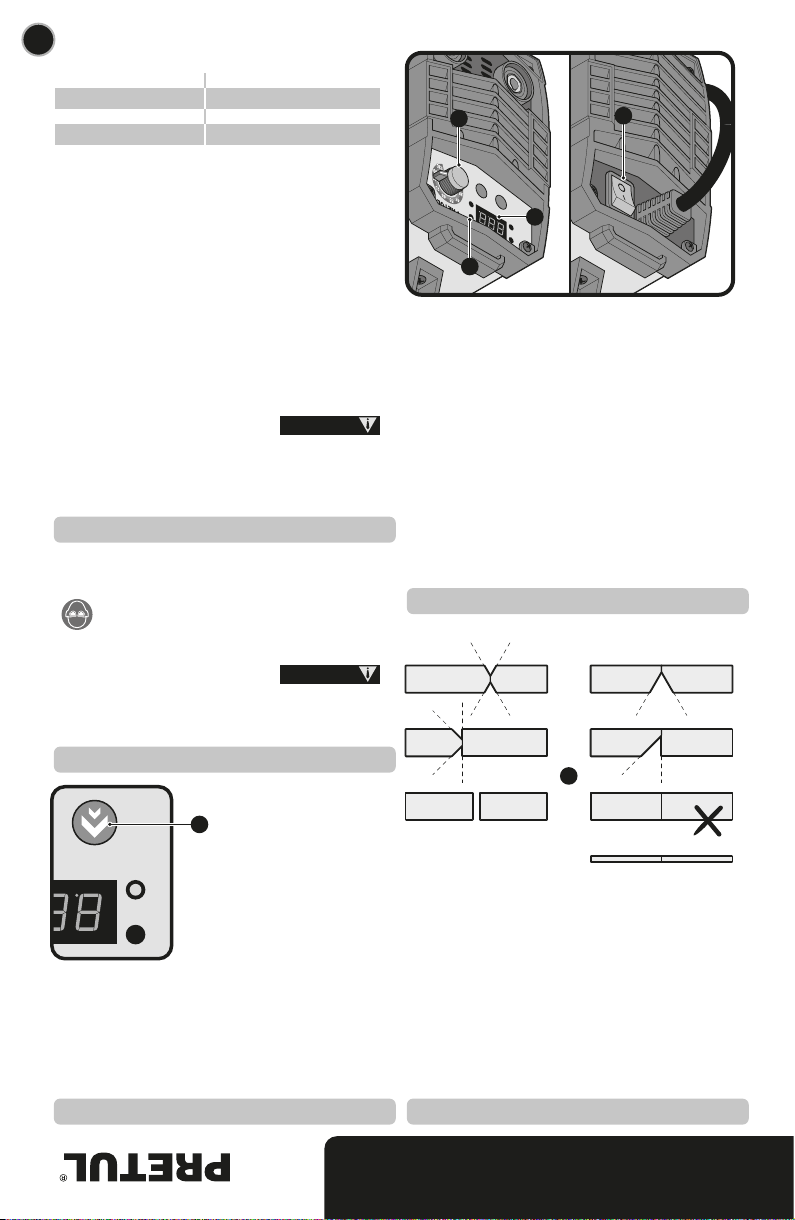

VRD Security

System

Current

Control

Welding

Process

Selector

(SMAW or TIG)

Positive

Connection ( + )

Negative

Connection (

-

)

Ventilation

Slots

Carrying

Handle

Power

Cord

Welding Process

Indicator Lights

ON

Lights

Switch

Electrode

Holder

6

Parts

TIG soldering torch

AN-SI-12/16/20

(not included)

To get better results use a Brand

cable set with soldering clamp CAB-200 and

TIG soldering torch AN-SI-12/16/20

ENGLISH

Protective

Mask

Hammer-Brush

for Slag Removal

Grounding

Clamp to the

Work Piece

D

7

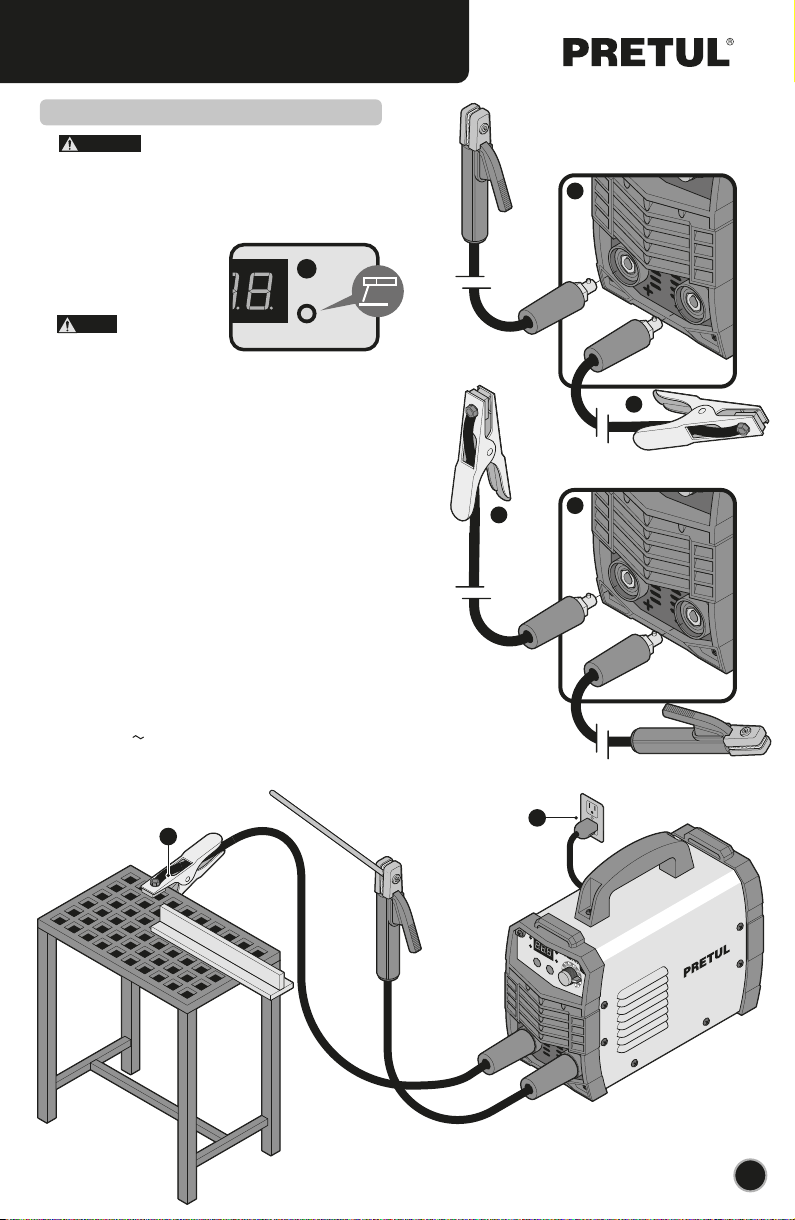

Installation (SMAW)

Connections

Set the electrode

that is adequate

for the job into the

electrode holder

Metal

Work Table

To prevent an electric shock, the user must

see the information in “Power Requirements” in page 3 and 5.

• The fast connections of the electrode holder and the ground

clamp are inserted and turned one quarter of a turn in a

clockwise direction in the outlets set in the front panel to

secure perfectly.

• Press the process selector to

set the welder working in

SMAW mode (coated

electrode).

The upper LED in

the selector will light on.

Reverse Polarity (A)

• Connect the grounding clamp cable to the negative (-)

output clamping screw of the welder.

• Connect the grounding clamp (C) to the work piece.

• Connect the electrode holder cable to the positive (+)

output clamping screw of the welder.

This configuration generates more heat in the electrode,

which produce more penetration with basic electrodes,

making it ideal to weld thick pieces.

Direct Polarity (B)

• Connect the grounding clamp cable to the positive (+)

output.

• Connect the grounding clamp (C) to the work piece.

• Connect the electrode holder cable to the negative (-) output.

This configuration generates more heat in the work piece, thus

producing less malformation in the work piece and narrower joints

making it ideal for thin pieces.

• Connect the power cable (D) to the power network to the work

voltage (127 V ).

NOTE

CAUTION

ENGLISH

A

B

Reverse Polarity

Direct Polarity

C

C

ELECTRODO

C

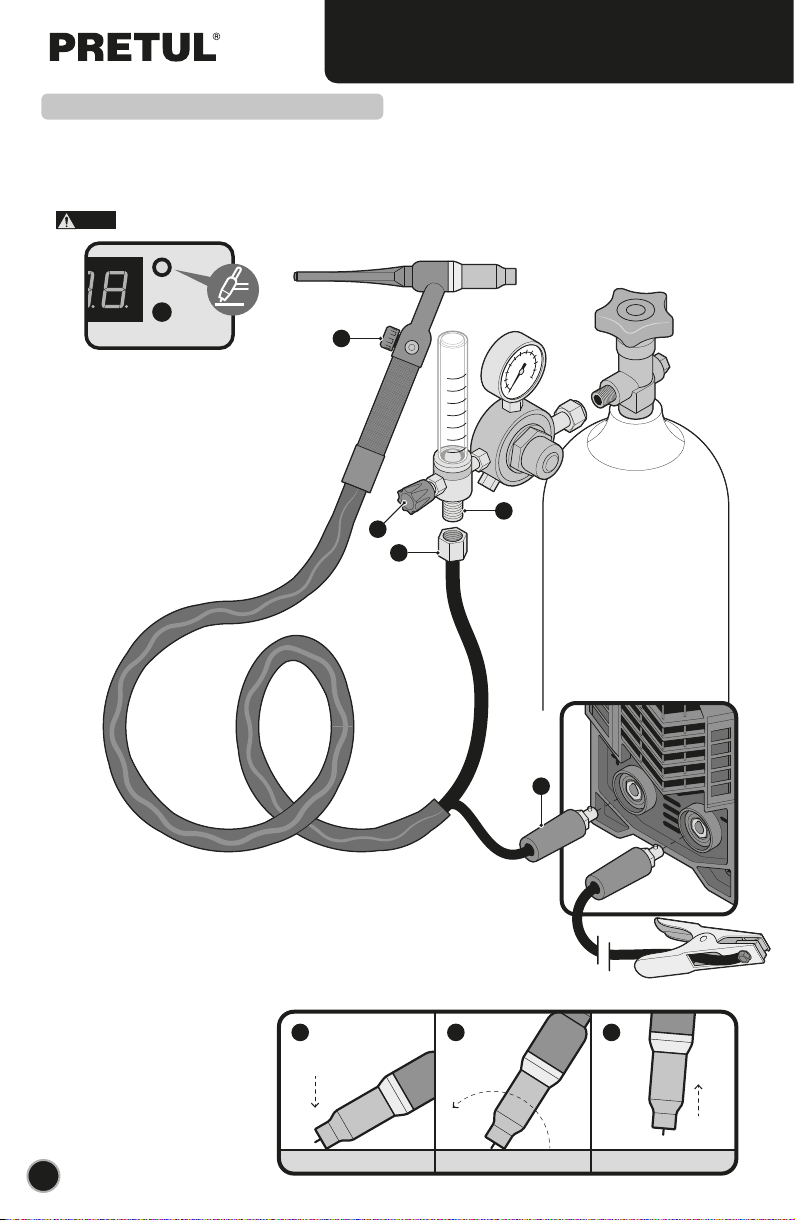

• This inverter welder can also be used for TIG welding, a high-quality welding process with non-consumable tungsten electrodes

and arch protected with inert gas like argon gas o helium.

• TIG welding is ideal to weld stainless steel, iron and copper.

• With this process, a AN-SI-12/16/20 torch and a can of protective gas are required (not included).

• Press the lower arrow in the process selector to set the welder into the TIG mode. (Tungsten electrode).

The LED facing down will turn ON.

• The connection shall be set in direct polarity:

• Connect the clamp cable to ground the positive outlet

terminal (+) of the welder and the grounding clamp to

the work piece.

• Connect the torch cable (A) to the negative outlet

terminal (-) of the welder.

• Connect the torch gas input (B) to the output

valve of the regulator (C) of the protection gas.

• Turn torch valve (D) to open gas flow. Turn

the knob (E) of the regulator to adjust the

gas flow until obtaining an approximate

flow in L / min of 6 times the diameter

of the electrode.

8

Installation (TIG)

A

C

D

B

123

• To start the arch, set the nozzle making an angle onto the

work piece (1).

• Lift the torch, not separating it from the work piece to

approach the electrode to the work piece (2).

• When starting the electric arc, lift the torch so that the

electrode tip is 0.08” away from the work piece (3) and start

welding.

• It is advisable to keep the

electrode 90° vertical during the

welding to guarantee the protection

of the gas.

TIG Connection

ENGLISH

NOTE

TIG

E

VRD

9

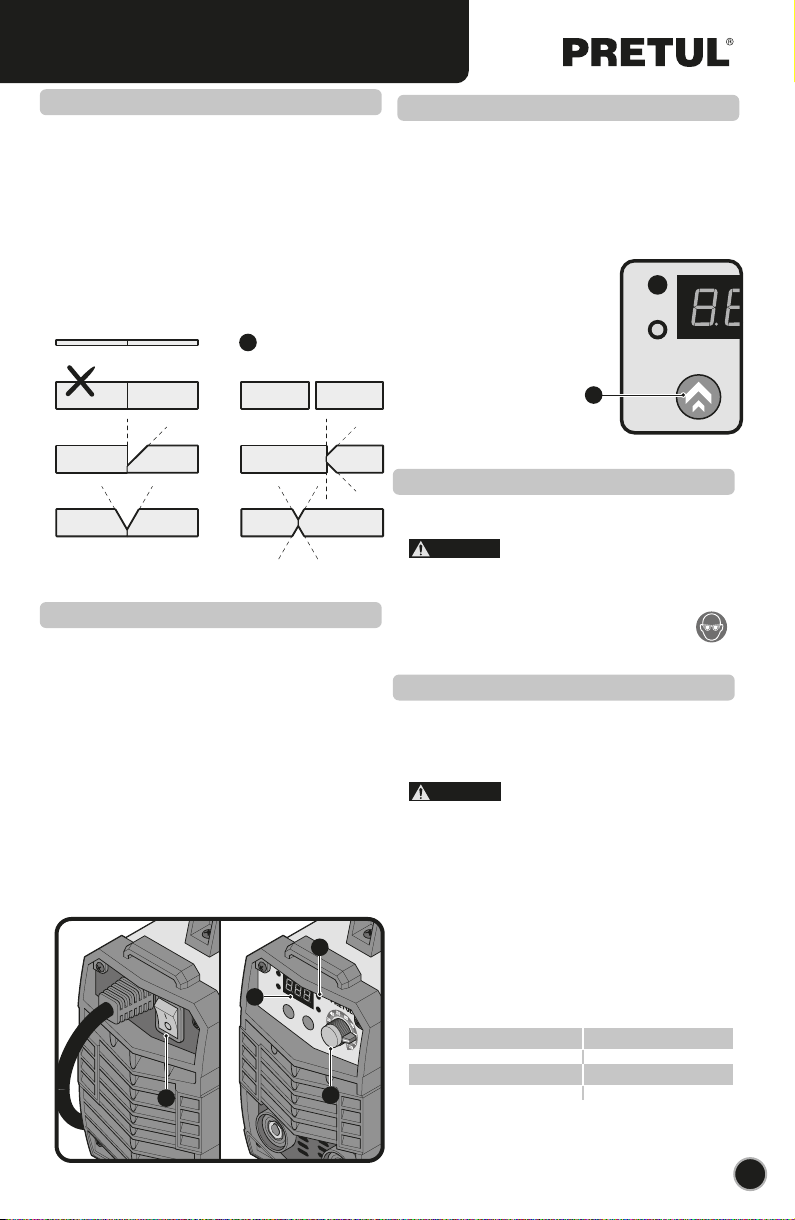

Start Up

BC

E

D

VRD security system

• Activate the VRD (Voltage Reduction Device) system by

pressing the button (F) to reduce voltage during the bait

phase to prevent possible discharge to the operator.

• It is recommended to activate it in risky situations, such

as when welding in confined spaces, wet environments,

working in heights and in mining industry.

• When the VRD system is

activated it is necessary to force

contact between the electrode and

the workpiece for up to two

seconds to generate the arc and

start welding.

F

A

45° 45°

45°60°

60°

60°

Electrode Replacement

SMAW:

• When the electrode has burned 0.4” to 0.7” from the

electrode holder, replace wit with a new one to be able to

keep on welding.

• The electrode burns in high

temperatures. Do not try to handle the electrode remains

with your hand. Put the remains in a metal container.

• Open the electrode holder tong to hold the uncovered

end of the new electrode. Do not hold the electrode in the

covered part.

TIG:

• Tungsten electrodes shall be sharpened to guarantee the

weld quality in a longitudinal direction.

• The tungsten electrode tip gets deformed due to the

heat. Therefore, when the tip is not showing an angle, it is

recommended to sharpen it again.

CAUTION

Preparation

• Only through experience, practice and care a good welding

process can be guaranteed.

• The factors arousing in the welding process are many: current

required, distance between the electrode and the work piece,

speed and direction of the welding, thickness and type of material,

position of the work piece and welding direction, and also, the

gauge, material and covering of the electrode. Thus, it is advisable

that before carrying out a weld, try to practice in scrap material to

determine which are the specific requirements for the job ahead.

• The area in the work pieces where the weld is to be applied shall

be clean, free of oxidation and paint.

• The joints between sheets with calibers larger than 1/8” shall be

beveled so the weld will be adequate (A).

Slag Removal

• Upon finishing the welding job, use a wire brush to

remove slag from the welding joint surface.

• Wait until the slag has cooled down

and hardened to be able to remove it.

• When hitting or brushing slag to remove it, there can

be particles shooting out. Wear eye protection and

keep bystanders away.

CAUTION

Welding

• Set the switch (B) in the ON position I.

• Adjust the current control adjustment (C) until reaching the

adequate arch current and intensity suitable for the job.

Current is indicated in the panel screen (D).

• Hold the electrode holder or torch in the most comfortable

position possible. Be aware that during the welding process, the

angle, movement and distance with regards to the work piece shall

be constant and uniform.

• Aim the electrode tip towards the joint to be welded to generate

the electric arch and be able to start welding.

• Once the arch is ON start welding, keeping always the electrode

tip 0,08” away from the work piece. If welding with the electrode

onto the work piece, it could stick and the weld would have a poor

quality.

• In the event of overheating, the welder will stop working and the

two thermal protection indicating lights (E) will be ON. Do not turn

OFF the welder. Wait for the indicator lights turns OFF to use it

again.

Welding Current (A)

20

20 - 100

100 - 200

Electrode Angle

30º

60º - 90º

90º - 120º

ENGLISH

10 ENGLISH

Start Up

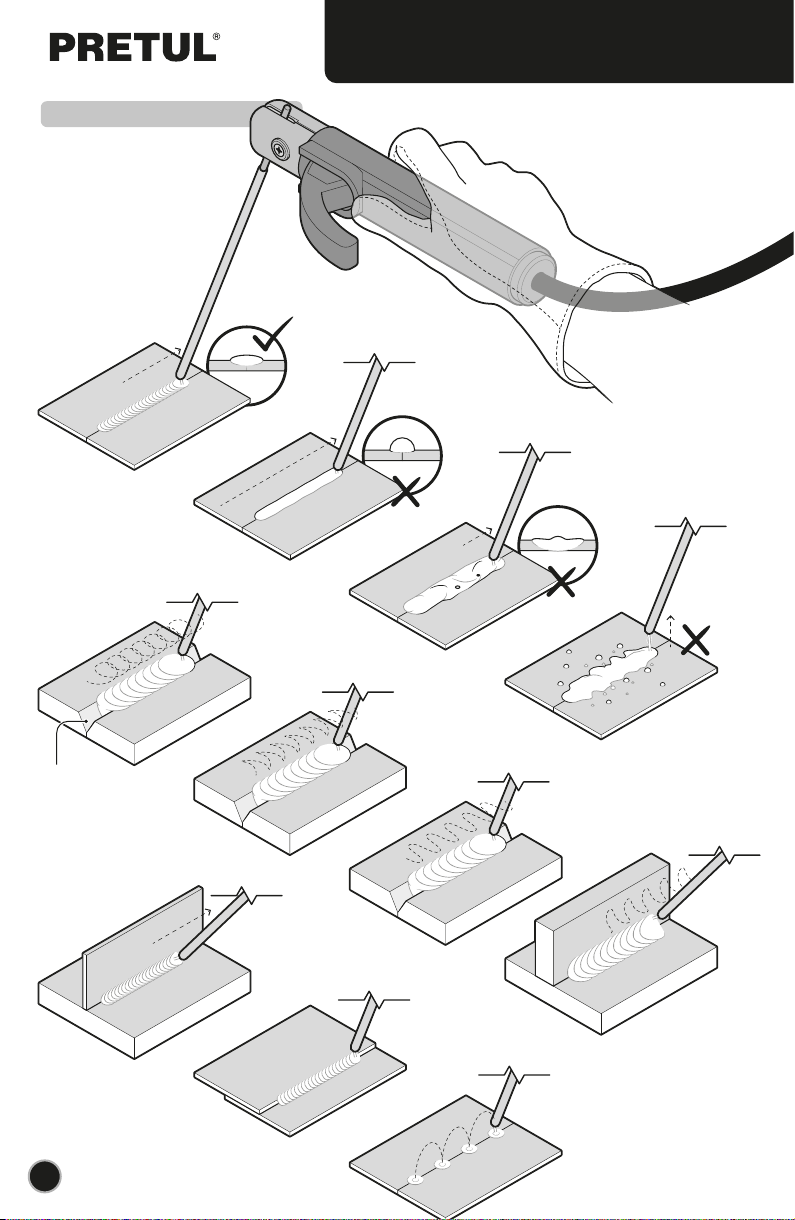

Examples of welding

Correctly

Applied Welding

Electrode

Electrode movement

too fast and / or

very low current.

Thin Sheets

Thick Sheets

Electrode movement

too slow and / or

very high current.

Spiral

movement.

Half-Moon

movement.

Zigzag

Movement.

Spot Weld.

Overlapped

Joint.

Angle welding

of thick sheets.

Angle welding of thin

sheets to thick sheets.

Electrode too

separated from

the work piece.

Bevel

11

Maintenance

ENGLISH

Troubleshooting

• The correct use and regular cleansing extend the useful life of the welder.

• Only qualified personnel shall carry out repairs. We recommend visiting a

Authorized Service Center to repair your welder, get supplies or accessories.

CAUTION

Regular Maintenance

• Clean dust from the welder with compressed air. If there

is too much dust present, clean immediately. Under

normal conditions clean once a year. If the welder is

exposed to a lot of dust, cleaning should be carried out

every three months.

• Altogether with cleaning make a checkup to assure there

are no loose parts or components in the welder.

• Keep the welder wiring in good repair.

• The plug shall be checked before each use.

Storage

• In the event the welder will be stored a long period of

time, keep it in a dry, well ventilated place to prevent

humidity getting inside, or to generate rust or toxic gas.

Storage temperature vary between -13 °F to 131 °F and

relative humidity shall not be over 90%.

The thermal protection

light is ON.

The current adjusting

control is not working.

The fan is not working

or turns very slowly.

There is no open

circuit voltage.

The electrode holder is

too hot; connections +

and - are hot.

Energy source is off.

Big splash.

• The welder has no adequate ventilation.

• Environment temperature is too high.

• The welder has been used longer than the

recommended work cycle.

• The potentiometer is broken.

• Faulty switch.

• Faulty fan.

• Fault in the connections.

• High Voltage, low voltage or one phase is

missing.

• The welder is overheating.

• Faulty switch.

• The electrode capacity is too low.

• The cable gauge is too small.

• Loose connections.

• More resistance between the

electrode holder and the cable.

• The welder is hover-heated.

• The connection of Output is wrong.

Problem Cause Solution

If after all the recommended actions have been carried out the problems persist,

contact a Authorized Service Center.

• Keep the welder least 11.8” away from any walls at to

allow air circulation.

• The welder will recuperate once the temperature gets

back to the right range to operate.

• The welder will recuperate once the temperature gets

back to the right range to operate.

• Go to a Authorized Service Center

to replace the potentiometer.

• Go to a Authorized Service Center

to replace the switch.

• Go to a Authorized Service Center

to repair the fan.

• Check all the connections.

• The welder will recuperate once the temperature is

back into the adequate range to operate.

• Go to a Authorized Service Center

to replace the switch.

• Replace the electrode holder with another one with more capacity.

• Replace the cable with another one within the requirements

(see page 3).

• Clean the rust accumulation and tighten the connections.

• Clean the rust accumulation and tighten the connections.

• There is no fault. It is normal that power supply gets cut when

the welder goes above its normal working temperature. Wait

until the temperature is back to the adequate working range to

turn it on again.

• Exchange the Output line.

12 ENGLISH

Notes

13

Authorized Service Centers

ENGLISH

In the event of any problem contacting a Truper Authorized Service Center, please see our webpage

www.truper.com to get an updated list, or call our toll-free numbers 800 690-6990 or 800 0187-8737 to get

information about the nearest Service Center.

AGUASCALIENTES

BAJA

CALIFORNIA

BAJA

CALIFORNIA SUR

CAMPECHE

CHIAPAS

CHIHUAHUA

CIUDAD DE

MÉXICO

COAHUILA

COLIMA

DURANGO

ESTADO DE

MÉXICO

GUANAJUATO

GUERRERO

HIDALGO

JALISCO

MICHOACÁN

MORELOS

NAYARIT

NUEVO LEÓN

OAXACA

PUEBLA

QUERÉTARO

QUINTANA ROO

SAN LUIS

POTOSÍ

SINALOA

SONORA

TABASCO

TAMAULIPAS

TLAXCALA

VERACRUZ

YUCATÁN

DE TODO PARA LA CONSTRUCCIÓN

GRAL. BARRAGÁN #1201, COL. GREMIAL, C.P. 20030,

AGUASCALIENTES, AGS. TEL.: 449 994 0537

SUCURSAL TIJUANA

AV. LA ENCANTADA, LOTE #5, PARQUE INDUSTRIAL EL

FLORIDO II, C.P 22244, TIJUANA, B.C.

TEL.: 664 969 5100

FIX FERRETERÍAS

FELIPE ÁNGELES ESQ. RUIZ CORTÍNEZ S/N, COL. PUEBLO

NUEVO, C.P. 23670, CD. CONSTITUCIÓN, B.C.S.

TEL.: 613 132 1115

TORNILLERÍA Y FERRETERÍA AAA

AV. ÁLVARO OBREGÓN #324, COL. ESPERANZA

C.P. 24080 CAMPECHE, CAMP. TEL.: 981 815 2808

FIX FERRETERÍAS

AV. CENTRAL SUR #27, COL. CENTRO, C.P. 30700,

TAPACHULA, CHIS. TEL.: 962 118 4083

SUCURSAL CHIHUAHUA

AV. SILVESTRE TERRAZAS #128-11, PARQUE INDUSTRIAL

BAFAR, CARRETERA MÉXICO CUAUHTÉMOC, C.P. 31415,

CHIHUAHUA, CHIH. TEL. 614 434 0052

FIX FERRETERÍAS

EL MONSTRUO DE CORREGIDORA, CORREGIDORA # 22,

COL. CENTRO, C.P. 06060, CUAUHTÉMOC, CDMX.

TEL: 55 5522 5031 / 5522 4861

SUCURSAL TORREÓN

CALLE METAL MECÁNICA #280, PARQUE INDUSTRIAL

ORIENTE, C.P. 27278, TORREÓN, COAH.

TEL.: 871 209 68 23

BOMBAS Y MOTORES BYMTESA DE MANZANILLO

BLVD. MIGUEL DE LA MADRID #190, COL. 16 DE

SEPTIEMBRE, C.P. 28239, MANZANILLO, COL.

TEL.: 314 332 1986 / 332 8013

TORNILLOS ÁGUILA, S.A. DE C.V.

MAZURIO #200, COL. LUIS ECHEVERRÍA, DURANGO,

DGO.TEL.: 618 817 1946 / 618 818 2844

SUCURSAL CENTRO JILOTEPEC

PARQUE INDUSTRIAL # 1, COL. PARQUE INDUSTRIAL

JILOTEPEC, JILOTEPEC, EDO. DE MÉX. C.P. 54257

TEL: 761 782 9101 EXT. 5728 Y 5102

CÍA. FERRETERA NUEVO MUNDO S.A. DE C.V.

AV. MÉXICO - JAPÓN #225, CD. INDUSTRIAL, C.P. 38010,

CELAYA, GTO. TEL.: 461 617 7578 / 79 / 80 / 88

CENTRO DE SERVICIO ECLIPSE

CALLE PRINCIPAL MZ.1 LT. 1, COL. SANTA FE, C.P. 39010,

CHILPANCINGO, GRO. TEL.: 747 478 5793

FERREPRECIOS S.A. DE C.V.

LIBERTAD ORIENTE #304 LOCAL 30, INTERIOR DE PASAJE

ROBLEDO, COL. CENTRO, C.P. 43600, TULANCINGO,

HGO. TEL.: 775 753 6615 / 775 753 6616

SUCURSAL GUADALAJARA

AV. ADOLFO B. HORN # 6800, COL: SANTA CRUZ DEL

VALLE, C.P.: 45655, TLAJOMULCO DE ZUÑIGA, JAL.

TEL.: 33 3606 5285 AL 90

FIX FERRETERÍAS

AV. PASEO DE LA REPÚBLICA #3140-A, COL.

EX-HACIENDA DE LA HUERTA, C.P. 58050, MORELIA,

MICH. TEL.: 443 334 6858

FIX FERRETERÍAS

CAPITÁN ANZURES #95, ESQ. JOSÉ PERDIZ, COL.

CENTRO, C.P. 62740, CUAUTLA, MOR.

TEL.: 735 352 8931

HERRAMIENTAS DE TEPIC

MAZATLAN #117, COL. CENTRO, C.P. 63000, TEPIC, NAY.

TEL.: 311 258 0540

SUCURSAL MONTERREY

CARRETERA LAREDO #300, 1B MONTERREY PARKS,

COLONIA PUERTA DE ANÁHUAC, C.P. 66052, ESCOBEDO,

NUEVO LEÓN, TEL.: 81 8352 8791 / 81 8352 8790

FIX FERRETERÍAS

AV. 20 DE NOVIEMBRE #910, COL. CENTRO, C.P. 68300,

TUXTEPEC, OAX. TEL.: 287 106 3092

SUCURSAL PUEBLA

AV PERIFÉRICO #2-A, SAN LORENZO ALMECATLA,

C.P. 72710, CUAUTLACINGO, PUE.

TEL.: 222 282 8282 / 84 / 85 / 86

ARU HERRAMIENTAS S.A DE C.V.

AV. PUERTO DE VERACRUZ #110, COL. RANCHO DE

ENMEDIO, C.P. 76842, SAN JUAN DEL RÍO, QRO.

TEL.: 427 268 4544

FIX FERRETERÍAS

CARRETERA FEDERAL MZ. 46 LT. 3 LOCAL 2, COL EJIDAL,

C.P. 77710 PLAYA DEL CARMEN, Q.R.

TEL.: 984 267 3140

FIX FERRETERÍAS

AV. UNIVERSIDAD #1850, COL. EL PASEO, C.P. 78320,

SAN LUIS POTOSÍ, S.L.P. TEL.: 444 822 4341

SUCURSAL CULIACÁN

AV. JESÚS KUMATE SUR #4301, COL. HACIENDA DE LA

MORA, C.P. 80143, CULIACÁN, SIN.

TEL.: 667 173 9139 / 173 8400

FIX FERRETERÍAS

CALLE 5 DE FEBRERO #517, SUR LT. 25 MZ. 10, COL.

CENTRO, C.P. 85000, CD. OBREGÓN, SON.

TEL.: 644 413 2392

SUCURSAL VILLAHERMOSA

CALLE HELIO LOTES 1, 2 Y 3 MZ. #1, COL. INDUSTRIAL,

2A ETAPA, C.P. 86010, VILLAHERMOSA, TAB.

TEL.: 993 353 7244

VM ORINGS Y REFACCIONES

CALLE ROSITA #527 ENTRE 20 DE NOVIEMBRE Y GRAL.

RODRÍGUEZ, FRACC. REYNOSA, C.P. 88780, REYNOSA,

TAMS. TEL.: 899 926 7552

SERVICIOS Y HERRAMIENTAS INDUSTRIALES

PABLO SIDAR #132, COL . BARRIO DE SAN BARTOLOMÉ,

C.P. 90970, SAN PABLO DEL MONTE, TLAX.

TEL.: 222 271 7502

LA CASA DISTRIBUIDORA TRUPER

BLVD. PRIMAVERA. ESQ. HORTENSIA S/N, COL.

PRIMAVERA C.P. 93308, POZA RICA, VER.

TEL.: 782 823 8100 / 826 8484

SUCURSAL MÉRIDA

CALLE 33 #600 Y 602, LOCALIDAD ITZINCAB Y MULSAY,

MPIO. UMÁN, C.P. 97390, MÉRIDA, YUC.

TEL.: 999 912 2451

14 ENGLISH www.truper.com

01-2022

27225

Warranty

policy

Stamp of the business. Date of purchase:

Code

SOIN-130P

Model Brand

1

YEAR

This product is guaranteed for 1 year. To make the warranty valid or purchase parts and components you must

present the product in Corregidora 22, Col. Centro, Alc. Cuauhtémoc, CDMX C.P. 06060 or at the

establishment where you purchased it, or at any Truper®Service Center listed in the annex to the warranty

policy and/or in www.truper.com . Transportation costs resulting from compliance of this warranty will be

covered by

For questions or comments, call 800-690-6990. Made in China. Imported by Truper S.A. de C.V. Parque

Industrial 1, Parque Industrial Jilotepec, Jilotepec, Edo. de Méx. C.P. 54257

14 ESPAÑOL

Póliza de

Garantía

www.truper.com

01-2022

Sello del establecimiento comercial. Fecha de compra:

Código Modelo Marca

1

AÑO

27225 SOIN-130P

Este producto está garantizado por 1 año. Para hacer válida la garantía o adquirir piezas y componentes deberá

presentar el producto en Corregidora 22, Col. Centro, Alc. Cuauhtémoc, CDMX C.P. 06060 o en el

establecimiento donde lo compró, o en algún Centro de Servicio Truper®de los enlistados en el anexo de la

póliza de garantía y/o en www.truper.com . Los gastos de transportación que resulten para su cumplimiento

serán cubiertos por

Para dudas o comentarios, llame al 800-690-6990. Hecho en China. Importado por Truper S.A. de C.V. Parque

Industrial 1, Parque Industrial Jilotepec, Jilotepec, Edo. de Méx. C.P. 54257

Centros de Servicio Autorizados

13

ESPAÑOL

En caso de tener algún problema para contactar un Centro de Servicio Autorizado Truper

®

consulte nuestra

página www.truper.com donde obtendrá un listado actualizado, o llame al: 800 690-6990 ó800 0187-8737

donde le informarán cuál es el Centro de Servicio más cercano.

AGUASCALIENTES

BAJA

CALIFORNIA

BAJA

CALIFORNIA SUR

CAMPECHE

CHIAPAS

CHIHUAHUA

CIUDAD DE

MÉXICO

COAHUILA

COLIMA

DURANGO

ESTADO DE

MÉXICO

GUANAJUATO

GUERRERO

HIDALGO

JALISCO

MICHOACÁN

MORELOS

NAYARIT

NUEVO LEÓN

OAXACA

PUEBLA

QUERÉTARO

QUINTANA ROO

SAN LUIS

POTOSÍ

SINALOA

SONORA

TABASCO

TAMAULIPAS

TLAXCALA

VERACRUZ

YUCATÁN

DE TODO PARA LA CONSTRUCCIÓN

GRAL. BARRAGÁN #1201, COL. GREMIAL, C.P. 20030,

AGUASCALIENTES, AGS. TEL.: 449 994 0537

SUCURSAL TIJUANA

AV. LA ENCANTADA, LOTE #5, PARQUE INDUSTRIAL EL

FLORIDO II, C.P 22244, TIJUANA, B.C.

TEL.: 664 969 5100

FIX FERRETERÍAS

FELIPE ÁNGELES ESQ. RUIZ CORTÍNEZ S/N, COL. PUEBLO

NUEVO, C.P. 23670, CD. CONSTITUCIÓN, B.C.S.

TEL.: 613 132 1115

TORNILLERÍA Y FERRETERÍA AAA

AV. ÁLVARO OBREGÓN #324, COL. ESPERANZA

C.P. 24080 CAMPECHE, CAMP. TEL.: 981 815 2808

FIX FERRETERÍAS

AV. CENTRAL SUR #27, COL. CENTRO, C.P. 30700,

TAPACHULA, CHIS. TEL.: 962 118 4083

SUCURSAL CHIHUAHUA

AV. SILVESTRE TERRAZAS #128-11, PARQUE INDUSTRIAL

BAFAR, CARRETERA MÉXICO CUAUHTÉMOC, C.P. 31415,

CHIHUAHUA, CHIH. TEL. 614 434 0052

FIX FERRETERÍAS

EL MONSTRUO DE CORREGIDORA, CORREGIDORA # 22,

COL. CENTRO, C.P. 06060, CUAUHTÉMOC, CDMX.

TEL: 55 5522 5031 / 5522 4861

SUCURSAL TORREÓN

CALLE METAL MECÁNICA #280, PARQUE INDUSTRIAL

ORIENTE, C.P. 27278, TORREÓN, COAH.

TEL.: 871 209 68 23

BOMBAS Y MOTORES BYMTESA DE MANZANILLO

BLVD. MIGUEL DE LA MADRID #190, COL. 16 DE

SEPTIEMBRE, C.P. 28239, MANZANILLO, COL.

TEL.: 314 332 1986 / 332 8013

TORNILLOS ÁGUILA, S.A. DE C.V.

MAZURIO #200, COL. LUIS ECHEVERRÍA, DURANGO,

DGO.TEL.: 618 817 1946 / 618 818 2844

SUCURSAL CENTRO JILOTEPEC

PARQUE INDUSTRIAL # 1, COL. PARQUE INDUSTRIAL

JILOTEPEC, JILOTEPEC, EDO. DE MÉX. C.P. 54257

TEL: 761 782 9101 EXT. 5728 Y 5102

CÍA. FERRETERA NUEVO MUNDO S.A. DE C.V.

AV. MÉXICO - JAPÓN #225, CD. INDUSTRIAL, C.P. 38010,

CELAYA, GTO. TEL.: 461 617 7578 / 79 / 80 / 88

CENTRO DE SERVICIO ECLIPSE

CALLE PRINCIPAL MZ.1 LT. 1, COL. SANTA FE, C.P. 39010,

CHILPANCINGO, GRO. TEL.: 747 478 5793

FERREPRECIOS S.A. DE C.V.

LIBERTAD ORIENTE #304 LOCAL 30, INTERIOR DE PASAJE

ROBLEDO, COL. CENTRO, C.P. 43600, TULANCINGO,

HGO. TEL.: 775 753 6615 / 775 753 6616

SUCURSAL GUADALAJARA

AV. ADOLFO B. HORN # 6800, COL: SANTA CRUZ DEL

VALLE, C.P.: 45655, TLAJOMULCO DE ZUÑIGA, JAL.

TEL.: 33 3606 5285 AL 90

FIX FERRETERÍAS

AV. PASEO DE LA REPÚBLICA #3140-A, COL.

EX-HACIENDA DE LA HUERTA, C.P. 58050, MORELIA,

MICH. TEL.: 443 334 6858

FIX FERRETERÍAS

CAPITÁN ANZURES #95, ESQ. JOSÉ PERDIZ, COL.

CENTRO, C.P. 62740, CUAUTLA, MOR.

TEL.: 735 352 8931

HERRAMIENTAS DE TEPIC

MAZATLAN #117, COL. CENTRO, C.P. 63000, TEPIC, NAY.

TEL.: 311 258 0540

SUCURSAL MONTERREY

CARRETERA LAREDO #300, 1B MONTERREY PARKS,

COLONIA PUERTA DE ANÁHUAC, C.P. 66052, ESCOBEDO,

NUEVO LEÓN, TEL.: 81 8352 8791 / 81 8352 8790

FIX FERRETERÍAS

AV. 20 DE NOVIEMBRE #910, COL. CENTRO, C.P. 68300,

TUXTEPEC, OAX. TEL.: 287 106 3092

SUCURSAL PUEBLA

AV PERIFÉRICO #2-A, SAN LORENZO ALMECATLA,

C.P. 72710, CUAUTLACINGO, PUE.

TEL.: 222 282 8282 / 84 / 85 / 86

ARU HERRAMIENTAS S.A DE C.V.

AV. PUERTO DE VERACRUZ #110, COL. RANCHO DE

ENMEDIO, C.P. 76842, SAN JUAN DEL RÍO, QRO.

TEL.: 427 268 4544

FIX FERRETERÍAS

CARRETERA FEDERAL MZ. 46 LT. 3 LOCAL 2, COL EJIDAL,

C.P. 77710 PLAYA DEL CARMEN, Q.R.

TEL.: 984 267 3140

FIX FERRETERÍAS

AV. UNIVERSIDAD #1850, COL. EL PASEO, C.P. 78320,

SAN LUIS POTOSÍ, S.L.P. TEL.: 444 822 4341

SUCURSAL CULIACÁN

AV. JESÚS KUMATE SUR #4301, COL. HACIENDA DE LA

MORA, C.P. 80143, CULIACÁN, SIN.

TEL.: 667 173 9139 / 173 8400

FIX FERRETERÍAS

CALLE 5 DE FEBRERO #517, SUR LT. 25 MZ. 10, COL.

CENTRO, C.P. 85000, CD. OBREGÓN, SON.

TEL.: 644 413 2392

SUCURSAL VILLAHERMOSA

CALLE HELIO LOTES 1, 2 Y 3 MZ. #1, COL. INDUSTRIAL,

2A ETAPA, C.P. 86010, VILLAHERMOSA, TAB.

TEL.: 993 353 7244

VM ORINGS Y REFACCIONES

CALLE ROSITA #527 ENTRE 20 DE NOVIEMBRE Y GRAL.

RODRÍGUEZ, FRACC. REYNOSA, C.P. 88780, REYNOSA,

TAMS. TEL.: 899 926 7552

SERVICIOS Y HERRAMIENTAS INDUSTRIALES

PABLO SIDAR #132, COL . BARRIO DE SAN BARTOLOMÉ,

C.P. 90970, SAN PABLO DEL MONTE, TLAX.

TEL.: 222 271 7502

LA CASA DISTRIBUIDORA TRUPER

BLVD. PRIMAVERA. ESQ. HORTENSIA S/N, COL.

PRIMAVERA C.P. 93308, POZA RICA, VER.

TEL.: 782 823 8100 / 826 8484

SUCURSAL MÉRIDA

CALLE 33 #600 Y 602, LOCALIDAD ITZINCAB Y MULSAY,

MPIO. UMÁN, C.P. 97390, MÉRIDA, YUC.

TEL.: 999 912 2451

Notas

12 ESPAÑOL

11

Mantenimiento

Solución de problemas

• Mantenga la soldadora apartada de cualquier pared al

menos 30 cm para permitir que el aire circule.

• La soldadora se recuperará una vez que la temperatura

regresa al rango adecuado para operar.

• La soldadora se recuperará una vez que la temperatura

regresa al rango adecuado para operar.

• Acuda a un Centro de Servicio Autorizado

para reemplazar el potenciómetro.

• Acuda a un Centro de Servicio Autorizado

para remplazar el interruptor.

• Acuda a un Centro de Servicio Autorizado

para reparar el ventilador.

• Revise las conexiones.

• La soldadora se recuperará una vez que la temperatura

regresa al rango adecuado para operar.

• Acuda a un Centro de Servicio Autorizado

para remplazar el interruptor.

• Reemplace el porta electrodo por otro de mayor capacidad.

• Reemplace el cable por otro dentro de los requerimientos

(consulte la página 3).

• Limpie la acumulación de óxido y apriete las conexiones.

• Limpie la acumulación de óxido y apriete las conexiones.

• No hay falla. Es normal que el suministro de energía se

corte cuando la soldadora sobrepasa su temperatura normal

de trabajo. Espere a que la temperatura regrese a al rango

adecuado de trabajo para poder encenderla de nuevo.

• Cambie la línea de salida.

La luz de protección

térmica está

encendida.

El control de ajuste de

corriente no funciona.

El ventilador no

funciona o gira muy

lentamente.

No hay tensión de

circuito abierto.

El porta electrodo se

calienta demasiado;

las conexiones + y - se

calientan.

La fuente de energía

se corta.

Chorro grande

• La soldadora no cuenta con ventilación

adecuada.

• Temperatura ambiente muy alta.

• La soldadora se utilizó por más tiempo

del recomendado en su ciclo de trabajo.

• El potenciómetro está roto.

• Interruptor descompuesto.

• Ventilador descompuesto.

• Falla en las conexiones.

• Tensión alta, tensión baja o falta una fase.

• La soldadora se está sobrecalentando.

• Interruptor descompuesto.

• La capacidad del porta electrodo es

muy baja.

• La medida del cable es muy pequeña.

• Conexiones flojas.

• Mayor resistencia entre el porta

electrodo y el cable.

• La soldadora se ha sobrecalentado.

• La conexión de polaridad de salida no

es correcta.

Problema Causa Solución

Si los problemas persisten a pesar de realizar las acciones correctivas recomendadas,

contacte a un Centro de Servicio Autorizado . ESPAÑOL

• El uso correcto y una limpieza regular prolongan la vida útil de la soldadora.

• Sólo personal calificado debe hacer las reparaciones. Se recomienda visitar un Centro de Servicio

Autorizado para reparar la soldadora, adquirir suministros o accesorios.

ATENCIÓN

Mantenimiento regular

• Se debe limpiar el polvo de la soldadora con aire

comprimido. En caso haber mucho polvo, se debe limpiar

de inmediato. Bajo condiciones normales se requiere

limpieza una vez al año, en caso de que la soldadora esté

expuesta a mucho polvo, la limpieza debe realizarse cada

tres meses.

• Junto con la limpieza se debe realizar una revisión para

asegurar que no haya partes o componentes sueltos en la

soldadora.

• Mantenga los cables de la soldadora en buen estado.

• Las terminales deben revisarse antes de cada uso.

Almacenamiento

• En caso que la soldadora vaya a estar almacenada por un

periodo largo de tiempo, se debe mantener en un sitio

seco y bien ventilado para evitar que le entre humedad, se

genere óxido o gases tóxicos. La temperatura de

almacenaje varía de -25 °C a 55 °C, y la humedad relativa

no debe ser superior a 90%.

10 ESPAÑOL

Ejemplos de soldadura

Soldadura

aplicada

correctamente

Electrodo

Movimiento muy

rápido del electrodo y/o

corriente muy baja.

Láminas delgadas

Láminas gruesas

Movimiento muy lento

del electrodo y/o

corriente muy alta.

Movimiento

en espiral.

Movimiento

en media luna.

Movimiento

en zigzag.

Soldadura

por puntos.

Unión

traslapada.

Soldadura en ángulo

de láminas gruesas.

Soldadura en ángulo

de láminas delgada

a gruesa.

Electrodo muy

separado de la

pieza de trabajo.

Bisel

Puesta en marcha

VRD

9

Puesta en marcha

ESPAÑOL

A

45° 45°

45°60°

60°

60°

Reemplazo de electrodo

SMAW:

• Cuando el electrodo se ha consumido de 1 cm a 2 cm

del porta electrodo, es necesario cambiarlo por uno nuevo

para poder seguir soldando.

• El electrodo se quema a alta

temperatura. No intente manipular los restos del electrodo

con la mano. Ponga los restos en un contenedor de metal.

• Abra la tenaza del porta electrodo para sostener el

electrodo nuevo por el extremo sin recubrimiento. No

sostenga el electrodo por la parte recubierta.

TIG:

• Los electrodos de Tungsteno deben ser afilados para

garantizar la calidad de la soldadura en su dirección

longitudinal.

• La punta del electrodo de Tungsteno tiende a deformarse

debido al calentamiento, es por eso que una vez que la

punta no presente el ángulo recomendado, debe afilarse

nuevamente.

ATENCIÓN

Preparativos

• Sólo con experiencia, práctica y cuidado se puede garantizar un

buen trabajo de soldadura.

• Los factores que intervienen en el proceso de soldadura son

muchos: corriente requerida, distancia entre el electrodo y la pieza

de trabajo, velocidad y dirección de soldeo, grosor y tipo del

material, posición de la pieza de trabajo, ángulo del electrodo y

además el calibre, material y recubrimiento del electrodo. Por lo

que es recomendable que antes de realizar una soldadura realice

prácticas en material de desecho para determinar cuáles son los

requerimientos específicos del trabajo a realizar.

• El área de las piezas de trabajo donde será aplicada la soldadura

debe de estar limpia, libre de óxido y pintura.

• Las uniones entre láminas con calibres mayores de 1/8” (3 mm)

deben de ser biseladas para que la soldadura sea adecuada (A).

Retiro de escoria

• Al terminar el trabajo de soldado, utilice un cepillo de

alambre para retirar la escoria de la superficie del cordón

de soldado.

• Espere a que la escoria se haya

enfriado y endurecido para poder retirarla.

• Al golpear o cepillar la escoria para retirarla

pueden salir partículas despedidas. Utilice

protección para los ojos y mantenga a las personas

alejadas.

ATENCIÓN

Sistema de seguridad VRD

• Active el sistema VRD (Voltage Reduction Device)

presionando el botón (F) para reducir la tensión durante la

fase de cebado y así evitar una posible descarga al

operador.

• Se recomienda activarlo en situaciones de riesgo, como

al realizar soldadura en espacios confinados, en ambientes

húmedos, trabajos en altura y en

la industria minera.

• Cuando el sistema VRD está

activado es necesario forzar el

contacto entre el electrodo y la

pieza de trabajo hasta por dos

segundos para generar el arco y

comenzar a soldar.

Soldadura

• Coloque el interruptor (B) en posición de encendido I.

• Ajuste las perillas de control de corriente (C) hasta alcanzar la

corriente e intensidad de arco adecuados para el trabajo.

La corriente se indica en la pantalla del panel (D).

• Sostenga el porta electrodo o antorcha de la manera más

cómoda posible. Tome en cuenta que durante el proceso de

soldado, el ángulo, movimiento y distancia con respecto a la pieza

de trabajo deben de ser constantes y uniformes.

• Dirija la punta del electrodo hacia la unión a trabajar para generar

el arco eléctrico y comience a soldar.

• Una vez que el arco encienda comience a soldar, manteniendo

siempre la punta del electrodo a 2 mm de la pieza de trabajo. Si

realiza la soldadura con el electrodo apoyado en la pieza de trabajo

podría adherirse y la soldadura sería de mala calidad.

• En caso de sobrecalentamiento la soldadora dejara de funcionar y

las luces indicadoras de protección térmica (E) se encenderán, no

apague la soldadora y espere a que las luces indicadoras se

apaguen para volverla a utilizar.

Corriente de soldadura (A)

20

20 - 100

100 - 200

Ángulo de electrodo

30º

60º - 90º

90º - 120º

BC

E

D

F

This manual suits for next models

1

Table of contents

Other PRETUL Welding System manuals

Popular Welding System manuals by other brands

Lincoln Electric

Lincoln Electric COUGAR K2704-2 Operator's manual

EWM

EWM Phoenix 401 Expert 2.0 puls MM FKG operating instructions

EWM

EWM Tetrix 200 Smart puls 5P TG operating instructions

pela tools

pela tools 513137 manual

EWM

EWM Tetrix 352 AC/DC SYNERGIC PL. AW GR operating instructions

Hobart Welding Products

Hobart Welding Products Beta Mig 135 P owner's manual