SIWM Paris 500 User manual

OPERATING INSTRUCTIONSOPERATING INSTRUCTIONS

Paris500 Cutting Machine

Register now

and benefit!

Jetzt Registrieren

und Profitieren!

www.smart-iwm.com

VECTOR DIGITAL – We optimize the quality and prices

Looking to the future, sustainability, environment friendly and high on the customer-oriented

competence - the key words to which we are responsible.

For this reason, we develop our own powerful brand VECTOR .

In VECTO R weldin g equipm ent c omb ines adv anced i nvert er techn olo gy,th e hig hest

quality standards of a premium brand and low prices to a unique value for money. Inverter

technology is an essential component of process improvement and minimizes energy

consumption. In all our equipment, we therefore trust on the MOSFET technology from

Toshiba and Infineon IGBT technology from SIEMENS. Their innovative solutions are

setting new standards in welding technology.

VECTOR welding equipment can be used on nearly all weld able metals. It is particularly

suitable when quality welds are extremely important. Private gardening - motorcycles,

cars, trucks, classic cars, model making, stair and balcony railings or in the professional

and industrial sectors such as Oil pipeline, chemical, automotive, shipbuilding, boiler,

electric power construction, nuclear power, aerospace, military, industrial installation,

brid g e c o nstr u ction and othe r indu s tries , the high e st q uali t y r e quire m ents a re met

successfully with VECTOR welding equipment.

V E C TOR i s o n e o f t h e l e ading s uppli e r s o f w e l d i ng e q u ipmen t - d i s c o v e r o u r

possibilities - profit from our vision to offer modern, high-performance welding

equipment at unbeatable prices.

On the basis of 4 strategic objectives, our company work day by

day to optimize this vision:

◆Number 1 in Technology

◆Number 1 in the prices

◆Number 1 in Service

◆Number 1 in the environmental compatibility

More than 30,000 enthusiastic customers trust our equipment in the welding and plasma

technology. They confirm the success of these trendsetting strategy. In addition to the

stringent quality test and the test in the production, we subject the equipment a thorough

inspection before delivery. We guarantee delivery of spare parts and repair of all equipment.

The customer is served during and after the warranty period from us. In case of problems,

call us , we are always available. You are also welcome to visit us. Highly qualified employees

are dedicated to carrying out their various tasks with expertise and passion. Our motivated

team will always find a positive solution for you. Everyone is welcome to test our equipment

in detail under the guidance of our experts.

Private gardening, industry or professional, in every area you win if you rely on technology

of welding equipment from VECTOR.

For questions or suggestions, please contact us.www.smart-iwm.com

WARNINGS

Read and understand this entire Manual and your employer’s safety

practices before installing, operating ,or servicing the equipment.

While The operating instructions provide an introduction to the safe

use of the products.

• Read the operating instructions for all system components!

• Observe accident prevention regulations!

• Observe all local regulations!

• Confirm with a signature where appropriate.

Record the following information for Warranty purposes:

Where Purchased:

Purchase Date:

Serial NO.:

Published by:

VECTOR WELDING TECHNOLOGY GMBH

Hansestrasse 101.

51149, Koln, Germany

www.smart-iwm.com

1.1 Arc welding damage--------------------------------------------------------------01-04

1.2 Effects of low frequency electric and magnetic fields----------------------- 04-04

1.3 Symbol chart------------------------------------------------------------------------ 05-05

1. Safety instructions

3.Operation

3.2 Installation Instructions------------------ ------------------------------------------- 11-13

3.1 Layout for the panel----------------------------------------------------------------- 08-10

4.Troubleshooting

4.1 Troubleshooting--------------------------------------------------------------------- 14-15

5.Maintenance

5.1 Maintenance------------------------------------------------------------------------- 16-16

2.Summary

2.2 Specifications------------------------------------------------------------------------ 06-07

2.1 Brief Introduction-------------------------------------------------------------------- 06-06

2.4 Packaged Items---------------------------------------------------------------------- 07-07

2.3 -----------------------------------------------------------------------------07-07Duty cycle

WARNING

PROTECT YOURSELF AND OTHERS FROM POSSIBLE SERIOUS INJURY OR DEATH.

KEEP CHILDREN AWAY. PACEMAKER WEARERS KEEP AWAY UNTIL CONSULTING

YOUR DOCTOR. DO NOT LOSE THESE INSTRUCTIONS. READ OPERATING/INSTRU-

CTION MANUAL BEFORE INSTALLING, OPERATING OR SERVICING THIS EQUIPMENT.

Welding products and welding processes can cause serious injury or death, or damage

to other equipment or property, if the operator does not strictly observe all safety rules

and take precautionary actions.

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal shocks or severe burns. The electrode and

work circuit is electrically live whenever the output is on. The input power circuit and

machine internal circuits are also live when power is on. In semi-automatic or automatic

wire welding, the wire, wire reel, drive roll housing, and all metal parts touching the welding

wire are electrically live. Incorrectly installed or improperly grounded equipment is a hazard.

1. Do not touch live electrical parts.

2. Wear dry, hole-free insulating gloves and body protection.

3. Insulate yourself from work and ground using dry insulating mats or covers.

4. Disconnect input power or stop engine before installing or servicing this equipment.

Lock input power disconnect switch open, or remove line fuses so power cannot be

turned on accidentally.

5. Properly install and ground this equipment according to its Owner’s Manual.

WARNING

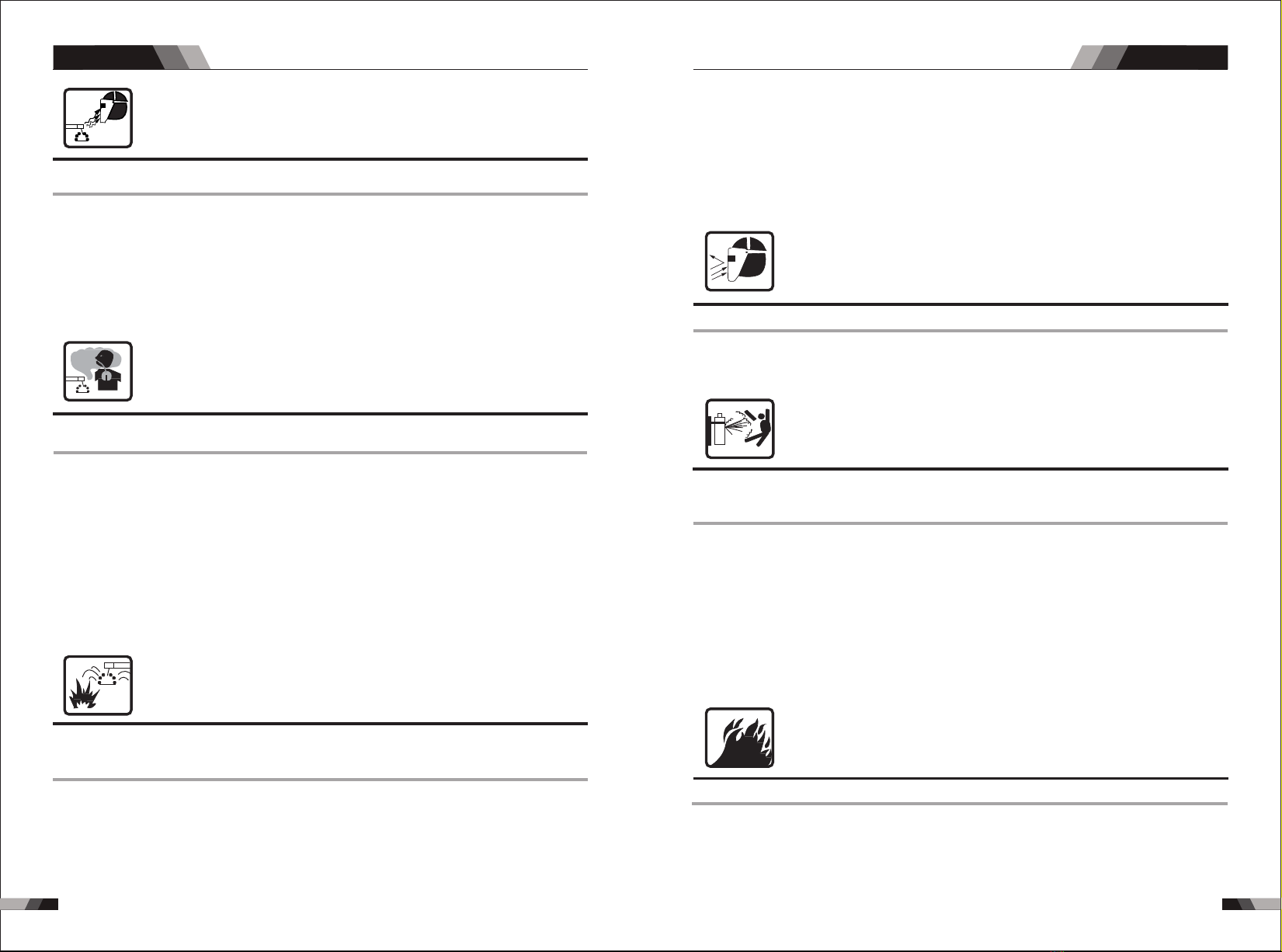

1.1 Arc Welding Damage

Safe practices have developed from past experience in the use of welding and cutting.

These practices must be learned through study and training before using this equipment.

Some of these practices apply to equipment connected to power lines; other practices

apply to engine driven equipment. Anyone not having extensive training in welding and

cutting practices should not attempt to weld.

Safe practices are outlined in the European Standard EN60974-1 entitled: Safety in

welding and allied processes Part 2: Electrical HAVE ALL INSTALLATION, OPERATION,

MAINTENANCE, ANDREPAIR WORK PERFORMED ONLY BY QUALIFIED PEOPLE.

Safety instructions

01

CUTTING SERIES EQUIPMENT

WARNING FLYING SPARKS and HOT METAL

can cause injury.

Chipping and grinding cause flying metal. As welds cool, they can throw off slag.

1. Wear approved face shield or safety goggles. Side shields recommended.

2. Wear proper body protection to protect skin.

WARNING ARC RAYS can burn eyes and skin,

NOISE can damage hearing.

Arc rays from the welding process produce intense heat and strong ultraviolet rays that

can burn eyes and skin. Noise from some processes can damage hearing.

1. Wear a welding helmet fitted with a proper shade of filter to protect your face and eyes

when welding or watching;

2. Wear approved safety glasses. Side shields recommended;

3. Use protective screens or barriers to protect others from flash and glare;

warn others not to watch the arc;

4. Wear protective clothing made from durable, flame-resistant material(wool and leather)

and foot protection;

5. Use approved ear plugs or ear muffs if noise level is high;

6. Never wear contact lenses while welding.

WARNING FUMES AND GASES can be hazardous

to your health.

Welding produces fumes and gases. Breathing these fumes and gases can be hazardous

to your health.

1. Keep your head out of the fumes. Do not breathe the fumes.

2. If inside, ventilate the area and/or use exhaust at the arc to remove welding fumes

and gases.

3. If ventilation is poor, use an approved air-supplied respirator.

4. Work in a confined space only if it is well ventilated, or while wearing an air-supplied

respirator. Shielding gases used for welding can displace air causing injury or death.

Be sure the breathing air is safe.

5. Do not weld in locations near degreasing, cleaning, or spraying operations. The heat

and rays of the arc can react with vapours to form highly toxic and irritating gases.

6. Do not weld on coated metals, such as galvanized, lead, or cadmium plated steel, unless

the coating is removed from the weld area, the area is well ventilated, and if necessary,

while wearing an air- supplied respirator. The coatings and any metals containing these

elements can give off toxic fumes if welded.

WARNING WELDING can cause fire or explosion.

Sparks and spatter fly off from the welding arc. The fly sparks and hot metal, weld spatter,

hot workpiece, and hot equipment can cause fires and burns. Accidental contact of

electrode or welding wire to metal objects can cause sparks, overheating, or fire.

1. Protect yourself and others from flying sparks and hot metal.

2. Do not weld where flying sparks can strike flammable material.

3. Remove all flammables far away from the welding arc. If this is not possible, tightly

cover them with approved covers.

4. Be alert that welding sparks and hot materials from welding can easily go through small

cracks and openings to adjacent areas.

5. Watch for fire, and keep a fire extinguisher nearby.

WARNING CYLINDERS can explode if damaged.

Shielding gas cylinders contain gas under high pressure. If damaged, a cylinder can

explode. Since gas cylinders are normally part of the welding process, be sure to treat

them carefully.

1. Protect compressed gas cylinders from excessive heat, mechanical shocks, and arcs.

2. Install and secure cylinders in an upright position by chaining them to a stationary support

or equipment cylinder rack to prevent falling or tipping.

3. Keep cylinders away from any welding or other electrical circuits.

4. Never allow a welding electrode to touch any cylinder.

5. Use only correct shielding gas cylinders, regulators, hoses, and fittings designed for the

specific application; maintain them and associated parts in good condition.

6. Turn face away from valve outlet when opening cylinder valve.

7. Keep protective cap in place over valve except when cylinder is in use or connected

for use.

8. Read and follow instructions on compressed gas cylinders, associated equipment.

WARNING ENGINE FUEL can cause fire or explosion.

Engine fuel is highly flammable.

1. Stop engine before checking or adding fuel.

2. Do not add fuel while smoking or if unit is near any sparks or open flames.

3. Allow engine to cool before fuelling. If possible,check and add fuel to cold engine before

beginning job.

4. Do not overfill tank — allow room for fuel to expand.

5. Do not spill fuel. If fuelling is spilled, clean up before starting engine.

6. Be aware that welding on a ceiling, floor, bulkhead, or partition can cause fire on the

hidden side.

7. Do not weld on closed containers such as tanks or drums.

8. Connect work cable to the work as close to the welding area as practical to prevent

welding current from travelling long, possibly unknown paths and causing electric

shock and fire hazards.

9. Do not use welder to thaw frozen pipes.

10. Remove stick electrode from holder or cut off welding wire at contact tip when not

in use.

0302

Safety instructions Safety instructions CUTTING SERIES EQUIPMENT CUTTING SERIES EQUIPMENT

WARNING

SPARKS can cause battery gases to explode;

BATTERY ACID can burn eyes and skin.

Batteries contain acid and generate explosive gases.

1. Always wear a face shield when working on a battery.

2. Stop engine before disconnecting or connecting battery cables.

3. Do not allow tools to cause sparks when working on a battery.

4. Do not use welder to charge batteries or jump start vehicles.

5. Observe correct polarity (+ and –) on batteries.

WARNING STEAM AND PRESSURIZED HOT COOLANT

can burn face, eyes, and skin.

The coolant in the radiator can be very hot and under pressure.

1. Do not remove radiator cap when engine is hot. Allow engine to cool.

2. Wear gloves and put a rag over cap area when removing cap.

3. Allow pressure to escape before completely removing cap.

NOTE

To reduce magnetic fields in the workplace, use the following procedures.

1. Keep cables close together by twisting or taping them.

2. Arrange cables to one side and away from the operator.

3. Do not coil or drape cable around the body.

4. Keep welding Power Source and cables as far away from body as practical.

5. The people with heart-pacemaker should be away from the welding area.

1.2 Effects Of Low Frequency Electric and Magnetic Fields

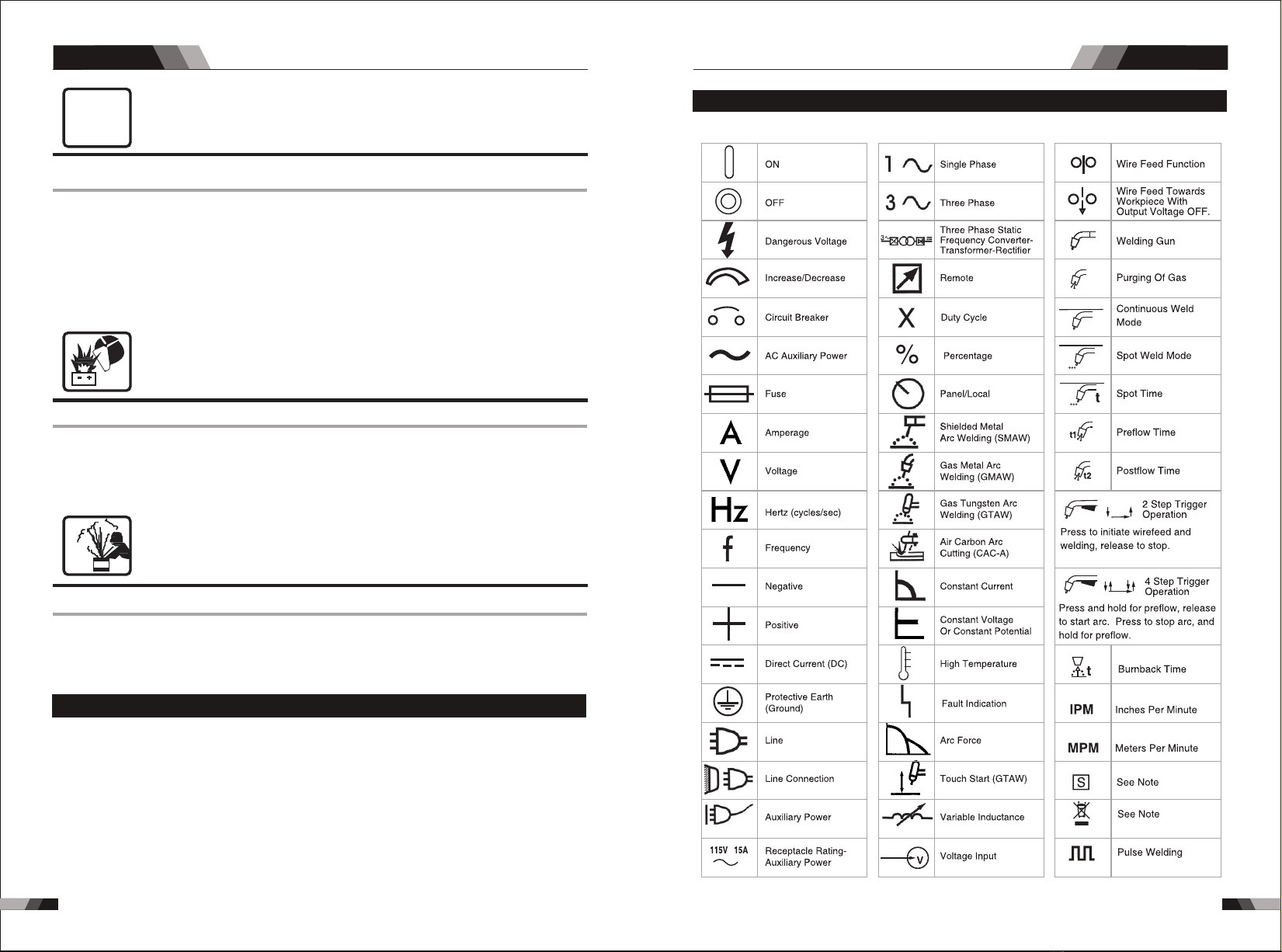

1.3 Symbol Chart

Note that only some of these symbols will appear on your model.

Electric current flowing through any conductor causes localized Electric and Magnetic

Fields (EMF). The discuss on the effect of EMF is ongoing all the world. Up to now, no

material evidences show that EMF may have effects on health. However, the research

on damage of EMF is still ongoing. Before any conslusion, we should minimize exposure

to EMF as few as possible.

WARNING MOVING PARTS can cause injury.

Moving parts, such as fans, rotors, and belts can cut fingers and hands and catch loose

clothing.

1. Keep all doors, panels, covers, and guards closed and securely in place.

2. Stop engine before installing or connecting unit.

3. Have only qualified people remove guards or covers for maintenance and troubleshooting

as necessary.

4. To prevent accidental starting during servicing, disconnect negative (-) battery cable

from battery.

5. Keep hands, hair, loose clothing, and tools away from moving parts.

6. Reinstall panels or guards and close doors when servicing is finished and before

starting engine.

0504

Safety instructions Safety instructions CUTTING SERIES EQUIPMENT CUTTING SERIES EQUIPMENT

Table of contents

Popular Welding System manuals by other brands

Hobart Welding Products

Hobart Welding Products AirForce 375 owner's manual

GF

GF MSA 330 instruction manual

Hakko Electronics

Hakko Electronics FX-888D instruction manual

Abicor Binzel

Abicor Binzel ABIPLAS WELD 100 W operating instructions

EWM

EWM Taurus 355 Basic TDM operating instructions

Thermal Dynamics

Thermal Dynamics PakMaster 100 XL plus operating manual