PRIAM DISKOS 3450 User manual

OEM/SERVICE MANUAL

DISKOS 3450

DISKOS 7050

EIGHT INCH

WINCHESTER

DISC DRIVES

IPIRllAM

a-Inch

Winchester

Disc

Drives

OEM/Service

Manual

JULY

1982

IPRllAM

a-Inch

Winchester

Disc

Drives

OEM/Service

Manual

Changes

to

this

Manual

This manual

will

be changed

periodically

to

keep

it

current

with

improvements as we make them.

Changes

start

with

Field Engineering

Bulletins

that

alert field service

technicians

to

critical

prob-

lem areas and changes in maintenance procedures.

After

aseries

of

these notes are issued

or

acriti-

cal one is issued, we

will

publish

changed pages,

which

are the remove-the-old and insert-the-new

type. Avertical bar in the margin

of

the changed

page

indicates

the revised material.

After

about

20%

of

the

manual's

pages are changed, we

will

reissue the entire manual. When PRIAM prepares

achange package,

it

sends

announcements

to

its

users. The change packages are available upon

request and

without

charge.

Reader

Comments

If you are

dissatisfied

with

this

publication,

we

want

to

hear from you. Tell us

about

inaccurate

in-

formation,

typographical

errors,

or

missing

infor-

mation. If you

know

away

to

improve aprocedure,

please let us know

about

that, too. Please be spe-

cific

and give the page number, line reference, and

the paragraph number,

if

possible.

Change

Notation

Avertical line in the

outer

margin

of

apage indi-

cates the

portion

of

text

affected

by changes.

Shaded areas

indicate

changes

to

illustrations

and diagrams.

The total number of pages

in

this document is 69.

Safety Precautions

As

with

any

electronic

equipment,

precautions

consistent

with

all standard

industrial

safety

prac-

tices

must

be observed

while

servicing

this

equip-

ment

since

it

contains

potentially

dangerous

voltages. Any servicing

that

requires removing

cabinet

covers should be performed by

qualified

service personnel. Always

disconnect

power prior

to

inspection

or

servicing.

Admonishments

are included

throughout

this

manual

to

alert the reader

to

problem areas

or

situations

that

could

cause loss

of

data, hardware

damage,

or

personal injury.

AWARNING

statement

precedes the

text

of

pro-

cedures that,

if

not

strictly

observed, could result

in injury

to

the service technician. ACAUTION state-

ment

precedes the

text

of

aprocedure that,

if

not

strictly

observed, could result in damage

or

de-

struction

of

equipment

(hardware

or

software). A

NOTE

statement

highlights

essential operating

or

maintenance

procedures,

conditions,

or

clarifying

facts. NOTEs also provide information that, though

not

necessary, is helpful

to

the understanding

of

a

concept

or

the

completion

of

aprocedure.

The

following

are general

safety

precautions

that

are not related

to

any

specific

procedure and

therefore

do

not

appear elsewhere in

this

manual.

Personnel

must

heed these

warnings

during many

phases

of

installation

and maintenance.

WARNING

Page No. Change Number* Page No. Change No.*KEEPAWAY FROM LIVE CIRCUITS.

Dates of issue for original and changes pages are: *0

in

this

column indicates an original page.

Observe

safety

precautions

at all times. Observe

all the CAUTIONS and WARNINGS in

this

manual

when

working

with

the equipment.

DO

NOT SERVICE

OR

ADJUST ALONE.

Never reach

into

the

cabinet

to

service the equip-

ment unless someone capable

of

giving aid is

present.

The

following

WARNING applies

to

any service

inside the

equipment

cabinet.

It

appears else-

where in the

text

of

this

manual and is introduced

here

for

emphasis:

WARNING

Voltage hazardous

to

human

life

are exposed in

the cabinet. Use extreme

caution

when servicing

either

the power

supply

or

any area where power

terminals

are exposed.

Warranty

For warranty

information,

contact

PRIAM:

(408) 946-4600.

TABLE

OF

CONTENTS

3.

FUNCTIONAL DESCRIPTION. .......... 9

3.1 Overview. ..................... 9

3.2 Servo

Surface.

................. 9

3.3 Servo Pattern. ...............

..

9

3.4 Data

Surface..................

10

3.5 Track

Format..................

11

3.6 Defect

Location

Record

Format..

11

3.7 Data

Sector

Format.

..........

..

11

3.8 Overview. ...................

..

12

3.9 Drive

Selection................

12

3.10 Power Up/Down Sequences 12

3.11

Motor

Control

Circuitry.

.......

..

12

Spare Parts

List

".

64

Schematics.

................

..

65

4.

TROUBLESHOOTING

".

57'

4.0

Introduction.

................

..

57

4.1

Field

Adjustments

and Preventive

Maintenance

".

57'

4.2 General

Inspection

".

57

4.3

Status

and Error Codes

".

57

4.4

Symptoms

and Causes

".

57

4.5 Seek Errors and Fault

Conditions.

62

4.6

Precautions.

................

...

63;

4.7 Head Disc

Assembly

".

63

4.8 Servo and

Motor

Control PCB

..

".

63

4.9 Read/Write Digital PCB

".

63

4.10 Power Supply

".

63

Section

1.

GENERAL INFORMATION .

1.1

Overview .

1.2

Options

.

2.

INSTALLATION .

2.0

Introduction

.

2.1

Unpacking and Receiving

Inspection .

2.2 Shipping Damage

Inspection

.

2.3 System Unpacking .

2.4 Inspection Procedures .

2.5 Reshipping Procedures .

2.6

Switch

Settings

.

2.7 Cabling .

2.8

Unlocking

.

2.9 Locking .

2.10 Repacking .

2.11 Storage .

2.12

Shipping

.

2.13 Spindle and Head Locks .

2.14 Powering Up/Down .

2.15 Performance Check .

Page

1

1

1

3

3

3

3

3

3

3

3

3

4

4

5

5

5

5

7

7

ii

Section

3.12

3.13

3.14

3.15

3.16

3.17

3.18

3.19

3.20

3.20.1

3.20.2

3.20.3

3.20.4

3.20.5

3.20.6

3.20.7

3.20.8

Page

Seek Modes 12

Servo

Circuitry.

..............

..

14

Data Read/Write

Functions.

...

..

14

PLO/VFO 17

Microprocessor

Flow

Charts.

. .

..

18

PRIAM

Interface...............

18

Connectors

and Pin

Assignments.

18

Interface Signal

Descriptions..

..

35

SMD Interface

".

45

Overview. ...................

..

45

Connectors

and Pin

Assignments.

45

Interface Signal

Descriptions

..

".

46

Interface

DC

Characteristics

".

50

Interface

Timing

".

52

Format Design

".

54

Write Format Procedure

".

54

Control

Timing

".

55

LIST

OF

FIGURES

Figur~

Page Figure Page

2-1.

Read/Write Digital

PCB

...........

4

3-26.

Calibrate Flow Chart.

.............

34

2-2.

Servo and

Motor

Control PCB

......

4

3-27.

DBUS Transceiver

................

38

2-3.

Daisy-Chaining an 8-inch Drive

with

3-28.

Single End Line Receiver Gated By

PRIAM Interface

.................

5DRIVE SELECT

..................

38

2-4.

Location

of

Head and Spindle

Lock.

6

3-29.

Single End Line Receiver

..........

38

3-1.

Servo and Data Surfaces

..........

9

3-30.

Single End Line Driver

.............

39

3-2.

Servo Track Signals

...............

10

3-31.

Differential Line Drivers and

3-3.

Simplified Block Diagram

of

aPRIAM Receivers

.......................

39

8-inch Disc Drive

.................

13

3-32.

Register Load Timing

.............

40

3-4.

Motor

Controller

.................

14

3-33.

Register Read Timing

.............

40

3-5.

Servo Circuitry

...................

15

3-34.

Reset Timing

....................

40

3-6.

Read/Write Timing and Encoding

...

16

3-35.

INDEX and SECTOR MARK Timing

..

40

3-7.

Data Read and Write Circuitry

......

17

3-36.

WRITE DATA and

3-8.

Initialization Flow Chart

......

'

.....

19

WRITE CLOCK Timing

............

40

3-9.

First Idle Flow Chart

..............

20

3-37.

READ DATA and

3-10.

Idle Flow Chart

...................

21

READ CLOCK Timing

.............

41

3-11.

Command Decode Flow Chart

......

22

3-38.

Record Writing Timing

............

41

3-12.

Sequence Up Flow Chart

#1

........

23

3-39.

Record Reading Timing

...........

42

3-13.

Sequence

Up

Flow Chart

#2

........

24

3-40.

Read and Write Transitions

3-14.

Sequence Down Flow Chart

........

25

During Gap

......................

42

3-15.

Restore Flow Chart

...............

25

3-41.

Typical Read/Write Data and

Clock

3-16.

Seek Flow Chart

.................

25

Transmitter and Receiver

..........

50

3-17.

Restore Subroutines Flow Chart

....

26

3-42.

Control Line Transmitter

...........

51

3-18.

Seek Subroutines Flow Chart

#1

....

27

3-43.

Control Line Receiver

.............

51

3-19.

Seek Error Flow Chart.

............

28

3-44.

Tag and Bus Timing

...............

52

3-20.

Last Track Flow Chart

#1

..........

29

3-45.

Typical Read Timing

..............

53

3-21.

Last Track Flow Chart

#2

..........

30

3-46.

Typical Read Control Timing

.......

53

3-22.

Seek Done Flow Chart.

............

31

3-47.

Typical Write Control Timing

.......

53

3-23.

Fault Reset Flow Chart

............

32

3-48.

Index and Sector Mark

............

53

3-24.

Read Drive IDand

3-49.

Drive Select Timing

...............

53

Read Bytes/Sectors Flow Chart

.....

32

3-50.

NRZ Data and Read

Clock

Timing

...

54

3-25.

Seek Start Flow Chart.

............

33

3-51.

Recommended Sector Format

......

55

iii

LIST

OF

TABLES

Table Page Table Page

1-1.

Specifications

for

PRIAM 8-inch

3-10.

Reset AC

Characteristics

...........

40

Disc Drives

.......................

2

3-11.

INDEX and SECTOR MARKAC

2.4.

S~itch

Settings

on the Read/Write

Characteristics

.................

".

40

Digital PCB

.......................

3

3-12.

WRITE DATA and WRITE CLOCK

3-1.

Head Selection

...................

37

AC

Characteristics

................

40

3-2.

DBUS Transceiver

DC

3-13. READ DATA and READ CLOCK

Characteristics

...................

38 AC

Characteristics

................

41

3-3.

Single End Line Receiver Gated by 3-14. Record

Writing

Control AC

DRIVE SELECTED

Characteristics

...

38

Characteristics

...................

41

3-4.

Single End Line Receiver

DC

3-15.

Record Reading Control AC

Characteristics

...................

38

Characteristics

...................

42

3-5.

Single End Driver

DC

3-16.

Register Selection

.................

43

Characteristics

...................

39

3-17.

Command Code Summary

..........

43

3-6.

Differential Receiver

DC

3-18.

Drive ID

Assignments

..............

44

Characteristics

...................

39

3-19.

Status

Register

Bit

Definitions

......

44

3-7.

Differential Line Driver

DC

3-20. Address Register

Bit

Definitions

.....

45

Characteristics

...................

39

3-21. Tag Bus I/O Interface

("A"

Cable)

....

46

3-8.

Register Load AC

Characteristics

....

39

3-22. Tag Bus Decode

("A"

Cable)

........

47

3-9.

Register Read AC

Characteristics

...

40

3-23.

"B"

Cable Interface

................

47

iv

1.

GENERAL INFORMATION

1.1

The DISKOS 3450 and 7050 use advanced

Winchester

and

microprocessor

technol-

ogies

to

provide users

with

low-cost

disc

drives

having high capacity, fast access, and long-term

reliability. Linear

motor

voice

coil

positioners

with

track

following

servos enable the DISKOS 3450

and 7050

to

position

Winchester

type heads

quickly

and precisely. These low-force heads as-

sure high

data

reliability.

Advanced 8-inch Winchester-technology

discs

are

driven by an outer-rotor, brushless

DC

motor. The

head

positioner

coil

and carriage, heads and

discs

are enclosed in asealed,

contamination-

resistant

chamber

to

assure high reliabilIty.

One head serves each

disc

surface, and afull sur-

face is

dedicated

to

servo

information

for

fully

servoed

track

following,

head

positioning,

and

write

timing.

Three

discs

recorded

at

480

tracks

per inch are used in the DISKOS 3450

to

provide a

capacity

of

35

megabytes,

unformatted.

In the

DISKOS 7050, the three

discs

are recorded at 960

tracks

per

inch

to

accommodate

70

megabytes

(unformatted)

of

data.

Microprocessors

are used in the disc-drive elec-

tronics

to

provide interface

flexibility

and

to

moni-

tor

drive operation. For example, they

control

power up and

down

sequencing, and aself-test

program

checks

drive performance

during

each

power-up sequence. Any

malfunction

detected

by

these

tests

will

prevent drive start-up, reducing

the chance

of

loss

of

data

or

damage

to

the drive.

PRIAM

disc

drives are

constructed

in a

modular

fashion, so

that

defective

assemblies

can be

easily replaced. This greatly reduces down

time

due

to

servicing. The three

assemblies

are:

Head Disc

Assembly

Servo and

Motor

control

PCB

Read/Write

Digital

PCB

The Head Disc Assembly(HDA) is asealed enclo-

sure. It

contains

the drive

spindle

assembly, drive

motor, Hall

Effect

sensors, voice

coil

actuator,

head carriage assembly,

read/write

heads, mag-

netic

discs, and

air

filter

assemblies.

The Servo and

Motor

Control PCB

contains

the

circuitry

associated

with

driving the

spindle

mo-

tor. This

circuitry

receives an

On/Off

command

from the Read/Write Digital PCB, and

spindle

ro-

tation

feedback from the Hall

Effect

sensors in

the HDA.

1

The Servo and

Motor

control

PCB also

contains

the

circuitry

used

for

processing the servo

signals

from the servo read head, and

for

controlling

the

position

of

the head carriage.

The Read/Write Digital PCB

contains

all the cir-

cuitry

associated

with

read/write

control,

com-

mand execution, and

information

transfers across

the user interface.

1.2

Options

1.2.1

Interface

Options. The PRIAM 8-inch

disc

drives are available

with

avariety

of

interface

options.

Each

of

these

interface

options

can be used,

without

modification,

on any

disc

drive in the 8-inch family. All PRIAM

interfaces

in-

clude

on-board

data

separation.

The standard PRIAM

interface

is designed

for

low

cost

and

for

efficient

use

with

microprocessor-

based systems. Up

to

four

drives may be daisy-

chained, when

this

interface

is used. The PRIAM

intEHface provides abasic 8-bit

bidirectional

bus,

which

may be used

with

the

currently

popular

8-bit

and 16-bit microprocessors. It

also

provides bit-

serial NRZ data exchange. No elaborate handshak-

ing

protocols

are required. The PRIAM

interface

is

built

into

the

disc

drive's

read/write

digital

PCB. A

50-conductor

flat

ribbon cable is

Ulsed

between

the PRIAM

interface

and the

host

system.

The SMD Interface

permits

aPRIAM drive

to

be

used

with

existing

Storage

Module

Drive (SMD)

controllers. In the 8-inch drives the SMD

interface

is available as an adapter

which

is

installed

be-

tween the drive electronics and the SMD controller.

The line drivers and line receivers in the SMD in-

terface are

matched

to

those

of

typical

SMD con-

trollers. There are

two

interface cables between

the host

system's

SMD

controller

and the PRIAM

disc

drive's SMD Interface- a 60-conductor

twisted-pair

flat

cable

("A"

cable) and a26-con-

ductor

flat

ribbon cable

("B"

cable).

The ANSI

interface

complies

with

the

disc

drive

interface

standard proposed by ANSI Technical

Committee

X3T9.

Characteristics

of

the ANSI in-

terface

include

variable and fixed

sector

sizes,

data

transfer

rates up

to

10

megabits

per second,

and radial

attention

and

select

capability. Up

to

eight

drives may be daisy-chained, on a

single

50-conductor

flat

ribbon cable.

1.2.2 Interface Cables and Terminators. I/O

cables are available from PRIAM,

for

con-

necting the user's controller

to

the PRIAM

disc

drive, and

for

connecting

daisy-chained drives

to

one another.

Terminators are available for I/O signal lines, to

minimize reflections and

to

ensure maximum data

integrity. One set

of

terminators is required for a

single drive, orforthe last drive in adaisychain.

1.2.3 Power Supplies and Cables. PRIAM's

optional power supply allows-PRIAM disc

drives to operate from

100,

120,220, and

240

VAG,

50

or

60

Hz

power. The optional power supply

must

be

mounted separately from the drive. It

does not

fit

within the drive frame.

1.2.4 Mounting Hardware. PRIAM a-inch

drives may be mounted horizontally or

ver-

tically. Standard floppy disc mounting may be

used.

Table

1·1.

Specifications

for

PRIAM a-inch

Disc DrivesDISKOS DISKOS

OPERATING CHARACTERISTICS

3450

7050

Capacity (unformatted)

Transfer rate (megabytes/second)

Track-to-track seek time (typical)

Average seek time (typical)

Maximum seek time (typical)

Average latency

Tracks per inch

Bits per inch

Number

of

data surfaces

Number

of

data cylinders

Nominal RPM

Bytes per track

35

MB

0.806

8msec

42

mse.c

75

msec

8.3msec

480

6,670

5

525

3,600

13,440

70

MB

0.806

8msec

42

msec

75

msec

8.3 msec

960

6,670

5

1,049

3,600

13,440

Power Requirements

Power requirements are the same for both drives:

DC

Voltage Maximum Typical

+24

VDC

(±5%)

4.0 A

3.5

seeking

2.2

non-seeking

+5

VDC

(±5%)

2.0

A1.5 A

-5

VDC

(±5%)

2.0

A

1.5

A

-12

VDC

(±

5%)

0.7

A

0.4

A

NOTE: This data does not include adapter/inter-

face option power requirements.

Dimensions

Physical dimensions are the same for both drives:

Weight 20.00 pounds

7.80

±.05

TYP

NO. 8-32-2B x3/8DP

4HOLES

8.12

TYP

-----/-ot-

BOTTOM

8.00

-----11+--

-----iL-

__

______

.J

I

~--l

I I

II

f------

J

I~f_+---------_r_--_J_---

.....

I

_____

~--

-J-=-~

~

---i+-e-"t+---'-

--------

14.25

±.02

LEFT SIDE

J5

REAR

8.55

±.03

J1

GND-POWER SUPPLVCABLE

NO. 8-32 HOLES

2

2.

INSTALLATION

2.0

Introduction.

This Chapter

contains

pro-

cedures

for

installing

the 3450 Disk Drive.

It includes

instructions

for

unpacking and in-

specting, and procedures

for

interconnecting

the

equipment

to

the powersource.

2.1

Unpacking and Receiving Inspection. When

the 3450 Disc Drive is delivered by atrans-

fer company,

it

must

be carefully inspected (inside

the shipping

container

as well as out)

for

damage.

If

the

unit

is

to

be reshipped,

it

must

be repacked

in amannerthatwill prevent damage while in transit.

2.2 Shipping Damage Inspection. Prior

to

accepting

delivery

of

the 3450 Disc Drive

from the carrier, carefully inspect the shipping

container

for obvious damage.

If

damage is found,

note

it

on the waybill and require the delivery

agent

to

sign the waybill.

Notify

the transfer com-

pany

immediately

and

submit

adamage report

to

the carrier.

If

no exterior damage exists, unpack

the system and

inspect

for hidden damage.

2.3 System Unpacking. The 3450 Disc Drive

is shipped

with

the accessories and sche-

matics

in one shipping container.

Unpack the system from the shipping

container

with

care; avoid using sharp

instruments

to

open

the container.

We

recommend saving all packing

materials

for

possible reuse in reshipping the

equipment.

If

hidden damage is found, immediately

notify

the

transfer company

of

the damage. Save all packing

materials for the transfer

company's

inspection,

file

adamage report

with

the carrier. Damage

to

the equipment is not covered under warranty. All

repairs for shipping

will

be billed. Prompt notifica-

tion

of

damage

will

ensure

claim

validity

and

will

help expedite payment for necessary repairs by

the transfercompany

or

its

insurance agent.

2.4

Inspection

Procedures.

After

unpacking

the 3450 Disc Drive, Inspect

it

thoroughly

for damage hidden by the packaging and for loose

components

or

fittings,

as follows:

a.

Inspect the Interiorfor shipping damage.

b.

Examine internally mounted

components

for

loose or

missing

hardware.

c. Tighten all loose hardware.

d. Clean the cabinet

interior

by removing loose

debris.

e.

Check

that

head and spindle

lock

is secure.

3

2.5 Reshipping Procedures. Should the equip-

ment

be reshipped prepare the

equipment

for

shipping

as follows:

a.

Check the

integrity

of

the cabling and the secu-

rity

of

internal mounting hardware.

b.

Place the drive

flat

on abench

top

and then

place the spindle head

lock

in the LOCK position.

c. Repack the equipment in the original shipping

container

or other

suitable

materials.

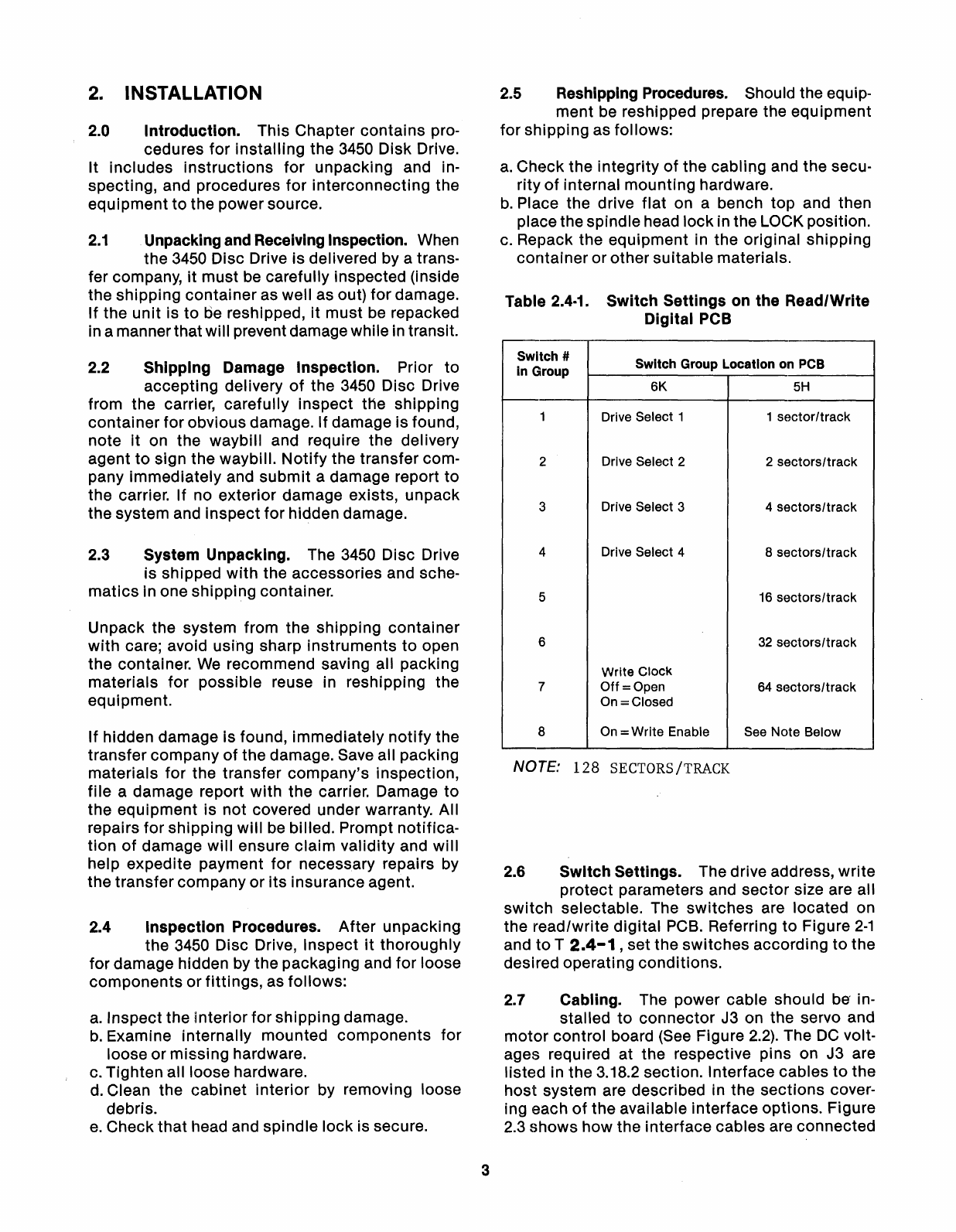

Table

2.4-1.

Switch

Settings

on the Read/Write

Digital PCB

Switch #Switch Group Location on PCB

in

Group 6K

5H

1Drive Select 1 1

sector/track

2Drive Select 22

sectors/track

3Drive Select 34

sectors/track

4Drive Select 48

sectors/track

5

16

sectors/track

6

32

sectors/track

Write

Clock

7

Off=Open

64

sectors/track

On =Closed

8On =Write Enable See Note Below

NOTE:

128

SECTORS

/TRACK

2.6

Switch

Settings. The drive address,

write

protect parameters and

sector

size are all

switch

selectable. The

switches

are located on

the read/write

digital

PCB. Referring

to

Figure

2-1

and

to

T

2.4-1

,set the

switches

according

to

the

desired operating conditions.

2.7 Cabling. The power cable should

be

in-

stalled

to

connector

J3 on the servo and

motor

control board (See Figure

2.2).

The

DC

volt-

ages required at the respective pins on J3 are

listed in the 3.18.2 section. Interface cables

to

the

host

system are described in the

sections

cover-

ing each

of

the available interface options. Figure

2.3 shows how the interface cables are connected

oSECTOR

oSELECT

____

J3_~

TO

SERVO/MOTOR

CNTL

BOARD

tj

0M

lJ035

J253

2716 IlP. BUS

DRIVER

J1

BW

TO

CONTROLLER

EJ

DRIVE

SELECT

6K

WRT

CLK

PHASE

•WRT

CLK

LOOP

WRITE PROTECT

D9JB

D9JA

J2

~

"-;:===~

J1

MOTOR &

HALL

EFFECT

SENSORS

POR

J3

POWER

CONNECTOR

f8l

CURVE

l!!1

GEN.

f61

FPOSITION

~

SIGNAL

rJWRITE

~DELAY

r------,

I

VFO

I

II

L

..J

R15

O

DATA

WINDOW

ADJ.

CC

W

FC

3

TRKXING

0

VOICIJ

=

COIL

J5

GUARD

BAND

r;;l

DELAY

L:J

LINE

o

0ENTIATOR

LJ

LIMITED

DATA

Figure 2·1. Read/Write

Digital

PCB

for the PRIAM interface. Cabling between assem·

blies within the discdrive is completed at the factory

prior

to

shipment. More

details

on inter-assembly

cabling

are given in the ASSEMBLY REPLACE-

MENT PROCEDURES section.

2.8 Unlocking. Both the drive

spindle

and

the head carriage assembly are locked

prior

to

shipment.

After

the drive has been com·

pletely

mounted and cabled, these

must

be

unlocked

to

enable normal operation.

The drive spindle and head carriage

lock

is

fully

accessible

from one end

of

the HDA (Head Disc

Assembly). Referring

to

Figure 2·4, place

this

lever

in the UNLOCK

position.

4

o

INDEX

IT]

Figure 2·2. Servo and

Motor

Control PCB

CAUTION

Avoid manual rotation

of

the

spindle

or

movement

of

the carriage. Damage

to

the

disc

surface may

occur

if

the heads

are moved across anon-rotating

disc

surface. Do

not

move the drive

with

the

spindle

and head carriage assembly

unlocked.

2.9 Locking. The drive

spindle

and the head

carriage shou

Id

be locked whenever the

drive is

to

be

physically

moved, even

if

it

is

not

to

be shipped.

To

lock

the drive, refer

to

Figure

2-4,

and place the lever in the LOCK Position.

•

~

........

.........

........

",

TO SPECIAL CONN.

ON FIRST

DRIVE

PN

NO. 922576-50-1

................

................ ................

........

........

........

TOJ1

SECOND

DRIVE

,

........

........

........

........

........

'...--

PART NO. 922576-50-1

PLUGS

INTO

J1

CONN.

ON

DRIVE

TOP

PCB

•

FROM

CONTROLLER

BOTH CABLES PLUG

INTO

PN

NO. 922576-50-1

CONNECTOR

*

MAY

BE

DUPLICATED

FOR

UP

TO 3

DRIVES

Figure

2-3.

Daisy-Chaining an a-inch Drive

with

PRIAM

Interface

2.10 Repacking. Repacking is the reverse

of

the

unpacking

procedure. Prior

to

repack-

ing the drive, make sure

that

the

spindle

and car-

riage

lock

level is in the LOCK

position.

2.11

Storage. When the environment is severe,

or

when

the

drive is

to

be stored

for

along

time,

it

should be repacked

prior

to

storage.

When

storing

unpacked drives, avoid

dusty

or

un-

stable

environments.

2.12 Shipping.

Contact

PRIAM

Customer

Ser-

vice

for

areturn

authorization

number

prior

to

shipping

adrive

or

assembly

to

PRIAM.

5

After

locking

the drive

spindle

and head carriage,

pack

the drive in

its

original

carton

or

an equiva-

lent one.

2.13

Spindle

and Head Locks. Before the

drive can be operated,

it

is necessary

to

have the drive mounted

or

placed

flat

on abench,

then place the

spindle

and head

lock

lever in the

UN

LOCK

position.

Refer

to

Figure

2-4

for

the

location

of

this

lever.

CAUTION

Whenever the drive is

to

be moved

for

any reason,

the

spindle

and head

lock

lever should be placed

in the

lock

position.

;iiiiiiiiiiiiiiiii';_iiiiiiHi

iiiiiiiiiiiiiiiiiiiiiiiiiii_iiiiiiii_=

_

SPINDLE LOCK

o

Figure 2·4.

Location

of

Head and Spindle

Lock

2.14 Powering Up/Down. The

exact

proce-

dure

for

powering up the drive depends on

the

interface

option

present:

If the drive has astandard PRIAM interface,

apply

DC

power,

select

the drive (via the -DRIVE

SELECT lines) and issue aSequence Up

command.

If the drive has an SMD interface, apply

DC

power,

select

the drive (via the UNIT SELECT

lines), then bring PICK and HOLD

to

ground.

If

the drive has an ANSI interface,

apply

DC

power,

select

the drive (via the SELECT/ATTEN-

TION lines), then issue aSpin Up command.

Similarly, the procedure

for

powering

down

also

depends on the interface

option

present:

If

the drive has astandard PRIAM interface, is-

sue aSequence Down

command

and discon-

nect

DC

power

supply.

If the drive has an SMD interface, remove the

ground from PICK

or

HOLD and

disconnect

DC

powersupply.

6

If the drive has an ANSI interface, issue aSpin

Down command and disconnect

DC

powersupply.

2.15 Performance Check. The

following

pro-

cedures are recommended as an

initial

check

for

properoperation on the

disc

drive:

a.

Watch for the drive

to

become Ready.

If

no faults

are detected during the power up sequence,

this

will

take

about

30

seconds.

If

a

fault

is de-

tected

(by the

safety

circuits

within

the drive),

Ready

will

be

inhibited

and a

fault

condition

will

be reported. If,

after

two

minutes, the micro-

processor

within

the drive is unable

to

sense

that

the

spindle

is

rotating

at the

specified

speed, READY

will

be

inhibited

and

spindle

ro-

tation

will

stop.

b.

Check the head positioning operation by issuing

seek commands. The

following

seek pattern

is

suggested:

From 000

to

001

to

000

to

002

to

000

to

003

to

000

to

004

to

000

to

005

to

000

...

to

maximum

cylinder

address.

c.

Check

for

proper

data

transfer

operation by writ-

ing and then reading data with each read/write

head.

CAUTION

Write operations alter previously recorded data

Most

disc

s/ystems require aformatted

disc

be-

fore datatransfer can be performed.

7

A

disc

surface

defect

map is supplied by PRIAM

with

each

disc

drive. The defect map indicates

the location

of

defects

discovered during manu-

facturing and testing. Adefect location is spe-

ci'fied by the number

of

byte

positions

from the

index mark.

NOTES

8

3. FUNCTIONAL DESCRIPTION

3.1

Overvh!w. The PRIAM 3450 Disc Drive

has three discs, with atotal

of

six magnetic

surfaces. Each surface accommodates one head,

as shown in Figure

3-1.

On the

"bottom"

surface,

the head reads the servo information. The remain-

ing heads write and read datasurfaces0through

4.

r---

-

DATAH~

DISC

NO.4

)

DATAH~

NO.3

w

DIHAHE~

t:l

«

DISC

NO.2

~

)«

u

DATAHE~

0

w

NO.1

~

....

:I:

0

Z

g;

DIHAHE~

DISC

NO.O

)

SER\~

HEAD

I-

.....----....

Figure

:~·1.

Servo and Data Surfaces

The PRIAM 7050 has exactly the same configura-

tion

of

disc

surfaces and heads as the

3450,

but

it

achieves

twice

the storage capacity by having

twice

as many data tracks per inch.

3.2

Servo Surface. The purpose

of

the servo

surface is

to

provide acoordinate system

by which the electrical

circuitry

of

the

disc

drive

can locate spe'cific areas for writing or reading data.

The servo surface is written once at the factory,

and thereafter is aread-only area. The information

on the servo surface determines the angular posi-

tion

of

the disc, as well as the radial position

of

the head carriage.

The servo surface is divided into four

distinct

groups

of

tracks. From the inside (hub) out, these

are as follows:

a.

Guardband 2(landing zone)

b.

Guardband 1

c.

Servo Data Band

d.

Guardband 1

Within each

of

these bands, ,there are four types

of

tracks-odd normal tracks, odd quadrature

tracks, even normal tracks, and even quadrature

tracks. Each track type produces acharacteristic

signal at the servo read head, as described below

in the SERVO

PATTERN

section. The closer the

servo read head is

to

aparticulartrack, the greater

9

will

be

that track's contribution

to

the servo

head's output.

The servo

circuitry

compares the amplitudes

of

the signals from adjacent tracks, and identifies an

equal-ampliture

condition

as a

"track

crossing."

During seek operations, the

servo

circuitry

counts

the track crossing in order

to

stop at the cylinder

address requested by the controller. During write

and read operations, the servo

circuitry

adjusts

the position

of

the head carriage in such amanner

as

to

preserve the equal-amplitude condition,

thus keeping the write/read head

"on

track."

3.3

Servo Pattern. Figure

3-2

shows the four

kinds

of

servo track signals. The normal

servo data patterns are written on the integer

tracks, and the quadrature servo data patterns are

written on the half-integer tracks.

The negative pulses are sync pulses.

In

the all

"0"

pattern, these pulses

occur

at regular intervals,

and serve to define the frame boundaries. When

the servo head reads a

"1,"

an

additional negative

pulse occurs in the mid-frame position. The frame

time interval

(T)

is equal

to

16

write/read data

bit

times. Most

of

agiven track is written

with

the

"0"

pattern. The

"1"

pattern occurs once each revolu-

tion

of

the disc, and serves

to

define the INDEX

location.

The positive pulses are used by the servo

circuitry

to

recognize track crossings or

to

maintain the on·

track condition. Referring again

to

the all

"0"

pattern,

it

can be seen that the even normal track

generates positive pulses occurring one-third

of

the way across the frame, while the odd normal

track generates positive pulses occurring at the

two-thirds point. The quadrature track patterns

have positive pulses alternately at the one-third

and two-thirds positions.

When the servo read head is midway between

two

adjacent tracks

(a

"track-crossing"

position) the

output

resembles the patterns shown at the

bottom

of

Figure

3-5.

Successive frames

produce the equal-amplitude positive peaks,

alternating

with

single large peaks. By analyzing

which frames have the equal-amplitude peaks,

and whether the large peaks

occur

at the one-third

or the two-thirds locations

within

the frame, the

servo

circuitry

is able

to

determine which

of

the

four kinds

of

"track-crossing"

positions is being

indicated. Note that the servo read head is mid-

way between

two

adjacent tracks when the data

write/read heads are

"on-track."

The servo

circuitry

counts the track crossing in

order

to

determine the current cylinderaddress.

In

the 3450, data tracks are written at alternate cylin-

der address (all integer or all half-integer).

In

the

7050,

data tracks are written at both the integer

and half-integer cylinder addresses.

3.4 Data Surface. The configuration

of

tracks

on the data surfaces has aone-to-one cor-

LOGICAL

FRAME

FRAME

BOUNDARY

ODD

NORMAL

WRITE

DATA

READ BACK

ON

ODD

NORMAL

SERVO

TRACK

ODD

QUADRATURE

WRITE

DATA

READ BACK

ON

ODD

QUADRATURE

SERVO

TRACK

EVEN

NORMAL

WRITE

DATA

READ BACK ON EVEN

NORMAL

SERVO

TRACK

EVEN

QUADRATURE

WRITE

DATA

READ BACK

ON

EVEN

QUADRATURE

SERVO

TRACK

READ

BACK

ON

DATA

TRACK

BETWEEN ODD

NORMAL

AND

EVEN

QUADRATURE

SERVO

TRACK

READ

BACK

ON

DATA

TRACK

BETWEEN EVEN

NORMAL

AND

EVEN

QUADRATURE

SERVO

TRACK

respondence with the configuration

of

servo

tracks on the servo surface. Thus, for example,

when the servo head is in the servo data band, all

the write/read heads are in the corresponding po-

sitions

in their respective write/read data bands.

When the servo head is in the servo landing zone,

each data head is also in

its

own landing zone.

*MISSING SYNC

AT

THE FRAME

BOUNDARY

WILL

RESULT

IN

LOW

AMPLITUDE

SIGNAL

AS SHOWN

AT

A*

AND

B*

Figure 3·2. Servo Track Signals

10

The

format

for

the

Ski·p

Defect Record is as

follows:

The write/read

data

tracks

are numbered consec-

utively,

starting

with

track

0nearest the

outside

edge

of

the disc. Each write/read

data

track

is di-

vided

into

sectors. The division

of

tracks

into

sec-

tors can be adjusted by the user through

switch

settings

on

the

read/write

digital

PCB, as detailed

in the INSTALLATION section.

3.5 Track Format. In a

typical

track

format,

each

track

isdivided as

follows:

Data sync (FB hex)

1

st

defect

location

2nd

defect

location

3rd

defect

location

Checksum

Fill characters (zeros)

1byte

2bytes

2bytes

2bytes

2bytes

2bytes

Index Mark

Gap (type

1)

SkiPDefect Record

N

Identical

Data Sectors

Gap (type

3)

The index mark is a1.92

microsecond

(tWO-byte

times) pulse, derived from the index pattern on the

servo

data

surface.

The type 1gap

allows

for

VFO synchronization

for

data

separation. It

consists

of

zeros, and has a

minimum

length

of

23

bytes.

3.7 Data

Sector

Format. The N

identical

Data Sectors have the

following

structure:

Sector

Mark

Gap (type

1)-zeros

(23

bytes

minimum)

Address Field

Gap

(type2)-zeros

(11

bytes

minimum)

Data Field

The

sector

mark

is

a960 nanosecond (one byte

time) pulse

which

occurs

at

the beginning

of

each

sector. It is generated by

the

servo circuitry, using

abyte

clock

which

is

initialized

by the index

pulse.

The

format

for

the Address Field is as

follows:

The Data Field has the

following

structure:

The

composition

of

the Skip Defect Record and

of

the

N

identical

DataSectors are described below.

The type 3gap is a

function

of

sector

size, and is

used

to

fill

(with zeros) the space

left

over

after

the

largest

possible

integer

number

of

sectors

(com-

mensurate

with

the

switch

settings) have been

written.

It should always

be

remembered that the switch set-

tings determining sector size are read by the micro-

processor as part

of

the Sequence Up process.

Thus, achange in these switch settings will not take

effect

until

the drive is once again sequenced up,

or

re-initialized from apower

down

condition.

Sync pattern (F9 hex)

Head and high order

cylinder

address

Low order

cylinder

address

Sector

address

Sector

length and flag

CRC

Fi

II

characters (zeros)

Sync pattern (FD hex)

Data bytes (according

to

sector

length)

CRC

Fill characters (zeros)

1byte

1byte

1byte

1byte

1byte

2bytes

2bytes

1byte

2bytes

2bytes

3.6 Defect

Location

Record Format. The

De-

fect

Record (PRIAM

interface

only) can

identify

up

to

three

defective

sectors

on the track.

The

following

diagram summarizes

the

typical

track

format:

DATA GAP GAP SKIP GAP ADDRESS GAP DATA GAP ADDRESS GAP DATA

FIELD TYPE TYPE DEFECT TYPE FIELD TYPE FIELD TYPE FIELD TYPE FIELD

N 3 1RECORD 1 1 2 1 1 2 22

t

INDEX

MARK

t

SECTOR

MARK

1

11

t

SECTOR

MARK

2

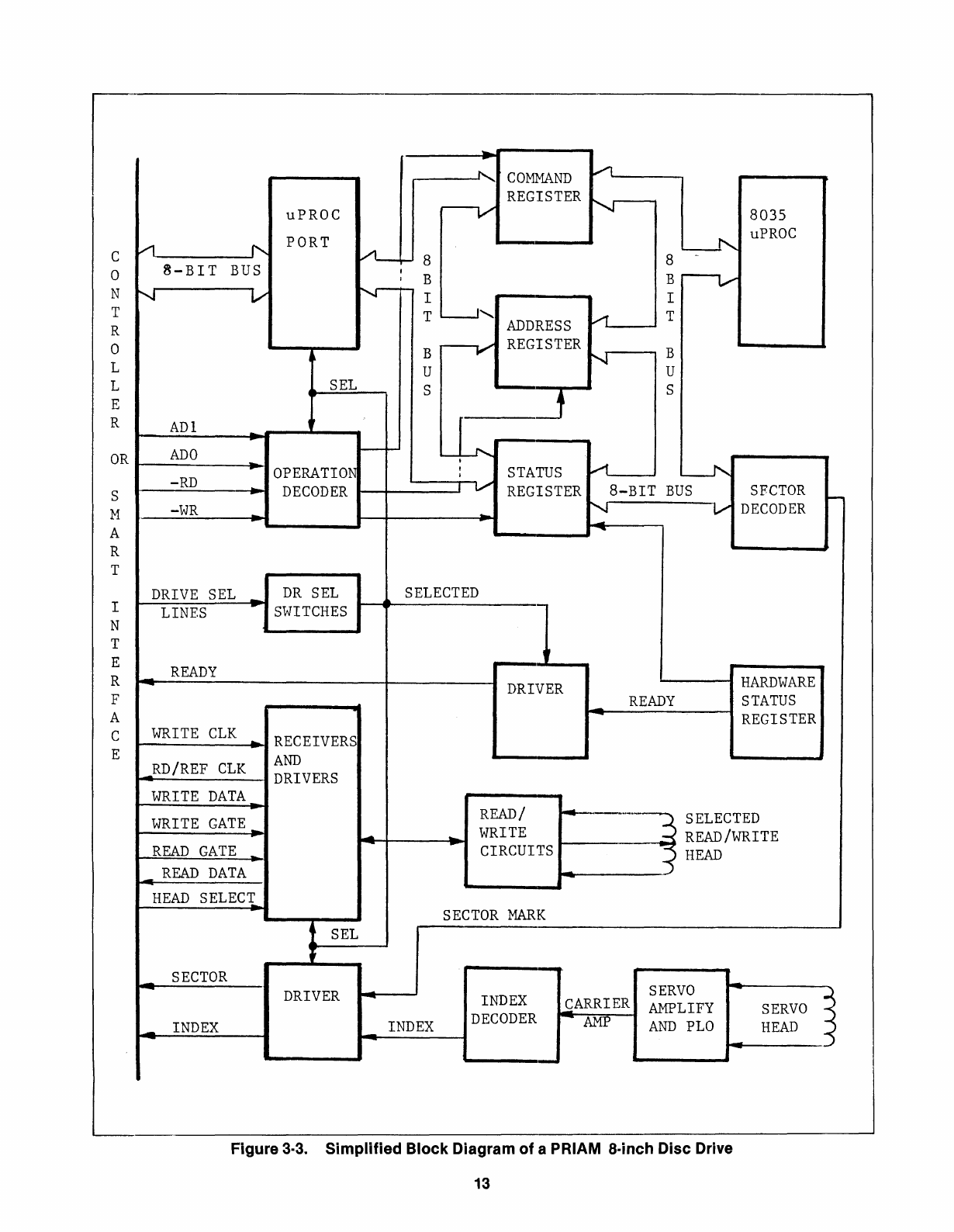

3.8

Overview. Figure

3-3

is asimplified

block

diagram

of

aPRIAM 8-inch

disc

drive with

the standard PRIAM interface. The overall organi-

zation shown is the same for all drives in the

8"

family. However, the names

of

the

specific

inter-

face signals vary as afunction

of

the interface

option present.

The

disc

drive has its own

(8035)

microprocessor,

which controls the sequencing

of

all the opera-

tions

that

occur

in the drive.

3.9

Drive Selection. The

disc

drive must

be

properly selected before

it

wi

II

respond

to

any

of

the signals on the controller interface. On

the standard PRIAM interface, this is accomplished

by placing the proper address on

t11e

DRIVE

SELECT

1-4

lines.

On

the SMD interface, the

proper address is placed on the UNIT SELECT

1,

2,

4and 8lines and the UNIT SELECT

TAG

line is ac-

tivated.

In

general, the interface lines

to

be used

may

be

determined by referring

to

the section

(below) describing the

specific

interface involved.

The address

of

an

individual drive is determined

by

switch

settings on the read/write digital

PCB,

as discussed in the INSTALLATION section. The

drive responds

to

the selection procedure only

when

its

switch-selected address matches that

placed on the interface by the controller.

3.10 Power Up/Down Sequences. When power

is applied, the Microprocessor Initialization

sequence occurs automatically. The microproces-

sor then goes

into

the idle state, in which

it

moni-

tors the controller interface for acommand.

The controller may then issue aSequence

Up

command

to

the drive (the exact manner in which

this

is done depends on the interface option

present). The microprocessor recognizes

this

command and starts the spindle motor. When the

motor

is running at the proper speed, the micro-

processor reads the sector length switches, and

configures the drive

to

operate in terms

of

the

chosen sector length. Next

it

calls the

RSTRGO

subroutine, which moves the heads

to

cylinder

zero. It then enables the drive ready status, resets

the busy condition, and returns

to

the idle state.

The drive is'stopped by issuing aSequence Down

command. This causes the heads

to

return

to

the

landing zone, and stops the spindle motor.

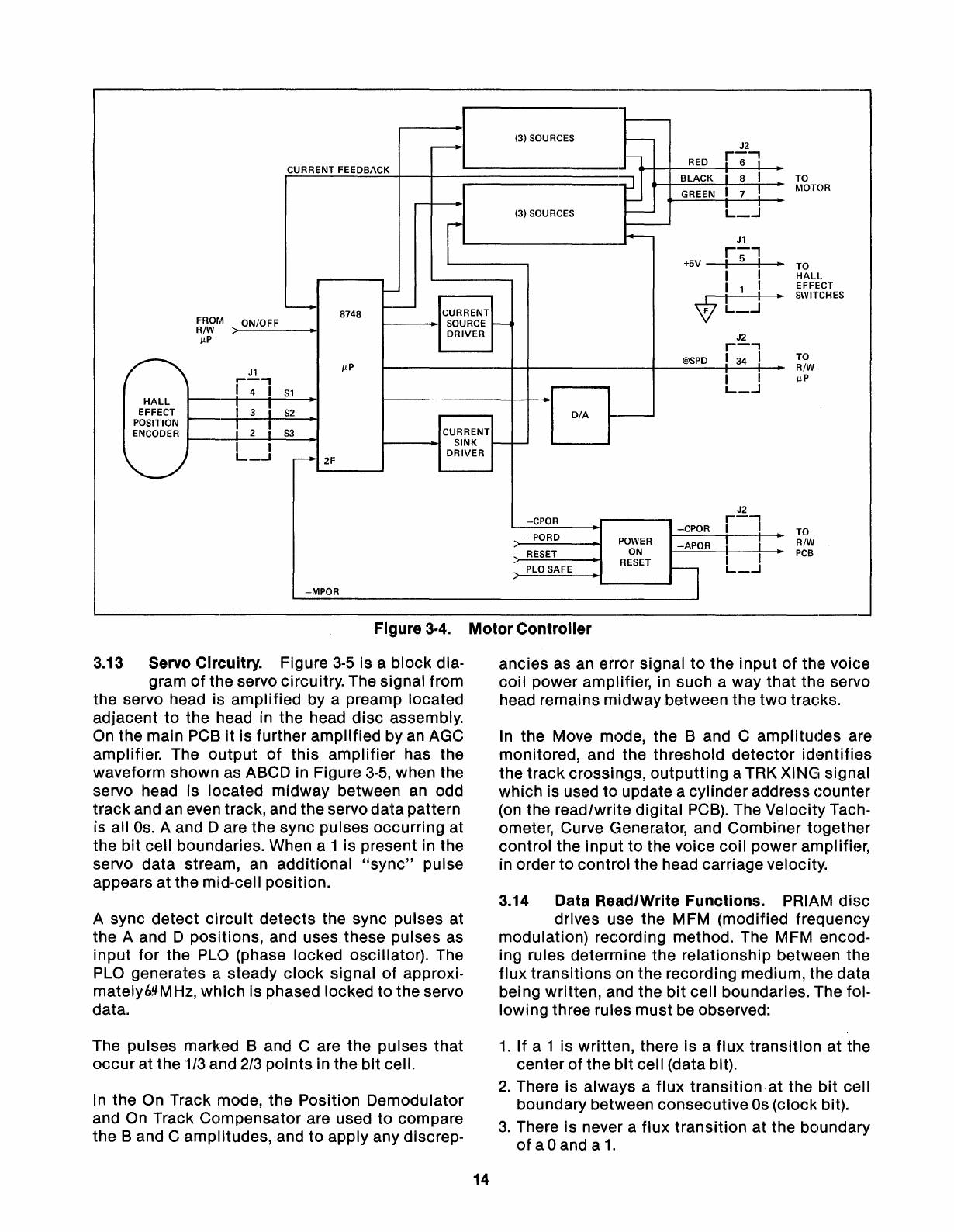

3.11

MotorControl Circuitry. The spindle motor

is abrushless (electronic commutating)

permanent magnet

DC

motor. The speed

of

the

12

motor

is controlled by aclosed-loop

circuit

con-

taining Hall

effect

sensors and acomparator.

Figure

3-4

is a

block

diagram

of

the motor control

circuitry. The microprocessor sets the OFF signal

true

to

inhibit

spindle rotation, or false

to

allow

spindle rotation. The microprocessor monitors

the speed

of

spindle rotation. If, during the power

up sequence, the

motor

does not reach

its

speci-

fied speed

within

one minute, or if, during normal

operation, the

motor

speed passes outsicJe the

specified speed range, the microprocessor

will

set the Fault condition, restore the heads

to

the

landing zone, and

inhibit

the spindle rotation.

3.12 Seek Modes. The servo system has

two

main

mocJes

of operation -

On

Track mode

(also called Position mode) and Move mode.

Move mode becomes active when the drive is

commanded

to

move the heads. The microplroces-

sor receives the new target cylinder address and

the seek command, determines the direction

of

travel and the number

of

tracks

to

be

crossed, and

sets Move mode.

When the servo is in Move mode, avelocity profile

(produced by adigital-to-analog converter) is com-

pared (via asumming junction) with the

output

of

an electronic tachometer, which indicates the

ve-

locity

of

headmotion. The difference signal from

the summing

junction

is fed

to

the servo power

amplifiers, which control the voice coil motion.

The heads are driven toward the new cylinder

address. The servo

circuitry

monitors the track

crossings and decreases the velocity

of

head

motion as the selected cylinder is

approachE~d.

When the heads are

within

100

microinches

of

the

new cylinder, the On Track mode becomes active.

In

the On Track mode, the heads are held precisely

over the designated track. Any unintended head

movement is detected by the electronic tachom-

eter and fed

to

the summing junction. This in turn

causes the servo power amplifiers

to

adjust the

head position, so that the heads remain at the

desired location.

Servo safety

circuits

drive the heads

to

the land-

ing zone upon detection

of

alow power condition,

or

if

both Move and

On

Track modes

occur

simul-

taneously. The safety

circuits

also

monitor

the

voice coil speed. If the specified speed is ex-

ceeded,

or

if

the continuous position information

is lost, an Overspeed signal is established and the

servo power amplifiers are disabled. Seek Fault is

set

if

any

of

the above

conditions

develop.

C

o

N

T

R

o

L

L

E

R

OR

S

M

A

R

T

--

~

COMMAND

/l

REGISTER

~

uPROC r----v 8035

PORT

L-f'..

uPROC

V1

'"

VL-.- 88-

B-BIT

BUS

IB

r---v-

IB

........,-

V

N--

I I

T

L-J

........

ADDRESS

.....-1

T

--V

REGISTER

BNB

UU

SEL

SS

ADI

ILL

-

ADO

--i

-

OPERATION

,

STATUS

A

--.1'.;

-RD

;V

DECODER

REGISTER

8-BIT

BUS

SFCTOR

--

-WR

-

"'i

V

DECODER

-

"'

SECTOR

MARK

SELECTED

I

N

T

E

R

F

A

C

E

DRIVE

SEL

_

DR

SEL

LINES

..

SWITCHES

READY

-

WRITE

CLK

~

RECEIVERS

AND

_RD/REF

CLK

DRIVERS

WRITE

DATA

WRITE

GATE_

READ

GATE

_

_

READ

DATA

HEAD

SELECI

SEL

-

..

DRIVER

READ/

WRITE

CIRCUITS

~----~

HARDWARE

_

READY

STATUS

~------~--~

REGISTER

SECTOR

...

_

INDEX

DRIVER

INDEX

INDEX

DECODER

SERVO

~ARRIER

AMPLIFY

AMP

AND

PLO

-

~

SERVO

~

HEAD

"')

-<

Figure 3·3. Simplified Block Diagram of aPRIAM a·inch Disc Drive

13

(3) SOURCES

CURRENT FEEDBACK

J2

hRED

r-;l

Ioo-.-------

...

~J.-+-l-----:....:.:;;.;;;;....--......-.:i:........a.-

BLACK

8ITO

MOTOR

-

-

TO

R/W

/-LP

TO

HALl.

EFFECT

SWITCHES

~I

I·

'V'

L_.J

J1

r-'

+5V

I5I •

II

I1I

J2

r-"

@SPD

!34 I

CURRENT

1-----1

SOURCE

1---4

DRIVER

8748

J1

r--,

I4I

S1

FROM ON/OFF

RIW

>----

..

/-LP

HALL

I!

EFFECT I3 ,

S2

POSITION I2

,I

53

ENCODER

t------0I-------.I

I I

L_.J

r--+

2F

CURRENT

1-----1

SINK

r---""-

DRIVER

D/A

-MPOR

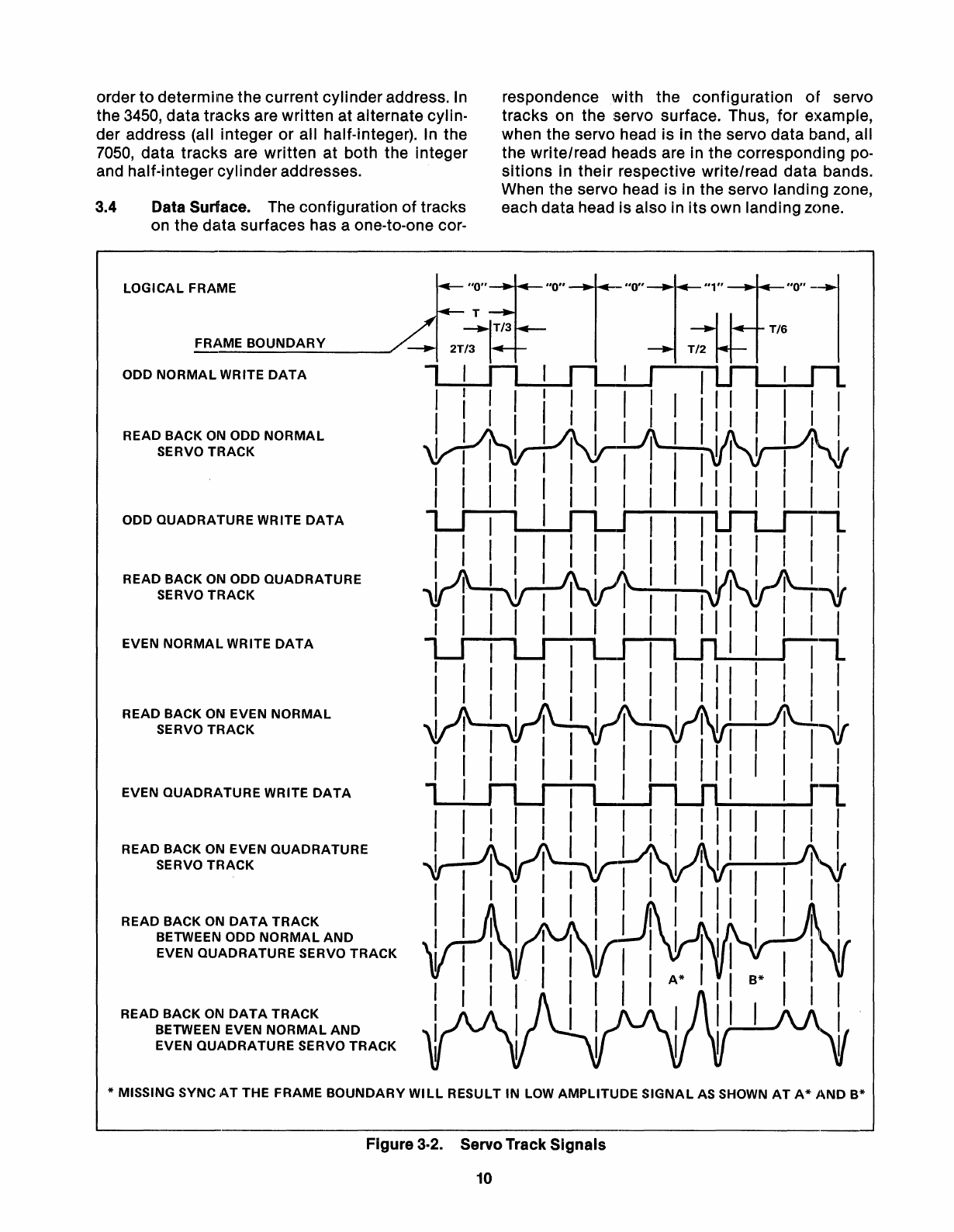

J2

L.::£!CP~O~R

--11---'

-CPOR

r-l

-PORD

POWER

~--A-PO-R~!~-~I-

RESET

ON

II

PLO SAFE RESET

r--l

L_...J

L..------I'

I

TO

R/W

PCB

Figure

3-4.

Motor

Controller

3.13 Servo Circuitry. Figure

3-5

is ablock dia-

gram

of

the servo circuitry. The signal from

the servo head is amplified by apreamp located

adjacent

to

the head in the head

disc

assembly.

On

the main PCB

it

is further amplified by

an

AGC

amplifier. The

output

of

this

amplifier

has the

waveform shown as ABCD in Figure

3-5,

when the

servo head is located midway between

an

odd

track and an even track, and the servo datapattern

is aliOs. Aand Dare the sync pUlses occurring at

the

bit

cell boundaries. When

a1

is present in the

servo data stream, an additional

"sync"

pulse

appears at the mid-cell position.

Async detect

circuit

detects the sync pulses at

the Aand Dpositions, and uses these pulses as

input for the

PLO

(phase locked oscillator). The

PLO

generates asteady

clock

signal

of

approxi-

mately69-MHz, which is phased locked

to

the servo

data.

ancies as an error signal

to

the input

of

the voice

coil power amplifier, in such away that the servo

head remains midwaybetween the

two

tracks.

In

the Move mode, the

Band

Camplitudes are

monitored, and the threshold

detector

identifies

the track crossings,

outputting

aTRK XING signal

which is used to update acylinder address Gounter

(on the read/write digital

PCB).

The Velocity Tach-

ometer, Curve Generator, and Combiner together

control the

input

to

the voice coil power amplifier,

in order

to

control the head carriage velocity.

3.14 Data Read/Write Functions. PRIAM

disc

drives use the MFM (modified frequency

modulation) recording method. The MFM encod-

ing rules determine the relationship between the

flux transitions on the recording medium, the data

being written, and the

bit

cell boundaries. The fol-

lowing three rules must

be

observed:

The pulses marked

Band

Care the pulses that

occur

at the 1/3 and

2/3

points in the

bit

cell.

In

the On Track mode, the Position Demodulator

and

On

Track Compensator are used

to

compare

the

Band

Camplitudes, and

to

apply any discrep-

1.

If

a 1 Is written, there is aflux transition at the

center

of

the

bit

cell (data bit).

2.

There is always aflux transition-at the

bit

cell

boundary between consecutive

Os

(clock bit).

3.

There is never aflux transition at the boundary

of

a0 and a

1.

14

This manual suits for next models

1

Table of contents

Other PRIAM Storage manuals

Popular Storage manuals by other brands

Seagate

Seagate STD224000N - DAT Scorpion 24 Tape Drive installation manual

Kingston Technology

Kingston Technology Wi-Drive user guide

ECOSAFE

ECOSAFE ASDM22 instruction manual

Huawei

Huawei OceanStor S2600 manual

IBM

IBM StorVize V7000 Gen2 Quick installation guide

Huawei

Huawei OceanStor Dorado V3 Series Parts Replacement

Sparehand Systems

Sparehand Systems TF-408 quick start guide

IBM

IBM DATA MIGRATION SERVICES - brochure

Seagate

Seagate ST3146707LW - Cheetah 146 GB Hard Drive datasheet

Samsung

Samsung MZ-5PA064 user manual

Silicon Graphics

Silicon Graphics TP9400 RAID owner's guide

Apricorn

Apricorn Aegis Padlock A25-PLE256 256GB quick start guide