PrimeVOLT G2000 User manual

Revision History

Ver.

Date

Contents

Prepared

Approved

0.0

2019/

11/07

First released

Ted Chen

Rick Hsu

POWER LIMITER

G2000

Installation & Operation Manual

Version 0.0 Nov. 2019 Printed on Recycled Paper

1

Table of Contents

1. Safety Precautions .................................................................................................. 1

2. Contact Information ............................................................................................... 2

3. Warranty Terms ......................................................................................................3

4. Installation .............................................................................................................. 4

5. LED Indication ......................................................................................................... 9

6. Setting...................................................................................................................10

7. RS485 Communication Interface ..........................................................................12

8. Troubleshooting....................................................................................................15

9. Specifications ........................................................................................................16

1. Safety Precautions

Before beginning your journey, please read the following safety instructions

carefully.

Qualified Personnel ONLY!

Only Qualified technicians shall install or service unit(s) in

accordance with local wiring regulations.

PrimeVOLT PV Inverter ONLY!

Designed for PrimeVOLT PV inverter and solar power conversion

only; do not use for other PV inverter or conversion purposes.

Recycle

Do not throw this electronic device in a trash dumpster when

being disposed of. To minimize pollution of environment, please

consult your local service provider.

3

3. Warranty Terms

Warranty or liability will be void if damage caused by, but not limited to the

following:

1. Unauthorized opening of unit

2. Installation faults such as improper environment, wiring and applications

3. Working conditions beyond specified

4. Improper operation of unit

5. Violation of safety instructions in this manual

6. Damage during transportation

7. Any internal modifications

8. Replacing or installation of unauthorized software

9. Unforeseen calamity or force majeure

4

4. Installation

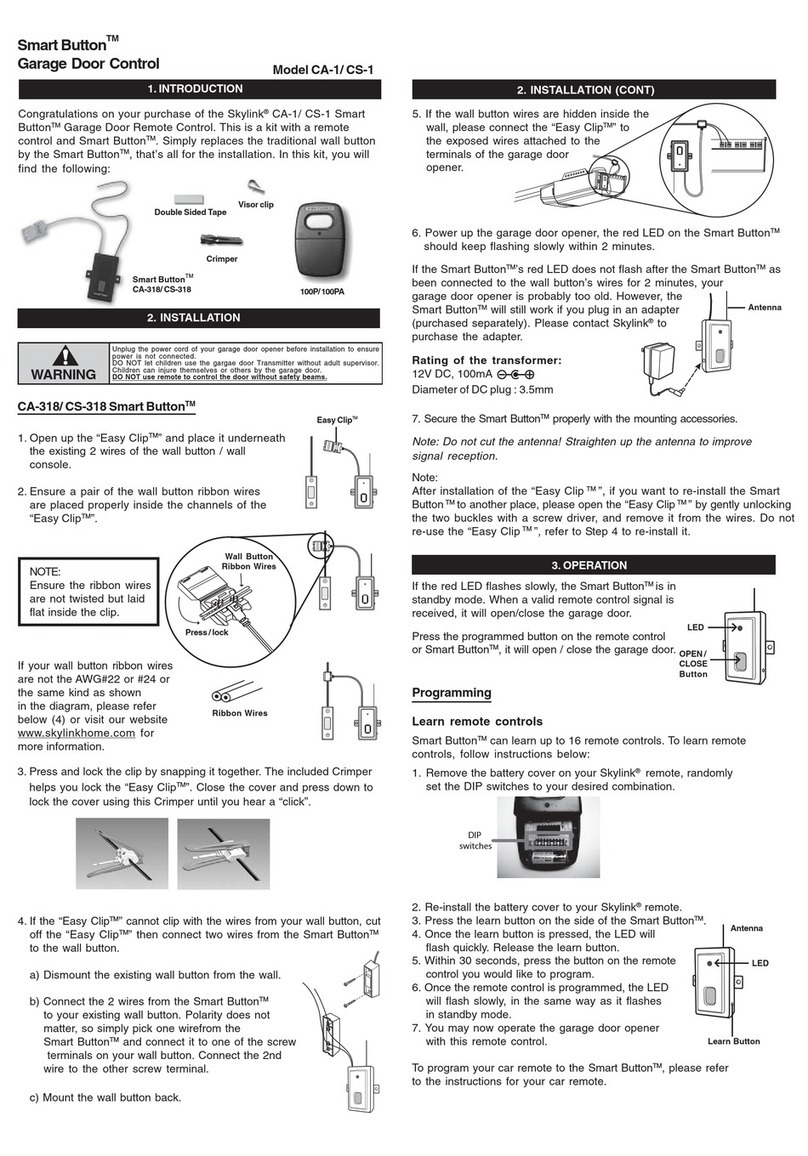

Product Overview

T/R + T/R - L3 L2 L1

+-+-+-

L3 L2 L1 N G

Product Label

O p e r a t i n g t e m p . - 2 0 ~ 5 0 o C

M a d e I n T a i w a n

Model : G2000

FA C n o m

0 . 5 A

5 0 / 6 0 H z

IA C m a x

VA C n o m 1 0 0 ~ 2 4 0 V

Front

LED

130mm

28mm

100mm

Rear

5

Unpacking

(1) Power Limiter(G2000)X 1

(2) AC Voltage Connector(6Pin)(big size) X 1

(3) AC Current Connector(6Pin)(small size) X 1

(4) RS485 Connector(2Pin) X 1

(5) User Manual

Choosing Proper Installation Site

Suitable for indoor ( temperature should not exceed 50˚C, humidity should not

exceed 95% )

Wire Connections

(1) Connecting “AC Voltage Connector” of the unpacking accessories to the “AC

Voltage Terminal”

(2) Connecting “AC Current Connector” of the unpacking accessories to the “AC

Current Terminal”

(3) Connecting “RS485 Connector” of the unpacking accessories to the “ RS485

Terminal”

(4) One limiter can connect up to 20 inverters through RS485 interface

RS485

Voltage

Current

Dip Switch

1 2 3 4

DIP

ON DIP

1 2 3 4 5 6 7 8

When the AC power is on, the LED will appear in solid green and it appears in

flashing green when RS485 communication is in normal condition. .

RS485 Connector

AC Current

Connector

AC Voltage Connector

6

Overview of Connection

(1) AC Voltage Terminal

(2) RS485 Terminal

(3) AC Current Terminal

L3 L2 L1 N G

T/R + T/R - L3 L2 L1

+-+-+-

③

①

②

7

AC Wiring Connection (Voltage Input)

1. For single-phase wiring input, the AC voltage terminals need to be connected

to L1-N.

2. For three-phase wiring input, the AC voltage terminals need to be connected

to L1/L2/L3/N.

N

L1

G

N

L1

G

N

L1

G

L2

L3

AC Wiring Connection(Current Input)

1. For single-phase wiring input, the AC current terminals need to be connected

to L1 k/l.

2. For three-phase wiring input, the AC current terminals need to be connected

to L1 k/l , L2 k/l and L3 k/l.

L1 k ( )

l ( ) L1 k ( )

l ( )

L3 k ( )

l ( )

L2 k ( )

l ( )

NOTE:1. Refer to the CT specification for the CT wiring k/l

2. (W) means white color wire, (B) means black color wire

CT Configuration

To ensure the CT ring buckle is in the correct direction before connection, please

refer to following application diagram. Choose one of the application and set

through the power limiter’s dip switch DIP7.

Single phase

Three phase

W

B

B

B

B

W

W

Three phase

Single phase

W

8

(1) Connecting CT buckle toward to grid side ①

(2) Connecting CT buckle toward to load side ②

Please follow the below configuration and make sure the direction of the CT buckle

is mainly in the direction of K->L.

T/R -

T/R +

G2000

L K

L K

Attention

In the three phases application, power limiter is ONLY applied

to 3Ø 4W power system, isn’t applied to 3Ø 3W power system.

Choose one position

of the CT application

CT ①

CT ②

Grid

Load

RS485 cable

Power cable

Inverter

Inverter

Inverter

RS485 Connector

RS485 Connector

RS485 Connector

Power Limiter

9

5. LED Indication

The LED on the power limiter left side will show the power limiter operation status

by different colors. In normal operation, the LED appears in green color. It

appears in red color when the current flow is from the load side to the grid side.

LED light sequence from left to right side definition is as follow :

Color

Indication

Power on and inverter RS485 connection

L1 current flow

L2 current flow

L3 current flow

LED light status definition is as follow :

Status

Indication

Power limiter is disconnected to AC.

Solid Green: Power limiter is power ON.

Flashing Green: RS485 connection with inverter is in normal

Solid Red: Current flow to grid

10

6. Setting

1 2 3 4

ON DIP

1 2 3 4 5 6 7 8

The relevant setting parameters and functions can be set through the dip switch of

power limiter which are including the firmware CT ratio, CT position and

communication mode.

Firmware CT ratio

Item

DIP4

DIP5

DIP6

CT Ratio

Max. Current

(R.M.S)(A)

1

OFF

OFF

OFF

1000:1

50

2

ON

OFF

OFF

2000:1

100

3

OFF

ON

OFF

2500:1

125

4

ON

ON

OFF

3000:1

150

5

OFF

OFF

ON

4000:1

200

6

ON

OFF

ON

5000:1

250

7

OFF

ON

ON

6000:1

300

8

ON

ON

ON

10000:1

500

To adjust the switch ON or OFF for dip switch pin 4~6, it depends on the CT

specification and please refer above table to adjust the ON or OFF selection of

each pin of 4~6.

NOTE:Please pay attention that the power limiter will fail to achieve the power

limitation to the gridif the dip 4~6 setting are presenting incorrect ON / OFF.

CT position

Item

DIP7

Limiter Mode

1

OFF

CT on the grid side

2

ON

CT on the load side

If dip switch DIP7 is OFF, it indicates that the CT position is on the grid side.

If dip switch DIP7 is ON, it indicates that the CT position is on the load side.

11

Communication Mode

Item

DIP8

Communication Mode

1

OFF

Host

2

ON

Device

If dip switch DIP8 is OFF, it indicates that the power limiter is in Host

communication mode.

If dip switch DIP8 is ON, it indicates that the power limiter is in Device

communication mode.

12

7. RS485 Communication Interface

About RS485

A typical RS485 connection is as below.

Some Noteworthy Points:

1. Wires between devices and computer shall be twisted.

2. Maximum allowable wire length is 1000 meters.

3. The terminal-end device should have a terminal resistor.

4. Due to multiple connections, each individual device should be assigned an

IP address as to send/receive.

RS485 Hardware Interface

T/R + T/R -

L3 L2 L1

+-+-+-

Connecting to device or computer with RS485 interface

Terminal

Resistor

Device 1

Device 2

Device N

T/R -

T/R +

T/R +

T/R -

RS485 wiring

illustration

13

Wiring Diagram

T/R -

T/R +

G2000

Pin:Off Pin:Off Pin:On

ON

1

ON

1

ON

1

1. Connecting T/R1+ and T/R1- of inverter RS485 connector to the T/R+ and

T/R- of the data logger respectively.

2. Between two inverters, connecting T/R2+ of first inverter with T/R1+ of next

inverter, and connect T/R2- of first inverter with T/R1- of next inverter.

3. Set terminal resistor switch “ON” of the terminal-end inverter (the last

inverter of the row) only. The others should be set as “OFF”.

Setting the Terminal Resistor

Each inverter has built-in terminal resistor, if RS485 is connecting to multiple

inverters or the total communication length is too long to cause the abnormal

communication, please set the terminal resistor switch to “ON” of the last inverter

in the row connection, all other remaining inverters shall switch to “OFF”.

ON Terminal Resistor is active

1 (OFF) Terminal Resistor is invalid

Inverter

RS485 Connector

Inverter

Inverter

RS485 Connector

RS485 Connector

Power Limiter

14

Attention!

Improper setting of the terminal resistor will cause

communication failure.

Use Standard RS485 Wire

In order to achieve good communication, be sure to use

standard copper mesh shielding of RS485 twisted. Do not use

general network cable as RS485 wire.

RS485 Cable AC and DC Cable Separately

To maintain good communication and reduce interference,

please separate the RS485 cables from the AC and DC wiring

and keep at least 10cm far away or use a cable with metal

shield isolation.

15

8. Troubleshooting

Please pay attention to the following matters by regularly visual check to ensure the

power limiter is operating normally.

1. Clean the dust on the power limiter.

2. Check the operation and status of the power limiter.

3. Check all wiring to confirm there is no corrosion or breakage.

4. Check all the terminals and make sure they are not loose.

Referring to below table to resolve accordingly. If the problem persists, please

contact your local service partners for further assistance.

Abnormal

Solution

LED no display

1. Check if the AC power is connected to the L1-N

position.

2. Switch off the AC power and switch on again.

LED in solid red color

1. Check if the direction of the CT buckle is on the

correct position.

2. Check if the CT +/- wiring is correct.

3. Check if the wiring of L1 / L2 / L3 voltage and

current are corresponding.

4. Check if the RS485 communication is operating

in normal (check if the green LED is flashing).

RS485 disconnection

1. Check the wiring and connector.

2. Check if the IP address of inverter is configured

correctly, and shall not duplicate the same IP

address of the other inverter.

3. Check if the last inverter in the row connection

is set terminal resistor switch “ON” , and all the

remaining inverters shall switch “OFF”.

If there is only one inverter, do not switch on

the terminal resistor.

4. Check if the cable is well twisted.

5. Keep the RS485 cable at least 10cm far away

from the AC and DC wires or use the cable with

metal shield isolation.

16

9. Specifications

Item

Unit

Specification

Input (AC)

Nominal Voltage

V

220/230/240(1Ø ),

220/380;230/400;240/415(3Ø )

Nominal Frequency

Hz

50/60

Power consumption

W

2.5

General

Operating Temperature

°C

-20 ~ 50

Ingress Protection

IP20

Protection

Class II

Humidity

%

0 ~ 95

Detection signal

Voltage Signal

1Ø (2 wire) ; 3Ø (4 wire)

Current Signal

1Ø (1); 3Ø (3)

Supporting CT Type

8 types (Refer to Firmware CT ratio)

CT Detection Position

Grid side / Load side

Communication Interface & Display

LED

Green/Red

RS485

Standard, Half-Duplex

Number of inverters

20

Mechanical

Dimension ( W x H x D)

mm

130 x 100 x 28

Weight

kg

0.32

Certification

Safety

CE

Note: Specifications are subject to change without prior notice.

Note: Power limiter contains shunt resistor. Please don’t parallel resistor or use CT

type with built-in resistor.

P/N: 614-37138-00

Table of contents