Prism Hardscapes PH Ignite Operation and maintenance manual

WARNING!THISAPPLIANCEISFOROUTDOORUSEONLY!

Thismanualshouldremainwiththehomeownerorpartiesresponsibleforoperation.

TableofContents

Section1GeneralDescription

1.1SystemOverview

1.2ProductContents

1.3ProductDimensions

Section2SafetyInstructions

Section3InstallationDetails

3.1GasRequirements

3.2InitialSet‐Up

3.3WiringDiagram

3.4Installation

Section4Operation

4.1Media

4.2Operation

Section5Troubleshooting

Section6Warranty

DONOTDISCARDINSTRUCTIONS

Section1GeneralDescription

1.1SystemOverview

ElectronicIgnitionforfast&convenientfirefeaturelighting

Electronicflamesensingforinstantflamesafety&monitoring

ThisproductisdesignedandassembledtocomplywithANSIZ21‐97

Operateson12VoltsACandcomplieswithNEC2014Article680

Thisproductmaybeinstalledwithin5feetofpoolwater

Operateswithahotsurfaceignitionsystemwithrobustconstructionandreliableignitionsource

Pottedelectronicsformoistureresistanceandreliableoperation

Pilotburnerwiresaremadeofhightemperaturematerialtowithstandtemperaturesupto450

degreescentigrade(UL5335/5107)

InternalelectronicsareCSACertifiedtoZ21.20‐2014

Operatingtemperaturesarebetween‐20Fto185F

Weatherproofstainless‐steelconstructionwithwaterproofconnectors

1.2ProductContents

PARTNAMEQTY

BURNER&BURNERPLATE1

PILOTASSEMBLY(PILOTBURNER,IGNITOR,SENSORHOOD)1

IGNITIONCONTROLBOX1

HEATSHIELD 1

HEATSHIELDJAMNUT 1

ORIFICESET(BURNER&PILOT)1

TRANSFORMER(120VAC/12VAC)1

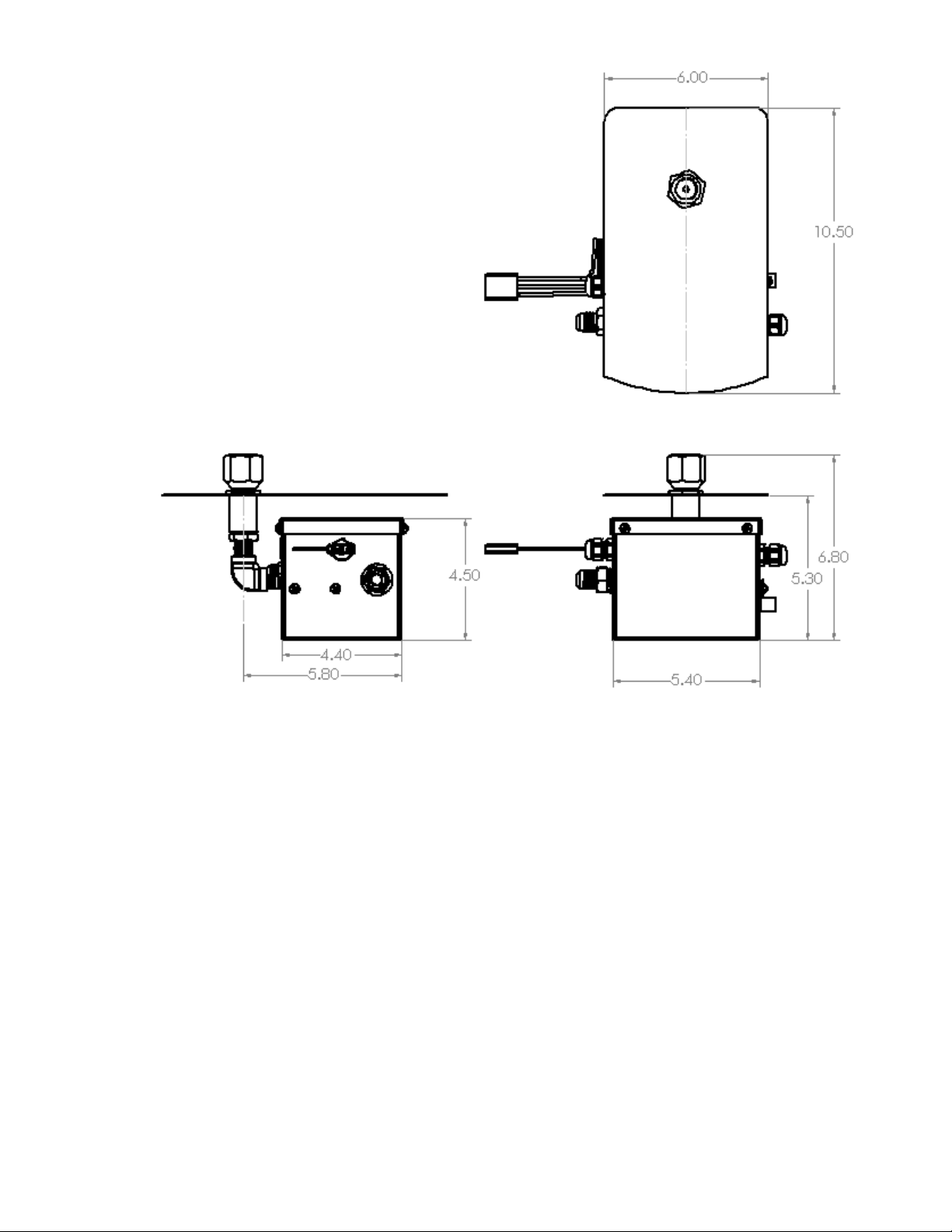

1.3ProductDimensions

Allmeasurementsininches

Section2SafetyInstructions

WARNING

Beforeinstallingthisproduct,readandfollowallwarningnoticesandinstructionsprovided.Failuretodoso

mayresultinseriousinjury,propertydamageand/ordeath.

Foradditionalfreecopiesoftheseinstructions,visitourwebsiteatprismhardscapes.com

DANGER:ELECTRICALSHOCKORELECTROCUTION

ThisproductmustbeinstalledbyalicensedorcertifiedelectricianinaccordancewiththeNationalElectrical

Code®andapplicablelocalcodesandordinances.InCanada,theCanadianElectricalCodeandallapplicable

localcodesandordinancesmustbeadheredto.Improperinstallationwillcreateanelectricalhazard,which

couldresultininjury,propertydamage,and/ordeath.

Thisproductisonlyavailablefor12‐voltACpower.Forsupplyconnections,useonlyanisolatinglowvoltage

powersupplywithungroundedoutputevaluatedandlistedbyanationallyrecognizedtestinglaboratory.

Thisproductmustbeinstalledandservicedbyacontractororqualifiedinstallerwhoislicensedand/or

certifiedwithinthejurisdictionwheretheproductwillreside.Intheeventnosuchstateorlocal

requirementexists,theinstallerormaintainermustbeaqualifiedprofessionalwithsufficientexperience

ininstallationandmaintenanceofgasappliances.Priortoinstallation,readandfollowallwarning

noticesandinstructionsthatprovidedwiththisproduct.Failuretodosomayresultinpropertydamage,

personalinjury,and/ordeath.Improperinstallationand/oroperationmayresultinexposuretocarbon

monoxideandfluegaseswhichcancauseseriousinjury,propertydamage,and/ordeath.For

installationsinthevicinityofoccupied/livingareas,PrismHardscapesstronglyrecommendsinstallation

ofcarbonmonoxidedetectorswithinreachofthisapplianceandinanyadjacentoccupiedspaces.

Im

p

ro

p

erinstallationand/oro

p

erationwillvoidwarrant

y

.

Donotstoreorusegasolineorotherflammablevaporsandliquids

withinthevicinityofthisoranyotherappliance.

WHATTODOIFYOUSMELLGAS

•

Immediatelyswitchoffmaingassupply.

•

Donottrytolightanyappliance.

•

Donottouchanyelectricalswitch;donotuseanyphonenearunit

•

Immediatelyremoveyourselffromthearea,callyourgassupplierandfollow

theirinstructions.

•

Ifyoucannotreachyourgassupplier,callthefiredepartment.

Installationandservicemustbeperformedbyaqualifiedinstaller,serviceagency

orgassupplier.

WARNING

Theappliance/systemmayproducecarbonmonoxidewhichhasnoodor.Usingthisappliance/systeminan

enclosedspacesuchasamotorhome,camper,carorhomemayresultindeath.

PrismHardscapesutilizesCSAcertifiedcomponents.Installationmustconformtolocalcodes,NationalFuel

GasCodeANSIZ223.1/NFPAand/orNationalFuelGasCode.

ApplianceshouldbeservicedannuallybyaprofessionalgastechniciancertifiedintheUnitedStatesbythe

NationalFireplaceInstitute(NFI).Anypartsthatrequirereplacementshouldbereplacedonlybyacertified

serviceprofessionalusingpartsrecommendedbymanufacturer.

Donotalteranycomponentordesignofthisunitasitmayaltertheoperation.

Firefeatureisnotintendedforcooking.Donotplaceanythingonorinfirefeature.

Neverusefirefeatureinwindyconditions.

Donotreachacrossortouchhotsurfacesoropenflames.

Donotignitefirefeaturewhenmedia(rocks/glass)iswet.Doingsomaycausemediatocrackandburst.

Itisimportanttoinspectthefirefeaturebeforeeveryuse.Makesuretherearenoobstructionsor

combustiblematerialsonornearunit.

Wipedownfirefeaturesurfacebeforeeveryuseandimmediatelycleananyspillsormessesonoraroundit.

Consistentlycheckhosesandfittingsforcracks,abrasionsandleaks(atleastonceamonth).

Alwayskeepchildrenandanimalsawayfromfirefeature.

Useadesignatedfirepitorbarbecuecoverwhennotinuse.

CALIFORNIAPROPOSITION65

ThisproductcanexposeyoutoChromium,whichisknowninthestateofCalifornia

tocausecancer,birthdefectsorotherreproductiveharm.

(formoreinformation,goto:www.p65warnings.ca.gov)

Section3InstallationDetail

3.1 GasRequirements

Ifthisitemwaspurchasedwithafirefeature,itshouldbeinstalleduponarrival.Allhardwarewillneed

tobecheckedforpropertightnessaftertransportation.Refertothecorrespondingsectionbelowfor

set‐uponyourunit.Allfirefeaturesmusthaveclearancetocombustiblesurfaceof4ftonsides&6ft

fromthetop.Refertothesectionsbelowaccordingtothegastypeused.

3.2 InitialSet‐Up

Allgasset‐upandinstallationshouldbedonebyalicensedgasprofessional.

Allelectrical/wiringset‐upandinstallationshouldbedonebyalicensedelectrician/contractor.

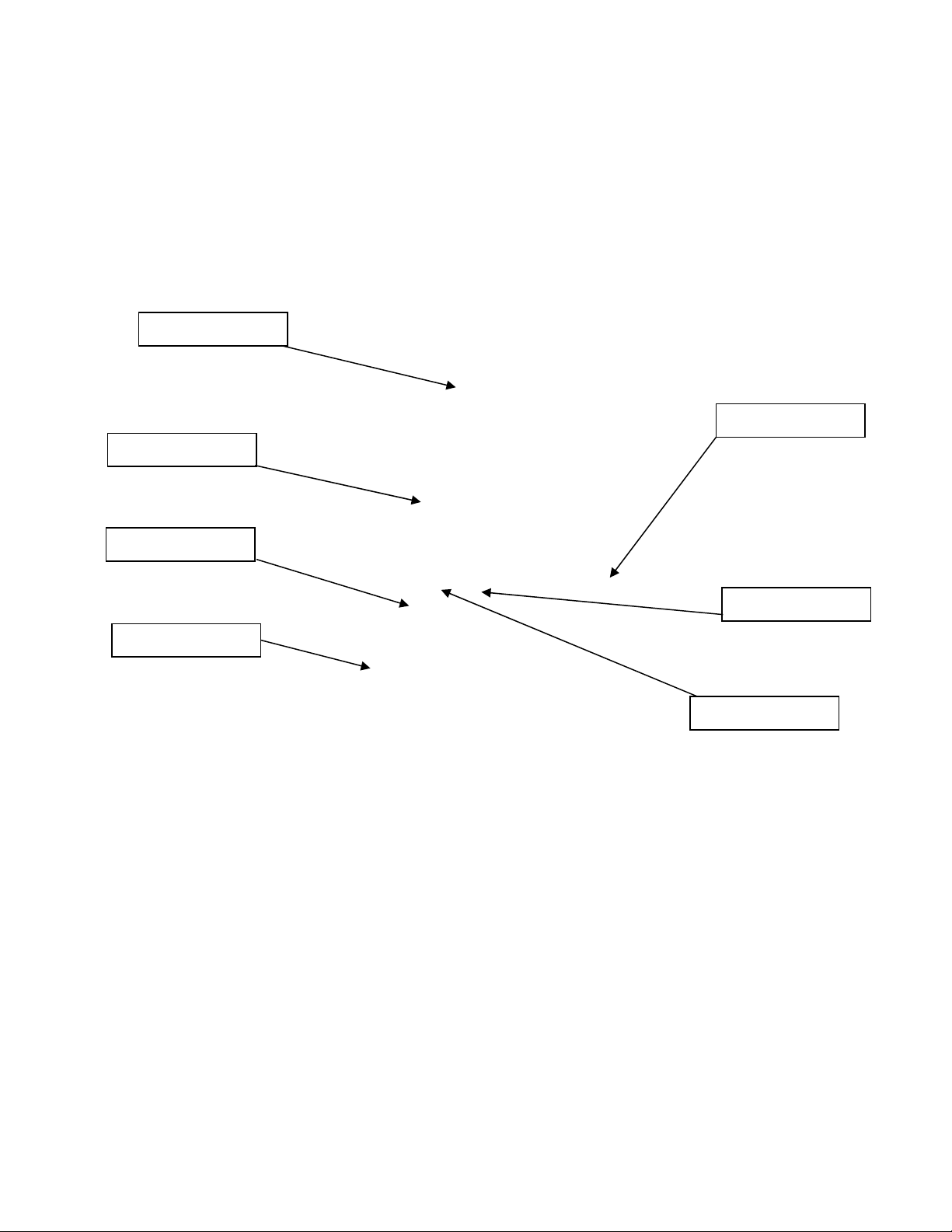

Thefirefeaturewillrequirebothgasandelectricalpower.Makesuregasandelectricityisturnedoff

beforeinstallingpipesandwires.InstallthecontrolpanelandgaspipingasshowninFigure1:Natural

Gas,Figure2:PropaneGas.

Note:Pipingandfirebowl/firepitconstructionisdifferentfornaturalgasandpropanegas.Internalgas

linesmustbecleanandfreefromanydirt,debris,orcontamination.

1. Thegaspipingandelectricalconduitmustbeinstalledundergroundbetweenthecontrol

panel/gasmeterandthefirefeature.Pleaseconsultwithagasprofessionalforpropergaspipe

andfittingsizing.Usingsmallerpipingoverlonglengthswillresultinadiminishedflamedueto

pressuredrop/pipingresistance.

2. Maintaingoodpipingpracticebykeepingpipelengthandelbowstoaminimumtoeliminate

unnecessarypressuredrops.IMPORTANT:Corrugatedflexgaslinesshouldnotbeused

undergroundaspermanentpiping.Rigidpipeshouldalwaysbeusedforpermanentinstallation.

3. Thegaspipingmustbereducedto3/4″pipeatthefirefeaturewiththemeanstoshutoffthe

gassupplyfromthegasmeter.

4. Installa3/4″to1/2”reduceratthefirefeature“stub‐out”riser.Thegasandelectricrisers

shouldnotbemorethat3”to4”abovetheinstallationsurface.

5. Installthe1/2”flareto1/2”NPTfittingintothereducerfitting/pipe.Youmayplaceamanual

shutoffvalvebetweentheelbowandthereducerforfuturemaintenance.Testgaspipingfor

leaks.

Note:Thegasandelectricalconnectionshouldbelocatedatornearthecenterofeachfirebowl/table.

Fortheelectrical,youwillneed2wiresandagroundtotheappliance.

6. Installwiring(14or16ga.)undergroundbetweenthecontrolpanelandtheburnerassembly.DO

NOTUSEBELLORSPRINKLERWIRE.Lowergaugewireisnotcapableofcarryingthecurrent

neededtooperatetheappliance.FollowthewiringdiagraminSection3.3.Theapplianceshould

bewiredtoaswitchordrycontactonthe120VACsideofthetransformer.

NOTE:Alightswitch,emergencyswitch,relaycontact,mechanicaltimershouldalwaysbeinstalledon

the120VACsideofthetransformerinordertooperatethefirefeature.The12VACsidemaybewired

asfaras150feetawayfromthetransformerusing14‐gaugewire.

7. Onlyplaceyourfirefeatureonalevelsurfaceandensurepipingiscentered,anchorifnot

directlyontheground.

8. Takethe1/2”flexhose(provided)andtightentotheflarefittingfromthesupplyline.Donot

kinkormakeatightradiusbendonthegashoseasitmayrestricttheflowofgas.

9. Thereareseveralventsanddrainageholesinthefirebowl/tablewhichmustnotbeblocked.The

electricalandgaspipeholeissealedsuchthatwatercannotpenetratethecopingsurfaceunder

thebowlandwillflowfreelyawayandouttotheedges.

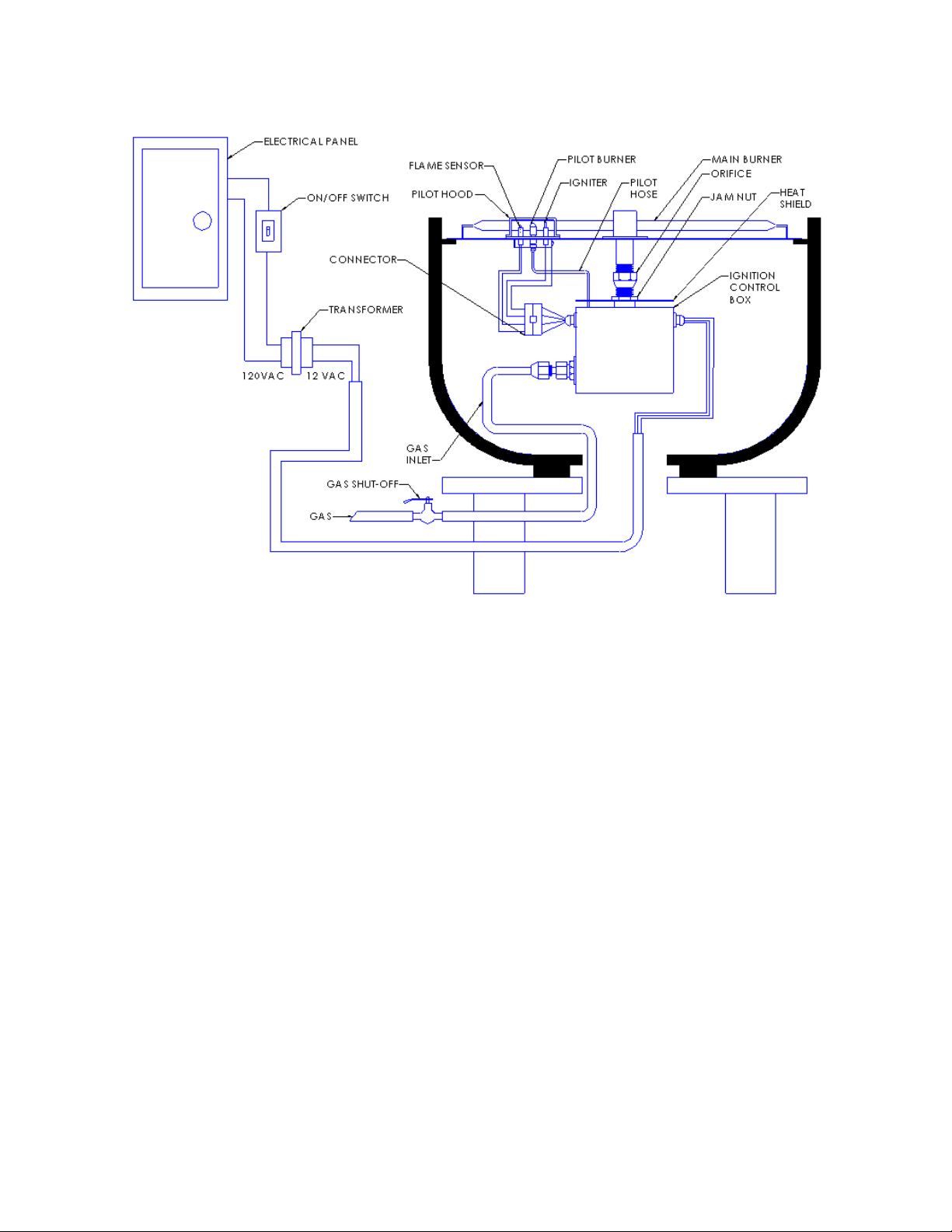

3.3 WiringDiagram

Allgasset‐upandinstallationshouldbedonebyalicensedgasprofessional.

Allelectrical/wiringset‐upandinstallationshouldbedonebyalicensedelectrician/contractor.

3.3Installation

Allgasset‐upandinstallationshouldbedonebyalicensedgasprofessional.

Allelectrical/wiringset‐upandinstallationshouldbedonebyalicensedelectrician.

3.4Installation

1. TheBurner/panandcontrolwillneedtobeconnectedtothegasandelectricallinescomingup

fromthefirefeature.Makesureyouhavethecorrectorificesonthepilotandtheburnerinlet

forthegasyouareusing.Youmustusetheproperorificesfornaturalgasorpropanegasfor

boththepilotburnerandthemainburner.RefertoSection3.4.2fororificereplacement.

2. Connecttheflexiblegashosetotheinletflarefittingonthecontrolbox.Usingawrench,

tightenthehosetothefittingtoavoidgasleaks.Ifthisfittingisnottightenedcorrectlyitwill

leakandpotentiallyigniteandcandamagethecontrolsystem.

3. Connectthe12VACwires,fromthecontrolbox,totheelectricalwirescomingoutofthe

conduitusingwirenutstosecureconnections.Linkthecoppergroundwiretothe

ground/bondinglugonthecontrolbox.

4. Repositiontheburnerandpanontothefirefeatureandturnonthegastocheckforleaks.

3.4.1Installingacontrolboxonanon‐PrismHardscapesfirefeature

BesuretouseonlyPrismHardscapesapprovedburnerswithfirefeature/PH‐Ignitesystemas

theyhavebeenpre‐testedandratedfortheinputandgasdesignatedonthecontrolbox.

1. Theburnerplateiscutandfittedforthepilotburnerassemblyinorderforthemainburner

toigniteandoperateproperly.

2. Themainburnermusthaveaflameportdirectlyinfrontofthepilotfortheignitionsystem

tolightthemainburnerandsensetheflame.

BURNEREDGE

PILOTCUTOUT

PILOTCUTOUT

MOUNTINGHOLES

BURNERPORTHOLE

3. Priortoinstallingthecontrolbox,taketheburnerandplateandturnitupsidedown.Add

threadsealerontotheburnerpipethreadswithparticularattentiontothelastthreethreads.

4. Takethecontrolboxandinstalltheheatshieldontothepipe.Todothis,threadthebrass

pipenutontotheburnerorificeasfardownaspossible.Placetheheatshieldovertheoutlet

pipeofthecontrolboxandthreadtheorificeintotheoutletpipeuntiltight.Useawrenchon

theburnerorificetotightenfully.Aligntheheatshieldsuchthatitfullyshadesthecontrol

boxandtightenthebrasspipenutenoughsothattheheatshieldwillnotmove.

5. Now,takethecontrolboxandinstallitontotheburnerpipe,threaduntilfullytightened.

Alignboxsothatthepilotholeisexposedandaccessibletoinstallthepilotassembly.

6. Turntheburnerplaterightsideupandinsertpilotassemblyintothepancutoutwiththe

pilothoodslotsfacingtheburner.

7. Alignthetwomountingholesoverthetwoholesontheburnerplate.Usingtheself‐drilling

screws,securethepilotburnerassemblyontotheburnerplate.

PIPETHREADSEALER

8. Turntheburnerbackoverexposingthecontrolboxandpilotassemblywires.Refertothe

imagebelow,thisiswhatyourunitshouldlooklikethisfar.

9. Taketheflexiblestainlesssteelpilothoseandsecureontothe1/4”flarefittingatthecontrol

box.Makesureitistightbutdonotovertightenasitmaystripthethreads.

10. Takeeachhalfofthe4‐pinconnectorandjointhetwohalvestogether.Pushtheconnectors

firmlyuntilthelatchclicksintoplace.

11. Takethe1/2”stainlesssteelhoseandsecureontothe1/2”gasflarefittingonthecontrol

box.Theotherendshouldbeconnectedandtightenedontothe1/2”flarefittinglocatedat

thesupplypipestub‐outriser.

12. Placetheburnerandplatebackintopositiononthefirefeature.

13. Turnonthegasandtestforoperation.Itmaytakeafewtriestopurgealltheairfromthegas

line.

14. Oncetheburnerlights,turnofftheunitandletcool.

3.4.2ReplacingGasOrifice

Locatethetwoorifices,oneisatthebaseofthepilotburnerandtheotherisattheendofthemain

burner(seepicturesbelow).Eachorificeismeantforaspecifictypeoffuel;NaturalGasorLiquid

Propane.

BURNERORIFICEPILOTORIFICE

BURNERORIFICE

NATURALGAS

BURNERORIFICE

PROPANEGAS

PILOTORIFICE

1. Turnofftheelectricandgassupplytothefirefeature.

2. Removeanyfiremediathatisontopoftheburnerplate.

3. Unscrewthe2screwsholdingthepilotassemblyinplace.

4. Carefullypickuptheburnerplateandturnupsidedown.

5. Unplugthe4‐pinconnectorfromthecontrolboxtothepilotassembly.

6. Disconnecttheflexiblepilotgashosefromthecontrolbox.

7. Fromthetopoftheburnerplate,gentlypullupthepilotassemblyandremovefromtheplate.

3.4.3ReplacingthePilotOrifice

3.4.4PilotHeadAssembly

1. Disconnecttheflexiblegashosefromthepilot.Becarefulnottoputpressureontheceramic

flamesensor;damagingtheflamesensorwillrendertheflamesensorinoperable.

2. Removetheflarefittingfromthepilotassembly.

3. Removethepilotorificefromthepilotassemblyandreplacewiththenewone.

4. Hand‐tightentheorificeuntilseated.Usewrenchtosecurebutdonotover‐tighten.

5. Hand‐tightentheflarefittinguntilsnug.

6. Takeflexiblepilothoseandtightenontotheflarefitting.Oncesnug,usewrenchtotighten

thehosefitting.

PILOTHOOD

PILOTSENSOR

GROUNDWIRE

PILOTORIFICE

PILOTGASHOSE

FLAREFITTING

PILOTPLATE

3.4.5ReplacingtheBurnerOrifice

1. Turnofftheelectricandgassupplytothefirefeature.

2. Removeanyfiremediathatisontopoftheburnerplate.

3. Unscrewthe2screwsholdingthepilotassemblyinplace.

4. Carefullypickuptheburnerplateandturnitupsidedown.

5. Makesurepilotassemblyhasbeendisconnectedandremoved.

6. Usingawrench,unscrewtheburnerorificefromthepipe,keepahandunderthecontrolbox

sothatitdoesn’tfallwhentheorificedisengages.

7. Placetheremovedassemblyonaflatsurfaceandholdfirmly.

8. Usingawrench,removeburnerorificefromthecontrolboxoutletpipe.Becarefulofthe

heatshieldasitwillcomeoffoncetheorificeisremoved.

ORIFICE

JAMNUT

HEATSHIELD

OUTLETPIPE

PILOTHOSE

9. Removethejamnutfromtheorifice.

7.Placenutontotheneworificeandthreadituntilitwillnolongerturn.

8.Placepipethreadsealerontotheneworificethreadscovering,besuretocoverthelastthree

threadswell.

9.Placetheheatshieldoverthecontrolboxoutletpipeandbeginthreadingtheorificeinto

place.Tightenwithawrenchuntilsecure.

10.Oncetheorificeistightened,therewillbeseveralthreadsleftbetweenthejamnutandthe

heatshield.Withthewrench,tightenthejamnutuntiltheheatshieldisfirmlysecuredinto

place.

12.Placepipethreadsealerontotheburnerpipe.

13.Placethecontrolboxoutletontotheburnerpipeandturnclockwiseuntiltight.

14.Alignthecontrolboxtowherethepilotholeisaccessible.

PILOTHOLE

3.4.6FinalBurnerandPilotAssembly

1.Turntheburnerplaterightsideup.Insertthepilotconnectorandhosethroughthepilothole

ontheplate.Makesuretheslottedsideofthepilothoodisfacingtheburner.

2.Alignthepilotplatemountingholesandsecurethetwomountingscrewsthroughthepilot

platetotheburnerplate.

3.Turntheburnerplateupsidedown.Takethe4‐pinconnectorfromthepilotandconnectitto

thematching4pinconnectorfromthecontrolbox.Pushfirmlytomakesureitclicksinto

place.

MOUNTINGSCREWS

4.Taketheflexiblestainlesssteelpilothoseandconnectittothecontrolboxfitting.Securewith

wrenchbutbecarefulnottoover‐tightenasitmaydamagethebrassthread.

5.Attachthegassupplyflexhosetothecontrolboxgasinletfittingandsecurewithwrench.

15. Placetheburnerandplatebackintopositiononthefirefeature.

16. Turnonthegasandtestforoperation.Itmaytakeafewtriestopurgealltheairfromthegas

line.

17. Oncetheburnerlights,turnofftheunitandletcool.

Section4Operation

4.1Media

Carefullyspreadthefiremediaevenlyontotheburnerplate,donotoverfill.Youmaycovertheburner

untilitisnotvisiblebutdonotcoverthepilothood,seeimagebelow.

4.2Operation

Turnonthepowerswitchtotheunit.After3seconds,theigniterwillbegintoglowred.Thepilotburner

willthenigniteandstaylitfor6to8secondsuntilthemainburnerproducesflames.Oncetheburneris

lit,theignitorwillturnoffandtheflamesensorwillkeeptheflamesgoing.

Note:Windgustsmaydisplacetheflameawayfromtheflamesensorcausinga7secondsystemtoshut

downandre‐startthefiringsequence.Thesystemwilltry3timestolight.Ifitstillfailstoignite,itwill

lockout(turnoffcompletely)andwillneedtoberesetbyturningthepoweroffandthenonagain.

Donotoperateinrainyconditionsastheflamewillnotoperateoptimally.

Alwaysturnoffyoursystemwhenfirefeatureisnotinuseandneverleavetheunattended.

Itisrecommendedtocoveryourfirefeatureifitwillbeoutofuseforalongperiodoftime.

Table of contents