PRO.SIS.TEL. PST User manual

PRO. SIS. TEL.

Produzione sistemi telecomunicazioni

Antenna Rotator

Azimuth “D” DC version

ser’s manual

Rev.1.7b-usb

FCC

C.da Conghia 298 - 70043 Monopoli BA Italy

Tel-Fax ++39 080 8876607

E-mail:[email protected]

Copyright ® PRO.SIS.TEL. 2017

Warning

This manual must be read carefully before proceeding to assembly.

Warranty

1) The rotator with the control box, hereinafter called “product”, or “rotator”, is warranted for 2

years from date of purchase, provided that it is supported by the document of sale issued by the

manufacturer or authorized distributor.

2) The warranty covers replacement or repair of any defective component.

3) This warranty does not apply to product which have been subjected to misuse, ne li ence,

accident, incorrect wirin performed by the user, improper installation or non-compliance to

instructions furnished by us, dama e to product which has been repaired or altered without

authorization or to injury or loss resultin from careless maintenance. The warranty does not cover

dama e due to transportation and all causes not arisin from defects in workmanship, and faults

caused by adjustment of internal trimpots.

4) The warranty does not cover costs of transport or insurance for material returned to our

workshops.

5) The manufacturer is not responsible for personal injury or property dama e resultin from

improper or careless use of the product.

6) All product is tested after assembly and is supplied without defect. We exclude the

substitution or the prolon ation of warranty for a possible dama e.

7) After the 2 years warranty period, maintenance or repair will be subject to parts and labor

char es.

8) No person is authorized to assume for us any liability in connection with the sale of our

products.

9) This warranty does not cover dama e to people or thin s due to misuse, improper or

careless installation, or misunderstandin of instructions furnished by us.

10) The ri ht of recession must be exercised in accordin to the law.

11) Our products are subject to continuous improvement. We reserve the ri ht to implement

improvements and chan es without prior notification.

12) The le al code applyin in MONOPOLI, Italy, will apply, in cases of dispute.

13) Purchasers of product are deemed to accept para raphs 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12

and 13 as above.

Model: PST

S/N:

Date of purchase:

2

Important

Read this instruction manual carefully before attemptin to operate with the antenna rotator.

Save this instruction manual.

This instruction manual contains important safety and operatin instruction for antenna rotator.

Precautions

! WARNING, never connect or disconnect rotor cable or USB connectors while

power is on. This may results in electrical shock or burn.

Table of contents

Section 1: Description;

Section 2: Installation and use;

Section 3: Principle of operation ;

Section 4: Technical specifications;

Section 5: CD

Appendix 1: Declaration of conformity

Appendix 2: Warnin

Table:

Note:

Last up-date 28 March 2017

3

Section 1

The controller “D” version

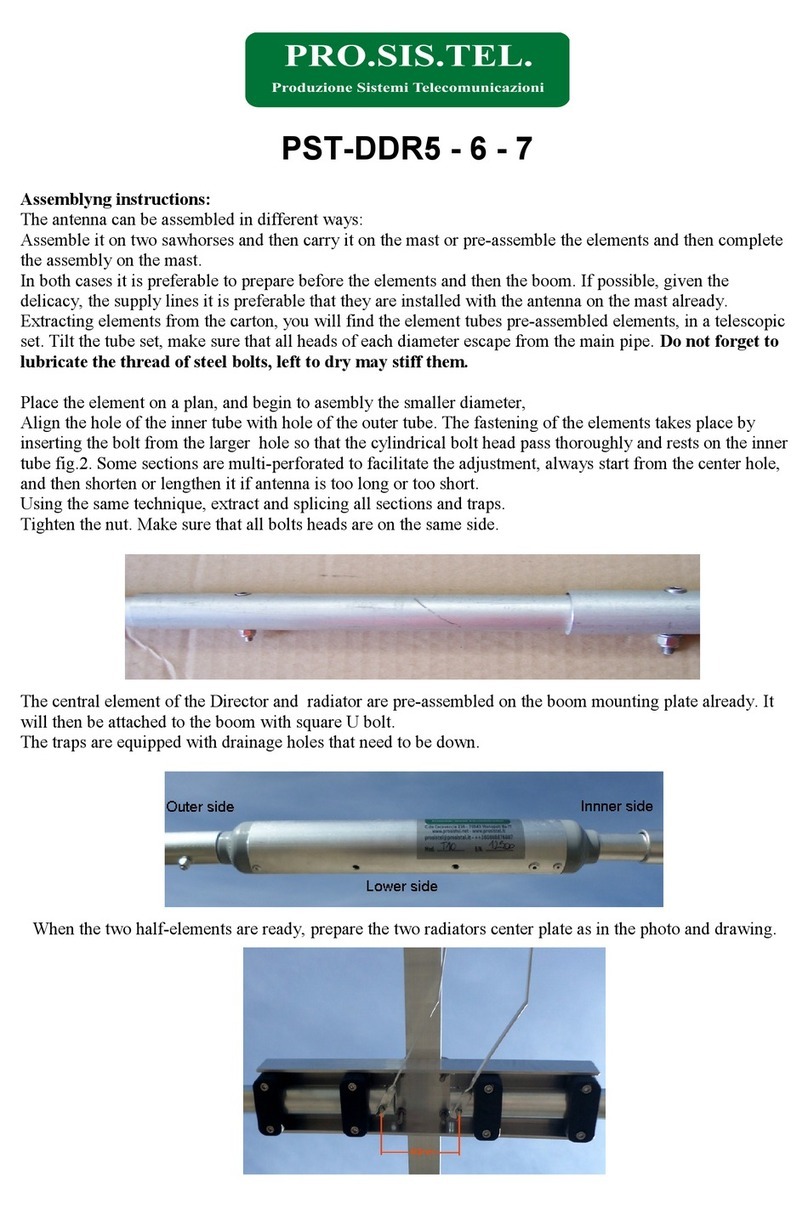

1-1 Front panels description.

1 - POWER SWITCH (POWER)

Turns power ON and OFF

2 – Right lever: CW momentary switch

Pushin and holdin this switch will make the rotator turn clockwise

If you have used the preset, or computer control to start rotation, you can over-ride those commands

by momentarily depressin the switch.

3 – Left Lever: CCW momentary switch

Pushin and holdin this switch will make the rotator turn anti-clockwise

If you have used the preset, or computer control to start rotation, you can over-ride those commands

by momentarily depressin the switch.

4 - Display

The display will show the current bearin in de rees.

When the preset knob is turned, the display will show the preset bearin .

The decimal points on the LED display blink

* when you turn the tar et position knob on the front panel

* rotation be ins and is in pro ress

* when rotation is complete. At that time the display will blink for the pro rammed delay time before

further rotations are permitted. (Note - if the CW or CCW keys have been used, further rotations in the

same direction are not subject to this delay time)

5 - Preset rotating encoder

To preset rotation, turn the knob to the desired bearin . 3 seconds later, rotation towards the preset

position will start, with the display showin the bearin as it chan es. "Err" is displayed if the preset

knob is turned to a position outside the rotation limits.

4

1-2 Rear panel description.

1 – SB connector

Enables connection to a PC port for remote operation.

Pin 5 = computer round

Pin 2 = serial data out (to computer data in)

Pin 3 = serial data in (from computer data out)

2 - Rotator control cable male connector.

Connect the rotator to the controller

3 – AC Main Power male socket (230Vac or 115 Vac)

4 – Fuse holder.

19x5mm, 1.6A fuse is required.

1-3 “D” Controller features.

Warning:

this is a complex controller, make sure you understand before using it.

This controller has several features settable via SB serial port and some of such features are

even settable manually. A four ways dip-switch allows manual selections.

Controller parameters settable in either modes:

Soft start – Soft stop

South stop or North stop

Rotation range 360 or 500

Calibration

Off-set

Controller parameters settable via SB only:

Reverse delay

Preset delay

PWM duty cycles

Rotation range

Optimizer

Rotor chk

Controller display mode settable manually only:

Absolute or relative display mode.

Entering in Absolute mode

The controller uses an ADC which accepts 0-5V volta es. The antenna position volta e readout is

mapped to be inside the 0-5V ran e. In the absolute mode the display shows directly the rotator

position expressed in absolute de rees: you read values from 0 to 500. In the other operational modes

(north/south-stop) the absolute readin s are converted into different an ular position numbers, but

only for input/display purposes: internally the pro ram works with absolute an les.

The absolute mode can be only entered turnin -on the CBOX with the CW key pressed until the

display shows a blinkin “---“ (three minus): now you can release the key and the absolute mode is

entered. You can move the motor usin CW and CCW keys between the rotation limits.

To exit from such a mode you must recycle CBOX power (forcin another mode by USB command

isn’t effective).

In the absolute mode the rotor can be only operated by the CW/CCW

The absolute mode is usefull for CBOX calibration (see CALIBRATION para raph).

It is NOT recommended to turn bi antennas which need to be started and stopped softly.

5

The bearin values in de ree as shown by the display, are not absolute but relative, as show in the

conversion tables:

000 250 500

110

070

000 240

430

180 180270 090

340160Vdc

De .

absolute values

relative values

east side west sideNS SW E

outran e outran e

000 250 500

290

070

180 070

430

000 000090 270

340160Vdc

De .

absolute values

relative values

east sidewest side NS SW E

outran e outran e

South stop

North stop

South stop

North stop

That means when the VDC applied at ADC converter input is 000V or less, the ABS value is 000 and

the display show 110 de . if setted on South stop (default) while show 290 de . if setted on North

stop.

With an applied volta e of 2.50V the display will show 000 de when in South stop and 180 de when

in North stop, while with an applied volta e of 5V the display will show 250 de . when in South stop

and 070 de . when in North stop.

The on-board dip-switch

There is an on-board dip-switch that allows the user to chan e some operatin modes without usin

the supplied PC pro ram.

Remember that the dip-switch status is read only at power-up and copied into the EEPROM: you

must turn-off and turn-on the main power for a dip-switch chan e to be effective.

There are four switches:

#1: select the source of the three followin parameters: if ON the source is the other three

switches status, otherwise the relative EEPROM contents modifiable throu h the W command

#2: operatin mode: if ON is north-stop, otherwise is south-stop

#3: rotation ran e: if ON the rotation ran e is 0 to 500 absolute de rees, otherwise is 70 to

430 absolute de rees

#4: PWM: if ON the PWM is enabled, otherwise is disabled

The above parameters (ENA_PWM, LOWLIM, UPLIM, MODE) are not modifiable by USB serial

commands if the switch #1 is ON (dip-switch selected). LOWLIM and UPLIM chan e accordin ly with

the POS_OFFSET values.

Soft start and soft stop:

A MOSFET controlled PWM is included. When it is in active it permits soft-start and soft-stop for the

rotator.

Default value: included.

South stop or North stop:

Selectable via USB port or on board dip-switch, it’s possible to switch the display readin mode.

Default value: South stop.

Rotation range 360 or 500:

500 de rees of travel is enabled as the default value. This allows 70 de rees travel past 360 de rees,

in both directions. Some users may wish to limit travel to 360 de rees. There are two ways to do this

- By settin the on-board dip-switch as described above.

- By usin the supplied software - which will allow any limits to be set, to one de ree accuracy. Note -

Absolute values must be entered in the input fields.

Default value: 0-500 De rees

6

Calibration

Two on board trimmers are provided to calibrate the controller.

Note – adjustment of these trimmers which leads to a “fault” is not covered by the warranty.

Please do not adjust them if you are not sure of the correct procedure.

If necessary, you can recalibrate your controller via USB port. See calibration procedure issue.

Off-set

If the initial antenna direction it’s not coincident with the eo raphic direction, you can fix it manually

usin an on board off-set trimmer as well via USB.

Default value: 0

Revers delay

A reverse delay time is provided. This is to reduce stress on your rotator / tower and antenna systems

caused by too-rapid reversal of direction. The default time is 3 seconds, but this may be altered in the

software to suit your antenna system.

Preset delay

A preset delay time is provided. This allows you time to finalise the preset position before the rotator

starts to turn. The default is 3 seconds, which may be altered in the sofware.

PWM duty cycles

This feature controls the accelleration / deceleration of the rotator between rest and full rotation speed.

This feature is kind to your antenna system as it ives smooth startin and stoppin of your antenna.

Rotation range

This controller allows you to have 500 de rees of total rotor rotation ran e with 70 de rees of extra

travel for each side. An on board dip switch allow you to choose between two rotations ran es, 0-500

de rees (default) or 0-360 de rees.

Optimiser

If you select rotation by preset knob or computer control, the optimiser will determine the shortest

direction to tar et.

Rotor chk

If implemented, if you select a tar et with preset or computer control, the CPU will check the feeback

si nal from the rotator, and within 5 seconds will prevent the rotator from turnin in the event of an

abnormality.

Controller internal view

7

Calibration procedure.

Initial calibration is carried out in the factory.

Note – adjustment of these trimmers incorrectly may require service attention by your dealer.

THIS IS NOT COVERED BY THE WARRANTY and your dealer may raise a time and labour

charge for the work.

To use the on-board OFFSET trimmer to perform subsequent calibration

1. Turn the antenna to a known position if the true position differs from the controller display.

2. Adjust the on-board OFFSET trimmer until they are the same.

Note

The Calibration potentiometer will only permit a minor amount of adjustment. If your antenna position

is rossly incorrect, you will need to correct it by repositionin the antenna on the mast.

The complete calibration procedure is the SB - RS232 philosophy.pdf file for expert only)

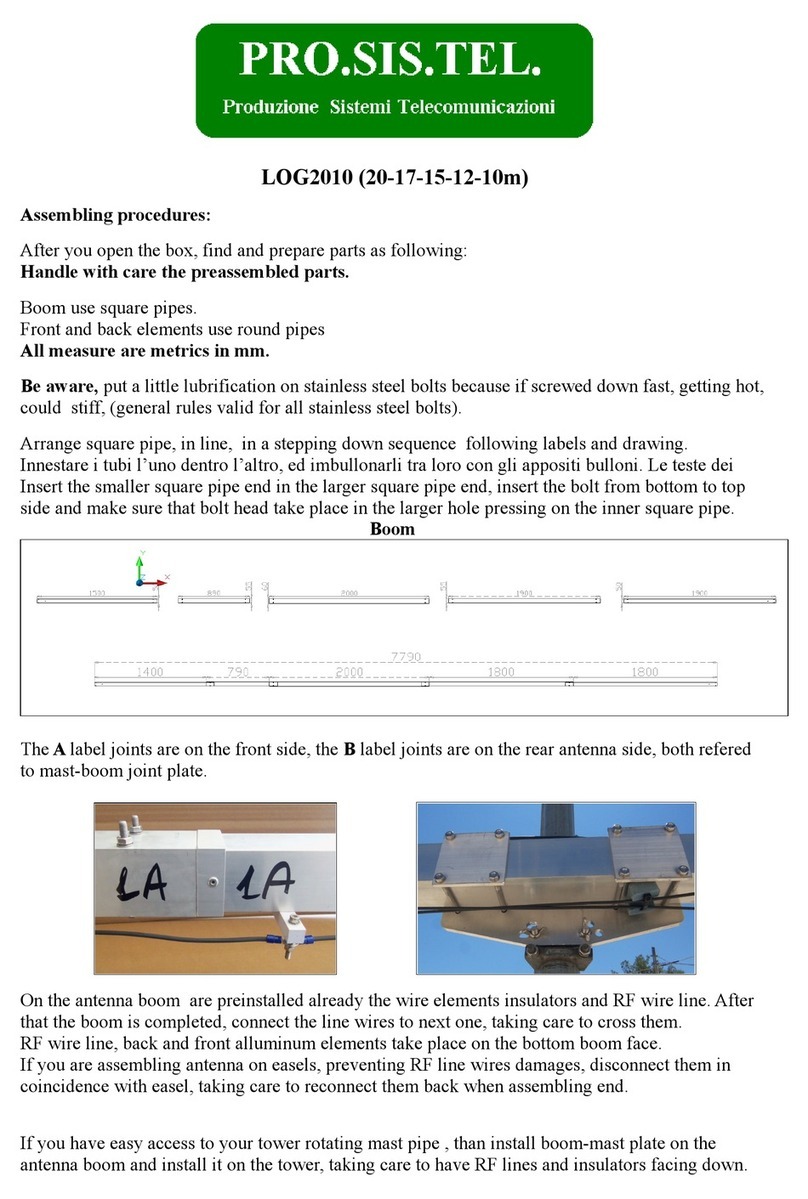

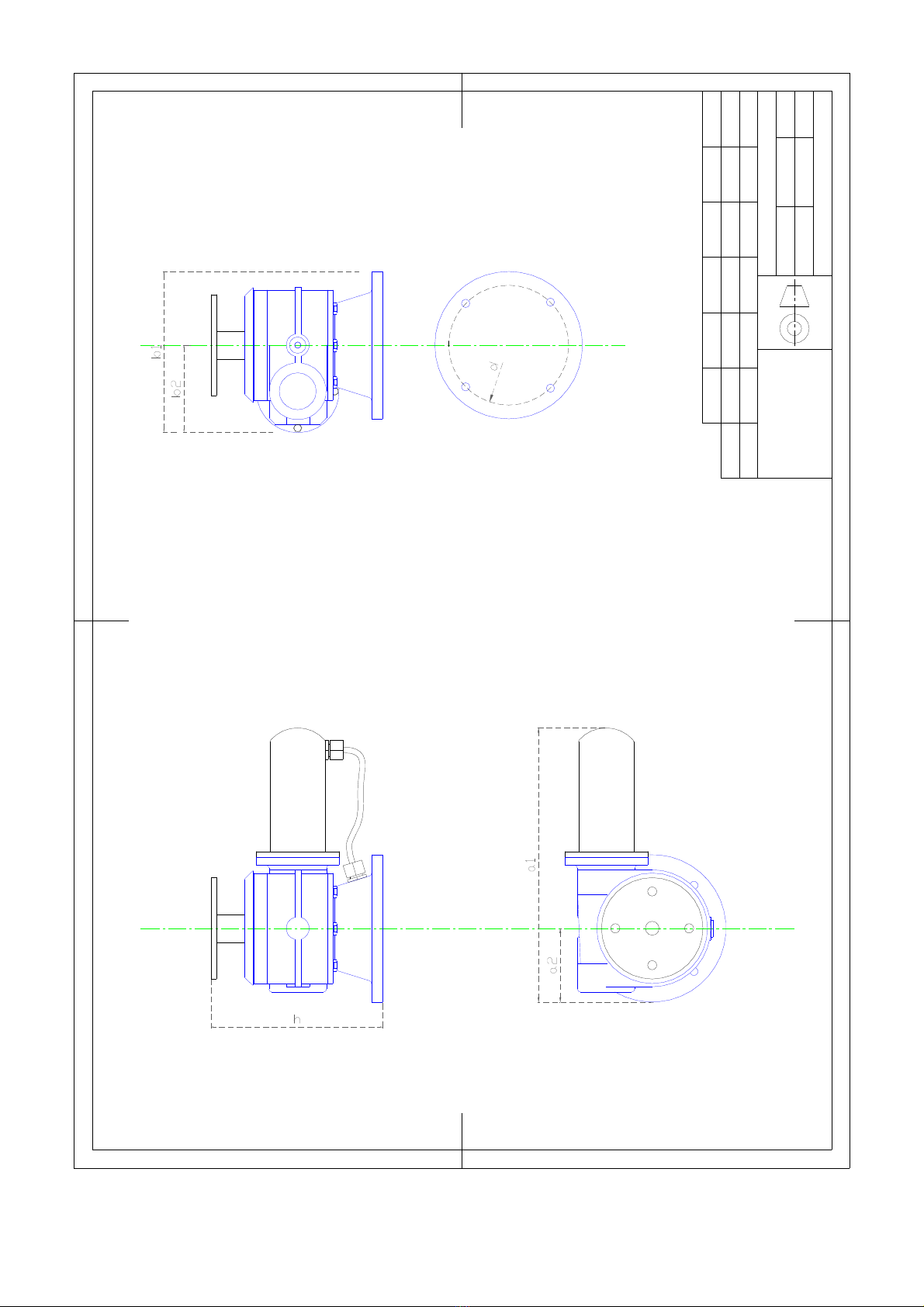

1-4 The rotator

The rotator has a unique desi n. The motor is located on the side of the machine.

The motor output shaft terminates on a flan e, where different kinds of mast clamp, available from us,

may be fixed with bolts. Users may also supply their own clamp.

On the motor side is located a five-contact connector for motor power supply and potentiometer

terminals.

The potentiometer, used as the antenna position reader, is located inside the foot plate, and driven by

the transmission output shaft.

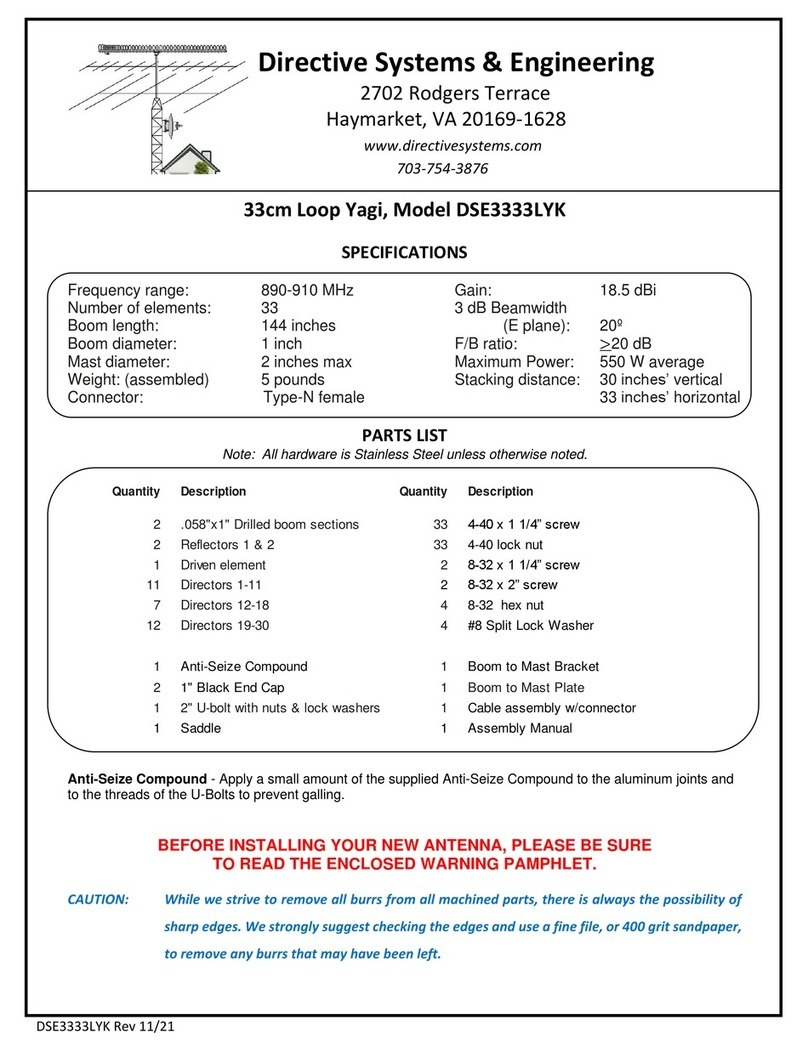

PST 110 - 71 - 61 PST2051 - 641

Rotator cable ends

Rotators end 110-71-61 2051-641 controllers end

8

Section 2

Installation and connections

2.1 npacking

After unpackin , immediately report any dama e to the deliverin carrier or dealer.

Keep the shippin cartoon.

2.2 Power supply connection

Connect the power cable and switch power on, display will show PHH and 110. Switch power OFF.

2.3 Rotator control cable preparation & connection

Before installin the rotator inside a tower, you need to prepare male connector for remote

control cable, make all connections and test rotator operation throu hly on the round, as described

below.

Connect the rotator and control box with a 5-core control cable. Two cores are used for the

motor DC power supply, and three for the position readin potentiometer. If the diameter of the control

cable is too thin, it will limit the volta e and reduce the torque.

Do not use cable with less than 0.5 mm² of section area.

Before connectin rotator and controller, make sure that power switch is OFF.

Cable plug Motor terminals board

Wire no. 1 must be connected to 1 (VDC motor power) >= 1mm²

Wire no. 2 must be connected to 2 (VDC motor power) >= 1mm²

Wire no. 3 must be connected to 3 (P to pot central lead)

Wire no. 4 must be connected to 4 (+5 Vdc pot lead)

Wire no. 5 must be connected to 5 (0 Vdc pot lead/GRO ND)

Warning: Improper wiring can result in damage to the rotator

circuitry when the power is swiched on.

THIS IS NOT COVERED BY THE WARRANTY.

2.4 Rotator cable inspection

Ensure the cable is correctly wired before connectin it to the controller.

Chekin the rotor cable you need a di ital multimeter.

Rotator truth table

Pins 1 and 2 (DC motor resistence = 4 ~19 ohm)

Pin 1 and 2 to ground = open

Pins 1-2 to pins 3-4-5 = open

Pins 3 and 4 = ~ 2.06K (positive wiper to potentiometer)

Pins 3 and 5 = ~ 7.65K (negative wiper to potentiometer)

Pins 4 and 5 = ~ 10K (entire potentiometer)

Pins 3-4-5 to ground = open

Those values are valid when rotator is pointin North, a small tollerance is acceptable.

If you don’t see these values, check your cable connections.

se truth table each time you notice something wrong on your controller.

2.5 Preinstallation check

! Warning, use only CW and CCW switch while preinstallation check is in pro ress.

Switch power ON, display will show PHH and after than the rotator position.

If display shows 110. or 2.50, check the connection cable.

Fully depress the CW lever switch for 1-2 seconds. the rotator should start to move in the CW

direction. Release the switch and try the same test for CCW. The opposite rotation will be a little

delayed by the preset delay time, which is normal. Note the controller display durin this test. The

9

readout should increase for CW and decrease for CCW. If these tests ive incorrect results, refer to

the troubleshootin section of this manual. If the results are correct, test full rotation to the electronic

limits in both CW and CCW directions. When this test has been performed turn the rotator to 000

de rees with the leverl switches. Then test the preset feature by settin a new direction with the preset

knob. Observe that the rotator will turn to that position and stop. The optimiser feature will ensure that

travel to the preset position is always in the shortest manner.

2.6 Troubleshooting

-Power

- Check the presence of the house power at power outlet;

- Check that the power cable plu s is correctly connected.

- Check the fuse. If it’s blown, replace it with one of the correct value and switch power on. If it

blows a ain, the user contacts the local service a ent.

-Motor turns in the wrong direction

-If while you were pushin CW switch the rotator started in counter clock wise sense, then the

motor is ettin reversed DC polarity. Chan e over the motor wires.

-Rotator follows the right CW and CCW commands but display shows the opposite.

- With a di ital voltmeter, check the presence of +5Vdc on the motor board, lead no. 4

If +5Vdc is not there, check the rotator cable connections/continuity.

- Display shows 110. and rotate only CW.

Potentiometer is misali ned, check the resistence as in the “truth table” if the resistence

valoue is lower than what it should be, than rotate the rotator CW till you et the ri ht

resistence valoue.

- Display shows 250. and rotate only CCW.

Potentiometer is misali ned, check the resistence as in the “truth table” if the resistence

valoue is hi her than what it should be, than rotate the rotator CCW till you et the ri ht

resistence valoue.

2.7 Rotator installation

Before drillin holes in the mountin plate, place the rotator inside the tower and adjust its

position so there will be no interference between rotator body and tower.

Put the antenna mast inside the mast clamp and lock centrally. The centre axis line must be within

0.5° of true.

By a pen, mark the position of the mountin holes on the mountin place, remove the rotator, and

drill the holes .

Use the four bolts with washers and self-lockin nuts to secure the rotator on the mountin plate.

Before ti htenin the bolts, insert the antenna mast in mast clamp, turn the rotator for 1 revolution

and adjust its position until the central axis line is within 0.5° . Now ti hten the bolts.

Note: Keep you rotator base dry, make sure that your tower rotator plate has enough

dreinage holes. Your rotator could get moisture in the base bell from the water standing on the

plate. If your tower rotator plate doesn’t have drainage holes and you can’t drill some, than put

some washers between the rotator base and the tower rotator plate.

2.8 Antenna direction adjustement

Antenna rotator ali nement is mechanical. After the antenna is installed on the mast, turn

rotator to the desired bearin . Unlock the bolts on mast clamp and with a ma netic compass turn the

antenna mast until the antenna beam direction is like that shown on the rotator control box. Lock the

antenna mast with the mast clamp bolts. The antenna beam direction now is fixed. If you want to

chan e it, you must rotate the antenna clamp on antenna mast. See Calibration Offset issue.

2.9 Rotator maintenance

The worm- eared motors are lubrificated for life and no maintenance is required. If you live in

an industrial zone or sea area, after a time you may have some corrosion to the outer casin . Rotators

are coated with anticorrosive paint at the factory and if repaintin is necessary, use ordinary

anticorrosive paint for ferrous metal.

10

Section 3

Principles of operation

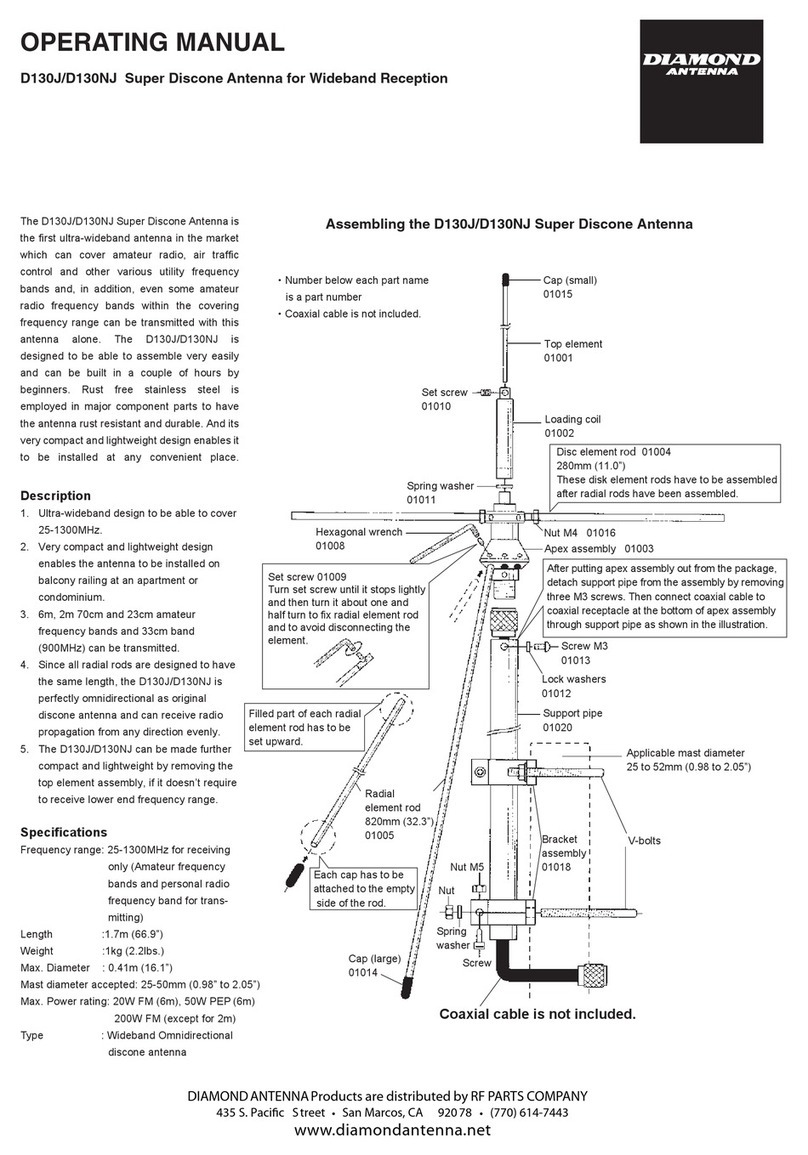

3.1 Rotator

The rotator is manufactured with a worm-wheel eared motor drived by a hi h torque dc

motor.This method, normally used in heavy duty industrial and professional machinery, permits a very

hi h reduction ratio, with hi h power torque with both low power motor drive and hi h brake torque,

due the self-brakin property of the worm-wheel eared motor.

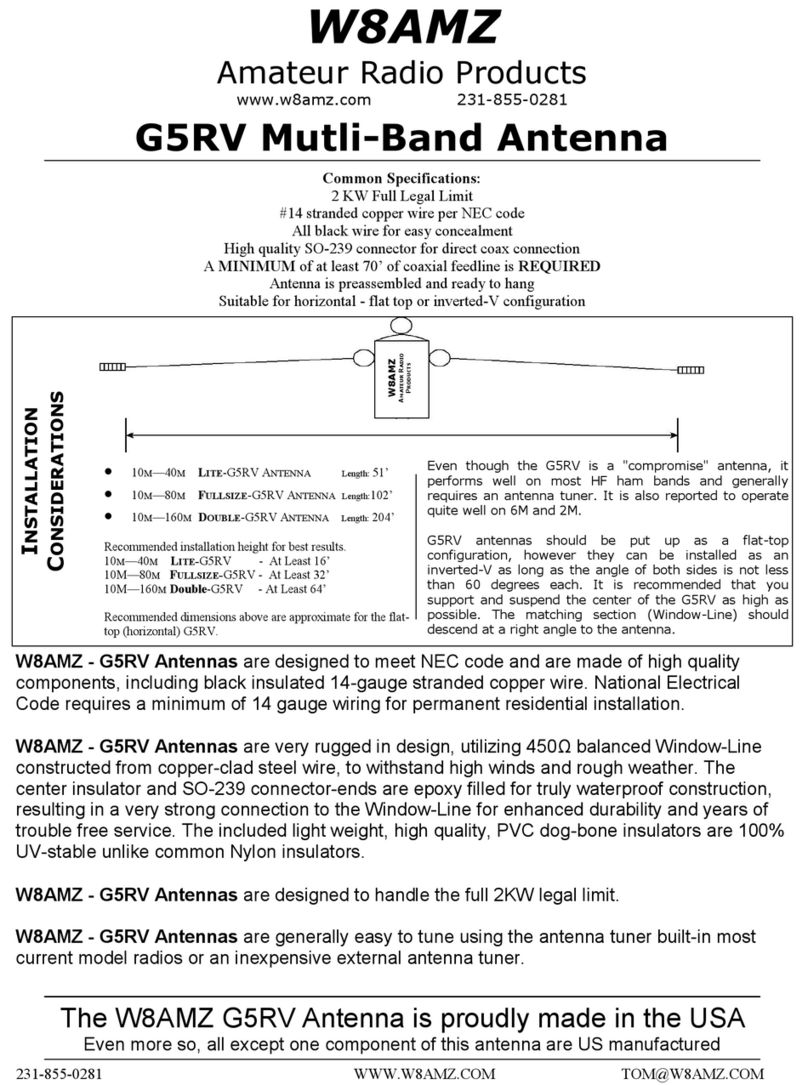

3.2 Electrical configuration

3.2.1 Indicator circuit

Three di it, 7 se ments led display are used for the direction indicator and the antenna direction

is displayed in de rees.

A 10 turns 10K potentiometer is used as position readin , only 1 turn of the 10 turns is used to

read antenna headin . See truth table.

3.2.2 Motor power switch

The motor is powered throu ht two 10 Amps lon life relays.

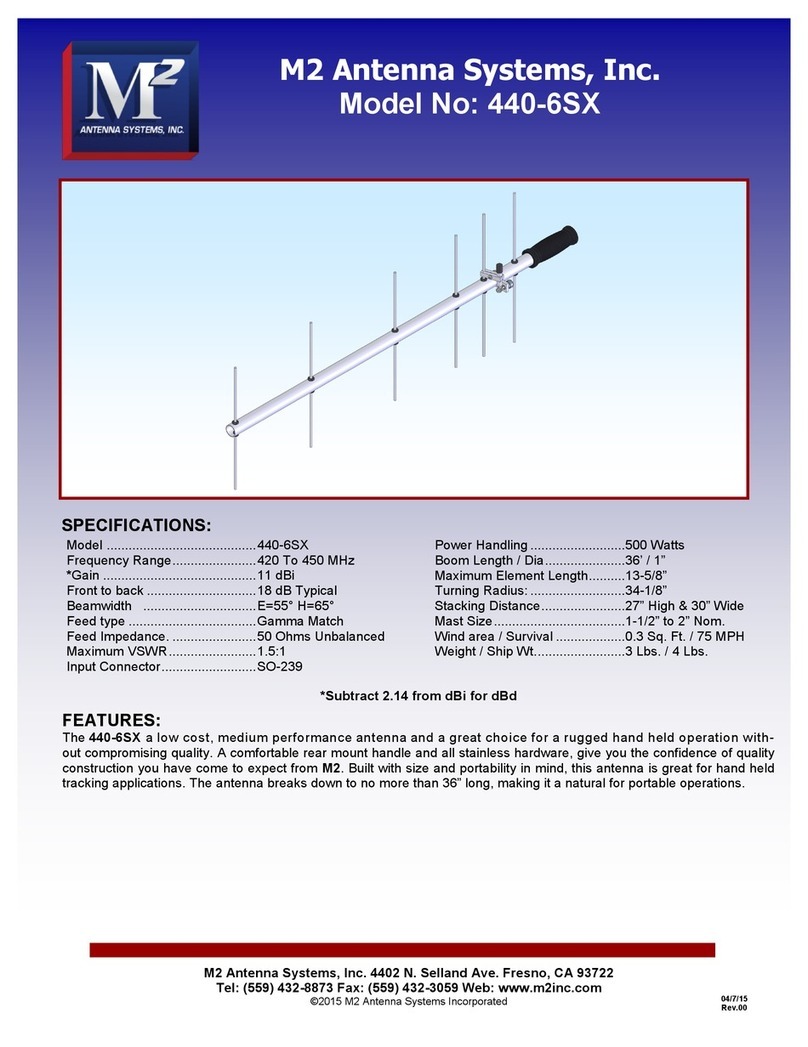

DRAW

: PST61DC, working basic block scheme

115V 60Hz

230V 50Hz

POWER

SUPPLY

AC

FILTER

PRO.SIS.TEL.

C.d Conghi 298

70043 Monopoli BA

tel.- f x ++39 80 8876607

www.prosistel.it

DRAWN BY

: Capitanio Piero

S/N

: A005

INPUT

RS232

0-12V c

0-9V c

CCW

ENCODER

CW

TRANSF

0-42V c

DISPLAY

CPU

DC

MOTOR

POWER

DATE

: December, 15 2003

REV

: 1

GND

POT.

2 -

3 P

4 +5VDC

1 +

M

11

Section 4

Specifications

4.1 Worm gear box

The worm ear box has a waterproof aluminium case conforms to the CEE 89/392/CEE

standard.

4.2 Motor

The motor, in a steel waterproof case conforms to CE and FCC class B.

4.3 Control unit

Microprocessor controlled di ital readout display havin USB serial port built inside.

The controller has ferrous parts painted. Conform to CE and FCC class B.

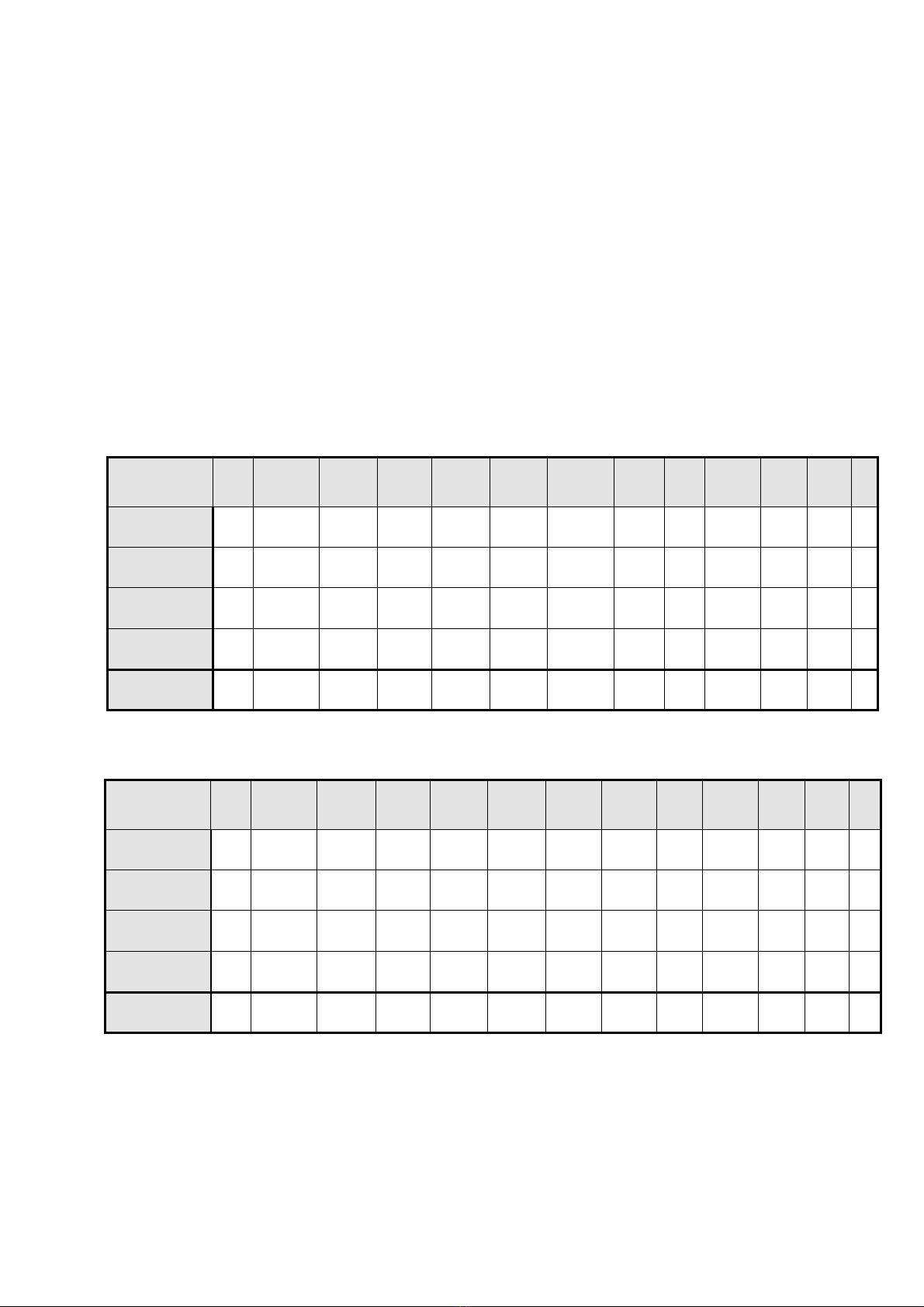

Rotators Specifications

METRICS

Model Wind

area

m2

Motor

torque

Kg/cm

Brake

torque

Nm

Vert.

load

Kg

Rotor

speed

360°

Variable

speed

Rotation

range

Motor

Volts

Wires

N. Redout RS232 Preset Kg

PST 641D 1.2 1.000 400 450 ± 60” yes 500 12 Vdc 5 digital yes yes 10

PST 2051D 2.5 2.000 600 650 ± 60” yes 500 12 Vdc 5 digital yes yes 14

PST 61D 3.9 3.800 1.180 850 ± 90” yes 500 12 Vdc 5 digital yes yes 25

PST 71D 8.8 6.000 2.172 1.000 ± 120” yes 500 24 Vdc 5 digital yes yes 35

PST 110D 10 6.000 3.400 1.200 ± 150” yes 500 24 Vdc 5 digital yes yes 45

S/ K

Model Wind

area

Sq.ft

Motor

Torque

Lbs ft

Brake

torque

Lbs ft

Vert.

load

Lbs

Rotor

speed

360°

Variable

speed

Rotation

range

Motor

Volts

Wires

N. Redout RS232 Preset Lbs

PST 641D 12 73 703 990 ± 60” yes 500 12 Vdc 5 digital yes yes 22

PST 2051D 25 147 1.000 1.430 ± 60” yes 500 12 Vdc 5 digital yes yes 31

PST 61D 39 280 2.100 1.870 ± 90” yes 500 12 Vdc 5 digital yes yes 55

PST 71D 88 1.032 4.032 2.200 ± 120” yes 500 24 Vdc 5 digital yes yes 77

PST110D 100 1.032 6.050 2.200 ± 150” yes 500 24 Vdc 5 digital yes yes 110

Note:

It is a good practice do not overpass the 50% of the maximum rotator wind load.

12

Section 5

With this user’s manual a CD is provided.

CD contains several folders in which there are some files with some extra informations about your

antenna rotator, as a copy of this manual as well.

We su est you pay attention on such extra informations, from which you can learn more about this

antenna rotator, but in meantime they are intended for expert technicians, so make sure to well

undestand what you are readin before to do anythin .

Setup Pro.Sis.Tel. Box D Vxxx.exe

an self-installer file, when you run it, the PC creates a copy of the contents of the CD and

install the software tool PRO.SIS.TEL. Box D V. X.XX.X

Drivers folder for PC SB port

Use such drivers when the PC operatin system does not have their own drivers.

Folder manuals and service documents

In this folder you will find a copy of the printed manual and service documents.

We recommend the readin of each of these.

Please read it carefully.

Service issues raised by incorrect use of the software are not covered by the warranty

This manual and the files on the CD are part of the equipment, store them carefully.

Dear customer,

thank you for purchase a Pro.Sis.Tel./BigBoyRotators, if you are happy with it please talk to

everybody, if you are unhappy with it please talk with us.

Your feed back and su estions, will be very appreciated, to improve our products.

Annamaria Fiume

IK7MWR

MADE IN ITALY

Protect your environment, in case of discontinuing of this unit, consign it to

specialized metal waste collector.

13

Appendix 1

DICHIARAZIONE DI CONFORMITA’

DECLARATION OF CONFORMITY

according to EN45014: 1998

Si dichiara che il prodotto: Rotore d’antenna mod. PST ……….D è conforme ai requisiti

essenziali delle seguenti direttive comunitarie:

This product: Antenna rotator model PST………..D is fully conforms

to the council directives:

-89 336 CEE

-92 31 CEE

-93 68 CEE marcatura CE per prodotti destinati ad essere utilizzati entro taluni limiti di

tensione

-93 97 CEE

-73 23 CEE

recepite dai seguenti decreti legislative

as amended by italian law.

-Nr. 791 del 18 10 1977 attuazione 73 23

-Nr. 615 del 12 11 1996 recepimento direttive 92 31 CEE, 93 68 CEE, 93 97 CEE

-Nr. 626 del 25 11 1996 attuazione della direttiva 93 68 CEE

-Nr. 277 del 31 07 1997 modifiche alla Nr. 626 del 25 11 96

E’ conforme ai requisiti di prodotto indicati dalle seguenti norme armonizzate:

It is conforms to product’s requirements as indicate in the following armonized rules:

- CEI EN 50082-1 Compatibilità elettromagnetica, norma generica sull’immunità. Ambienti

residenziali, commerciali ed industria leggera.

- CEI EN 50081-1 Compatibilità elettromagnetica, norma generica sull’emissione. Parte 1,

ambienti residenziali, commerciali e dell’industria generica.

- CEI EN 60335-1 Sicurezza degli apparecchi elettrici d’uso domestico e similare. Parte 1,

norme generali.

Esso è certific to FCC cl sse B.

It is cl ss B FCC certified.

In fede

Annmaria Fiume

Monopoli lì, 01 07 2005

14

PST61 - 71:

6 1 2"

(ø165mm)

ø12mm

1 2"

ø10mm

3 8"

PST2051:

5 1 8"

(ø130mm)

PST641:

4 1 2"

(ø115mm)

DRAW: Rotor plates holes diagram

PRO.SIS.TEL.

C.da conghia 298

70043 Monopoli BA

ITALY

www.prosistel.it

Note – this drawing is not to scale

15

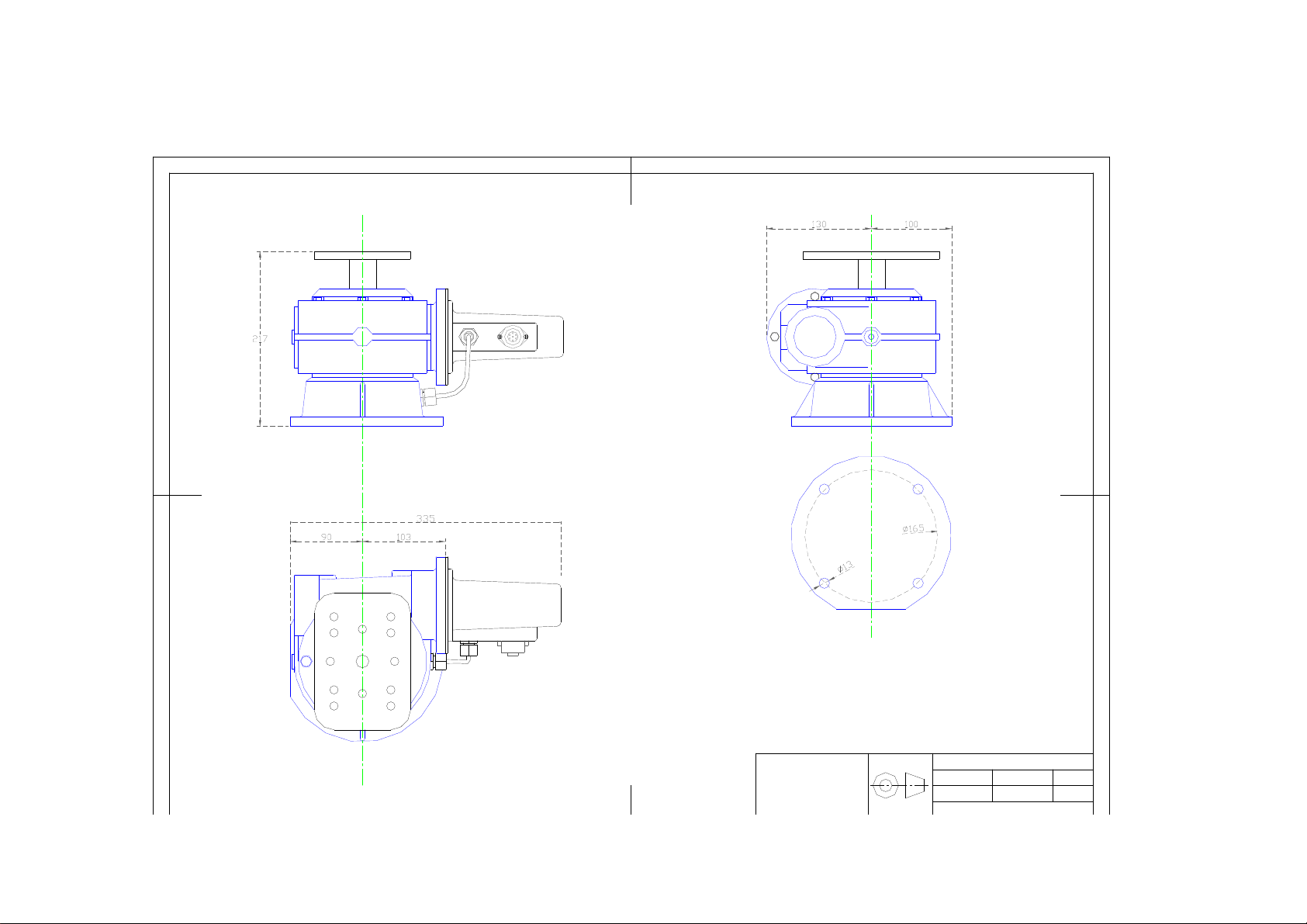

Dr w:

PST641-2051 general dimensions

Fixing plate

down view

PRO.SIS.TEL.

C.da Conghia 298

70043 Monopoli BA ITALY

tel. ++39 080 8876607

www.prosistel.it

280

298PST2051

PST641

a1

Drawn by:

Capitanio Piero

Scale:

1:1

a2

70

80

b1

150

175

b2

90

95

115

d

130

Note:

measurements in mm

Date:

May 05 2004

Checked by:

170

h

186

Rev:

16

PRO.SIS.TEL.

C.da Conghia 298

70043 Monopoli BA ITALY

tel. ++39 80 8876607

Dr w:

PST61D, general dim.

Drawn by:

Capitanio Piero

Checked by:

Rev:

Scale:

1:1

Date:

Feb 02 2007

Note:

measurements in mm

Fixing plate

down view

Serial number:

PRO.SIS.TEL.

C.da Conghia 298

70043 Monopoli BA ITALY

tel. ++39 80 8876607

Serial number:

Note:

measurements in mm

Dr w:

PST71DC general dimensions

Drawn by:

Capitanio Piero

Checked by:

Date:

April 09 2008

Scale:

1:1

Rev:

Fixing plate

down view

18

Company: Pro.Sis.Tel.

Draw: PST110D-Dimensions

Date: Sept. 03 2010

Rev:

Note: Quotes in millimeters

19

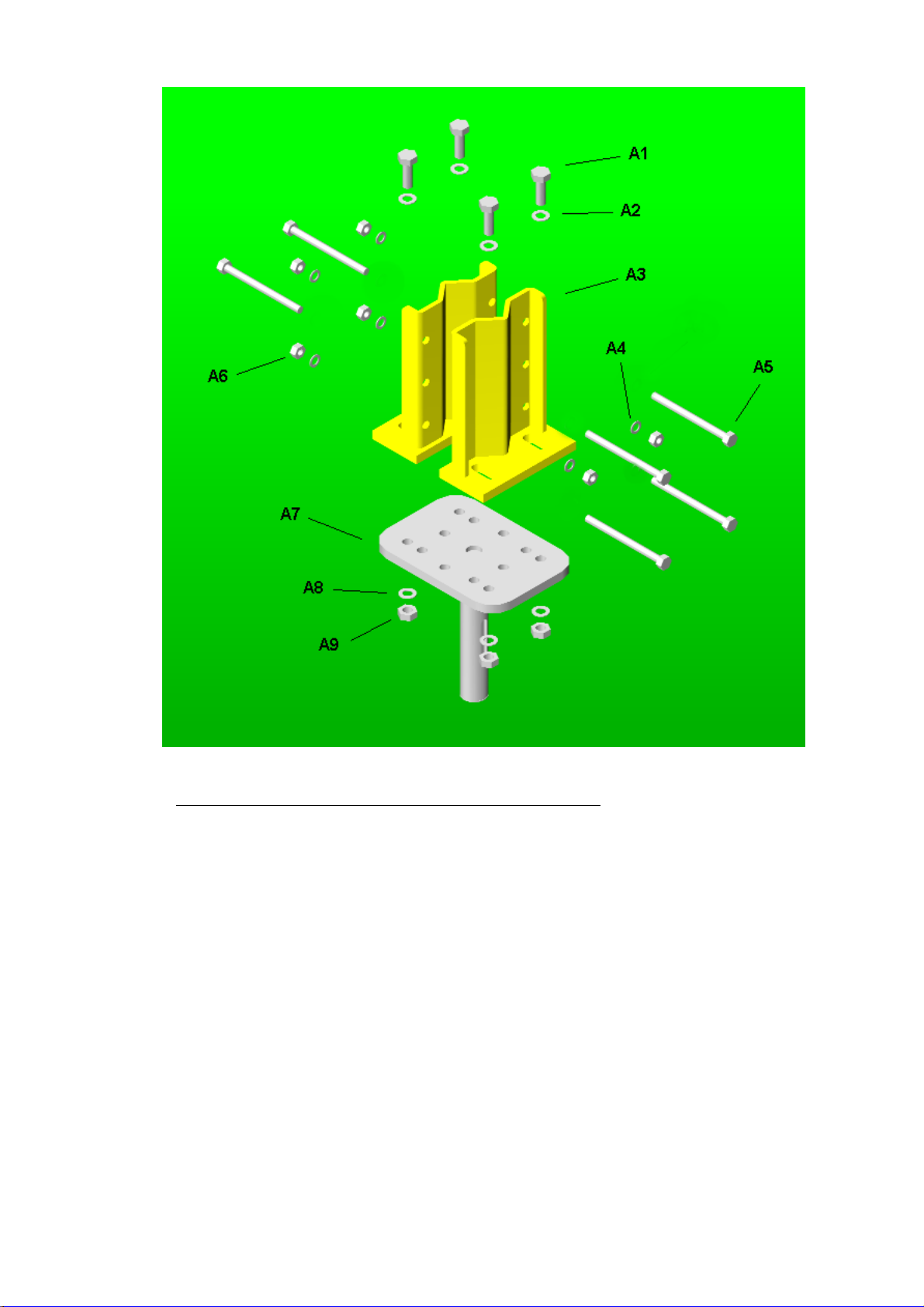

A1- Bolt, stainless steel, M10x40mm x 4

A2- Washer ø10mm, stainless steel x 4

A3- Mast clamps 3”, zinc galvanized steel x 2

A4- Split washer ø8mm, stainless steel x 6

A5- Bolt, stainless steel, M8x100mm x 6

A6- Stainless steel nut, M8 x 6

A7- Rotator shaft with plate, zinc galvanized steel x 1

A8- Split washer ø10mm, stainless steel x 4

A9- Nut M10, stainless steel x 4

This manual suits for next models

10

Other PRO.SIS.TEL. Antenna manuals

PRO.SIS.TEL.

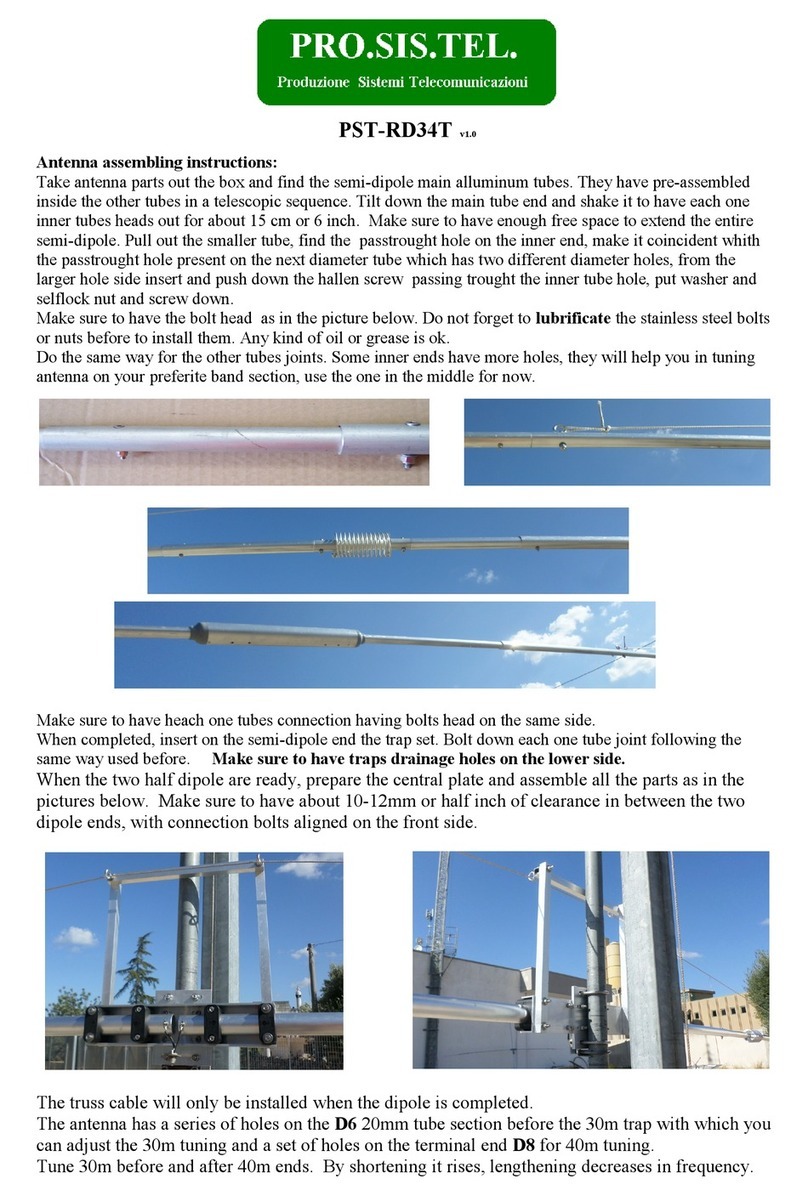

PRO.SIS.TEL. PST-RD34T User manual

PRO.SIS.TEL.

PRO.SIS.TEL. PST-34TV User manual

PRO.SIS.TEL.

PRO.SIS.TEL. PST152VC Installation guide

PRO.SIS.TEL.

PRO.SIS.TEL. PST-40VF Installation guide

PRO.SIS.TEL.

PRO.SIS.TEL. PST-1524TV User manual

PRO.SIS.TEL.

PRO.SIS.TEL. PST-20VF Installation guide

PRO.SIS.TEL.

PRO.SIS.TEL. PST-32 Installation guide

PRO.SIS.TEL.

PRO.SIS.TEL. PST-152TV User manual

PRO.SIS.TEL.

PRO.SIS.TEL. PST-27 Installation guide

PRO.SIS.TEL.

PRO.SIS.TEL. PST-30VF User manual