Procon V3D Series Operating and maintenance manual

H - I - J

frequency converters

programmer’s manual

from software version V8.94.11 onwards

P

Since

1984

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 3 -

Table of contents

Instructing graphic symbols.........................................................................................................................................5

Important information ..................................................................................................................................................5

Programming the frequency converters.......................................................................................................................5

Serial line communication.......................................................................................................................................6

Length of the serial line .....................................................................................................................................6

Programming terminal............................................................................................................................................7

Operation of the push buttons of the lower (control) group.................................................................................8

Operation of the push buttons of the upper (programming) group.......................................................................8

The setting procedure........................................................................................................................................9

Procedure of resetting.......................................................................................................................................9

Display mode..................................................................................................................................................10

Programming mode.........................................................................................................................................10

Operating from the computer................................................................................................................................11

Operating terminal................................................................................................................................................11

Controlling terminal ..............................................................................................................................................11

Functions of the push buttons (operating and controlling terminal)...................................................................12

Programming procedure (operating and controlling terminal)...........................................................................12

Features and capabilities of the frequency converter and the program..................................................................13

Some programming options (differs for the V3D, VLD and VHD types!):...........................................................13

Information about the program versions................................................................................................................14

Information on program update........................................................................................................................14

Procedure of programming...................................................................................................................................14

Packed menu system................................................................................................................................................15

0. Quick menu...........................................................................................................................................................16

Adopting parameters in the quick menu................................................................................................................16

Removing parameters from the quick menu..........................................................................................................16

Factory setting of the quick menu.........................................................................................................................17

1. Operation mode menu...........................................................................................................................................18

Function of the modifying signal ...........................................................................................................................21

PID regulation......................................................................................................................................................22

Explanation of the parameters.........................................................................................................................23

Explanations to the PID regulations.................................................................................................................23

An example for the regulation..........................................................................................................................24

Some hints......................................................................................................................................................24

2. Starts menu...........................................................................................................................................................25

Explanation of the acceleration time.....................................................................................................................25

Explanation of the acceleration with breakpoints...................................................................................................26

Effect of the “S” curve (the same at acceleration and deceleration).......................................................................26

3. Stops menu...........................................................................................................................................................28

Explanation of the deceleration time.....................................................................................................................28

Explanation of the deceleration with breakpoints...................................................................................................29

Start command with pulse control, from terminal blocks........................................................................................31

Direction change while running.............................................................................................................................31

Permissible load of the brake resistor (typical curve).............................................................................................31

4. Inputs menu..........................................................................................................................................................32

Analogue inputs ...................................................................................................................................................32

Explanation of the lower and upper levels of the analogue inputs.....................................................................32

Control function...............................................................................................................................................32

Special functions (rise time, fall time, U boost, torque, f max, f min) .................................................................32

Digital inputs ........................................................................................................................................................32

Explanation of the logical functions..................................................................................................................36

Explanation of the program functions...............................................................................................................38

Explanation of other functions..........................................................................................................................38

Virtual inputs........................................................................................................................................................38

Slave equipment parameters................................................................................................................................39

Marker adjustment...........................................................................................................................................39

Incremental rotation speed signal transmitter (IRE) parameters............................................................................41

Incremental rotation speed signal transmitter inputs.........................................................................................41

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 4 -

5. Outputs menu........................................................................................................................................................42

Analogue outputs.................................................................................................................................................42

Digital outputs......................................................................................................................................................42

Timings...........................................................................................................................................................45

Example for the operation of the timer.............................................................................................................45

Comparators...................................................................................................................................................46

Time periods...................................................................................................................................................47

Example for the operation of the digital output, timer and comparator ..............................................................48

6. Motor menu...........................................................................................................................................................49

Programming vector mode frequency converters (with IRE)..................................................................................50

Parameters to be set at vector type operation..................................................................................................50

The motor current vs. time....................................................................................................................................54

Permissible steady motor current vs. frequency....................................................................................................54

Permissible motor overcurrent vs. time.................................................................................................................54

7. U/f ratio menu........................................................................................................................................................55

U/f characteristics.................................................................................................................................................56

8. Frequencies menu.................................................................................................................................................57

9. Programs menu.....................................................................................................................................................58

Activation of the programs and sequences (programs 1 - 15, sequences 1 - 3).....................................................61

Example for activating from the terminal block.................................................................................................61

10. Displays menu.....................................................................................................................................................62

Displayable items.................................................................................................................................................62

Editing paged values............................................................................................................................................62

Dynamic state back indications.............................................................................................................................63

The possible dynamic operation states............................................................................................................63

Productivities........................................................................................................................................................64

Display image with big characters.........................................................................................................................65

11. System parameters menu....................................................................................................................................66

Parameter sets.....................................................................................................................................................66

Saving the parameter set.................................................................................................................................67

Loading up the parameter set..........................................................................................................................67

Exceptions at loading the parameters set ........................................................................................................68

Modifying parameters based on saved parameter set......................................................................................68

Macros.................................................................................................................................................................69

Using macros..................................................................................................................................................69

Variable system parameters.................................................................................................................................70

Explanations to the CAN bus...........................................................................................................................71

Features and capabilities of the master/slave connection.................................................................................71

Read only parameters..........................................................................................................................................73

Date.....................................................................................................................................................................73

System parameters changeable with the manufacturer password.........................................................................73

Remarks to the system parameters......................................................................................................................74

12. Events menu.......................................................................................................................................................75

13. Errors menu........................................................................................................................................................76

Error acknowledgement........................................................................................................................................77

List of errors.........................................................................................................................................................77

Programming guide...................................................................................................................................................80

Control from terminal between 5 and 60 Hz..........................................................................................................80

Control from terminal blocks with potentiometer between 10 and 50 Hz................................................................80

Control from terminal, reference signal change between 1 and 100 Hz with motor potentiometer function.............80

Regulation on pressure using a 4 to 20 mA pressure remote transmitter...............................................................81

Regulation on rotation speed, using IRE...............................................................................................................82

Explanation of important definitions / abbreviations....................................................................................................83

User settings.............................................................................................................................................................85

Notes........................................................................................................................................................................86

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 5 -

Thank you for having decided in favour of PROCON Ltd’s frequency converter.

This Instruction Manual contains all information necessary for starting up, programming and operating the frequency

converter.

Instructing graphic symbols

Following graphic symbols will be used in this manual:

8

This symbol is used for those instructions whose negligence could cause personal injury, damage in the

equipment and property damage.

i

Important information

Important information

8CAUTION

Prior to setting up, operating, maintaining or servicing the frequency converter please carefully read this

Programmer’s manual!

Please entirely comply with all safety measures, warnings and instructions described in the manual!

Absolutely follow the safety notes described in the manual!

The operating company is responsible for any personal injury and property damage caused by the negligence of the

warnings described in the manual.

Programming the frequency converters

The tools, which can be used for programming:

•Programming terminal

•Operating terminal

•Controlling terminal

•Computer

i

When connecting more than one tool, the programming can be madefrom any of them, and the process will

be shown on the other tools, too.

With remote control, when transmitting “Write” messages on the MOD bus (e.g. reference signal setting),

parameter setting with the terminal is not possible.

In this case, the parameters can bemodified with remote control, orfor the duration of the parameter setting

the “Write” messages on the bus have to be suspended.

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 6 -

Serial line communication

The RS485 serial line communication is implemented with a 6-pole telephone connector and a 6-wire telephone cable

of custom length.

If the cable becomes faulty or a new cable is needed for any other reason, followings have to be considered for the

replacement:

8CAUTION

Since the serial line connectors also carry supply voltage (+9 V), the assignment of the connector socket pins is

identical in any case!

The connecting cables always must connect pin 1 of a connector socket to pin 1 of the other connector socket (and

all other pins in this way, respectively)

Simple commercial telephone extender cables reverse the pin assignment therefore they are not suitable here,

because they cause short circuit!

The demands pertaining to the serial cable (length, design etc) must be co-ordinated with the frequency converter’s

manufacturer!

A correct connection can only be established with this arrangement of the 6-wire telephone cable:

Length of the serial line

In case of a remote located terminal or display, the length of the terminal connecting cable is limited by the ohmic

resistance because - due to the display’s background lighting - the current consumption is not negligible.

In case of standard 6-wire telephone cable a maximum length of 10 m can be used. This assures that the 9 V supply

voltage will still be sufficient for the externally connected terminal or the internal power supply of the display. If the

terminal is connected through a thicker cable and adapter, the ohmic resistance of one cable wire should be calculated

for not to exceed the value of 2 ohms.

e.g. at using a wire with a cross section of 0.5 mm2the maximum length can be 50 m.

at using a wire with a cross section of 1.0 mm2the maximum length can be 100 m.

When connecting more than one equipment to the serial line, this applies for the total length of the connecting cables,

since the supply voltage for the externally connected terminal or display may happen to be supplied by the farthest

equipment, if it is the only one being switched on!

If the terminal or display is powered through a short cable (e g. from an independent external power supply, the length

of the connecting cables is not limited!

i

When using long cables, shielded cable or at least twisted-pair cable should be used!

The serial line can accept two equipment with backlight, at the same time.

Two displays or one (programming or operating) terminal plus one display. Beyond these, connecting a

computer is allowed.

These can operate in parallel without disturbing each other.

The 2x8-character controlling terminal can be connected to any equipment irrespective of the other equipment with

backlite, because it loads not the supply voltage of the serial line. It cannot be of external mounting, it can only be used

built in the equipment!

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 7 -

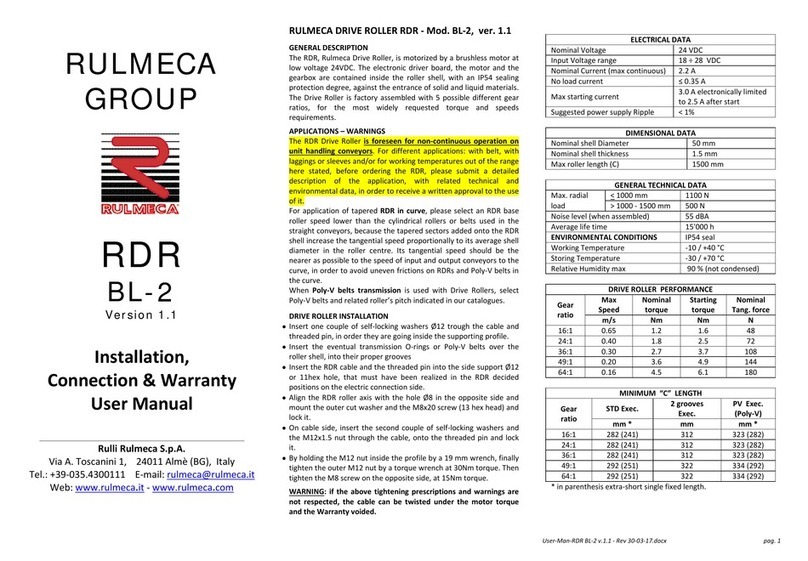

Programming terminal

Using the programming terminal, setting, inspection and display can be made through the serial line.

The programming terminal is equipped with a 4x16-character display, 11 push buttons as well as error and operating

state signalling.

It can be used as a built-in unit or in casing as a standalone unit.

The pane of the push buttons is arranged in two groups:

•Upper group:, , , , DISPLAY, ESCAPE, ENTER,

•Lower group:JOG, DIRECTION, START, STOP.

HIBA ÜZEM

ERROR RUN

P

ELFOGAD

ENTER

KIJELZŐ

DISPLAY

KILÉP

ESCAPE

KÚSZÁS

JOG

IRÁNY

DIR. START STOP

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 8 -

Operation of the push buttons of the lower (control) group

Withthe push buttonsof thelower group, theoperation of thefrequency convertercan be controlled,if earlier theterminal

was selected for the control (4-8-1 terminal control menu item). The lower four push buttons operate independently of

the upper push buttons. Thus –if the control is given to the terminal –evenduring datasetting, themotor can bestopped

or started etc.

i

To the digital inputs can be selected even inputs identical with the functions of the terminal control buttons,

thus for operating the control from the terminal only, the functions of the digital inputs have to be set to

differing meanings.

Jog: The motor starts to rotate with a preset small frequency (8-4-1, 8-5-1 menu item) in the preset direction with

the preset rising slope (8-4-2, 8-5-2 menu item). On releasing the button, the motor stops, on the repeated

push the motor starts again. The Jogging mode serves for the adjustments needed by the technology (e g.

threading the paper in the printing industry etc.)

i

The “Jog” push button is only effective in the standing state of the motor (STOP state).

Direction: The directionof therotation changes. When pushed several times, themotor changes the direction of rotation

each time: it stops according to the preset way then starts rotation in the opposite direction and accelerates

to the preset frequency.

Start: the motor starts rotation.

Stop: the motor stops rotation. (It functions as “Emergency stop” if the selected source of the logic control is not

the terminal. (In this case also an error signal is given!

Operation of the push buttons of the upper (programming) group

With the push buttons of the upper group, it can bemoved between the menu items of the data setting and display, data

can be entered and the data to be displayed can be selected, after changing from display mode to programming mode

by pushing the “Escape” button.

The most important parameters are included in the quick menu (menu 0), which is directly accessible by pushing the

“Escape” button.

In basic state, in the quick menu following seven parameters are available:

•control rise time,

•control fall time,

•motor nominal current,

•maximum frequency,

•minimum frequency,

•motor starting voltage,

•selecting the active menu.

The parameter set of the quick menu can freely be changed up to 15 parameters. The adopted parameters are included

also in their natural placesin themenu system. The way of adopting and removing parameters is given in the description

of the quick menu.

Setting the operation data (e.g. maximum frequency, rising time, etc.) can be made in the menu system.

The menu system consists of series of submenus proceeding from the items of the main menu (tree structure). The

submenus go to that depth where the requested data can be set unambiguously. This way of parameter setting was

chosen to make the handling easy.

The main menu denotes a group of self-evident parameters:

•Frequencies,

•Starts,

•Outputs, etc.

The submenus proceeding from these, tighten more and more the scope of the parameters, until finally the parameter

to be set is reached.

i

Note, that not all parameters of frequency dimension are included in the main menu item “Frequencies” (and

this also applies to the other parameters), rather at their natural place of setting.

Within the individual menu levels, moving is made with the and buttons, while the next submenu is reached with

the “Enter” button and the previous one with “Escape”.

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 9 -

At the end of the menu the setting follows.

The setting procedure

•On pushing the “Enter” button the cursor in the lower row starts to blink, signalling the parameter tobereadyfor setting.

•When using the selector switch, the push buttons can be used for selecting from the offered options.

E.g. in the 1-3 selection menu, at selecting the operation mode, the “Operation” or the “Control” switch can be

selected.

•At numeric setting, the setting occurs by digits. Between the digits, moving can be made with the push

buttons. When stopping on a digit, its value can be increased or decreased with the push buttons.

After „9” upward „0” follows, after „0” downward „9” follows, and the higher positional value changes according

to the sense.

i

If the setting would overstep the limit value, the push buttons become ineffective.

•Setting textual parameters is made similarly to the numeric setting, but here the parameter position can be

selected with the push buttons and from the characters can be selected with the push buttons.

The available characters are following:

space, numbers 0-9, letters A-Z, letters a-z, accented letters, punctuation marks, special characters

•After having selected the proper parameter and having set all digits and/or characters, by pushing the “Enter”

button the data can be validated (it will be written in the non-volatile memory, too).

i

If altering of the parameter is not possible, a warning message appears for 1 second in the lower row

of the terminal or display or on the regulator terminal.

Possible warning messages:

▪Go to Stop! - The parameter can only be altered in Stop state.

▪Permit altering! - Altering of the parameter has been disabled in menu item 11-1-3 enable

parameter modification.

▪User password!- For altering the parameter, entering of the user password is necessary.

▪Setup password! - For altering the parameter, entering of the setup password is necessary.

▪Manuf. password! - For altering the parameter, entering of the manufacturer password is

necessary.

When setting the reference signal in both the control and the regulation mode, at Start, with buttons

and also the so called terminal motor potentiometer function can be implemented. This means

that the reference signal can be set (with a speed depending on the place value of the actual digit)

with running motor. If the reference signal reached the desired the value, it can be validated with the

Enter button. Pushing Escape sets back the reference signal to its previous value!

Prior to setting thevaluesof theindividual parametersin the submenus, they arefactory set totheir default values, which

appear at the very first setting. The default values of all parameters can be recalled at any time with a single command.

This can be useful if the actual parameters cannot be used by the system for any reason e g. due to a mistaken setting,

and there is no time to check up each parameter value.

Procedure of resetting

There is possibility of resetting any parameter to its factory value. This can be needed, if the factory setting is not known

or resetting would be complicated (e.g. textual parameters)

With selecting the desired parameter, pushed and kept depressed the “Enter” button, on pushing the “Escape” button

the factory setting will be offered.

After releasing the buttons, between two options can be selected:

•On pushing the “Enter” button the offered factory setting will be entered,

•On pushing the “Escape” button the earlier setting returns.

This operation permits also inspection of the factory setting of any parameter

i

With the frequency converters of different power values, the factory values and the available limit values

may differ!

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 10 -

Display mode

On pushing the “Display” button the display changes to data display mode. Return to programming mode is made with

the “Escape” button.

In Display mode, a possible state of the screen is shown below:

(The display layout can freely be configured: any parameter can be displayed in any row)

Row 1shows the state consisting of three parts:

- the motor’s state: Run / Stop,

- dynamic feedback of the state (e.g. I limit),

- identification mark of the frequency converter (e.g. 1).

Row 2shows the actual running direction Forward / Backward

Row 3shows the frequency (e.g. f=50.00Hz),

Row 4shows the motor current (e.g. Imotor=6.4A)

If morethan onefrequency converteris used, looped on the Terminal serial line, indisplay mode the individual frequency

converters can be selected with the and buttons. The identifier always indicates the actual frequency converter!

The functions of the push buttons during display can be selected (e.g. operating the motorized potentiometer,

changing the parameter displayed in row 4 etc.)

In case of error, the ! Error ! state feedback appears in the state display. On pushing the „Escape” button, it will be

jumped to the error menu, where the error can be inspected!

Programming mode

After switching on, the DISPLAY mode is active on the programming terminal connected to the frequency converter.

Pushing the „Escape” button changes to PROGRAMMING mode. Pushing the “Display” button switches backwards.

Examples for the appearance of the display in programming mode:

Menu item number

( - -1)21

Equipment identifier

(1)

Parameter to be set

( 00s)5.

The parameter is

included in the

quick menu, too

(+)

Menu item number

(1-5-1) Equipment identifier

(1)

Parameter to be set

()terminal

The parameter does

not comply with

the factory setting

(.)

Equipment identifier

(1)

Parameter to be set

(reg.ref.)

Menu item number

(10-4)

Does not appear in

the display among

the paged items

(–)

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 11 -

Operating from the computer

The frequency converter can be connected to the computer through RS485-T line using RS 232 / 485 or USB / RS 485

adapter (interface).

Here the TermOnly program permits setting the frequency converter from the computer and provides a user interface

with the same look as that of the programming terminal.

The ProContact program beyond handling the frequency converter permits reading out, modifying and archiving the

actual parameter set as well as reading out and archiving the event- and error log.

Both programs are available on CD as attachment of the adapter (interface) unit or can be downloaded

from www.procon.hu

Operating terminal

▪This terminal allows programming the parameters of the quick

menu, displaying 2 parameters and generating reference

signal.

▪Includes a 2x16 character display, 4 push buttons and displays for

error state and operation state.

▪Reading in display mode: first row - the frequency, second row -

another parameter (e.g. voltage, current), which can be stepped with

the and arrows.

▪Reading in programmingmode:first row- the name of the parameter

along with its main menu ordinal number (e.g.

2 Control Tup), second row - the submenu ordinal number and

the value of the actual parameter (e.g. 1-1 5.00s), that can be

modified with the push buttons.

▪In case of error at the end of the first line the ordinal number of the

error, in the second line the name of the error is displayed. The error

list can be stepped with the and arrows.

▪The terminal can be used as a built-in unit (VHD), in casing as a

stand-alone unit or as an externally mounted unit (e.g. to the door

off the control cabinet)

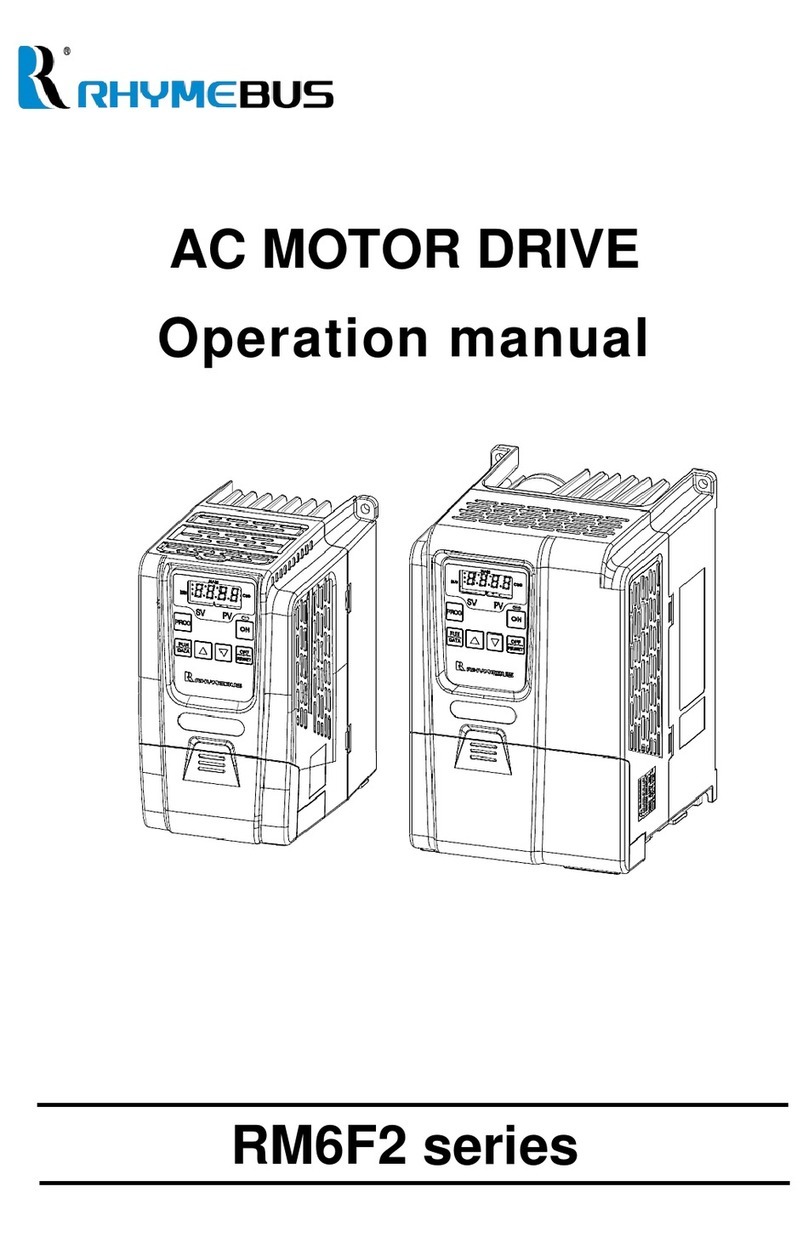

Controlling terminal

▪This terminal allows programming, displaying 1 parameter and

reference signal generation.

▪Equipped with a 2x8 character display and 4 push buttons.

▪Reading in display mode: first row - the name of a displayable

parameter (e.g. f=), second row - its value (e.g. 50,00Hz).

The display can be stepped with the and arrows.

▪Reading in programming mode: first row - the parameter’s ordinal

number in the menu (e.g. 3-1-1), second row - (in case of a variable

parameter) the value of the actual parameter

(e.g. 5.00s), that can be modified with the push buttons.

▪The terminal can be used built in the front panel of the frequency

converter only!

ERROR RUN

ESCAPE ENTER

ENTER

ESCAPE

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 12 -

Functions of the push buttons (operating and controlling terminal)

(Escape)

▪Change between display mode and programming mode

▪Parameter setting mode: shift the cursor to the left

▪Repeated push: exit parameter setting mode without saving (until the cursor blinks)

▪At error display: displaying the cause of the error

▪Display mode: scrolling the displayed variables downward

▪Programming mode: moving in the menu downward

▪Parameter setting: decreasing the value or scrolling the selector switches downward

▪With selected terminal motor potentiometer: decreasing the reference signal

▪With enabled motor potentiometer start / stop: Stop

▪Display mode: scrolling the displayed variables upward

▪Programming mode: moving in the menu upward

▪Parameter setting: increasing the value or scrolling the selector switches upward

▪With selected terminal motor potentiometer: increasing the reference signal

▪With enabled motor potentiometer start / stop: Start

(Enter)

▪Programming mode: starting the parameter setting

▪Parameter setting mode: shift the cursor to the right

▪Repeated push: save parameter value (until the cursor blinks)

▪Acknowledgement at error

Programming procedure (operating and controlling terminal)

(Escape)

▪Changing from display mode to programming mode

▪Moving between the menu items

(Enter)

▪Starting parameter setting

▪Parameter setting

(Enter)

▪Repeated push: save parameter value (until the cursor blinks)

or

(Escape)

▪Repeated push: exit parameter setting mode without saving (until the cursor blinks)

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 13 -

Features and capabilities of the frequency converter and the program

For changing the parameters, the programmer or operator terminal (built in the frequency converter or stand-alone unit)

or the regulator terminal (built in the frequency converter).

For the continuous inspection of all parameter values use of a display may be needed.

Some options for being built in the equipment (differs for the V3D, VLD and VHD types!):

•PID extension, or adding further relays for further feedbacks,

•fitting with further digital inputs,

•analogue output,

•fitting with IRE reception for rotation speed control or position adjustment,

•CAN bus connection (e.g. master / slave),

•a second RS 485 serial line for remote control (MOD bus).

Through the features and capabilities, the manufacturer aims to make the frequency converter proper for the most

possible scopes of application.

The analogue and digital inputs, outputs and relays facilitate solving complex control and regulation tasks

Some programming options (differs for the V3D, VLD and VHD types!):

•programmability of procedures up to 15 steps (even different in each parameter chart),

•arbitrary acceleration and deceleration times, frequencies, regulation parameters, durations etc.,

•a maximum of 3 kinds of digital feedback on the internal state of the frequency converter

(on optocouplers or relays),

•two free programmable analogue output back indications,

•two (optionally four) free programmable analogue input signals for regulation or control

(potentiometer, voltage or current),

•“S”-curve type soft start and stop (for materials handling and passenger transport),

•timing functions, delayed starts and stops, preset operation periods,

•counting functions (to be activated with the digital inputs, or program group cycle counter), counting by piece,

or operation depending on the counted value (counting down and stop at zero)

•multifunction display (optionally selectable parameter displays)

•modification of the main parameter values from analogue input (e.g. acceleration time, fmax, etc.),

•several motor control tasks (one controlled and amaximum of three fix switchable),

•reception of the rotation speed feedback signal from the driven shaft (not necessarily the motor shaft)

(Incremental rotation speed encoder, IRE),

•rotation speed regulation tasks,

•position regulation tasks,

•torque regulation tasks,

•master/slave operation tasks,

•synchronised systems, also with acceptance of IRE reference signal,

•correct motor protection based on the preset motor parameters,

•automatic error acknowledgement (useful with unattended equipment which can restart in this way!),

•elimination of resonance frequencies by inhibiting,

•implementation of optional voltage/frequency characteristics (e.g. for special motors),

•keeping an error log with error numbers and chronology (256 errors can be stored inspected),

•Optional computer connection (query, program editing, data processing, etc.),

•etc.

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 14 -

Information about the program versions

Due to our continuous program developing and our efforts to meet our customers’ demands

we reserve our rights to alter the program!

The program versions are indicated in both the Programmer’s Manual and the 11 System menu of the frequency

converter (e g. 8.94.11)

In order to maintain compatibility, please note following about the meaning of the version number:

•The first two numbers refer to the system processor.

•With identical first figures, the frequency converters are fully compatible. (they work similarly, they can be

replaced by each other, and if necessary, they can be connected to each other)

•With increasing values of the second number, the capabilities of the given program are wider.

•The third number refers to the peripheral processor.

8CAUTION

Always use the manual with the same version number as that of the frequency converter!

In any uncleared question contact the manufacturer!

Information on program update

•The manufacturer provides all users with the latest program version free of charge, but they have to bring the

frequency converter to the manufacturer’s premises! The new program is downloaded while you wait!

•The user can request program upgrading on the site of the frequency converter to avoid interruption of the

production procedure (or for other reasons).

The program upgrading is free of charge in this case, too. The user has to bear the costs of the field-work only!

Procedure of programming

After defining the objective, programming should be started as follows.

OPERATION MODE

Control

(factory setting) Regulation

Select the

reference signal source

(e.g. An. IN1)

Select the

source of the logic controls

(e.g. start, direction)

Setting the

start / stop parameters

(e.g. Tup, Tdown, etc.)

Setting the

motor parameters

(e.g. Pn, Un, In, etc.)

Setting

other parameters

(e.g. display, etc.)

Select the

reference signal source

Suggested saving

(e.g. Memory 1, Terminal 1, etc.)

Select the

feedback signal source

Setting the

regulation parameters

Select the

source of the logic controls

Setting the

start / stop parameters

Setting the

motor parameters

Setting

other parameters

Suggested saving

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 15 -

Packed menu system

1 - Operation mode

1-1 control ref. signal

1-2 regulation ref. signal

1-3 selection

1-5 control

1-6 regulation

1-7 feedback

1-8 modification

1-10 PID settings

1-11 PID 1 data

1-14 PID 4 data

2-10 fly snips

2-11 flying start

2 - Starts

2-1 rise time

2-2 acceleration

2-3 multistep acceleration

2-4 S curve

2-5 start disable

2-6 direction change disable

2-7 restart

2-8 start type

2-9 brake release

3 - Stops

3-1 fall time

3-2 deceleration

3-3 multistep deceleration

3-5 stop type

3-6 normal brake

3-7 free time

3-8 DC brake

3-9 resistor brake

3-10 Udc hold

4 - Inputs

4-1 analogue input 1.

4-4 analogue input 4.

4-8 logical control source

4-9 logical parameters

4-10 fix start

4-11 digital input 1.

4-21 virtual input 1.

4-18 digital input 8.

4-26 virtual input 6.

4-30 slave data

4-31 IRE data

5 - Outputs

5-1 analogue output 1.

5-2 analogue output 2.

5-11 digital output 1.

5-16 timing 1.

5-21 comparator 1.

5-26 period 1.

5-13 digital output 3.

5-18 timing 3.

5-23 comparator 3.

5-28 period 3.

5-29 PID extension

10 - Displays

10-1 row 1.

10-4 row 4.

10-7 productivity 1.

10-10 4.productivity

10-12 big characters

10-11 user define units

10-13 consumption meter clear

10-14 active menu

11 - System

11-1 parameters

11-4 macro

11-5 remote control

11-6 modulation

11-7 slip-compensation

11-8 output

11-9 language

11-10 CAN bus

11-12 terminal function

11-13 automatic error ackn.

11-14 save event

11-18 manufacturing number

11-19 software version

11-20 date

11-21 currents

11-22 voltages

11-23 special data

11-24 clear log

11-25 password

11-27 menus with password

READ ONLY

PASSWORD PROTECTED

0 - Quick menu

0-1 control Tup

0-2 control Tdown

0-3 motor In

0-4 f maximum

0-5 f minimum

0-6 U boost

0-7 active menu

12 - Events

The event log can store

256 events along with

the belonging point of times.

13 - Errors

The error log can store

256 errors along with

the belonging point of times.

6 - Motor

6-1 nominal power

6-2 nominal voltage

6-3 nominal frequency

6-4 nominal current

6-5 nominal rotation speed

6-6 cooling type

6-7 limit

6-9 torque limit

6-10 test

6 - Motor

6-12 n maximum

6-11 R stator meas.

6-13 R stator

6-14 L stator

6-15 magnetizing current

6-16 linearity of the magn. current

6-17 exponent of the magn.current

6-18 R rotor correction

6-19 nominal start time

6-20 I regulator

6-22 n regulator

6-23 field weakening

6-24 sensorless

6-25 blocking

6-26 R rotor adaptation

6-27 sync. offset

6-28 type

continued

7 - U/f ratio

7-1 characteristic types

7-2 U/f modification

7-3 user characteristic

8 - Frequencies

8-1 f maximum

8-2 f minimum

8-3 frequency inhibit limit

8-4 jog normal

8-5 jog inverse

8-6 inhibited bands

9 - Programs

9-1 counter 1.

9-3 3.counter

9-10 program activation

9-11 program 1.

9-25 program 15.

9-26 sequence 1.

9-28 3.sequence

3-11 brake operation

3-12 Udc filter

3-13 emergency fall time

3 - Stops

continued

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 16 -

0. Quick menu

This menu permits the parameters frequently modified by the user to be set at the same place. The parameters here

can be set in their own menus, too!

Following parameters can be set here (in basic state):

•regulation rising time

•regulation fall time

•nominal motor current

•maximum frequency

•minimum frequency

•staring voltage

•selecting the active menu

The number of parameters can be maximum 15! This has two reasons:

•Limitation of the number of parameters in the quick menu to avoid retaining the really quick setting.

•The operating terminal (2x16 character display + 4 direction buttons) cannot replace the programming terminal

(4x16 character display + 11 buttons), but permits this number of parameters to be programmed still comfortably.

The display permits the parameters of the quick menu to be identified through displaying them along with their menu

item numbers:

2-1-1 control Tup: 2Starts

1rise time

1 control Tup: 5.0 s

Adopting parameters in the quick menu

In programming mode, each parameter can be adopted in the quick menu with button . This is indicated by a “+” sign

after the number of the main menu. Those parameters being already parts of the quick menu are indicated in this way.

One parameter can be included in the quick menu once only. If the sign “+" does not appear, the quick menu is filled.

i

Adopting and omitting parameters applies to the quick menu, if in menu 11-4-2 change the quick menu is

set (this is the default state).

Removing parameters from the quick menu

In programming mode, each parameter which is part of the quick menu, that is, following its main menu item number a

”+” sign appears, can be removed from the quick menu with button .

This operation can be made in both the menu of the actual parameter and the quick menu. For removing parameters in

the quick menu, with the button pressed, the „Enter” button needs to be pushed.

After removing a parameter the quick menu will be renumbered automatically.

Menu item number

(0)

Actual menu

(2-1-1)

Equipment identifier (1)

Parameter to be set

(5.0s)

Parameter number (-1-)

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 17 -

Factory setting of the quick menu

Submenu

Explanation, further submenus

Values

Default setting

Unit

Parameter - 1 -

2-1-1

control Tup

The time of linear acceleration, in control mode.

(the time for reaching fmax or fnom starting from 0

Hz)

0,05 - 3276,7

5,00

s

Parameter - 2 -

3-1-1

control Tdown

The time of linear deceleration, in control mode.

(the time for reaching 0 Hz starting from fmax or

fnom)

0,05 - 3276,7

5,00

s

Parameter - 3 -

6-4

motor In

The motor current permitted durably. This current

value corrected with the current limit is the

maximum, which can develop.

0,5 - type-dep.

type-dependent

A

Parameter - 4 -

8-1

f maximum

fmax, the highest frequency.

Even if the frequency reference signal is set to a

higher value, the fmax value is effective!

* For V3D type equipment without controlling terminal

the default setting is 100 Hz

0,1 - 1050,0

50,0 *

Hz

Parameter - 5 -

8-2

f minimum

fmin, the lowest frequency.

Even if the frequency reference signal is set to a

lower value, the fmin value is effective!

0,1 - 1000,0

1,0

Hz

Parameter - 6 -

7-2-1

U boost

The starting voltage to be given on the motor in

standstill after start, for providing the initial flux.

0,0 - type-dep.

type-dependent

V

Parameter - 7 -

10-14

active menu

This decides the menu accessible from the

regulator terminal. With „quick” is the quick menu

accessible only, whereas with „full” the whole

menu system.

quick

full

quick

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 18 -

1. Operation mode menu

In this menu, the most important parameters of the operation mode of the frequency converter can be set.

Following parameters can be set here:

•terminal regulation reference signal,

•terminal control reference signal,

•operational mode selection,

•data of the regulation,

•data of the control,

•data of the control signal,

•data of the modifying signal,

•PID selection,

•PID data

Submenu

Explanation, further submenus

Values

Default setting

Unit

1-1

control

ref. signal

If the source of thereference signalis the terminal,

it means the prescribed value of the output

frequency in control mode.

0,01 - 1000,0

1,00

Hz

1-2

regulation

ref. signal

In regulation mode, the value of the regulation

reference signal if the source of the reference

signal is the terminal.

0,00 - 100,00

0,00

%

1-3

selection

Permits the selection of the operation mode.

control

regulation

control

1-5

control

Permits the settings of the parameters used with control tasks.

1-5-1 source of the control reference signal

Selects the source of the control reference signal.

(Setting the parameters of the control reference

input is made in the 4. Inputs menu!)

* IRE 2 for VLD and VHD types only

analogue IN 1-4

IRE

IRE 2 *

terminal

motor pot.

MOD bus

CAN bus

analogue IN 1.

1-5-3 control reference signal limits

If the source of the reference signal is an analogue input, these limits will come to effect, in so far

as they are within the limits of 8-1 f maximum and 8-2 f minimum.

1-5-3-1 maximum

0,01 - 1000,0

1000,0

Hz

1-5-3-2 minimum

0,01 - 1000,0

0,01

Hz

reference

signal

modification

signal

fout

max

f U/f up

control T

min

fdown

control T

driving /

technology

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 19 -

Submenu

Explanation, further submenus

Values

Default setting

Unit

1-5-6 correspondence

0,1 - 6000,0

100,0

1-5-7 dimension

This serves establishing and displaying the

reference signal corresponding to the

manufacturing process.

The correspondence needs to be related to 100

Hz.

If the product is e.g. a bag, its number of pieces

changes linearly with the reference signal, and

with 30 Hz reference signal 6 bags are produced.

Then the ratio is 30 / 6 = 5, that is setting the

correspondence to 100 / 5 = 20 and the dimension

to pieces in menu 1-1, the regulation reference

signal will be displayed in pieces instead of Hz.

Thus, adjusting the number of produced bags is

much easier, because the operator does not need

to recalculate it to frequency reference signal.

-

percent %

piece pc

mass kg

mass t

length mm

length m

speed m/s

speed m/m

speed km /h

volume l

volume m3

revolution rpm

pressure bar

pressure Pa

temp. °C

frequency Hz

user 1

user 2

frequency Hz

1-6

regulation

Permits the settings of the parameters used with regulation tasks.

1-6-1 source of the regulation ref. signal

Selects the source of the regulation reference

signal.

(Setting the parameters of the regulation

reference input is made in the 4. Inputs menu!)

* IRE 2 for VLD and VHD types only

analogue IN 1.

analogue IN 2.

analogue IN 3.

analogue IN 4.

IRE

IRE 2 *

terminal

motor pot.

MOD bus

CAN bus

analogue IN 1.

1-6-2 type of the regulation

normal: increasing error signal effects increasing

frequency.

inverse: increasing error signal effects decreasing

frequency.

bidirect: normal regulation with changing the

direction of rotation

normal

inverse

bidirect

normal

1-6-3 regulation reference signal limits

1-6-3-1 maximum

0,00 - 100,00

100,00

%

1-6-3-2 minimum

-100,00 - 100,00

0,00

%

1-6-4 regulation reference signal set-in times

1-6-4-1 acceleration

0,00 - 500,00

0,00

s

1-6-4-2 deceleration

0,00 - 500,00

0,00

s

H - I - J PROGRAMMER’S MANUAL V8.94.11-

- 20 -

Submenu

Explanation, further submenus

Values

Default setting

Unit

1-6-5 regulation start / stop

In Control mode, if the frequency converter operates durably near to the fmin frequency within a

given hysteresis, this appoints the time limit after which “waiting” state will be effectuated, and it

appoints also the value of the error signal which starts the control process again.

(e g. if a pump does not convey for a prolonged time, its operation is superfluous!)

1-6-5-1 time limitation

With setting “N”, the duration of operating

at fmin is not limited

N

0,1 - 3000,0

N

s

1-6-5-2 start error signal

At this value of the error signal, the

frequency converter exits the “waiting”

state

0,00 - 100,00

1,00

%

1-6-5-3 hysteresis

If the frequency is in this range above the

minimum frequency, time limitation starts,

if active.

0,0 - 100,0

1,0

Hz

1-6-6 correspondence

0,1 - 6000,0

100,0

1-6-7 dimension

This serves establishing and displaying the

reference signal in a way easier corresponded to

the manufacturing process.

The correspondence should refer to 100 %.

For example, in a printery compressed air will be

produced with a compressor for the machinery.

The pressure of the compressed air will be

measured with a remote transmitter and the

control occurs to this pressure.

If the 100 % reference signal corresponds to 20

bar pressure, then after setting the

correspondence to 20 and the dimension to bar in

menu 1-2 the control reference signal will be

displayed in bar instead of %.

-

percent %

piece pc

mass kg

mass t

length mm

length m

speed m/s

speed m/m

speed km/h

volume l

volume m3

revolution rpm

pressure bar

pressure Pa

temp. °C

frequency Hz

user 1

user 2

percent %

1-7

feedback

Permits the selection of the source of the feedback signal used with regulation tasks.

(Setting the parameters of the input is made in the 4. Inputs menu!)

1-7-1 source of the feedback signal

In case of simple torque control (6-28 Operation

mode:„U/f”) the motor parameters are ruling.

(6. Motor menu)

In case of torque control with signal transmitter

(6-28 Operation mode:„with signal transmitter”)

the measured rotation speed and the output

frequency are ruling.

It is important to set the nominal rotation speed

belonging to the nominal torque of the motor!

(6. Motor menu).

The output frequency sets between „0” and fmax

in the way that the motor can deliver as a

maximum those percent of its torque, set with the

control reference signal!

analogue IN 1.

analogue IN 2.

analogue IN 3.

analogue IN 4.

analogue IN 1-2.

analogue IN 3-4.

IRE rotation

IRE position

torque

analogue IN 2.

Other manuals for V3D Series

1

This manual suits for next models

2

Table of contents