7

Install the Brake Cover Plate using input brake bolts. Tighten

screws in such a way that to ensure the Brake Cover Plate remains

straight while being compressed into the brake cavity of the spindle.

Install the large retaining ring into the groove in spindle (1A),

making sure it is seated properly. Remove all remaining screws

from the brake piston and discard.

NOTE: USE CAUTION WHEN REMOVING SCREWS AS THEY

ARE SUBJECT TO SPRING PRESSURE. MAKE SURE THE

RETAINING RING IS SECURED BEFORE REMOVING BOLTS.

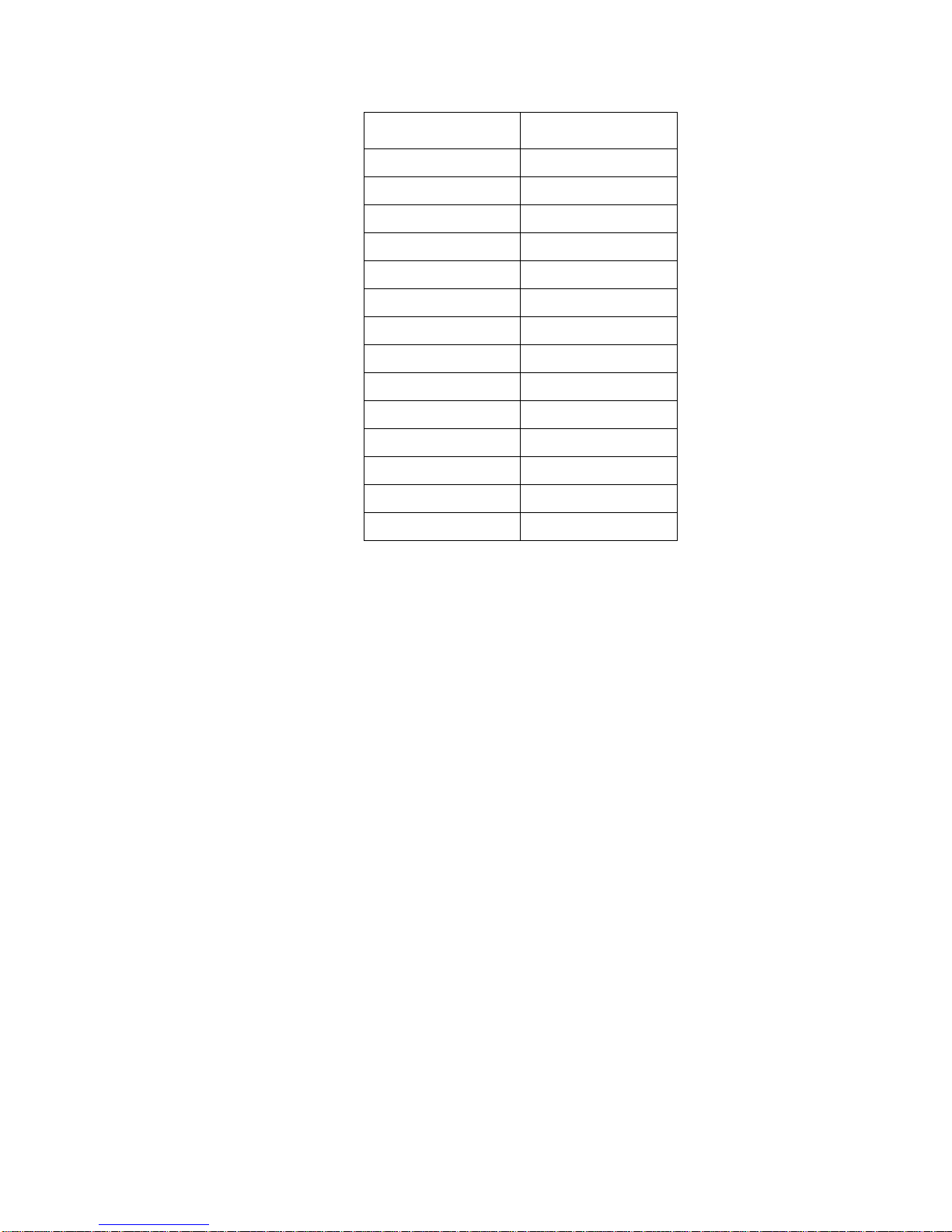

Re-test the input brake. If release and/or lockup pressures still do

not match the brake chart, contact the Oerlikon Fairfield service

department.

BRAKE LEAK REPAIR PROCEDURE:

Install input brake bolts into holes in the Brake Piston. Tighten

screws in such a way to ensure the Brake Cover Plate remains

straight while being compressed into brake cavity of Spindle.

Carefully remove the Retaining Ring from the Spindle. Using two

eyebolts threaded into opposite holes in the Brake Piston, remove

the Brake Piston from the Spindle.

Check O-rings, Backup Rings, and brake cavity in Spindle for

damage. If no damage is found, reinstall the Input Brake according

to the Input Brake Installation Procedure in the assembly

instructions chapter and perform pressure test again. If brake still

leaks, contact the Oerlikon Fairfield service department.

Reference: Sample Model CW18_ _ _ _ X _ _ _ _. The ‘X’ is the

brake option (Model Code). Consult Oerlikon Fairfield for other

brake options.

NOTE: Failure to perform this test may result in damaged or

ineffective brake parts.