ProFitter KFA50PF Instructions for use

Table of Contents Page

Description.......................1

Specifications.....................1

Introduction......................1

Unpacking .......................1

Product Features . . . . . . . . . . . . . . . . . . 2

General Safety Information . . . . . . . . 2-3

Assembly.......................4-5

Operation ......................5-8

Repair Parts Illustration Models

KFA50PF, KFA75PF, KFA125PF,

KFA170PF

KFA50PF, KFA75PF, KFA125PF,

KFA170PF

. . . . . . .. . . . . . ... . . . . . . 14

Repair Parts List Models

................... .. 14-15

Repair Parts Illustration Model

..................

....

....

. .

..

. .

. .

.. .. ..............

16

Repair Parts List Model

KFA210PF

KFA210PF

17

Repair Parts List, Wheels and

Handles.........................18

Troubleshooting Chart . . . . . . . . . . . . 19

Warranty Information . . . . . . . . . . . . . 20

Introduction

Please read this USER’S MANUAL

carefully. It will show you how to

assemble, maintain and operate this

heater safely and efficiently to obtain

the full benefits of its many features.

Consumer: Retain these instructions

for future reference.

Unpacking

1. Remove all packing items applied to

heater for shipment.

2. Remove all items from carton.

3. Check all items for shipping damage. If

heater is damaged, promptly inform

dealer where you purchased heater.

ProFitterTM

Oil-Fired Heaters

Operating Instructions & Parts Manual

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

Description

ProFitterTM Models KFA50PF, KFA75PF, KFA125PF, KFA170PF and KFA210PF

heaters are 50,000 to 210,000 BTU/Hr heaters.

These heaters use 1-K Kerosene (see Operation section for alternative fuels) for

combustion, and electricity to run the fan. It is primarily intended for temporary

heating of well ventilated buildings under construction, alteration, or repair. This

heater may be used in agricultural, industrial and com-mercial environments.

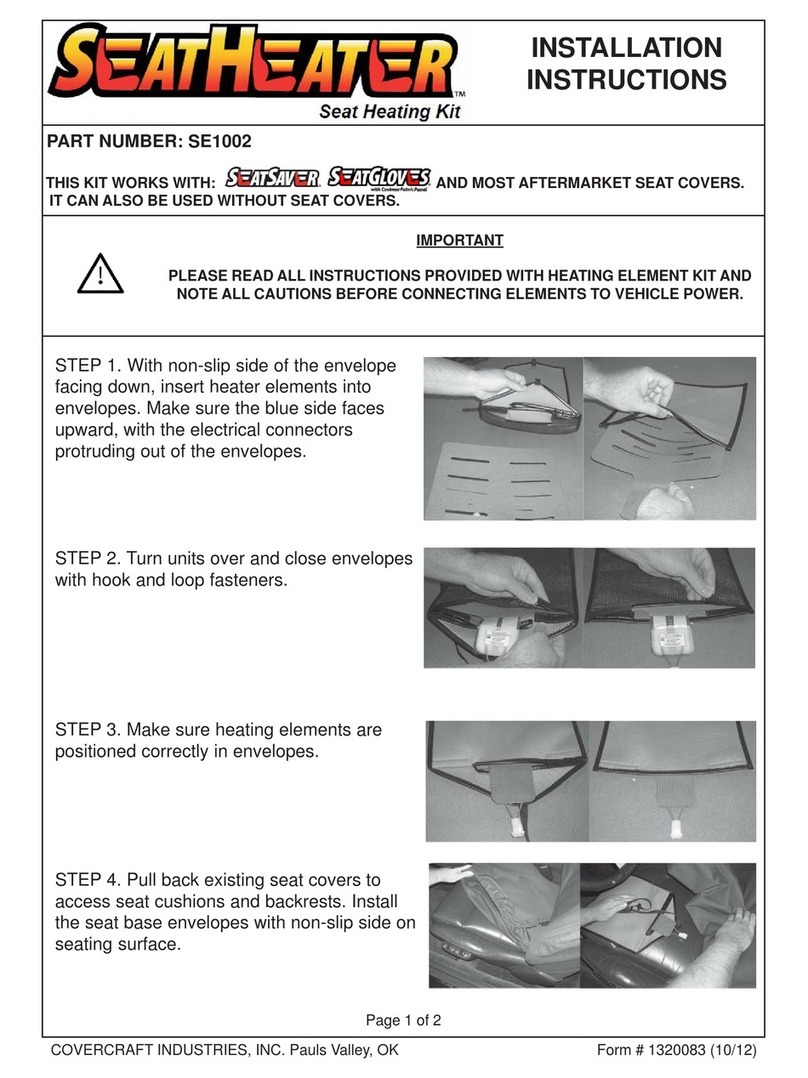

Figure 1 – Models

KFA50PF & KFA75PF

Figure 2 – Model KFA125PF

Specifications

ELECTRICAL SPECIFICATIONS

Electrical

Model Input Amperage Fuse Spark Plug Gap

KFA50PF 120V, 60 Hz 1.6 125V/8 amp .140” (3.5mm)

KFA75PF 120V, 60 Hz 1.6 125V/8 amp .140” (3.5mm)

KFA125PF 120V, 60 Hz 2.5 125V/8 amp .140” (3.5mm)

KFA170PF 120V, 60 Hz 3.2 125V/8 amp .140” (3.5mm)

KFA210PF 120V, 60 Hz 3.7 125V/8 amp .140” (3.5mm)

GENERAL SPECIFICATIONS

Type of Pump Fuel Tank Fuel Size Weight

Model Fuel Input Rating Pressure Capacity Consumption L x W x H (Inches) Lbs. (kg)

KFA50PF 1-K Kerosene 50,000 BTU/Hr 3.8 PSI 5.0 Gallons .38 Gal/Hr 32 x 113/4x 163/4

KFA75PF 1-K Kerosene 75,000 BTU/Hr 3.8 PSI 5.0 Gallons .57 Gal/Hr 32 x 113/4

11/2

x 163/4

KFA125PF 1-K Kerosene 125,000 BTU/Hr 5.5 PSI 10.0 Gallons .95 Gal/Hr 361/10 x 2 x 24 6/10

KFA170PF 1-K Kerosene 170,000 BTU/Hr 6.5 PSI 13.0 Gallons 1.3 Gal/Hr 41 8/10x 23 1/10

41 8/10x 23 1/10

x 26 1/10

x 26 1/10KFA210PF 1-K Kerosene 210,000 BTU/Hr 8.5 PSI 13.0 Gallons 1.6 Gal/Hr

Figure 3 – Models

KFA170PF & KFA210PF

26.9(12.2)

26.9(12.2)

51.4(23.3)

57.3(26.0)

59.5(27.0)

KFA50PF, KFA75PF,

KFA125PF, KFA170PF and KFA210PF

IMKFAPF-HDW

Fuels . . . . . . . . . . . . . . . . . . . . . .. . . 5-6

Overview of Heater Design. . .. . .. . . 6

Fueling Your Heater . . .. . .. . . . .. . . 6

Ventilation . .. .. .. . . . .. . . .. . . . .. . 7

Long-Term Storage . . . . . . . . . . . .. 7-8

Maintenance . .. .. . . . . . . .. .. . . . .8-12

Replacing Fuse . . . . . . . . . . . . . . . . . . . 12

Wiring Diagrams . . . . . . . . . . . . . . . . . 13

32"

W

L

H

11 3/4"

16 3/4"

2

ProFitterTM Operating Instructions and Parts Manual

ProFitterTM

Portable Oil-Fired Heaters

KFA125PF KFA170PF

KFA210PF

H 24 6/10” 26 1/10”

L 36 1/10” 41 8/10”

W 21

Dimensions

Figure 3 – Heater Dimensions

Figure 4 – Models KFA50PF and KFA75PF Features Figure 5 – Models KFA125PF, KFA170PF and KFA210PF Features

Fan Guard

Hot Air Outlet

Lower Shell

Fuel Tank

Side Cover

Lamp

Thermostat Knob

(KFA75PF model only)

Power/Reset Switch

Power Cord

Upper Shell

Handle

Pressure Gauge

Cord Wrap

Fuel Gauge

Fuel Cap

Hot Air Outlet

Lower Shell

Fuel

Gauge

Fuel Cap

Lamp

Side Cover

Room Temp. Display

Thermostat

Knob

Power/Reset Switch

Power Cord

(Piggy Back)

Cord Wrap

Pressure Gauge

Handle Rear

Handle Front

Upper Shell

Product Features

Models KFA50PF and KFA75PF Models KFA125PF, KFA170PF and KFA210PF

General Safety Information

Indicates an im-

minently hazardous

situation which, if not avoided, WILL

result in death or serious injury.

Indicates a poten-

tially hazardous

situation which, if not avoided, COULD

result in death or serious injury.

Indicates a poten-

tially hazardous

situation which, if not avoided, MAY

result in minor or moderate injury.

Before using this

heater, please read

this USER’S MANUAL very carefully. This

USER’S MANUAL has been designed to

instruct you as to the proper manner in

which to assemble, maintain, store, and

most importantly, how to operate the

heater in a safe and efficient manner.

Never leave the

heater unattended

while burning!

Improper use of this

heater can result in

serious injury or death from burns, fire,

explosion, electrical shock, and/or

carbon monoxide poisoning.

For optimal performance of this heater,

it is strongly suggested that 1-K kerosene

be used. 1-K kerosene has been refined

to virtually eliminate contaminants, such

as sulfur, which can cause a rotten egg

odor during the operation of the heater.

DANGER

DANGER

WARNING

WARNING

CAUTION

WARNING

23 1/10”

1/2”

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

3

General Safety Information

(Continued)

Risk of Indoor

Air Pollution!

- Use this heater only in well ventilated

areas! Provide at least a three square

foot (2,800 sq. cm) opening of outside

air for every 100,000 BTU/hr of heater

rating.

- People with breathing problems should

consult a physician before using the

heater.

- Carbon Monoxide Poisoning: Early

signs of carbon monoxide poisoning

resemble flu-like symptoms such as

headaches, dizziness, and/or nausea. If

you have these symptoms, your heater

may not be working properly.

- Get fresh air at once! Have the heater

serviced. Some people are more affected

by carbon monoxide than others. These

include pregnant women, those with

heart or lung problems, anemia, or

those under the influence of alcohol,

or at high altitudes.

- Never use this heater in living or

sleeping areas.

Risk of Burns/Fire/

Explosion!

- NEVER use fuels such as gasoline,

benzene, paint thinners, or other oil

compounds in this heater (RISK OF

FIRE OR EXPLOSION).

- NEVER use this heater where flam-

mable vapors may be present.

- NEVER refill the heater’s fuel tank

while heater is operating or still hot.

This heater is EXTREMELY HOT while

in operation.

- Keep all combustible materials away

from this heater.

Minimum Clearances

Outlet 8 feet (250 cm)

Sides, Top and Rear 4 feet (125 cm)

- NEVER block air inlet (rear) or air outlet

(front) of heater.

- NEVER use duct work in front or at

rear of heater.

- NEVER move or handle heater while

still hot.

- NEVER transport heater with fuel in

its tank.

When used with optional thermostat

or if equipped with a thermostat, the

heater may start at any time.

- ALWAYS locate heater on a stable and

level surface.

- ALWAYS keep children and animals

away from heater.

- Bulk fuel storage should be a minimum

of 25 ft. from heaters, torches, portable

generators, or other sources of ignition.

All fuel storage should be in accordance

with federal, state, or local authorities

having jurisdiction.

Risk of Electric

Shock!

- Use only the electrical power (voltage

and frequency) specified on the model

plate of the heater. Use only a three-

prong, grounded outlet and extension

cord.

- ALWAYS install the heater so that it is

not directly exposed to water spray,

rain, dripping water, or wind.

- ALWAYS unplug the heater when not

in use.

CALIFORNIA RESIDENTS:

This heater produces carbon

monoxide, which is listed by the State

of California as a reproductive toxin

under Proposition 65.

MASSACHUSETTS RESIDENTS:

Massachusetts state law prohibits

the use of this heater in any building

which is used in whole or in part for

human habitation. Use of this heating

device in Massachusetts requires

local fire dept. permit (M.E.L.C. 148,

Section 10A).

CANADIAN RESIDENTS:

Use of this heater shall be in accor-

dance with authorities having juris-

diction and CSA Standard B139.

NEW YORK CITY RESIDENTS:

For use only at construction sites in

accordance with applicable NYC codes

under NYCFD certificate of approval

#5034 and 5037.

WARNING

WARNING

WARNING

Models KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

- Use 1-K kerosene inthis heater. #1/#2

diesel/fuel oil, JET A or JP-8 fuels are

suitable substitutes.

However, #1/#2 diesel/fuel oil, JET A or

JP-8 fuels may also be used if 1-K

kerosene is notavailable. Be advised

that these fuels do not burn as clean as

1-K kerosene, and care should be taken

to provide more fresh air ventilation to

accommodate any added contaminants

that may be added to the heated space.

Use any fuel other than 1-K kerosene may

result in more periodic maintenance.

4

Assembly

Model KFA50PF,KFA75PF

KFA50PF / KFA75PF Models

KFA125PF / KFA170PF / KFA210PF Models

KFA125PF KFA170PF KFA210PF

Wheel Support Frame No Yes Yes Yes

Wheels No Yes Yes Yes

Front-Handle No Yes Yes Yes

Rear-Handle No Yes Yes Yes

Threaded Axle No Yes Yes Yes

Handle Yes No No No

Cord Wrap Yes Yes Yes Yes

Hardware Kit: HW-KFA1016 No Yes Yes Yes

Figure 6 – Component Identification

ProFitterTM

Portable Oil-Fired Heaters

KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

Front Handle

Rear Handle

Threaded Axle

Wheel Support Frame

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

Cap Nuts S

Hardware Kit : HW-KFA1016

(10" Flat Free)

Wheels

Cord Wraps

Screws Flange Screws

Nuts Bushings Cap Nuts L

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

Handle Cord Wraps

Assembly (Continued)

FOR MODELS KFA50PF AND

KFA75PF ONLY

FOR MODELS KFA125PF, KFA170PF

AND KFA210PF ONLY

TOOLS REQUIRED

5

Figure 7 – Handle and Cord Wrap

Installation KFA50PF and

KFA75PF only

Figure 8 – Models KFA125PF, KFA170PF and KFA210PF Assembly

- Medium Phillips Screwdriver.

- 3/4 inch socket or adjustable wrench

Assembling Handle & Wheel and

Cord Wrap

1. Slide threaded axle through the rear

sectioon of the wheel support frame.

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

Models KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

2. Slide one axle bushing on to each side

of the axle. Slide one wheel on to each

side of the axle. Attach one cap nut on

toeach side of the threaded axle and

tighten well.

3. Place heater on wheel support frame.

Align the holes on fuel tank flange

with holes on wheel support frame.

4. Position theHandles on top of fuel

tank flange.

Insert screws through handles, fuel

tank flange and wheel support frames

as shown in Figure 8and attach nut

finger tight after each screw is inserted.

5. Align the hole onthe handles with the

mounting hole on the Cord Wrap.

Insert Screws through Cord Wrap,

handles and attach nut finger tight

after each screw is inserted.

6. After all screws are inserted, tighten

nuts firmly.

Do not operate

heater without

support frame fully assembled to tank.

FUELS

For optimal performance of this heater,

it is strongly suggested that 1-K kero-

sene be used. 1-K kerosene has been

refined to virtually eliminate contami-

nants, such as sulfur, which can cause a

rotten egg odor during the operation

of the heater. However, #1/#2 diesel/fuel

oil, JET A or JP-8 fuels may also be used if

1-K kerosene is not available.Be advised

that these fuels do not burn as clean as

1-k kerosene, and care should be taken

to provide more fresh air ventilation to

accommodate any added contaminants

CAUTION

Front Handle

Hot Air Outlet

Wheel

Cap Nut L

Cap Nut S

Fuel Tank Flange

Nut

Wheel Support

Frame

Flange Screw

Cord Wrap

Screw

Rear Handle

Air Inlet

Threaded Axle

Wheel Bushing

TOOLS REQUIRED

- Medium Phillips screwdriver.

1. Lift front guardfor arrow direction

andmake sure that guard’s wedged

portion fits into the slit hole on the

upper housing.

2. Remove the pre-assembled screws on

the shell upper and side cover.

3. Align the holes in upper housing

withtwomounting holes on the

handle asshown in Figure 7.

4. Securehandle with the screws

removed.

5. Insert cord wrap into the rectangle

holes on the supporter andalign the

hole on thecord wrap withthe

mounting hole on the side cover as

shown in Figure 7.

6. Securecord wrap with the screws

removed.

Handle

Screw Front Guard

Wedged

Slit Hole

Side Cover

Cord Wrap

Screw

Shell Upper

Remove Screws

Remove Screws

Portion

6

SureFire Ignition: The electronic ignitor

sends voltage to a specially designed

spark plug. The spark plug ignites the

fuel and air mixture described above.

The Air System: The heavy duty motor

turns a fan that forces air into and

around the combustion chamber. Here,

the air is heated and then forced out

the front of the heater.

THE SAFETY SYSTEM

Temperature Limit Control: This heater

is equipped with a Temperature Limit

Control designed to turn the heater off

should the internal temperature rise to

an unsafe level. If this device activates

and turns your heater off, it may require

service.

Once the temperature falls below the

reset temperature, you will be able to

start your heater.

Electrical System Protection: This

heater’s electrical system is protected

by a fuse mounted to the PCB Assembly

that protects it and other electrical

components from damage. If your

heater fails to operate, check this fuse

first and replace as needed. Refer to

Specification chart on page 1.

Flame-Out Sensor: Utilizes a photocell

to monitor the flame in burn chamber

during normal operation. It will cause

the heater to shut off should the burner

flame extinguish.

FUELING YOUR HEATER

Never fill the heater fuel tank in the

living space: fill the tank outdoors.

Do not overfill your heater and be sure

heater is level.

Never refill fuel tank

when heater is

operating or still hot.

IMPORTANT: REGARDING FIRST

IGNITION OF HEATER. The first time

you light the heater, it should be done

OUTDOORS. This allows the oils, etc.,

used in manufacturing heater to be

burned off outside.

WARNING

Model

KFA125PF/KFA170PF

KFA50PF/KFA75PF

KFA210PF

Internal Shut-Off Temp.

+/-10 Degrees

230°F/110°C

176°F/80°C

194°F/90°C

Reset Temp.

+/-10 Degrees

194°F/90°C

122°F/50°C

140°F/60°C

Figure 9 – Overview of Heater Design

ProFitterTM

Portable Oil-Fired Heaters

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

Operation (Continued)

NOTE: Kerosene shouldonly be stored

in a blue container that is clearly

marked “kerosene”. Never storekero-

sene in ared container. Red is associ-

ated with gasoline.

- NEVER store kerosene in the living

space.Keroseneshould be stored in a

well ventilated area outside the living

area.

- NEVER use fuel such as gasoline,

benzene, alcohol, whitegas, camp

stove fuel, paint thinners, orother oil

compounds in this heater (THESE ARE

VOLATILE FUELS THATCAN CAUSE A

FIRE OR EXPLOSION).

- NEVER store kerosene in direct

sunlight or near a source of heat.

- NEVER use kerosene that has been

storedfrom oneseason to the next.

Kerosene deteriorates over time. OLD

KEROSENE WILL NOT BURN PROPERLY

IN THIS HEATER.

- Use 1-K kerosene inthis heater. #1/#2

diesel/fuel oil, JET A or JP-8 fuels are

suitable substitutes.

OVERVIEW OF HEATER DESIGN

Fuel System: This heater is equipped

with an electric air pump that forces air

through the air line connected tothe

fuel intake, and thenthrough a nozzle

in the burner head. When air passes in

front of the fuel intake, it causes fuel to

rise from the tank and into the burner

nozzle.

This fuel and air mixture is then sprayed

into the combustion chamber in a fine mist.

that maybe added to the heated space.

#2 diesel/fuel oil heavier than 1-K

kerosene in extreme cold temperatures

without nontoxic anti-icer additives

will not ignite properly.

Electric Outlet

Cover

Operation (Continued)

VENTILATION

Risk of indoor air

pollution. Use heater

only in well ventilated areas.

Provide a fresh air opening of at least

three (3) square feet (2,800 sq. cm) for

each 100,000 BTU/Hr. rating. Provide

extra fresh air if more heaters are

being used.

Example: A KFA210PF heater

requires one of the following :

1. A two-car garage door raised six

inches (15.24 cm).

2. A single-car garage door raised nine

inches (22.86 cm).

3. Two, thirty inch (76.20 cm) windows

raised fifteen inches (38.1 cm).

TO START HEATER

4. KFA50PF model Only: Push

power switch to “ON” position.

Power Lamp will light and heater will

start.

5. KFA75PF, KFA125PF, KFA170PF

and KFA210PF

models: Turn thermostat control knob

to desired setting and push power

switch to “ON” position. Power lamp

will light and heater will start.

NOTE: Room Temp. display indicates as

following:

- When room temp. is less than 0°F:

“lo”.

- When room temp. is between 0°F

and 99°F: Indicates in figure.

- When room temp is less than 99°F:

“Hi”.

If heater does1not start, the thermostat

setting may be too low. Turn

THERMOSTAT CONTROL KNOB to

higher position to start heater. If heater

still does not start, turn power switch to

“OFF” and then to “ON” position (See

Figure 10). If heater still does not start,

see Troubleshooting on page 18.

NOTE: The major electrical components

of this heater are protected by a safety

fuse mounted to the PCB board. If your

heater fails to start, check this fuse first

and replace as necessary. You should

also check your power source to insure

that proper voltage and frequency are

being supplied to the heater.

TO RESTART HEATER

1. Wait 10 seconds after stopping

heater.

2. Repeat steps under, “TO START

HEATER.”

PIGGYBACK POWER CORD

Shock Hazard!

Always cover electric

outlet when not in use. Don’t plug and

use an appliance of more than 5A

current in this outlet.

LONG-TERM STORAGE OF YOUR

HEATER

WARNING

CAUTION

7

Model KFA50PF Model KFA75PF

Model KFA125PF, KFA170PF

& KFA210PF

Lamp

Power/Reset

Switch

Power/Reset

Switch

Power/Reset

Switch

Lamp Lamp

Thermostat

Control Knob

Thermostat

Control Knob

Room Temp. Display

Figure 10 – Controls for All Models

FUEL TANK DRAIN

1. Drain fuel tank through fuel cap

opening. (For Models KFA50PF,

KFA75PF Only)

2. Remove fuel drain bolt from rear bottom

side of fuel tank using 3/4” socket or

adjustable wrench and drain.

(For Models KFA125PF, KFA170PF,

KFA210PF Only)

3. Using a small amount of kerosene,

swirl and rinse the inside of the tank.

NEVER mix water with the keroseneas it

will cause rust inside the tank.Pour the

kerosene out making sure that you

remove it all.

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

Models KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

TO SHUTDOWN HEATER

Turn switch to “OFF” and unplug power

cord.

NOTE : In cold weather, ignition may

be improved by holding a finger over

the end of the relief valve or block

fanguard in half with newspaper etc.

until the heater ignites.

1. Fill fuel tank with fuel.

NOTE : Kerosene is recommended

when the temperature drops below 0

℉(-18℃) to prevent ignition delay or

failure.

2. Attachfuel cap.

3. Plug power cord into three

prong,grounded extension cord.

Extensioncord must be at least six

feet long.

- Extension Cord Wire SizeRequire-

ments:

- 6 to 100 feet (1.8 to30.53 meters)

long, use 16 AWG conductor.

- 101 to 200 feet (30.8 to 61 meters)

long, use 14 AWG conductor.

Figure 11 - Piggyback Power Cord

8

Maintenance

Never service heater

while it is plugged in

or while hot!

USE ORIGINAL EQUIPMENT REPLACE-

MENT PARTS. Use of third-party or

other alternate components will void

warranty and may cause unsafe

operating conditions.

FUEL TANK

Flush every 200 hours of operation or as

needed (See Long-term Storage, page 7).

AIR INTAKE FILTER

WASH AND DRY WITH SOAP AND

WATER EVERY 500 HOURS OF

OPERATION, OR AS NEEDED.

- Remove screws along each side of

heater using medium Phillips

screwdriver.

- Lift off upper shell.

- Remove fan guard.

- Wash or replace air intake filter.

- Reinstall fan guard and upper shell.

REPLACE EVERY 500 HOURS OF

OPERATION OR ONCE A YEAR

- Remove upper shell and fan guard

(See Air Intake Filter Figure 13).

- Turn air pressure gauge counter-

clockwise and remove.

- Remove end filter cover screws using

medium Phillips screwdriver.

- Remove end filter cover.

- Replace air output and lint filter.

- Reinstall end filter cover and air

pressure gauge.

- Reinstall fan guard and upper shell.

FAN BLADES

CLEAN EVERY SEASON OR AS NEEDED

- Remove upper shell (See Air Intake

Filter).

- Use M6 Allen wrench to loosen set

screw which holds fan blade to motor

shaft.

- Slip fan blade off motor shaft.

- Clean fan blade using soft cloth

moistened with kerosene or solvent.

- Dry fan blade thoroughly.

- Reinstall fan blade to motor shaft.

- Place fan blade hub flush with end of

motor shaft.

WARNING

Figure 13 – Air Filter Access

Figure 14 – Filter Assembly

ProFitterTM

Portable Oil-Fired Heaters

- Make sure storage place is free of dust

and corrosive fumes.

- Store the heater in the original box

with the original packing material and

keep USER’S MANUAL with heater.

Figure 12 - Drain Bolt

Fuel Drain Bolt

Seal

6. Store heater in dry well ventilated

area. Make sure storage place is

free of dust and corrosive fumes.

7. Store the heater in the original box

with the original packing material

and keep the USER’S MANUAL

with the heater.

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

IMPORTANT : Do not store kerosene

over summer months for use during

next heating season. Using old fuel

could damage heater.

4. Reinstall fuel cap. Properly dispose

of old and dirty fuel. (For Models

KFA50PF, KFA75PF Only)

5. Reinstall Fuel Drain Bolt to Fuel tank

and tighten firmly using 3/4” socket or

adjustable wrench.

(For Models KFA125PF, KFA170PF,

KFA210PF Only)

Screw

Upper Shell

Air Intake Filter

Fan Guard

AIR OUTPUT FILTER, LINT FILTER

Air Output

Filter

Cover

End Filter

Air Intake

Filter

Screw

Air Pressure Gauge

Lint Filter

9

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

Maintenance (Continued)

- Place set screw on flat of shaft.

- Tighten screw firmly (40-50 inch-

pounds/4.5-5.6 N-m). Reinstall

upper shell.

NOZZLE

CLEAN NOZZLE AS NEEDED SPARK PLUG

CLEAN AND REGAP EVERY 600 HOURS

OF OPERATION OR REPLACE AS

NEEDED.

Figure 15 – Fan Assembly Figure 16 – Nozzle Replacement Figure 17 – Nozzle Replacement

(For Models KFA50PF, KFA75PF,

KFA125PF, KFA170PF only)

- Remove upper shell (See Air Intake

Filter, page 8).

- Remove fan blade (See Fan Blades).

- Remove fuel and air line hoses from

nozzle adaptor.

- Remove ignitor wire from spark plug.

- Remove spark plug from nozzle adaptor

using medium phillips screwdriver.

- Turn nozzle adaptor 1/9 turn(40°) to

counter clock wise and pull toward

motor to remove. (See Figure 14)

- Place plastic hex-body into vise and

lightlry tighten.

- Carefully remove nozzle from nozzle

adaptor using 5/8” socket wrench.

- Blow compressed air through face of

nozzle. (this will remove any dirt in nozzle)

- Reinstall nozzle into nozzle adaptor

until nozzle seats.

Tighten 1/3 turn more using 5/8” socket

wrench. (40~45 inch-pounds)

- Reinstall nozzle adaptor to bracket adaptor.

- Reinstall spark plug to nozzle adaptor.

- Attach ignitor wire to spark plug.

- Attach fuel and air line hoses to nozzle

adaptor.

- Reinstall fan blade and upper shell.

(For Model KFA210PF only)

- Remove upper shell (See Air Intake

Filter, page 8).

- Remove fan blade (See Fan Blades).

- Remove fuel and air line hoses from

nozzle adaptor.

- Remove ignitor wire from spark plug.

- Remove spark plug from nozzle adaptor

using medium phillips screwdriver.

- Turn nozzle adaptor 1/8 turn (45°) to

counter clock wise and pull toward

motor to remove. (See Figure 15)

- Place plastic hex-body into vise and

lightly tighten.

- Carefully remove nozzle from nozzle

adaptor using 5/8”socket wrench.

- Blow compressed air through face of

nozzle. (this will remove any dirt in nozzle)

- Reinstall nozzle into nozzle adaptor

until nozzle seats

Tighten 1/3 turn more using 5/8” socket

wrench (40~45 inch-pounds)

- Reinstall nozzle adaptor to burner

bracket

- Reinstall spark plug to nozzle adaptor.

- Attach ignitor wire to spark plug.

- Attach fuel and air line hoses to nozzle

adaptor.

- Reinstall fan blade and upper shell.

(For Models KFA50PF, KFA75PF,

KFA125PF, KFA170PF only)

- Remove upper shell (See Air Intake

Filter, page 8).

- Remove fan (See Fan Blades).

- Remove ignitor wire from spark plug.

- Remove spark plug from nozzle adaptor

using mediumphillips screwdriver.

- Clean and regap spark plug electrodes

to 3.5mm gap.(0.138”)

Set Screw

Motor Shaft

Fan Blade

Flush

Motor

Fuel Line

Air Line

Nozzle Adaptor

Combustion Chamber

Screw

Ignitor Wire

Spark Plug

Bracket-Burner

Nozzle Adaptor

Nozzle Face

Nozzle

Nozzle Adaptor

Models KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

Nozzle Adaptor

Bracket-Adaptor

Air Line

Fuel Line

Ignitor Wire

Screw

Nozzle Face

Nozzle Adaptor

Nozzle

Combustion Chamber

10

ProFitterTM

Portable Oil-Fired Heaters

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

Maintenance (Continued)PHOTOCELL

CLEAN PHOTOCELL ANNUALLY OR AS

NEEDED.

CLEAN OR REPLACE TWICE PER

HEATING SEASON OR AS NEEDED.

Figure 19 – Spark Plug Replacement

Figure 20 – Photocell Replacement

for KFA50PF

Figure 21 – Photocell Replacement for

KFA50PF, KFA75PF, KFA125PF,

KFA210PF

- Reinstall spark plug to nozzle adaptor.

- Attach ignitor wire to spark plug.

- Reinstall fan and upper shell.

(For Model KFA210PF only)

- Remove upper shell (See Air Intake

Filter, page 8).

- Remove fan (See Fan Blades).

- Remove ignitor wire from nozzle

adaptor.

- Remove spark plug from nozzle adaptor

using mediumphillips screwdriver.

- Clean and regap spark plug electrodes

to 3.5mm gap.(0.138”)

- ReInstall spark plug to nozzle adaptor.

- Attach ignitor wire to spark plug.

- Reinstall fan and upper shell.

(For ModeL KFA50PF only)

- Remove upper shell (See Air Intake

Filter, page 8).

- Remove fan (See Fan Blades).

- Remove photocell from its mounting

bracket.

- Clean photocell lens with cotton swab.

TO REPLACE: Remove side cover near

power switch.

- Disconnect wires from circuit board

and remove photocell.

- Install new photocell and attach wires

to circuit board.

- Reinstall fan and upper shell.

(For Models KFA50PF, KFA75PF,

KFA125PF, KFA170PF, KFA210PF only)

- Remove upper shell (See Air Intake

Filter, page 8).

- Remove fan (See Fan Blades).

- Remove photocell from its mounting

bracket.

- Clean photocell lens with cotton swab.

TO REPLACE: Remove side cover near

power switch.

- Disconnect wires from power switch

and remove side cover.

- Disconnect wires from circuit board

and remove photocell.

- Install new photocell and attach

wiresto circuit board.

- Replace switch wires to power

switchand side cover.

- Replace fan and upper shell.

(For Models KFA50PF, KFA75PF only)

- Remove side cover screws using medium

Phillips screwdriver.

- Disconnect switch wires from power

switch (KFA75PF only).

Nozzle Adaptor

Ignitor Wire

Spark Plug

Screw

GAP

Spark Plug

KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

Figure 18 – Spark Plug Replacement

Ignitor Wire

Spark Plug

Nozzle Adaptor

Spark Plug

GAP

Screw

FUEL FILTER

Photocell

Incorrect Correct

Install Photocell Lens

Switch

Photocell Wire

Bracket

Screw Wires

Switch

Side Cover Power

Side Cover

Screw

Circuit

Board

Wire

Photocell

11

Model Pump Pressure

KFA50PF 3.8 PSI

KFA75PF 3.8 PSI

KFA125PF 5.5 PSI

KFA170PF 6.5 PSI

KFA210PF 8.5 PSI

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

Maintenance (Continued)

- Remove side cover.

- Pull fuel line off fuel filter neck.

- Turn fuel filter counterclockwise

90 degrees, pull, and remove.

- Wash fuel filter with clean fuel and

replace in tank.

- Attach fuel line to fuel filter neck.

- Reinstall side cover.

(For Models KFA125PF, KFA170PF

and KFA210PF only)

- Remove side cover screws using

medium Phillips screwdriver.

- Disconnect switch wires from power

switch and remove side cover.

- Pull fuel line off fuel filter neck.

- Turn fuel filter clockwise 90 degrees

and pull to remove.

- Wash fuel filter with clean fuel and

replace in tank.

- Attach fuel line to fuel filter neck.

- Reinstall side cover.

PUMP PRESSURE ADJUSTMENT

- Start heater (See “Operation”, page 7).

- Allow motor to reach full speed.

- Adjust pressure (using flat blade

screwdriver).

- Turn relief valve clockwise to increase

pressure.

- Turn relief valve counterclockwise to

decrease pressure.

- Set pump pressure to correct pressure

for each model.

- Stop heater (see “Operation”, page 7).

NOTE: USE ONLY ORIGINAL

EQUIPMENT REPLACEMENT PARTS. Use

of alternate or third party components

will void warranty and may cause an

unsafe operating condition.

Figure 23 – Fuel Filter Replacement

Fuel Filter

Fuel Line

Switch Wires

Power Switch

Side Cover

Screw

Models KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

Figure 22 – Fuel Filter Replacement

Figure 24 – Adjusting Pump Pressure

Fuel Filter

Fuel Line

Switch Wires

Side Cover

Power Switch

Screw

Flat blade

Screwdriver

Pressure Gauge

Relief Valve

12

Maintenance (Continued)

REPLACING FUSE

NOTE: The heater is fuse protected. If

your heater fails to ignite, DO NOT

RETURN YOUR HEATER TO THE STORE.

Please follow the simple instructions

below to inspect and change the fuse.

SHOCK HAZARD. To

prevent personal

injury, unplug the power cord before

replacing fuse.

- Unplug heater.

- Remove side cover screws using

medium Phillips screwdriver.

- Disconnect switch wires from power

switch (KFA75PF, KFA125PF,

KFA170PF, KFA210PF Models Only).

- Remove fuse from fuse holder (See

Figure 25).

- Replace fuse.

FIRE HAZARD. To

avoid fire, Do not

substitute with a higher or lower

current rating.

- Replace switch wires to power switch

(KFA75PF, KFA125PF, KFA170PF,

KFA210PF Models Only).

- Replace side cover.

NOTE: Specified fuse rating: AC 125/8A

WARNING

WARNING

ProFitterTM

Portable Oil-Fired Heaters

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

Figure 25 – Replacing Fuse

Models: KFA75PF, KFA125PF,

KFA170PF, KFA210PF

Model KFA50PF

Fuse Holder

Fuse

Screw

Side Cover

Power Switch Switch Wire

Fuse Holder

Fuse

KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

Figure 26 – Wiring Diagram Model KFA50PF

Figure 27 – Wiring Diagram Models KFA75PF,

KFA125PF, KFA170PF and KFA210PF

13

Wiring Diagrams

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

Models KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

CN7

RED

CONTROL

SWITCH

EARTH

GREEN

60Hz

BLACK

PLUG

AC120V

8A/125VAC

WHITE

BLACK

ORANGE

POWER

BLACK

POWER

BLACK

PHOTO CELL

LIMIT FUSE

BLACK

PW-W/H

PW-BLK

RED

CN2

2P

(LED)

CN1 CN1

POWER LAMP CN3 RED

DISPLAY PCB CONTROL PCB

WHITE

15uF/230VAC

EARTH

GREEN

MOTOR WHITE

CAPACITOR

IGNITOR

BLACK

BLACK

BLACK

PUMP

SPARK PLUG

CN3

RED

RED

SWITCH CONTROL

BLACK

GREEN

EARTH

60Hz

PLUG 8A/125VAC

BLACK

WHITE

SPARK PLUG

(TEMP. CONTROL)

BLACK

BLACK

THERMOSTAT

CELL

PHOTO

POWER FUSE

SENSOR

ROOM

POWER LIMIT

BLACK

WHITE

CN2(AC2)/

CN1(AC1)/

CN6

CN5

WHT

BLK

EARTH

GREEN CAPACITOR

RED WHITE

MOTOR

POWER LAMP

(LED)

IGNITOR

ORANGE

CN4

BLACK

BLACK

PUMP

BLACK

CONTROL PCB

AC120V

KFA210PF

KFA170PF

20uF/350VAC

20uF/350VAC

15uF/230VAC

20uF/350VAC

KFA125PF

KFA50PF

CAPACITOR

MODEL

14

For Repair Parts, call 1-877-447-4768

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

:sledoMrofrebmuNtraPecnerefeR

NumberDescription KFA50PF KFA75PF KFA125PF KFA170PF Quantity

Repair Parts List for Portable Oil-Fired Heaters

Figure 28 – Repair Parts Illustration for Portable Oil-Fired Heaters Models KFA50PF, KFA75PF, KFA125PF, KFA170PF

KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Fuel Tank Assmebly

Fuel Drain-Bolt

Fuel Gauge

Fuel Filter Assmbly

Cord Bushing

Power Cord

Button Support

Display P.C.B Assembly

Shell Lower

Flange Screw

Bushing-Grommet(S)

Bushing-Grommet(L)

Air-Line

Temperature Limit Assembly

Flange-Screw

Chamber Assembly

Bracket Photocell

2151-0046-01

-

2156-0046-00

2155-0005-00

3712-0013-00

3980-0274-00

3713-0048-00

215A-0013-00

3111-0501-02

4319-0015-00

3231-0120-00

3231-0121-00

3341-0035-00

2153-0022-00

4319-0015-00

2152-0225-00

3131-0159-00

2151-0047-01

-

2156-0049-00

2155-0005-00

3712-0013-00

3980-0274-00

-

-

3111-0501-02

4319-0015-00

3231-0120-00

3231-0121-00

3341-0035-00

2153-0022-00

4319-0015-00

2152-0227-00

3131-0159-00

2151-0048-01

4329-0072-00

2156-0050-00

2155-0001-00

3712-0013-00

3980-0275-00

-

-

3111-0506-02

4319-0015-00

3231-0120-00

3231-0121-00

3341-0036-00

2153-0023-00

4319-0015-00

2152-0230-00

3131-0159-00

2151-0049-01

4329-0072-00

2156-0051-00

2155-0001-00

3712-0013-00

3980-0275-00

-

-

3111-0508-02

4319-0015-00

3231-0120-00

3231-0121-00

3341-0038-00

2153-0023-00

4319-0015-00

2152-0242-00

3131-0159-00

1

1

1

1

1

1

2

1

1

4

1

2

1

1

1

1

1

21

20

40

28

25

22-8

22-7

22-1

23

22

19 13

34

8

7

39

42

38

41

18

27

26

15

17

9

16

10

15

11

12

24

36

31

37

1

4

3

30

29

6

5

35

2

33

32

14

25-17

25-4

25-14

25-13

25-12

25-10

25-16

25-15

25-11

25-7

25-5

25-2

25-6

25-1

25-3

25-8

25-9

25-18

25-19

25-20

25-21

22-2

22-4

22-3

22-5

22-6

19

Screw-BH1

Photocell Assembly

4311-0068-00

SP-KFA1007

4311-0068-00

SP-KFA1007

4311-0068-00

SP-KFA1007

4311-0068-00

SP-KFA1007

2

1

18

15

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

(*) Parts included in tune-up kit.

:sledoMrofrebmuNtraPecnerefeR

NumberDescriptinKFA50PF KFA75PF KFA125PF KFA170PF Quantity

:sledoMrofrebmuNtraPecnerefeR

NumberDescriptinKFA50PF KFA75PF KFA125PF KFA170PF Quantity

Repair Parts List for Portable Oil-Fired Heaters (Continued)

1

2

3

Rotor kit

Filter kit

Plug/Pump adjuster kit

SP-KFA1000

SP-KFA1005

SP-KFA1010

SP-KFA1000

SP-KFA1005

SP-KFA1010

SP-KFA1000

SP-KFA1005

SP-KFA1010

SP-KFA1000

SP-KFA1005

SP-KFA1010

1

1

1

Models KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

21

22

22-1

22-2

22-3

22-4

22-5

22-6

22-7

22-8

24

23

25

25-1

25-2

25-3

25-4

25-5

25-6

25-7

25-8

25-9

25-10

25-11

25-12

25-13

25-14

25-15

25-16

25-17

25-18

25-19

25-20

25-21

27

26

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

Air Deflector

Flange Screw

Burner Head Assembly

Bracket Adaptor

Nozzle*

Washer-Nozzle Seal

Spring-Nozzle Seal

O-Ring

Nozzle Adaptor

Spark Plug*

Bolt-Flange

Flange Screw

Fuel Line

Motor and Pump Assembly

Motor

Capacitor

Motor Support

Nut-Hex

Holder Capacitor

Pump Body

Bolt-BH Special

Rotor*

Blade*

Insert*

End Pump Cover

Elbow

Lint Filter*

Bolt Flange

Output Filter*

End Filter Cover

Ball

Spring

Adjusting Screw

Bolt Flange

Intake Filter*

Fan Assembly

Bolt Headless Hex Socket

Pressure Gauge

Main P.C.B Assembly

Screw-TH2S

Ignitor

Side Cover-Right

Power Switch

Window Display

Flange Screw

Side Cover-Left

Flange Screw

Shell Upper

Clip Nut

Fan Guard

Flange Screw

Front Guard

Tune Up Kit

3131-0574-00

4319-0015-00

2152-0232-00

3131-0576-00

SP-KFA1026

4349-0016-00

3431-0010-00

3311-0002-00

3231-0239-00

SP-KFA1021

4329-0079-00

4319-0015-00

3341-0034-00

2154-0135-00

3970-0210-00

3820-0257-00

3111-0440-00

4331-0022-00

-

3541-0022-00

4321-0198-00

See SP-KFA10001

See SP-KFA10001

See SP-KFA10001

3531-0027-00

3231-0181-00

See SP-KFA10052

4329-0016-00

See SP-KFA10052

3221-0029-00

See SP-KFA10063

See SP-KFA10063

See SP-KFA10063

4329-0016-00

See SP-KFA10052

2154-0009-00

4323-0004-00

3740-0049-00

215A-0048-00

4312-0046-00

39E0-0071-00

3121-0496-03

39A0-0191-00

-

4319-0015-00

3121-0190-00

4319-0015-00

3111-0502-02

3131-0182-00

3221-0074-00

4319-0015-00

3561-0066-00

1XEY7A

3131-0574-00

4319-0015-00

2152-0228-00

3131-0576-00

SP-KFA1027

4349-0016-00

3431-0010-00

3311-0002-00

3231-0239-00

SP-KFA1021

4329-0079-00

4319-0015-00

3341-0034-00

2154-0135-00

3970-0210-00

3820-0257-00

3111-0440-00

4331-0022-00

-

3541-0022-00

4321-0198-00

See SP-KFA10001

See SP-KFA10001

See SP-KFA10001

3531-0027-00

3231-0181-00

See SP-KFA10052

4329-0016-00

See SP-KFA10052

3221-0029-00

See SP-KFA10063

See SP-KFA10063

See SP-KFA10063

4329-0016-00

See SP-KFA10052

2154-0009-00

4323-0004-00

3740-0049-00

215A-0073-00

4312-0046-00

39E0-0071-00

3121-0497-04

39A0-0191-00

-

4319-0015-00

3121-0350-00

4319-0015-00

3111-0502-02

3131-0182-00

3221-0074-00

4319-0015-00

3561-0066-00

1XEY8A

3131-0575-00

4319-0015-00

2152-0193-00

3131-0576-00

SP-KFA1003

4349-0016-00

3431-0010-00

3311-0002-00

3231-0180-00

SP-KFA1021

4329-0079-00

4319-0015-00

3341-0032-00

2154-0136-00

3970-0211-00

3820-0258-00

3111-0439-00

4331-0022-00

3231-0182-00

3541-0022-00

4321-0198-00

See SP-KFA10001

See SP-KFA10001

See SP-KFA10001

3531-0027-00

3231-0181-00

See SP-KFA10052

4329-0016-00

See SP-KFA10052

3221-0029-00

See SP-KFA10063

See SP-KFA10063

See SP-KFA10063

4329-0016-00

See SP-KFA10052

2154-0004-00

4323-0004-00

3740-0049-00

215A-0074-00

4312-0046-00

39E0-0071-00

3121-0498-04

39A0-0191-00

3231-0113-00

4319-0015-00

3121-0504-00

4319-0015-00

3111-0507-02

-

3221-0075-00

4319-0015-00

-

1XEY9A

3131-0575-00

4319-0015-00

2152-0194-00

3131-0576-00

SP-KFA1004

4349-0016-00

3431-0010-00

3311-0002-00

3231-0180-00

SP-KFA1021

4329-0079-00

4319-0015-00

3341-0032-00

2154-0138-00

3970-0212-00

3820-0258-00

3111-0439-00

4331-0022-00

3231-0182-00

3541-0022-00

4321-0198-00

See SP-KFA10001

See SP-KFA10001

See SP-KFA10001

3531-0027-00

3231-0181-00

See SP-KFA10052

4329-0081-00

See SP-KFA10052

3221-0029-00

See SP-KFA10063

See SP-KFA10063

See SP-KFA10063

4329-0016-00

See SP-KFA10052

2154-0007-00

4323-0004-00

3740-0049-00

215A-0074-00

4312-0046-00

39E0-0071-00

3121-0499-04

39A0-0191-00

3231-0113-00

4319-0015-00

3121-0506-00

4319-0015-00

3111-0509-02

3221-0075-00

4319-0015-00

-

1XEZ1A

2

2

1

1

1

2

1

1

1

1

1

3

1

1

1

1

1

2

1

1

2

1

4

1

1

1

1

6

1

1

1

1

1

4

1

1

1

1

1

2

1

1

1

1

4

1

4

1

2

1

8

1

20

16

KFA210PF

Figure 29– Repair Parts Illustration for Portable Oil-Fired Heater (Model KFA210PF)

For Repair Parts, call 1-877-447-4768

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

21

35

17

16

11

20

6

18-8

18-7

18-6

18-5

18-4

18-3

18-2

18-1

34

36

18 19

22

23

13

15

7

14

24

8

11

9

10

22

32

27

33

1

4

3

26

25

5

31

2

29

28

30

12

21-17

21-4

21-14

21-13

21-12

21-10

21-16

21-15

21-11

21-7

21-5

21-2

21-6

21-1

21-3

21-8

21-9

21-18

21-19

21-20

21-21

17

Model KFA210PF

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

Repair Parts List for Portable Oil-Fired Heater (Model KFA210PF)

traP.feR

No. Description No. Qty.

traP.feR

No. Description No. Qty.

(*) Parts included in tune-up kit.

1

2

3

traP.feR

No. Description No. Qty.

Rotor kit

Filter kit

Plug/Pump adjuster kit

SP-KFA1022

SP-KFA1005

SP-KFA1010

1

1

1

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

18-1

18-2

18-3

18-4

18-5

18-6

18-7

18-8

22

21

23

21-1

21-2

21-3

21-4

21-5

21-6

21-7

21-8

21-9

21-10

21-11

21-12

21-13

21-14

21-15

21-16

21-17

21-18

21-19

21-20

21-21

25

24

26

27

28

29

30

31

32

33

34

35

36

Fuel Tank Assmebly

Fuel Drain-Bolt

Fuel Gauge

Fuel Filter Assmbly

Fuel Cap

Power Cord

Shell Lower

Flange Screw

Bushing-Grommet(S)

Bushing-Grommet(L)

Air-Line

Temperature Limit Assembly

Flange-Screw

Chamber Assembly

Bracket Photocell

Screw-BH1

Photocell Assembly

Burner Head Assembly

Bracket Burner

Nozzle*

Washer-Nozzle Seal

Spring-Nozzle Seal

O-Ring

Nozzle Adaptor

Spark Plug*

Bolt-Flange

Flange Screw

Fuel Line

Motor and Pump Assembly

Motor

Capacitor

Supportor Motor

Nut-Hex

2151-0049-01

4329-0072-00

2156-0052-00

2155-0001-00

2151-0041-00

3980-0275-00

3111-0504-02

4319-0015-00

3231-0120-00

3231-0121-00

3341-0036-00

2153-0024-00

4319-0015-00

2152-0050-00

3131-0159-00

4311-0068-00

SP-KFA1007

2152-0124-00

3121-0477-00

SP-KFA1011

4349-0016-00

3431-0010-00

3311-0002-00

3231-0180-00

SP-KFA1021

4329-0079-00

4319-0015-00

3341-0039-00

2154-0139-00

3970-0213-00

3820-0258-00

3111-0439-00

4331-0022-00

1

1

1

1

1

1

1

4

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

2

HolderCapacitor

Pump Body

Bolt-BH Special

Rotor*

Blade*

Insert*

End Pump Cover

Elbow

Lint Filter*

Bolt Flange

OutputFilter*

End Filter Cover

Ball

Spring

Adjusting Screw

Bolt Flange

IntakeFilter*

Fan Assembly

Bolt Headless Hex Socket

Pressure Gauge

Main P.C.B Assembly

Screw-TH2S

Ignitor

Side Cover-Right

Power Switch

Window Display

FlangeScrew

Side Cover-Left

FlangeScrew

Shell Upper

Fan Guard

FlangeScrew

3231-0182-00

3541-0050-00

4321-0198-00

See SP-KFA10221

See SP-KFA10221

See SP-KFA10221

3531-0027-00

3231-0181-00

See SP-KFA10052

4329-0016-00

See SP-KFA10052

3221-0029-00

See SP-KFA10063

See SP-KFA10063

See SP-KFA10063

4329-0016-00

See SP-KFA10052

2154-0007-00

4323-0004-00

3740-0049-00

215A-0074-00

4312-0046-00

39E0-0071-00

3121-0499-09

39A0-0191-00

3231-0113-00

4319-0015-00

3121-0506-00

4319-0015-00

3111-0505-022

3221-0075-00

4319-0015-00

Tune Up Kit 1XEZ2A

1

1

2

1

4

1

1

1

1

6

1

1

1

1

1

4

1

1

1

1

1

2

1

1

1

1

4

1

4

1

1

8

18

1 Handle 3231-0073-00 1

2 Cord Wrap 3221-0041-00 2

Ref. Part

No. Description No. Qty. Ref. Part No. for Models:

No. Description Qty.

Replacement Parts List for

Models KFA50PF, KFA75PF

Replacement Parts List for

Models KFA125PF, KFA170PF, KFA210PF

For Repair Parts, call 1-877-447-4768

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

Front Handle

Rear Handle

Wheel Support Frame

Wheel

Threaded Axle

Cord Wrap

Hardware Kit

Screw

Flange Screw

Cap Nut S

Nut

Bushing

Cap Nut L

3551-0023-00

3551-0086-00

3551-0082-00

3720-0017-00

3551-0088-00

3221-0042-00

HW-KFA1016

INCLUDED IN HARDWARE KIT

INCLUDED IN HARDWARE KIT

INCLUDED IN HARDWARE KIT

INCLUDED IN HARDWARE KIT

INCLUDED IN HARDWARE KIT

INCLUDED IN HARDWARE KIT

3551-0022-00

3551-0087-00

3551-0084-00

3720-0017-00

3551-0089-00

3221-0042-00

HW-KFA1016

I

INCLUDED IN HARDWARE KIT

INCLUDED IN HARDWARE KIT

INCLUDED IN HARDWARE KIT

INCLUDED IN HARDWARE KIT

INCLUDED IN HARDWARE KIT

INCLUDED IN HARDWARE KIT

1

1

1

2

1

2

1

8

4

4

8

2

2

1

2

3

4

5

6

7

7-1

7-2

7-3

7-4

7-5

7-6

Figure 31 – Repair Parts Illustration for

Models KFA50PF, KFA75PF

Figure 32 – Repair Parts Illustration for Models

KFA125PF, KFA170PF, KFA210PF

KFA125PF KFA170PF/210PF

KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

2

1

5

7-2

2

1

3

4

6

7-1

7-3

7-4

7-5

7-6

19

Symptom Possible Cause(s) Corrective Action

Heater ignites but MAIN PCB

assembly shuts heater off

after a short period of time.

(Indicator Lamp is flickering

and room temp. display

indicates “E1”)

Heater will not ignite but

motor runs for a short period

of time. (Indicator Lamp is

flickering and room temp.

display indicates “E1”)

Fan does not turn when

heater is plugged in and

power switch was in the “ON”

position. (Indicator Lamp is on

or flickering)

(Indicator Lamp is flickering

and room temp. display

indicates “E2”)

(Indicator Lamp is flickering

and room temp. display

indicates “E3”)

Heater will not turn-on

(Indicator Lamp is off)

1. Wrong pump pressure

2. Dirty Air Output, Air Intake or Lint Filter

3. Dirty Fuel Filter

4. Dirt in Nozzle

5. Dirt Photocell Lens

6. Photocell Assembly not Properly Installed

(not seeing the flame)

7. Bad electrical connection between photocell

and MAIN PCB Assembly

8. Defective photocell

1. No fuel in tank

2. Wrong pump pressure

3. Carbon deposits on spark plug and/or

improper gap

4. Dirty fuel filter

5. Dirt in Nozzle

6. Water in fuel tank

7. Bad electrical connection between igniter

and MAIN PCB Assembly

8. Igniter wire is not attached to spark plug

1. Thermostat setting is too low

2. Bad electrical connection between motor and

MAIN PCB Assembly

1. Sensor Failure

1. Thermostat switch failure 1. Replace Switch.

See wiring Diagram, page 13

1. Temperature limit safety device is overheated

2. No electrical power

3. Blown fuse

4. Bad electrical connection between

temperature limit safety device and

PCB board

1. See Pump Pressure Adjustment, page 11

2. See Air Output, Air Intake and Lint Filters,

page 8

3. See Fuel Filter, page 11

4. See Nozzle, page 9

5. Clean Photocell Lens, page 10

6. Make sure photocell boot is properly seated in

bracket, Page 10

7. Check electrical components. See Wiring

Diagrams, page 13

8. Replace Photocell, page 10

1. Fill tank with kerosene

2. See Pump Pressure Adjustment, page 11

3. See Spark Plug, page 9

4. See Fuel Filter, page 11

5. See Nozzle, page 9

6. Flush fuel tank with clean kerosene, page 7

7. Check electrical components. See Wiring

Diagram, page 13

8. Attach igniter to spark plug. See Spark Plug,

page 9

1. Turn thermostat control knob to a higher

setting

2. Check electrical connections. See Wiring

Diagram, page 13

1.

page 13

Replace sensor. See Wiring Diagram,

1. Turn power switch to “OFF” and allow to cool

(about 10 min.)

2. Check to insure heater cord and extension

cord are plugged in. Check power supply

3. Replace safety fuse in PCB board. See

Replacing Fuse, page 12

4. Check electrical connections. See Wiring

Diagrams, page 13

Troubleshooting Chart

ProFitterTM Operating Instructions and Parts Manual

For Technical Support or Troubleshooting, Call: 1-877-447-4768, 8:30 am - 4:30 pm CST www.ghpgroupinc.com

Models KFA50PF, KFA75PF, KFA125PF,

KFA170PF and KFA210PF

NEVER LEAVE THE HEATER UNATTENDED WHILE BURNING!

This manual suits for next models

4

Table of contents

Other ProFitter Heater manuals

Popular Heater manuals by other brands

Atlantic

Atlantic TIMELIS CHROME Installation and operating manual

dreo

dreo DR-HSH010 user manual

Volkstechnik

Volkstechnik AHC 0622 Operation instructions

mecanair

mecanair THERMO SPHERE PH-9100WTXN owner's manual

Amerec

Amerec Steamy 6.0A Installation and operating instructions

RADSON

RADSON JAVA E - MOUNTING Instruction

Sovelor

Sovelor GA/N45C User and Maintenance

Rinnai

Rinnai ES38 RHFE-1004RFA OWNER'S OPERATION AND INSTALLATION MANUAL

Smith's Heating First

Smith's Heating First Sterling 3 EL Installation & user guide

Vortice

Vortice AIR DOOR ES Series Instruction booklet

Kero-Sun

Kero-Sun Radiant Fan 111 user guide

Heinner

Heinner HCEH-220 instruction manual