ProFlow PFETP-1000 User manual

1

OWNERS MANUAL

Multi-Function Fuel Transfer Pump

PFETP-1000

WARNING: PLEASE READ ALL INSTRUCTIONS BEFORE PROCEEDING. PROFLOW WILL NOT BE

RESPONSIBLE FOR ANY DAMAGE AS A RESULT OF THE INCORRECT INSTALLATION OF THIS

PRODUCT. IT IS RECOMMENDED THAT A QUALIFIED AUTOMOTIVE TECHNICIAN PERFORMS THIS

INSTALLATION.

WARNING: THE INSTALLATION OF THIS PRODUCT REQUIRES THE HANDLING OF FUEL. IT IS

RECOMMENDED TO WORK IN A WELL-VENTILATED AREA AND WEAR APPROPRIATE PERSONAL

PROTECTION. KEEP ALL IGNITION SOURCES AND FLAMES AWAY FROM WORKSPACE AT ALL TIMES.

Included Items

QTY

PFETP-1000 Transfer Pump

1

22” Length Intake Hose

1

51” Length Discharge Hose

1

Utility (Race Jug) Adaptor

1

Fuel Jug Adaptors

3

v

2

SPECIFICATIONS

IMPORTANT SAFETY INFORMATION

1. Do not use with corrosive liquids. Not for use with drinking water.

2. When pumping gasoline and flammable liquids, be alert to possible explosion

hazards. Flammable fluid fumes and gasoline vapours can be an explosive hazard.

Avoid sparks and use only with adequate ventilation.

3. Wear ANSI-approved safety goggles and heavy-duty, chemical resistant work

gloves during use.

4. This product is not a toy. Do not allow children to play with or near this item.

5. Use as intended only. Only use pump for transferring gasoline, water, oil, and other

non-corrosive liquids.

6. Do not use if pump is hot.

7. Verify that all connections are tight before using to eliminate leaking.

8. Do not pump used, dirty oil.

9. Do not use near open flame or heat sources.

10. Do not turn pump upside down after use.

11. Remove batteries when not in use.

12. Know and obey city and state laws for proper disposal of oil and gasoline. Dispose

of properly in accordance with all local laws and regulations.

13. Follow all guidelines regarding materials being pumped, including SDS instructions

and EPA regulations.

14. Do not mix up old and new batteries. Do not mix alkaline, standard (carbon-zinc),

or rechargeable (nickel-cadmium) batteries. Position batteries in proper polarity.

Do not use swollen or leaking batteries.

15. Do not operate when tired or when under the influence of drugs or medication.

16. Inspect before every usage; do not use if parts are loose or damaged.

17. Maintain product labels and nameplates. These carry important information.

Power

Requires 4x “AA” Batteries (NOT Included)

Delivery Volume

12 Litres Per Minute

Auto-Stop

Built In Auto - Stop System

Applications

Gasoline, diesel, kerosene, light oils, non-drinking water

3

1

Control Box

2

On Button

3

Off Button

4

LED Light

5

Battery Case Cover

6

Female Terminal

7

Discharge Nozzle Compartment

8

Adaptor

9

Intake Hose

10

Nut

11

Liquid Intake

12

Motor Inside

13

Discharge Hose

14

Sensor Inlet

15

Clip

OPERATING INSTRUCTIONS

Battery Operation

1. Open battery cover by placing thumb on grooves and sliding off in direction of

arrow.

2. Insert 4 AA batteries according to “+” and “-“ symbols. Replace all four batteries

at the same time and use the same type/brand of batteries.

Replace the batteries when motor does not operate, even after pressing ON switch or

if transfer rate becomes slower than normal. Batteries can begin to discharge if they

are stored for a long period of time. Check the expiration dates of batteries.

Emergency Use with Two Batteries

It is recommended to use all 4 AA batteries when you are able, but it is possible to

operate with 2 AA batteries during emergencies.

When using 4 batteries you can pump out approximately 50 x 22 litre fuel cans. When

usings 2 batteries you can pump out approximately 25 x 11 litre fuel cans.

PUMP DIAGRAM

1

2

3

4

5

6

7

8

9

10

11

12

10

10

13

10

15

14

4

PUMP OPERATION

Do not run unit dry. Make sure suction tube is fully submerged in liquid before turning

on. When the transfer is complete, turn the switch off. After use, do not turn pump upside

down.

Clean unit with cotton cloth and wipe dry. Remove batteries and store in a clean, dry

location, out of reach of children.

1. Find the adaptor that is the best fit for your can and make sure it is fastened tightly

to your supply tank.

2. Insert intake hose through the adaptor and fasten the pump’s joint nut tightly.

CAUTION: DO NOT LIFT UP OR PUSH DOWN THE PUMP WHILE IT IS ATTACHED TO THE FUEL

TANK.

3. Attach the discharge hose to your receiving tank using the clip. Make sure the

discharge nozzle is in a vertical position as per Figure 1.

Make sure that the supplying tank and receiving tank are on the same level when

pump is operating.

For tanks which do not fit with the clip, make sure discharge nozzle is in a vertical

position.

4. Start the flow of fuel by pressing the “On” button. Pump will automatically stop

when the fuel reaches the stop line.

CAUTION: MAKE SURE THE PUMP IS USED ON AN EVEN SURFACE. IF THE TANK FALLS OVER

DURING USE, LIQUID MAY LEAK CAUSING A FIRE RISK.

MAKE SURE THE PUMP IS TIGHTLY SECURED TO THE TANK BEFORE TURNING ON.

ENSURE THE SENSOR ON THE DISCHARGE NOZZLE IS VERTICAL, OTHERWISE PUMP MAY

NOT AUTOMATICALLY STOP, CAUSING FUEL TO OVERFLOW.

Figure 1

Figure 2

5

5. Once pump has automatically stopped, bring the discharge hose up above the tank

to drain excess liquid back into the supply tank as per Figure 2.

CAUTION: MAKE SURE TO REMOVE ANY LEFT-OVER FUEL IN THE PUMP AFTER EACH USE. IF

FUEL REMAINS AROUND SENSOR, IT MAY CAUSE PUMP FAILURE.

6. Put the discharge nozzle in the discharge nozzle compartment and lock into place

with clip as shown in Figure 3.

CAUTION: PLACE THE DISCHARGE NOZZLE INTO DISCHARGE NOZZLE COMPARTMENT

PROPERLY AFTER USE. IN THE EVENT THE FUEL TANK FALLS OVER, AND THE DISCHARGE

HOSE IS NOT STORED CORRECTLY, LIQUID CAN LEAK OUT.

DETACH THE TANK FROM THE PUMP WHEN MOVING.

PUMP STORAGE

When the pump is not being used for long periods of time, take the pump out of the tank,

make sure there is no remaining fuel in the hose, and wipe down with cloth before storing.

Make sure to remove batteries before storage. Do not store the pump in an enclosed

airtight container.

CAUTION

•Do not transfer fuel while the vehicle or the vehicle’s heater is on (may cause fire).

•Do not leave the pump unattended.

•Do not alter or disassemble the pump.

•Do not place the pump in a wet area.

•Do not use deteriorated or aged fuels.

•Do not use for drinkable liquids, or with thinners, solvents, hot liquid, aceton,

Benzen, Creoso, Ethy, Pheno, Methy, ethy concentrated caustic soda liquid, nitric

acid, hydrochloric acid, sulphuric acid, etc.

•Do not shock the pump.

•Do not run the pump ‘dry’ or let the pump idle without transferring.

•Do not close the hole of sensor inlet transparent vessel under direct sunlight (pump

may not stop automatically and overflow liquid).

•Do not put the product in a vehicle with all windows close, direct sunlight area, or

next to any heating appliances.

•Do not allow children to operate the product without adult supervision.

Figure 3

6

•Do not use the product on carpet, wood floor or combustible area (may cause fire).

Be careful not to damage the floor surface and or carpet by fuel leakage.

•Do not store the pump in an enclosed airtight container.

TROUBLESHOOTING

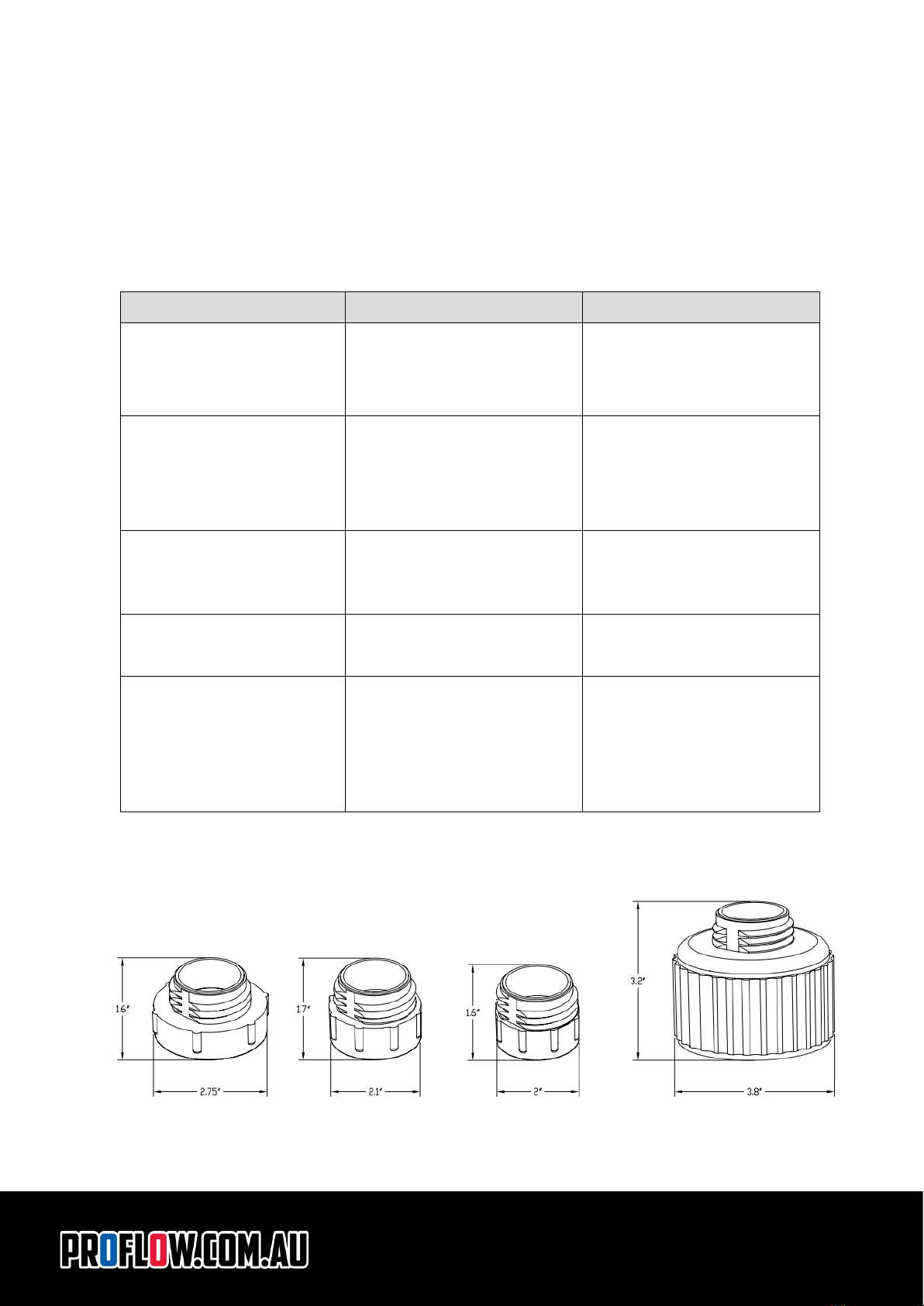

Included Adaptors

Fault

Possible Causes

Solution

Pump does not operate

even after pressing “On”

A: Batteries incorrectly

placed

B: Batteries are depleted

A: Ensure batteries are

placed correctly

B: Replace the batteries

Pumps performance is

low

A: Batteries are depleted

B: Elevation of tank is

higher than supplying tank

A: Replace the batteries

B: Make sure the receiving

tank is not elevated above

supply tank

Pump starts after

pressing “On” but then

stops unexpectedly

Filter of receiving tank may

be blocked with foreign

material

Clean foreign material from

the filter

Pump immediately stops

after pressing “On”

Batteries are depleted

Replace the batteries

Motor stops before

receptacle tank is full

A: Batteries are depleted

B: Sensor is too low and is

touching the liquid

A: Replace the batteries

B: Adjust the discharge

nozzle up so that the

sensor is closer to the top

of the supply tank

PROFLOW LIMITED WARRANTY

This product is warranted to be free from defects in materials and

workmanship for a period of one year from the original date of purchase.

EMAIL: sales@proflow.com.au PHONE: 1300 879 879

Table of contents

Other ProFlow Water Pump manuals

Popular Water Pump manuals by other brands

Pentair

Pentair Lincoln E Series owner's manual

Hi-Force

Hi-Force HP110 Operating instructions manual

Jesco

Jesco MIDIDOS E Series Operation & maintenance instructions

IWAKI PUMPS

IWAKI PUMPS EWN Series instruction manual

Sotera

Sotera 400B Series Owner’s Operation and Safety Manual

DAB

DAB K 36/200 Instruction for installation and maintenance

Ryobi

Ryobi RPTP196 owner's manual

Kamoer

Kamoer KSP-F01A user manual

Ingersoll-Rand

Ingersoll-Rand ARO LM2350E-B Series Operator's manual

Wheeler-Rex

Wheeler-Rex 39300 operating instructions

Alcatel

Alcatel Drytel 100 instruction manual

Stuart Turner

Stuart Turner PH 35 TS Installation, operation & maintenance instructions