Promag Easyfreeze 2000 User guide

USE AND MAINTENANCEUSE AND MAINTENANCE

USE AND MAINTENANCEUSE AND MAINTENANCE

USE AND MAINTENANCE

INSTRINSTR

INSTRINSTR

INSTRUCTIONUCTION

UCTIONUCTION

UCTION

MANUMANU

MANUMANU

MANUALAL

ALAL

AL

EasyfrEasyfr

EasyfrEasyfr

Easyfreeee

eeee

eezz

zz

ze2000e2000

e2000e2000

e2000

EasyfrEasyfr

EasyfrEasyfr

Easyfreeee

eeee

eezz

zz

ze3000e3000

e3000e3000

e3000

2File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

PROMAG

Via Emilia, 45/A - 40011 Anzola Emilia (Bologna) - Italy

Tel. 051 - 6505358 Fax 051 - 6505253

Il presente manuale non può essere riprodotto, trasmesso, trascritto, archiviato in un sistema di reperimento o

tradotto in altre lingue previo accordo scritto con PROMAG.

Si lascia all'acquirente la facoltà di riproduzione di copie ad uso interno proprio.

PROMAG persegue una politica di costante ricerca e sviluppo pertanto si riserva il diritto di apportare modifiche

ed aggiornamenti ogni qualvolta lo ritenga necessario senza obbligo di preavviso.

We would like to thank you for purchasing a Promag machine.

To guarantee you quality and reliability, Promag's Quality System has been officially approved by

the international norm ISO 9001-94 since 1993.

Promag machines also comply with all the requirements outlined in the following European

directives:

•98/37/CE "Machine” directive;

•73/23/CEE “Low voltage” directive;

•89/336/CEE “EMC”directive;

•97/23/CE "PED"directive;

•2004/1935/CE "Materials and objects in contact with foodstuffs" regulation

3

File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

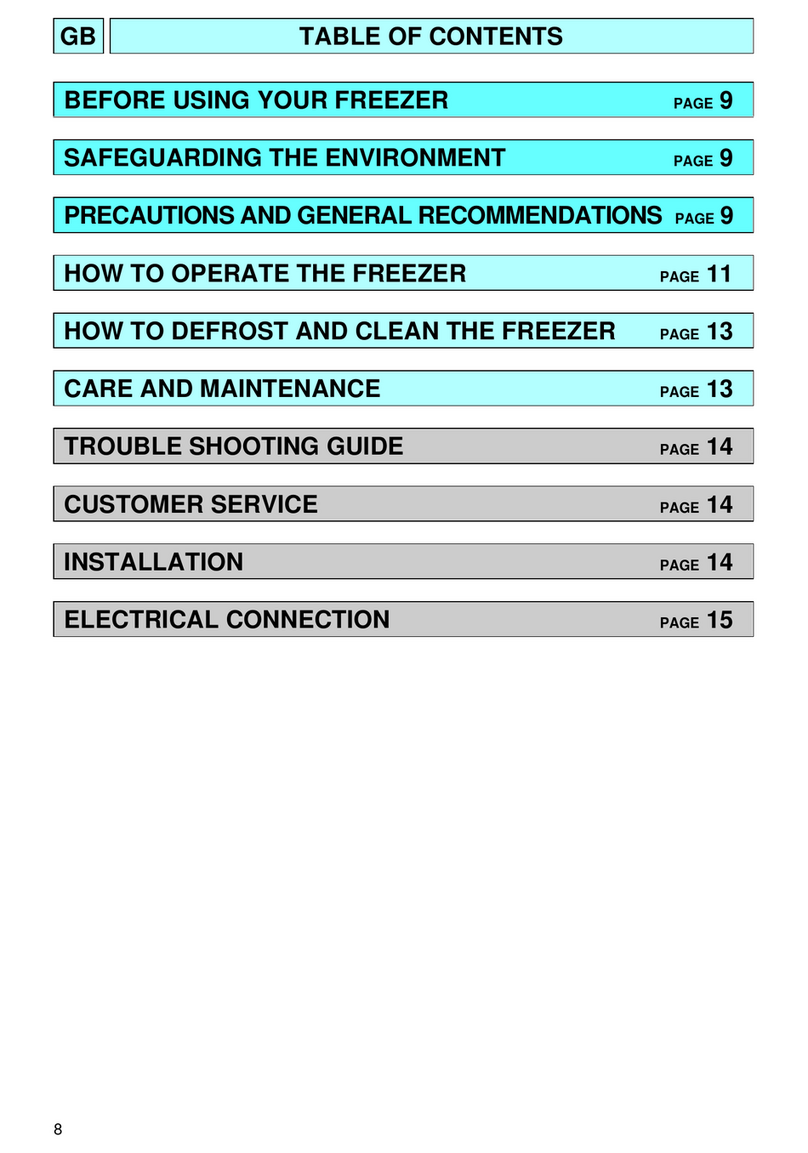

GENERAL CONTENTS

INTRODUCTION .................................................................................................................................................... 7

1. PRODUCT DESCRIPTION ......................................................................................................................... 8

1.1 USE ..................................................................................................................................................... 8

1.2 PRECAUTIONARY MEASURES ....................................................................................................... 8

1.2.1 AIR- COOLED MACHINE ................................................................................................ 8

1.2.2 WATER-COOLED MACHINE ........................................................................................... 8

1.2.3 ELECTRICAL CONNECTIONS ......................................................................................... 8

1.3 MACHINE IDENTIFICATION ........................................................................................................... 8

1.4 MACHINE UNIT IDENTIFICATION ................................................................................................. 8

1.5 SPECIFICATIONS .............................................................................................................................. 9

1.5.1 EASYFREEZE SPECIFICATIONS ..................................................................................... 9

1.6 VERSIONS ........................................................................................................................................ 10

2. SAFETY NORMS ........................................................................................................................................ 11

2.1 SYMBOLS ........................................................................................................................................ 11

2.2 PRINCIPLES ..................................................................................................................................... 11

2.3 GENERAL INFORMATION ............................................................................................................. 11

2.4 TRAINING ....................................................................................................................................... 11

2.5 MACHINE SAFETY DEVICES ......................................................................................................... 12

2.6 OTHER RISKS .................................................................................................................................. 12

2.7 PERSONAL SAFETY WEAR ........................................................................................................... 12

2.8 NOISE LEVELS ................................................................................................................................. 12

3. MACHINE STRUCTURE AND FUNCTION .............................................................................................. 13

3.1 INTRODUCTION ............................................................................................................................. 13

3.2 MACHINE STRUCTURE ................................................................................................................. 13

3.3 FUNCTION DESCRIPTIONS ............................................................................................................ 13

3.4 SAFETY COMMANDSAND DEVICES ........................................................................................... 13

4. OPERATOR COMMANDS AND FUNCTIONS ........................................................................................ 14

4.1 COMMANDS ................................................................................................................................... 14

4.1.1 DISPLAY ......................................................................................................................... 14

4.2 STOP BUTTON ................................................................................................................................ 15

4.3. CLEANING BUTTON ....................................................................................................................... 15

4.4 ICE CREAM PRODUCTION BUTTON ............................................................................................ 15

4.5 FRUITPRODUCTION BUTTON ...................................................................................................... 15

4.6 EXTRACTION BUTTON ................................................................................................................. 16

4.7 HEATING BUTTON ......................................................................................................................... 16

4.8 INCREASE AND DECREASE BUTTONS ........................................................................................ 16

4.9 ICE CREAM PRODUCTION (WHISKING) ...................................................................................... 17

4.10 ICE CREAM EXTRACTION ............................................................................................................ 17

5. ALARMS .................................................................................................................................................... 18

6. SETTING UP THE MACHINE .................................................................................................................... 19

6.1. FOREWORD .................................................................................................................................... 19

6.2. INSTALLATION .............................................................................................................................. 19

6.2.1. WATER-COOLED MACHINE ......................................................................................... 19

6.2.2. AIR- COOLED MACHINE .............................................................................................. 19

6.3. INSTALLATION (TO BE PERFORMED BY SPECIALIZED PERSONNEL ONLY)) .......................... 19

6.4. START UP ........................................................................................................................................ 19

4File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

7. MAINTENANCE ........................................................................................................................................ 20

7.1. DAILY MAINTENANCE .................................................................................................................. 20

7.1.1. REMOVING THE COVER ................................................................................................ 20

7.1.2. REMOVING THE WHISK ............................................................................................... 20

7.1.3. REMOVING THE ICE CREAM EXIT DOOR ................................................................... 21

7.1.4. STERILISING THE MACHINE ........................................................................................ 21

7.2. MONTHLY MAINTENANCE .......................................................................................................... 21

7.3. RECOMMENDED PRODUCTS ........................................................................................................ 22

7.3.1. COOLANT ...................................................................................................................... 22

7.3.2. COMPRESSOR OIL ......................................................................................................... 22

7.3.3. DETERGENTS ................................................................................................................. 22

7.3.4. STERILISER .................................................................................................................... 22

7.3.5 DETERGENT FOR STEEL ............................................................................................... 22

8. TROUBLESHOOTING .............................................................................................................................. 22

8.1. FOREWORD .................................................................................................................................... 22

8.1.1. SAFETY NORMS ............................................................................................................ 22

8.2 TROUBLESHOOTING ...................................................................................................................... 23

9. DISABLING THE MACHINEAND STORAGE ......................................................................................... 24

9.1. FOREWORD .................................................................................................................................... 24

9.1.1. SAFETY NORMS ............................................................................................................ 24

9.2. STORAGE REGULATIONS .............................................................................................................. 24

9.3. DISABLING ...................................................................................................................................... 24

9.4. RESTARTING ................................................................................................................................... 24

10. PACKAGINGAND TRANSPORT ............................................................................................................. 25

10.1. FOREWORD .................................................................................................................................... 25

10.1.1. SAFETY NORMS ............................................................................................................ 25

10.1.2. QUALIFIED PERSONNEL ............................................................................................... 25

10.2 PACKAGING .................................................................................................................................... 25

10.3 TRANSPORT .................................................................................................................................... 25

11. WASTE DISPOSALAND TREATMENT ................................................................................................... 26

11.1 FOREWORD .................................................................................................................................... 26

11.1.1 SAFETY NORMS ............................................................................................................ 26

11.1.2 QUALIFIED PERSONNEL ............................................................................................... 26

11.2 WASTE DISPOSAL AND TREATMENT ......................................................................................... 26

11.2.1 WEEE (WASTE ELECTRICALAND ELECTRONIC EQUIPMENT ) ............................... 26

11.3 ARRANGING MATERIALS FOR DISPOSAL .................................................................................. 26

11.4 WASTE DISPOSAL UNITS ............................................................................................................. 26

12. SPARE PARTS ........................................................................................................................................... 27

12.1 FOREWORD .................................................................................................................................... 27

13. INFORMATION IN CASE OF EMERGENCY ........................................................................................... 27

5

File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

6File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

7

File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

INTRODUCTION

Easyfreeze machines are available in 2 different versions with 12 and 20 litre tub sizes.

Easyfreeze machines freeze liquid mixtures for ice cream or sorbet production and does not include a

pasteurizing process.

Every cycle is programmed and run without interruption. .

Ice cream

Easyfreeze machines mix and freeze the ice cream mass by stirring it continually.

The work cycle therefore produces perfect, non-drip, smooth icecream.

8File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

1. PRODUCT DESCRIPTION

1.1 USE

Easyfreeze machines are designed to produce ice cream containing real pieces of fruit or vegetable.

The machine is not suitable:

- for producing pasta

- for freezing water, or rather for producing ice cream with a high percentage of water

- for mixing, processing etc explosive or harmful substances.

1.2 PRECAUTIONARY MEASURES

1.2.1 AIR-COOLED MACHINE

To guarantee that the air circulates as required, the machine must be installed in a position where it is at least

10 cm away from walls or other obstructions. .

1.2.2 WATER-COOLED MACHINE

Never leave the machine running in an environment where the temperature is below 0°C, as the water in the

cooling system will freeze.

1.2.3 ELECTRICAL CONNECTIONS

The machine must be connected up to a power socket that is earthed.

1.3 MACHINE IDENTIFICATION

The identification plate is positioned on the back of the machine.

The plate indicates the year of construction, type, serial number, rated current, rated frequency, installed

power, type and quality of coolant and EC logo.

1.4 MACHINE PARTS

CONTROL

PANEL

ICE CREAM

EXIT DOOR

TUB STAND

COVER

9

File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

1.5 SPECIFICATIONS

1.5.1 EASYFREEZE SPECIFICATIONS

2000 3000

Air-cooled machine dimensions

Width (mm) 505 550

Depth (mm) 800 910

Height (mm) 1180 1300

Water-cooled machine dimensions

Width (mm) 505 550

Depth (mm) 800 920

Height (mm) 1180 1290

Specifications

Tub capacity (litri) 12 20

Production per hour ** (litres) 50 90

Maximum capacity (litres) 7,5 14

Cycle length (minutes) 12 12

Compressor power (kW) 3 3,7

Whisk motor power (kW) 2,1/1,5 3/3,7

Refrigeration system =Pressure (Bar) 17 17

Protection (Bar) 29 29

Coolant R404a R404a

Refrigeration system refill (kg) 1 1,5

Water supply connection 3/4" 3/4"

Electrical supply connection* 3x400V/50Hz 3x400V/50Hz

Protection (A) 16 25

Weight(kg) 190 230

* Other voltages on request

** Production varies according to the type of mixture used and the temperature of the ice cream.

10 File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

1.6 VERSIONS

There are 3 different tub versions: 12 and 20 litres.

They are respectively:

- Easyfreeze 2000: 12 litre tub capacity

- Easyfreeze 3000: 20 litre tub capacity

11

File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

2. SAFETY STANDARDS

2.1 SYMBOLS

On the right amd left sides of the machine there is a symbol which indicates that you must turn the

machine OFF before removing the side panels.

If the machine needs repairing the power supply must be disconnected first.

The refrigeration and electrical systems must not be tampered with. Only specialised technicians

should be allowed to access them.

The refrigeration system may only be replaced by specialised technicians.

2.2 PRINCIPLES

The machine complies with technical standards and approved basic safety requirements.

The machine should only be used if it is in perfect condition and the instruction manual must be observed at

all times.

If the machine is used incorrectly it may cause considerable damage.

The machine is not suitable for .........., see section 1.1.

2.3 GENERAL INFORMATION

The machine is designed to produce ice cream containing real pieces of fruit.

The machine is not suitable for .........., see section 1.1.

The machine is protected by a magnetic code limited access switch.

2.4 TRAINING

The user will be shown how to use the machine by the manufacturer's expert personnel or by the local agent.

Operators must be trained so they can run the machine correctly using the instruction manual when necessary.

It is the user's responsibility to ensure that his/her own staff are trained properly.

Only specialised, expert personnel should be allowed to repair the machine (specialised personnel =

electricians, refrigerator installers).

In the event of malfunctioning the manufacturer's after sales service should be informed immediately.

Altering or reconstructing the machine is strictly forbidden.

12 File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

2.5 MACHINE SAFETY FEATURES

All corners are rounded and smooth.

The exit chute has 6 transversal rods welded around it to to avoid contact with the rotating whisk.

Operating pressure is 17 bars, the pressure switch is calibrated at 29 bars.

The machine can be moved thanks to its 4 wheels, 2 of which are pivot wheels.

2.6 OTHER RISKS

Tools or any other materials other than food products must not be put in the tub or through the exit chute.

Actions of this kind constitute a serious risk to anyone near the machine.

Only suitable food and sterilising products should be used.

2.7 PERSONAL SAFETY WEAR

When using disinfectants or discharging compressed air, safety googles and rubber gloves must be worn.

This personal safety wear must be provided by the owner.

2.8 NOISE LEVELS

The equivalent continuous A-weighted sound pressure level in the workplace is less than 70 dB(A), for both

water-cooled and air-cooled machines.

13

File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

3. STRUCTURE AND FUNCTION OF THE MACHINE

3.1 INTRODUCTION

The machine includes mechanical and electrical elements as well as a cooling system. It is available with

either a water or air cooling system.

3.2 MACHINE STRUCTURE

The cooling units are positioned at the bottom of the machine, whereas the tub, whisk and drive are located

at the top.

The control panel is located on the front of the machine as are the product exit chute, drip tray and tub stand.

3.3 MACHINE FUNCTIONS

The cooling circuit consists of a compressor with a supply tube that leads to the condenser, drier filter,

spyhole, solenoid valve, injection nozzle and on to the whisk cylinder. A reflow suction pipe then completes

the circuit by returning to the compressor.

The whisk cylinder contains a whisk powered by a gear reducer. A cover closes the cylinder at the top and the

exit chute is located at the front and can be closed with a sliding door.

3.4 SAFETY COMMANDS AND DEVICES

The machine must be connected to a socket protected against faulty currents. For more specific safety info,

see the Specification section 1.5.

The cylinder cover is protected by a magnet code lock switch. The cover is not fitted with a lock mechanism

as it does not need one.

If the cover is not on the machine, it will not start (see section 8.2. Troubleshooting).

All the drive units are protected against overloads by an overload cutout relay.

- Refit the spatula

- Turn the safety device on

14 File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

4. OPERATOR COMMANDS AND FUNCTIONS

4.1 COMMANDS

4.1.1 DISPLAY

When the machine is turned on the software version is shown on the screen.

If the machine does not start, your technician will need to inform the manufacturer of both the machine's serial

number found on the identification plate and the software version.

This will help the Promag.technical staff to solve the problem.

DISPLAY

STOP button

CLEAN button

ICE CREAM PRODUCTION button

FRUIT PRODUCTION button

EXTRACTION button

COOLING button

DECREASE button

INCREASE button

15

File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

4.2

STOP BUTTON

Press this button to stop the machine. The relative LED lights up and STOP is displayed on the screen.

4.3

CLEAN BUTTON

Press this button to start the whisk turning slowly for 3 minutes. After that the machine stops automatically

to avoid excessive wear on the cylinder and whisk.

The screen displays a timer that counts down the 3 minutes.

4.4

ICE CREAM PRODUCTION BUTTON

Press this button to cool the product in the cylinder until the time set on the display expires or the set

consistency is reached (HOT).

The display shows this message:

SET is the total number of whisk minutes (100 means 10 minutes, 110 means 11 minutes etc.). The time can

be varied from 1 to 30 minutes (resolution of 10 on the display) using the Increase and Decrease buttons.

ICE CREAM is the total number of whisk minutes already run. In this case the increase is 10 at a time.

When the time has expired the SET value can be increased again to extend the whisking time.

The time can ONLYbe INCREASED.

Press the Ice cream Production button to display the second check, i.e. the consistency, for 10":

When the set consistency is reached, the whisk keeps running and a siren indicates that the ice cream is

ready.

SET 100

ICE CREAM 000

SET 100

HOT 071

4.5

FRUIT PRODUCTION BUTTON

The cycle is exacly the same as the Ice cream Production cycle.

16 File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

4.6

EXTRACTION BUTTON

This function is only enabled when Production is on, HOT has been reached or the Whisk timer has run out.

When this function is activated the relative LED lights up, only the fast whisk motor is activated and the timer

countdown is displayed on the screen.

To stop the whisk press STOP or wait 3 minutes.

From Extract ON mode you can also access the Cooled Extraction function by pressing the Ice cream

Production button.

In this case the Production LED lights up for 20 seconds after which the machine returns to standard extraction,

unless the total extraction time of 3 minutes has expired, in which case the machine STOPS directly.

4.7

HEATING BUTTON

Press this button to heat the mixture in the tub. The screen will display this message:

The top line shows the set value that needs to be reached and the bottom line shows the actual temperature.

The set temperaure can be changed using the arrow keys. If the Set value is set in a range between 65 and

84°C (inclusive) a pause time is calculated automatically at which the mixture is maintained.

In this case the screen displays the pause time as follows:

where the top line shows the set temperature reached, followed by the coundown of the pause time and the

bottom line shows the temperature of the mixture.

When Set is paused it cannot be altered.

When the pause time expires the machine switches to Ice cream Production.

If, on the other hand, the set temperature is lower than 65°C or higher than 84°C when Set is reached the

machine switches directly to Ice cream Production.

The heating function is enabled only if the tub temperature is above 0°C.

4.8

INCREASE AND DECREASE BUTTONS

These buttons enable the Set temperature or values to be increased or decreased.

TIMER 03:00

SET 85°C

MIX 20°C

SET 075 15:00

MIX 76°C

17

File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

4.9 ICE CREAM PRODUCTION (WHISKING)

Having washed, sterilised and completely rinsed the machine before using it, take the mixture and pour it into

the tub abiding by the minimum and maximum quantities indicated in this manual.

Before pouring out the mixture make sure that the ice cream exit door is properly closed.

Select the PRODUCTION function and wait for the mixture in the tub to reach the set consistency. When the

machine reaches the required consistency a siren sounds to indicate that the ice cream is ready to be

extracted.

4.10 ICE CREAM EXTRACTION

When the production cycle is terminated, indicated by a siren, the ice cream should be extracted as follows

:

-Place the tub on the stand (ref. 1), under the ice cream exit chute (ref. 2).

-Turn the icecream exit door release lever to the left (ref. 3)

-Raise the door lever and turn it to the right to lock the door open.

-Select the EXTRACTION function

When the extraction time expires, press STOP and move the door back to the closed position. Turn the lever

to the left, lower the door lever and close it by turning the lever to the right.

1

2

3

18 File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

5. ALARMS

When an alarm is triggered a message appears on the display. Usually the alarm shown on the display can

be reset by pressing any of the buttons on the pushbutton panel. If the message is left on the display it means

that the alarm has not been reset.

The table below shows the alarms that may occur:

MRALA NOITPIRCSED

neporevoC

)neporevoc(hctiwstengamytefas:SMI

.potSstesenihcam,gninaelCmorF

,sedomgnimmargorPnI.deyalpsidtonsiti,gnitaeHdnanoitcudorPnI

revoC"egassemyalpsideht,revocehtgnisolcnehW.detacidnisiti,oot

.sraeppasidnoos"nepo

mralaRP

:RP hctiwSerusserP

ehtdnaFFOnrutstuptuoehtlla,dereggirtsihctiwserusserpehtnehW

tonseodsihT.deyalpsidsiegassemmralaRPehT.spotsenihcam

foynasserpegassemehteteledoT.tesersienihcamehtfiraeppasid

.snottubeht

mralaSRO

:LTR yalerdaolrevoksihwwolS

dnaFFOnrutstuptuoehtlla,dereggirtsidaolrevoksihwwolSehtnehW

seodsihT.deyalpsidsiegassemmralaSROehT.spotsenihcameht

ynasserpegassemehteteledoT.tesersienihcamehtfiraeppasidton

.snottubehtfo

mralaFRO

:VTR yalerdaolrevoksihwtsaF

dnaFFOnrutstuptuoehtlla,dereggirtsidaolrevoksihwwolSehtnehW

seodsihT.deyalpsidsiegassemmralaFROehT.spotsenihcameht

ynasserpegassemehteteledoT.tesersienihcamehtfiraeppasidton

.snottubehtfo

mralaROC

:CTR yalerdaolrevorosserpmoC

FFOnrutstuptuoehtlla,dereggirtsidaolrevorosserpmoCehtnehW

sihT.deyalpsidsiegassemmralaROCehT.spotsenihcamehtdna

egassemehteteledoT.tesersienihcamehtfiraeppasidtonseod

.snottubehtfoynasserp

mralaVET .ebdeenfi,tiecalperdnaVETrosneskcehC

mralaSET :CTR atsomrehtytefaS tyaler

.spotsenihcamehtdnadeyalpsidsiegassemmralaSETehT

19

File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

6. SETTING UP THE MACHINE

6.1. FOREWORD

Check the packaging before opening it. If the packaging is not in perfect condition the machine may be

damaged too. In this case open the packaging only with a representative of the shipping company present, so

that any damage caused during transportation can be reported.

6.2. INSTALLATION

6.2.1. WATER-COOLED MACHINE

Do not install the machine in a working environment with a temperature below 0°C.

If room temperature drops below freezing point check that the water circuit has been drained completely.

RISK OF FREEZING

6.2.2. AIR-COOLED MACHINE

To guarantee that air circulates properly the machine must be positioned at least 10cm from walls or other

obstacles.

6.3. INSTALLATION (TO BE PERFORMED BY SPECIALIZED PERSONNEL ONLY)

1. Put the plugs in the sockets to activate the power supply.

2. Check the rotation direction. The whisk must turn in an anti-clockwise direction.

This can be checked from the hopper. The rotation direction can be changed by inverting the phase wires.

3. Check the water inlet-outlet connection.

- Behind the machine there is a plate that says Inlet. Connector 3/4”.

6.4. START UP

1. Put the plug in the socket

2. Connect up the water supply and open the tap.

3. The machine is ready to start.

20 File:easyfreeze_G - 09/04 - ed. 2

EASYFREEZE

7. MAINTENANCE

7.1. DAILY MAINTENANCE

The machine must be turned OFF at the main switch or the plug must be pulled out.

The machine should not be cleaned with devices using compressed air.

The components that come into contact with the ice cream must be washed and sterilised daily. To do this,

follow the instructions below:

7.1.1. REMOVING THE COVER

To remove the cover (ref. 1) slide the lever (ref. 2) out from the two

hinges (ref. 3) fixed on the top of the machine.

Wash the cover with water and a detergent, rinse it and then soak it in

a sterilising solution. Then rinse the cover again and reassemble it.

When using the sterilising product, follow the

instructions provided by the product manufacturer.

7.1.2. REMOVING THE WHISK

Take off the pin (rif. 6) and remove the whisk (ref. 4) from the tub and disassemble the scraper blades (ref. 5).

Wash the pieces you have removed with water and a detergent, rinse them and then soak them in a sterilising

solution. Then rinse the whisk again and reassemble it.

When using the sterilising product,

follow the instructions provided by the

product manufacturer.

Reassemble all the pieces, taking care to grease the seals

with a thin film of lubricant.

Reassemble the scraper to the beater. Proceed as follows:

1.Insert the scraper into its seat, making sure it is in the

correct position. In fact, the side of the scraper with the

longest end must remain at the bottom (see photo 1).

2.Press down on the scraper, as illustrated in photo 2,

until it clicks into place.

3.Repeat steps 1 and 2 for the other scrapers.

4

5

5

5

6

Photo 1 Photo 2

2

1

3

This manual suits for next models

1

Table of contents