promesstec WTR 620 User manual

Special dangers

Personnel qualification

- The sensor has been manufactured exclusively for the intended use described here or in

the data sheet and may only be used in this way.

- The technical specifications in these operating instructions must be observed.

- Improper handling or operation of the device outside of the technical specifications

requires immediate shutdown and inspection by promesstec.

- If the unit is transported from a cold to a warm environment, condensation may cause

the unit to malfunction.

- efore using the appliance again, wait until the temperature of the appliance has adjusted

to the room temperature.

Claims of any kind are excluded due to improper use!!!

Improper handling of the sensor can lead to considerable personal injury and damage to

property. The activities described in this operating manual may only be carried out by

qualified personnel with the appropriate qualifications. For installation and commissioning

of the sensor, the relevant country-specific guidelines and standards must be observed.

Especially during installation, depending on the application, contact with aggressive media

may occur. The safety measures must be observed. Electrical installation and

commissioning may only be carried out by qualified and trained personnel.

Residues of measuring materials in dismantled devices can endanger persons, the

environment and equipment. Sufficient precautionary measures must be taken. The units

must not be used in safety or emergency stop installations.Incorrect use or operation of

the unit can lead to injuries. At Depending on the application, aggressive media with

extreme temperatures and high temperatures and high pressure or vacuum may be

present.We recommend installing and and dismantling of the unit only at ambient

temperature and in a depressurised state.

Dangers when operating the appliance

Our units have a very high protection class when properly assembled and installed.

When cleaning your unit with high-pressure cleaners, steam cleaners, etc., make sure

that neither the cover nor the cable gland or M12 connector are directly exposed to the

pressure jet. If the temperature falls below the dew point, condensation may form in the

connection compartment of the unit. In such extreme applications, contact our sales and

technical support before commissioning.

Quick guide temperature switch WTR 620

Intended product use

Safety instructions !!!

page 1/4

Temperature measurement technology

promesstec GmbH * Niedersachsenstraße 4 * 48465 Schüttorf * Tel.:+49 (0)5923/ 90229-0 * Fax +49 (0)5923/ 90229-29 * E-Mail: [email protected] * Internet: www.promesstec.com

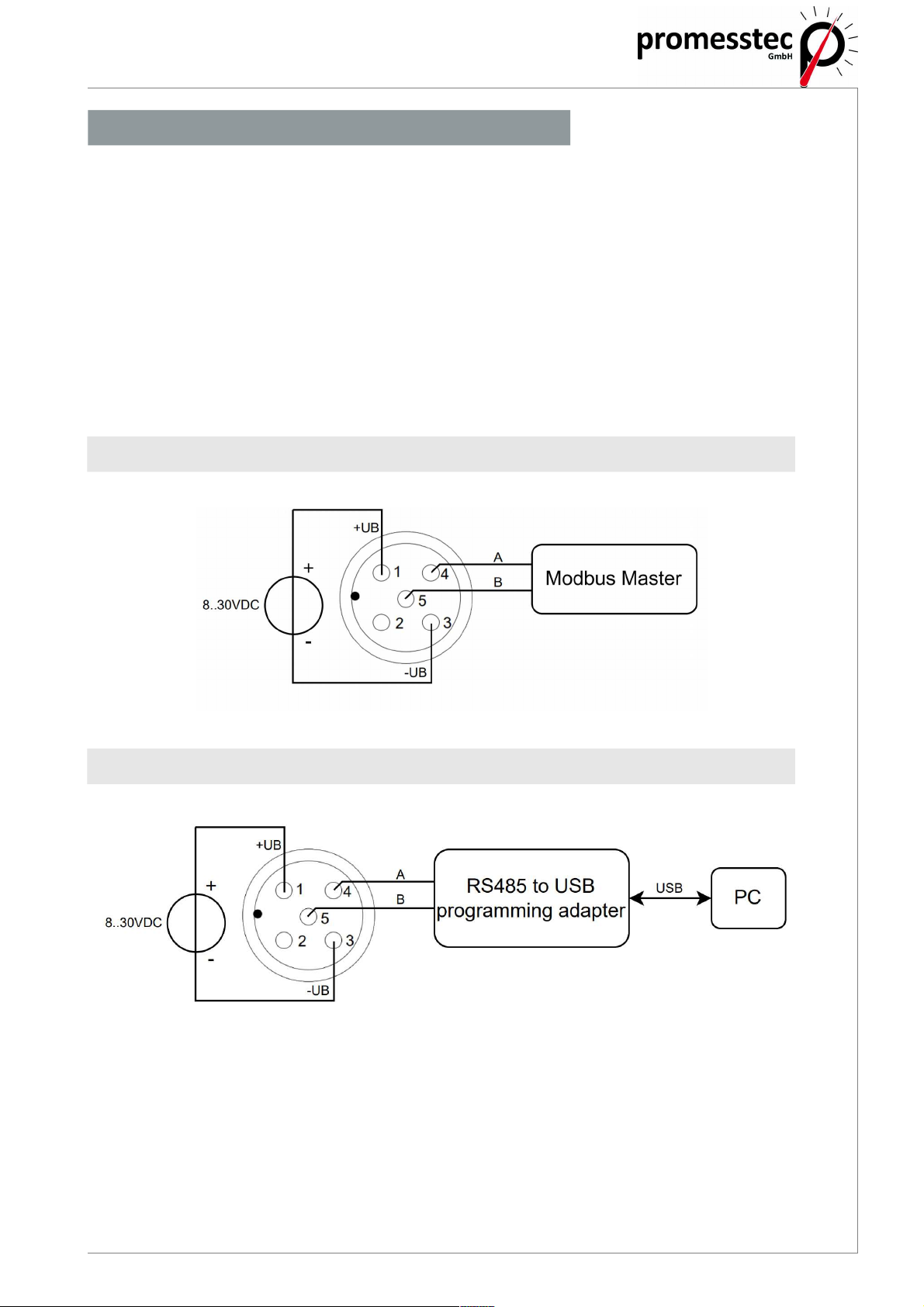

Connection WTR 620

page 2/4

Mechanical structure

Electrical connection WTR 620

Operating voltage U = 8...30 V DC

Current requirement 15 mA + output PNP

Switch-on delay <0.3s

Measured value recording PT100 class A

Measuring range -50°C to +150°C

Measurement deviation (accuracy) < ±0.1% of final value

Output PNP, (active max. 60 mA, short-circuit proof)

Control behaviour two-point controller

Factory setting of switching point 50°C

Factory setting hysteresis 1°C

Protection class IP69K according to DIN 60529

Electrical connection M12 5-pole

Interface RS485 Modbus protocol for configuration as well as readout of the

measurement results and statuses

Process connection G ½

Width across flats 24

Tightening torque 5..10 Nm

Material Protection tube Stainless steel 1.4571 (V4A)

Diameter 6 mm

Storage temperature -20 to 60 °C

Process pressure/operating pressure max. 10 bar

Humidity 0...95 % r. h.

Weight approx. 150 g

Technical spezification WTR 620

Temperature measurement technology

promesstec GmbH * Niedersachsenstraße 4 * 48465 Schüttorf * Tel.:+49 (0)5923/ 90229-0 * Fax +49 (0)5923/ 90229-29 * E-Mail: [email protected] * Internet: www.promesstec.com

page 3/4

Configuration WTR 620

The WTR 620 has an RS485 interface and works with the Modbus RTU protocol.

The interface can be used to read out the measured values and the status as well as

to carry out the configuration. The switching point, the hysteresis, the output logic

and the Modbus ID can be configured. The temperature switch has the address "1"

as standard and can be configured by a Modbus master. It is also possible to

configure the WTR 620 using the in-house Windows software "pmtKonfigTool". An

RS485 to US programming adapter is required for this.

The register table, designations and explanations are stored in the data sheet of the

WTR 620. A detailed explanation of the configuration can be found in the

instructions.

Configuration via Modbus Master

Configuration via Windows software

Temperature measurement technology

promesstec GmbH * Niedersachsenstraße 4 * 48465 Schüttorf * Tel.:+49 (0)5923/ 90229-0 * Fax +49 (0)5923/ 90229-29 * E-Mail: [email protected] * Internet: www.promesstec.com

Mechanical installation

Return and repair

Electrical assembly

The promesstec sensors have a modular design. This allows us to carry out repairs and

overhauls of defective devices. To do this, send the device to promesstec. You will find

a return form with the details to be provided on on our homepage under

"Technical information".

Disposal of the units

promesstec GmbH * Niedersachsenstraße 4 * 48465 Schüttorf * Tel.:+49 (0)5923/ 90229-0 * Fax +49 (0)5923/ 90229-29 * E-Mail: [email protected] * Internet: www.promesstec.com

Dispose of units, components and packaging in an environmentally friendly manner in

accordance with the waste treatment and disposal regulations typical for the country.

Pay attention to waste separation and recycling of high-quality materials such as

stainless steel, etc.

Further documentation

These operating instructions and the data sheets can be found as a file on our homepage

under the homepage under the respective units. The documentation is available in both

and in English. Other languages are available on request. Additional information such as

characteristic curves of temperature sensors etc. can be found on our homepage under

www.promesstec.de

Important notes !!!

ssembly instructions !!!

Temperature measurement technology

page 4/4

- Only use the welding sockets and process connections from promesstec for the

adaptation in your process. This is the only way we can guarantee you an optimum

measuring point.

- After installing the sensor, check the tightness of the measuring point.

- Install the sensor in your process before the electrical assembly. In this way you avoid

winding up the cable when mounting the measuring point.

- M12 plug: Screw the M12 socket by hand onto the plug on the promesstec sensor.

Mounting is done without tools.

- When installing the connection cable, ensure that both components are firmly and

positively connected. The permissible tightening torque can be found in the data sheet

of the data sheet of the respective connection cable

version 2.2.1

Popular Switch manuals by other brands

NETGEAR

NETGEAR GSM7224 - Switch user manual

ZyXEL Communications

ZyXEL Communications XGS1930-28 user guide

Analog way

Analog way QFX402 user manual

Allied Telesis

Allied Telesis x530 Series installation guide

Selve

Selve commeo Timer BT operating instructions

Ocean Matrix

Ocean Matrix OMX-4012 instruction manual