Proxel DTLED User manual

----------- PROXEL ENGINEERING -------------------- www.proxel-bg.com------------------------------ DTLED rev. 1.6/06.201 ------

1

DIFFERENTIAL TEMPERATURE CONTROLLER FOR SOLAR SYSTEM

WITH CIRCULATION AND TANK HEATER THERMOSTAT

Model DTLED

USER MANUAL

Description

The unit DTLED can be used to control the operation of

cirlucation pump of a solar system based on temperature

difference between solar (boiler,stove,etc) and water tank.

Also it can control supplementary heatin of water tank up to

a preset temperature.

Features:

1. Frost and overheat protection of solar and tank.

2. Separate outputs for circulation pump and supplementary

heater of up to 5A.

3. Monitors two temperatures.

4. Fast and easy pro rammable - 4 main settin s and one user defined parameter.

5. Modes of operation - „Auto” /”Holliday” easily selectable by a slide switch at front panel.

6. „Eco function” – postponds the heater activation if solar is active (if “there is sun” the

supplementary heater is switched off) – this mode can activated/deactivated by by user

at any time.

7. 2 pcs. PTC temperature probes – silicon cable 0.3m –PTC 1k

8. 2 separate Relay outputs for:

- Р1 – SPDT (N.O. +N.C.) contact. Outputs “live” for pump or valve (on and off) controll

- Р2 – SPST (N.O) contact for activation of suplimentary heater

9. LED display with 2 di its and 6 additional LEDs for indication.

10. Buttons – 1pcs.

11. Easy setup – each main settin can be selected amon a set of fixed values.

12. Main parameters settin – selectable by chan in jumper location:

- maximal temperature in tank: +65; +75; +85 °C

- frost protection of solar (forced activation of pump): -25; -10; +5 °C

- minimal temperature of solar to enable circulation based on dT: +40; +50 °C

13. Settin of dT (differential temperature – solar to tank) by a knob – fine : from 3 to 25°C

14. Settin of tank temperature (supplementary heatin ) – usin push button on front

panel: startin +25°C up to maximal temperature allowed in 5°C step;

15. Manual test/activation of pump – holdin the push button on front panel.

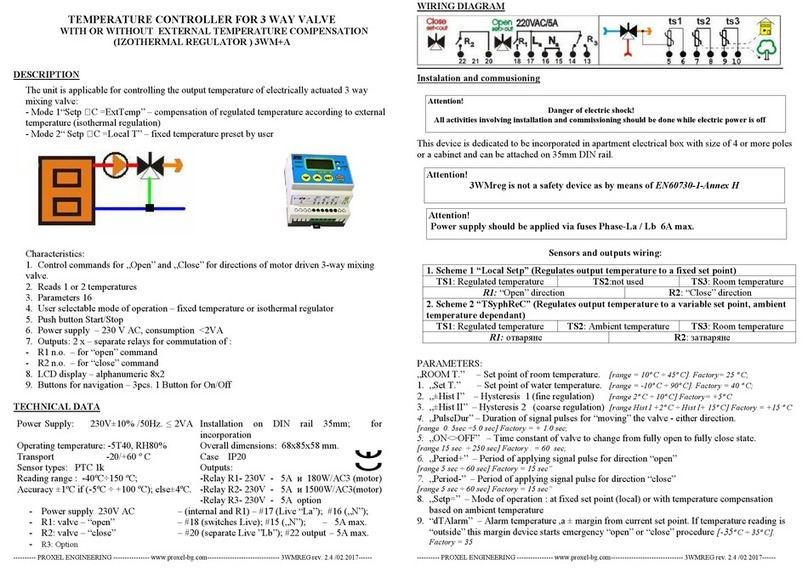

ЕСELECTRICAL WIRING

- Power supply 220V AC – internal and pump – term. 21 (Live in “L”) / 18 („N”-neutral)

- Pump output (N.O) – term. 19 (Live output) / 17 („N”-Neutral)

- Supplimentary heater (N.O.)– temr. 16 and 15 -5A max

* Additional external fuse should e connected to term.21 of up to 6A.

- Sensors

TS1 – term.5,6 – tank temperature TS2 – term 7,8 – solar tempetature.

----------- PROXEL ENGINEERING -------------------- www.proxel-bg.com------------------------------ DTLED rev. 1.6/06.201 ------

2

OPPE

RATION

Front pannel:

- “1” – LED indicator of tempetature (2 di its). Mostlly displays tank t° and each 10 sec. displays

solar t° for 2 sec. (if tank t° is displayed LED#6 is ON, if solar t° is displayed LED#9 is ON).

- “2” – slide switch for mode selection („Auto” / „HOLLIDAY”)

- “3” – push button

- LED “4” – if “On”, the displayed value is over 100°C. (if display=’25’ and LED#4 is ON means

t° =123°C)

- LED “5” – if “On”, ne ative displayed value (if display=’10’ and LED#5 is ON - t° = -10°C)

- LED “6” – if “On” displayed value is for tank tank temperature. If blinks – possible probe failure

- LED “7” – if “On” – pump is active

- LED “8” – if “On” – heater is active

- LED “9” – if “On” – displayed value is for solar temperature. If blinks – possible probe failure.

- If LED 9 and LED 8 blinks alternatively – dT value is displayed

Button operation:

1.

When pressed shortly, the followin information is displayed sequentially:

- boiler and solar temperatures - automatically alternatin each 3 sec.

- differential temperature (dT) settin . The temperature is alternated with the symbols "dt";

- maximal allowed temperature in the tank. The temperature alternates with the symbols

"bH";

- Minimal temperature of solar to enable circulation. The temperature alternates with the

symbols "cS" (Collector Start);

- Temperature settin for anti freezin protection. The temperature is alternated with the

symbols "cd" (Collector Defrost);

2.

When pressed and holded for 3-4 seconds displays/chan es the temperature of the tank’s

thermostat. The temperature alternates with "bt" / "bE" (Standard / Eco tank thermostat);

- Each subsequent pressin increases the set temperature by 5 de rees. If the set

maximum temperature in the tank is exceeded, the value returns to 15 ° C.

- Switchin between standard and Eco tank thermostat is cyclical, each time when the

maximal tank temperature is exceeded. The symbols chan es "bt" to "bE" and the mode is

chan ed also.

3.

When pressed and holded for more than 10 seconds, the pump is manually activated – as

lon the button is pressed;

*

To return to the basic mode leave the device without pressin the button for 1 minute.

Choosing an operation mode

- for normal operation "Auto mode" - move the slider to the "left" to position “Auto”

- to operate in holyday mode “vacation” mode - move the slider to the "ri ht"

Faulty sensor alarm - the correspondin indicator "6" or "9" blinks rapidly.

To chan e most settin s, you need to remove the product’s cover

----------- PROXEL ENGINEERING -------------------- www.proxel-bg.com------------------------------ DTLED rev. 1.6/06.201 ------

3

USAGE

Function Differential thermostat

Monitors the temperatures in the tank and collector, controls output "R1 - circulation pump"

„Auto” mode

Monitorin tº in the tank and collector

When both [tºcollector > tºtank + dT + 2ºC] and [tºcollector >T.CollectorStart] are

true, the circulation pump is activated till [tºcollector> tºtank + dT - 2ºC] or tº colector

falls below the T.CollectorStart.

„Vacantion” mode

- Durin enou h sunshine – it operates same way as in "Auto" mode

- Activation of Circulation when [tºcollector < tºtank -10 ºC ] to cool the tank up to 40 ºC

Build in Protections:

- Freezin of collector: when the tºcollector is lower than T.collector Defrost - 2ºC, the

pump is activated to raise the tºcollector above T.collector Defrost + 2ºC, but only if the

tºtank > 8ºC

- Overheatin of the tank: when the [tºtank > T.Boiler Max] is reached, the circulation is

disabled – unconditionally

- Overheatin of collector: when [tºcollector>100 ºC] and [tºtank < T.BoilerMax] are

reached, the pump is activated until tºcollector falls below 100 ºC

- Hi h temperature (overheat recovery): When tºcollector reaches a ran e of 110-140 ºC

and tºtank <T. Boiler MAX, the circulation is activated at short intervals of 1 sec. every 20

seconds - to slowly reduce the collector temperature. If tºcollector exceedes over 140°C,

the circulation is strictly forbidden to protect the system from heat shock.

- Pump blocka e: automatic forced activation for 60 sec. every 7 days of inactivity

Monitors temperatures in the tank and controls the output "R2 - Heater"

„Auto”mode

If tº tank < T.Boiler Thermostat , the output "R2 - Heater" is activated

“Tank thermostat and Eco function is OFF”

“R2-Heater” output is activated once it is necessary.

"Tank thermostat – and Eco function enabled"

Eco function:

Durin enou h sunshine and operation of the pump, the activation of the "R2 -Heater"

output is postponed for 15 minutes after the last activation of the pump.

„Vacantion” mode

The "R2 - Heater" output is not activated except for frost protection

Protection:

of freezin of the tank: if tºtank oes below 8°C, the "R2 -Heater" output is activated to

heat up the tank

----------- PROXEL ENGINEERING -------------------- www.proxel-bg.com------------------------------ DTLED rev. 1.6/06.201 ------

4

----------- PROXEL ENGINEERING -------------------- www.proxel-bg.com------------------------------ DTLED rev. 1.6/06.201 ------

TECHNICAL DATA

Power supply: 230V±10% / 0Hz. ≤ 2VА Instalation on DIN rail 3 mm; to be incorporated

Enviroment: -2 T4 , RH80%

Storage and transportation -30/+60 º C

Overall dimentions 68x8 x 8 mm.

Protection casing IP20

Sensors: durability 200 ºC

Measurment and display: -40ºC÷199 ºC;

Accuracy ±1ºC in range (- ºC ÷ +100 ºC);

±4ºC not in range

Outputs:

-Relay R1 - 220V - A or 180W/AC3 (motor)

-Relay R2 - 220V - А or 180W/AC3 (motor)

Two independent relay contacts!

Instalation and commusioning

This device is designed to be incorporated in apartment electrical box with size of 4 or more poles or a cabinet and

can be attached on 3 mm DIN rail. Assembly outside of the board is unacceptable.

Initial setup routine:

1. Turn off the power supply

2. Open the top of the body of the product by pushing the locking tabs on both sides of the

base.

3. Adjust the basic parameters according to the enclosed instruction.

4. Place the top cover until it is fully attached to the base

Att ntion!

Dang r of l ctric shock!

All activiti s involving installation and commissioning should b don whil l ctric pow r is off

.

Att ntion! To control tank’s h at r it is n c ssarys to add an xt rnal commutator

(pow rfull r lay) controll d by th th rmostat’s output and to k p all th prot ctiv

and switching l m nts provid d by th tank manufactur r (switch, th rmostat,

th rmal prot ction)!

DTLED is not a prot ctiv d vic within th m aning of EN60730-1-Ann x

Att ntion!

Th supply of th "Phas -La"

pow r supply to th d vic is

carri d out through a fus :

Class B 6A max. on t rminals

no. 21 and no. 16

----------- PROXEL ENGINEERING -------------------- www.proxel-bg.com------------------------------ DTLED rev. 1.6/06.201 ------

6

WARRANTY THERMS AND CONDITIONS:

The warranty period of the product is 24 months from the day of sale or installation by the installer but no more

than 30 months from the date of manufacture. The warranty covers defects attributable to the manufacturer

(manufacturing defects or defective materials). They are not subject to warranty defects in the product or damage to

other equipment as a result of improper or unskilled installation, improper workflow selection and / or adjustment,

unauthorized change of the product, natural disasters, non-standard power supply, improper storage or

transportation.

Тук гаранционна карта на английски прилага ли се???????

Table for diagnostic of temperature inputs

T mp ratur -r sistanc -voltag tabl of s nsor inputs KTY81-1К

TºC -40 -3 -30 -2 -20 -1 -10 - 0 10 1 20

R -[Ω] 67 602 624 6 3 684 714 747 780 81 849 886 922 961

Uвх-[V] 1.37

1.43

1.47

1.52

1.57

1.61

1.66

1.71

1.76

1.81

1.86

1.90

1.95

TºC 2 30 3 40 4 0 60 6 70 7 80 8

R- [Ω] 1000 1040 1081 1122 116 1209 12 4 1299 1346 1392 1441 1490 1 41

Uвх-[V] 2.00

2.05

2.09

2.14

2.19

2.23

2.28

2.32

2.36

2.41

2.45

2.49

2.53

TºC 90 9 100 10 110 11 120 12 130 13 140 14 1 0

R- [Ω] 1 91 1643 1696 17 0 1806 1861 191 1970 2023 207 2124 2172 2211

Uвх-[V] 2.57

2.61

2.65

2.69

2.73

2.77

2.80

2.84

2.87

2.90

2.93

2.96

2.98

Warranty card

Pl as compl t ly fill this card for valid guarant

Manufactur r: Prox l Engin ring Ltd Typ : T mp ratur controll r DTLED

Plovdiv, Bulgaria, [email protected]

S rial numb r: Data of manufactur :

............................. .................................

S ll r/Install r:.............................................................................................................................

.

Addr ss: ........................................................................................................................................

Dat of (sal ) Instalation: .........................................................................................

Install r/ s ll r :.........................................................................................................

(name and signature )

Instalation is mad by

Install r

Cli nt

(please mark the true one)

2004/ 08/EC

2006/95/EC

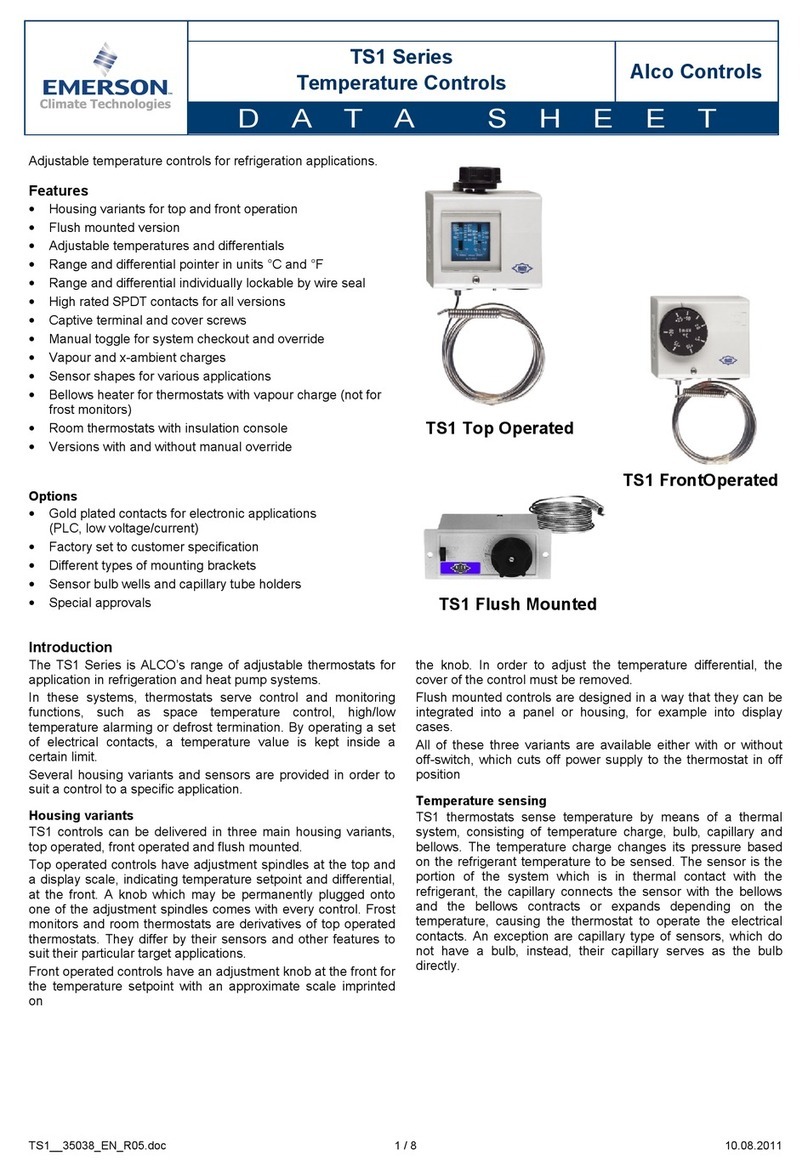

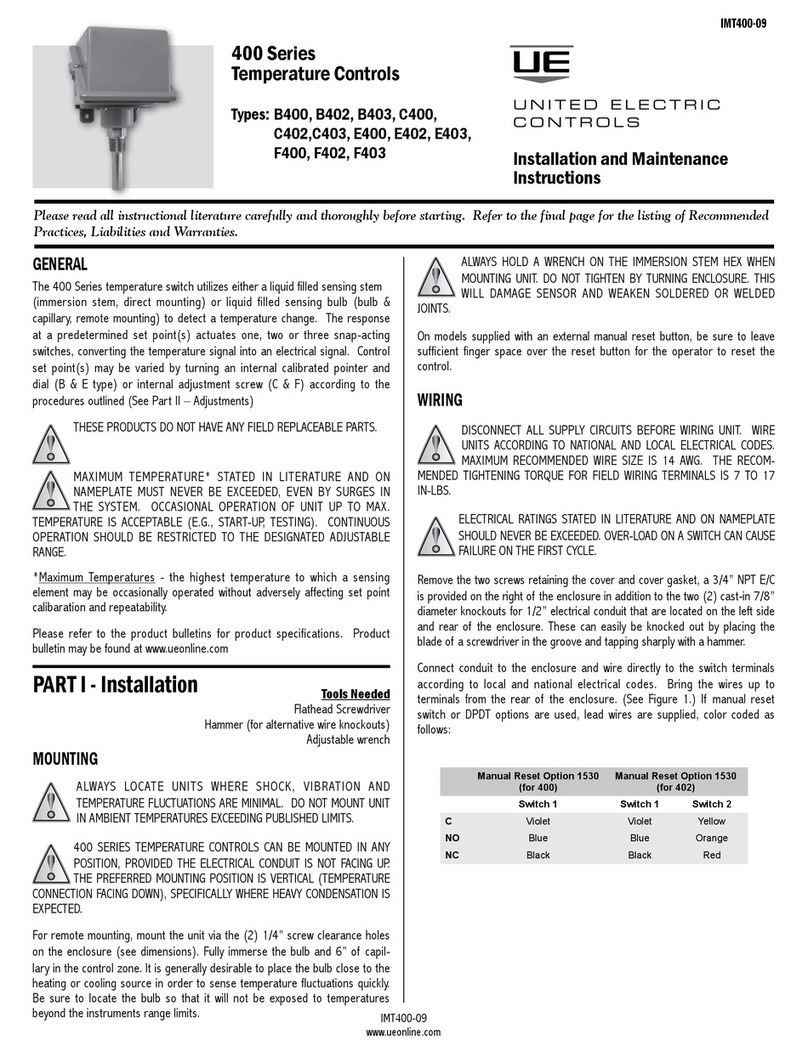

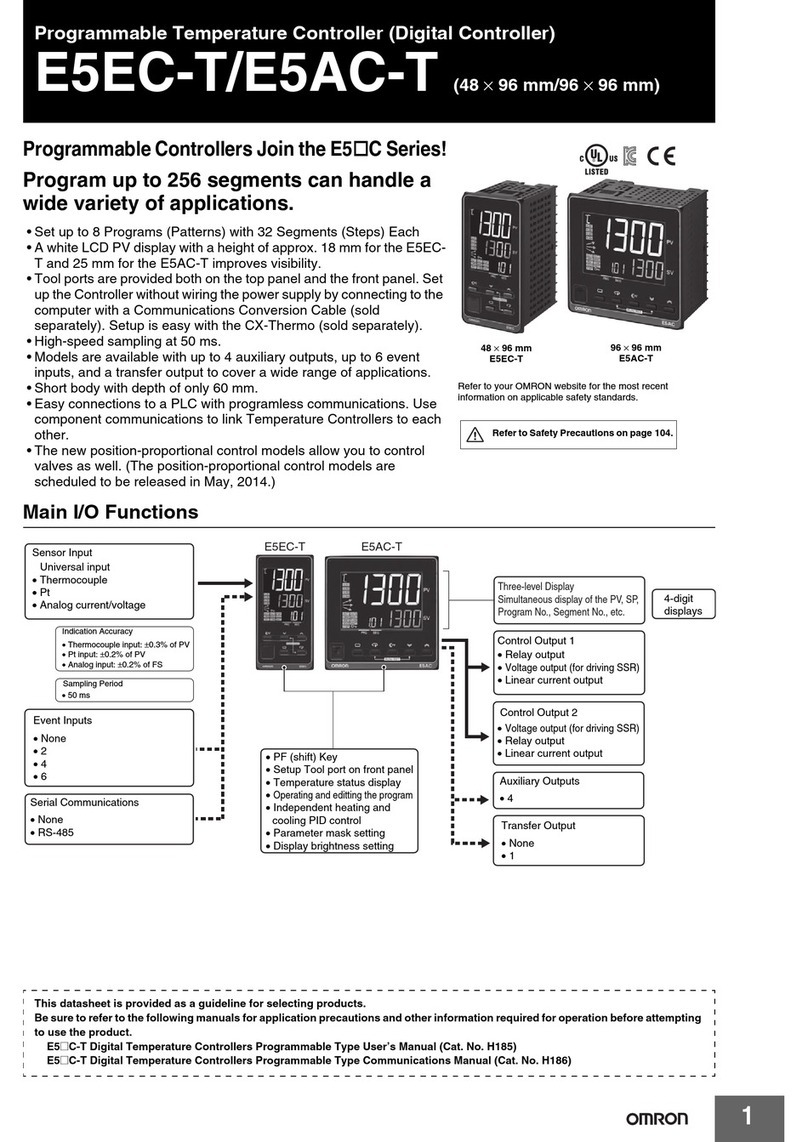

Other Proxel Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

Omron

Omron E5CSL instruction manual

ActronControls

ActronControls LE75 operating instructions

IFM Electronic

IFM Electronic TR7432 operating instructions

Elvaco

Elvaco CMa11L user manual

S+S Regeltechnik

S+S Regeltechnik HYGRASGARD VFF Operating Instructions, Mounting & Installation

Ketotek

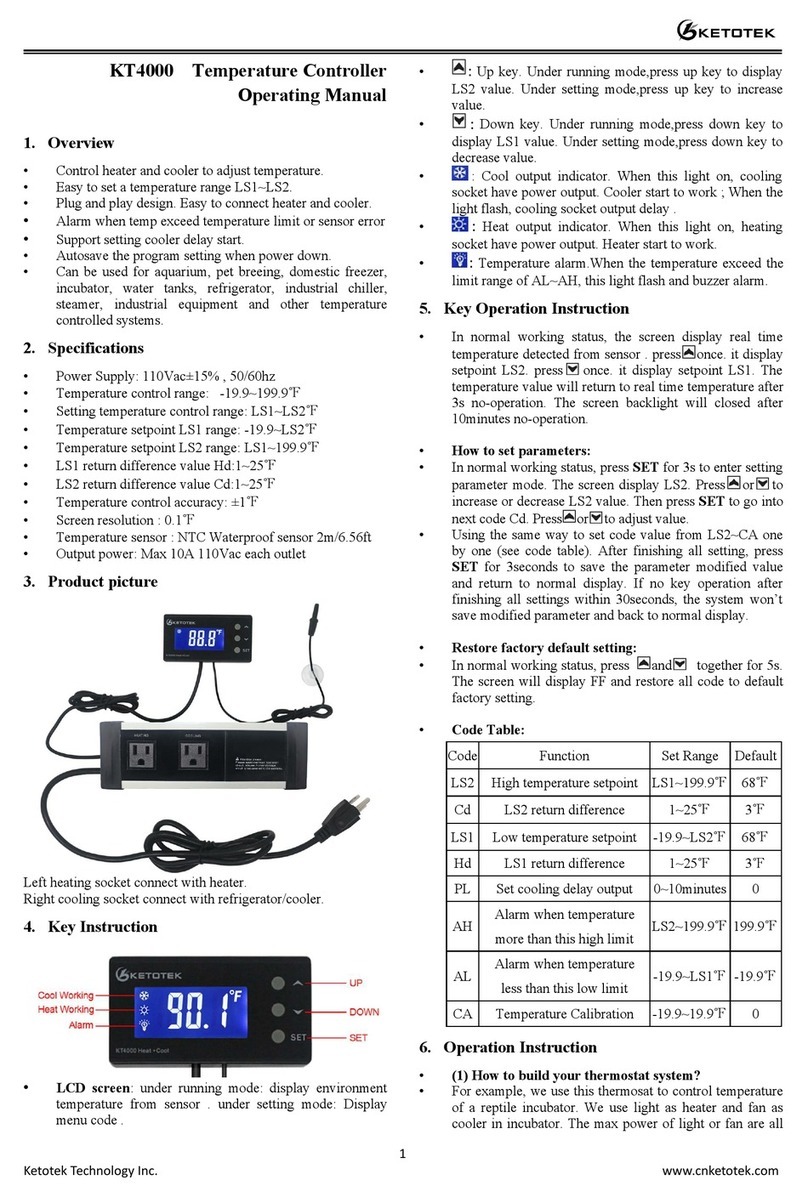

Ketotek KT4000 operating manual