PSG DC10 User manual

PSG

Translation of the German original

Operating Manual

Temperature Controller

DC10

BA/PSG/DC10/0.2/0513/EN

1. Introduction 1

1.1 Structure and use of the manual 1

1.2 Manufacturer details 1

2. Description of the temperature controller 2

2.1 Product description 2

2.2 Technical specifications 4

2.3 Intended use 5

2.4 EC Declaration of Conformity 6

3. Essential safety instructions 7

3.1 Safety symbols used 7

3.2 Primary hazards 8

4. Wall mounting 9

5. Electrical connection 10

6. Configuration 12

6.1 Start-up 12

6.2 Auto tuning 13

6.3 Limiter function 14

6.4 Set value limits 16

6.1 Menu structure and parameter values 19

Table of contents

BA/PSG/DC10/0.2/0513/EN

I

In this chapter you will find the following sections:

• Structure and use of the manual

• Manufacturer details

This manual applies to the following device:

Identification: Temperature controller

type DC10

Application: Temperature controlling

of non-inductive loads

May 2013

PSG Petro Service GmbH & Co. KG

Industriestr. 8a

D-61449 Steinbach/Ts.

Germany

Phone: +49 (0) 6171 / 9750-0

Fax: +49 (0) 6171 / 9750-30

Email: [email protected]

Web: www.psg-petroservice.de

BA/PSG/DC10/0.2/0513/EN

1. Introduction

1.1 Structure and use of the manual

1.2 Manufacturer details

Summary

Validity

Date of Issue

Manufacturer

1

2

In this chapter you will find the following sections:

• Product description

• Technical specifications

• Intended use

• EC Declaration of Conformity

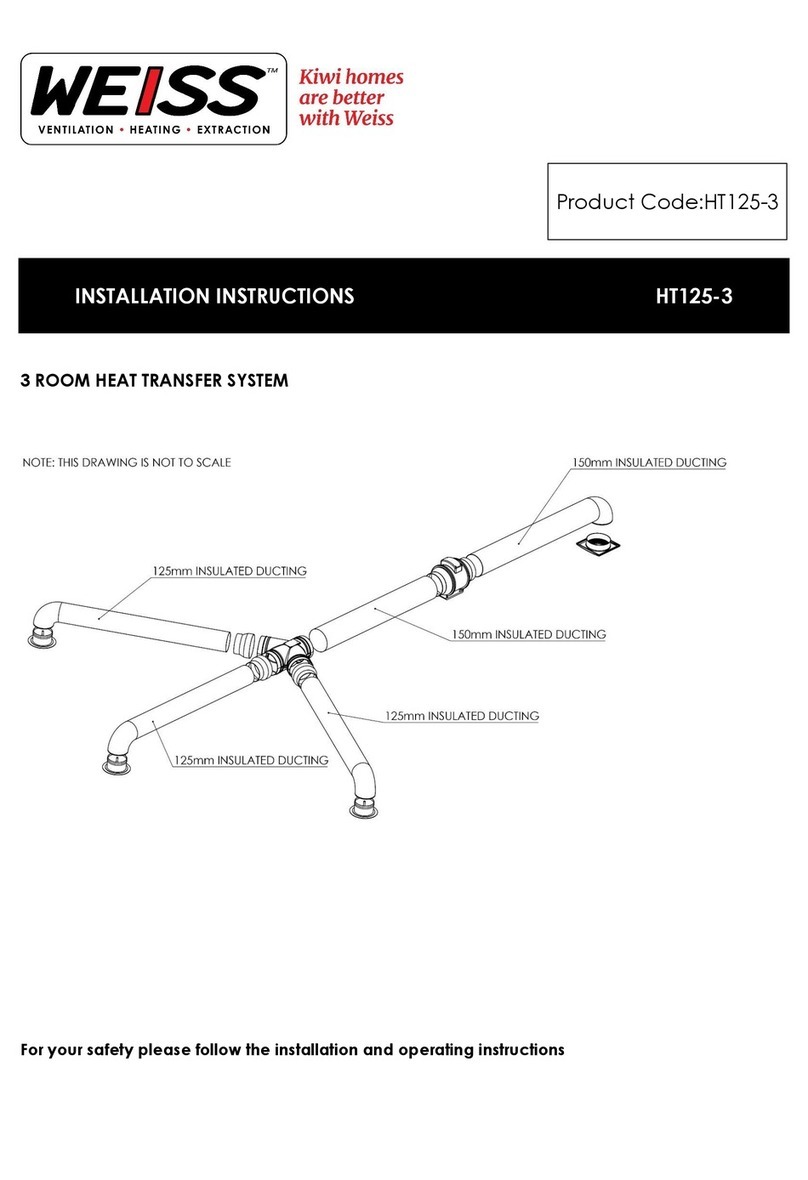

• clear display with process value and set value as well as

deviation indicators

• compact & easy to handle

• convenient and easy operation

• intelligent auto tuning for PID parameters

• internal solid state relay for pulsed controll of the heating

system (zero-crossing)

• limiter function

• switching capacity up to 10 A

• robust aluminium housing

The temperature controller is an electronic microprocessor-based

PID temperature controller.

The set value and the process value are permanently indicated by

a two color display. Additional LEDs indicate process information

allowing to monitor your heating system even at a glimpse.

Featuring a wall mounted quick coupling frame the temperature

controller can be both used as table top unit and as stationary

installed unit.

The housing of the temperature controller is made of aluminium

making the device ideal for the use in rough industrial environ-

ments and labs.

BA/PSG/DC10/0.2/0513/EN

2. Description of the temperature controller

2.1 Product description

Summary

Description

Features

& Benefits

set value

process value

output

process value

within limits

process value

outside limits

auto tuningexternal

communication

fuse

shift key

ON/OFF

increasing

decreasing

mode key

power supplyplug socket for load and

temperature sensor

PROCESS

VALUE

SET

VALUE

COM AUTO TUNE

ENERGIZED

IN RANGE

OUT RANGE

ALARM

DC-10

ON/OFF

alarm

BA/PSG/DC10/0.2/0513/EN

Illustration

Temperatur Controller

3

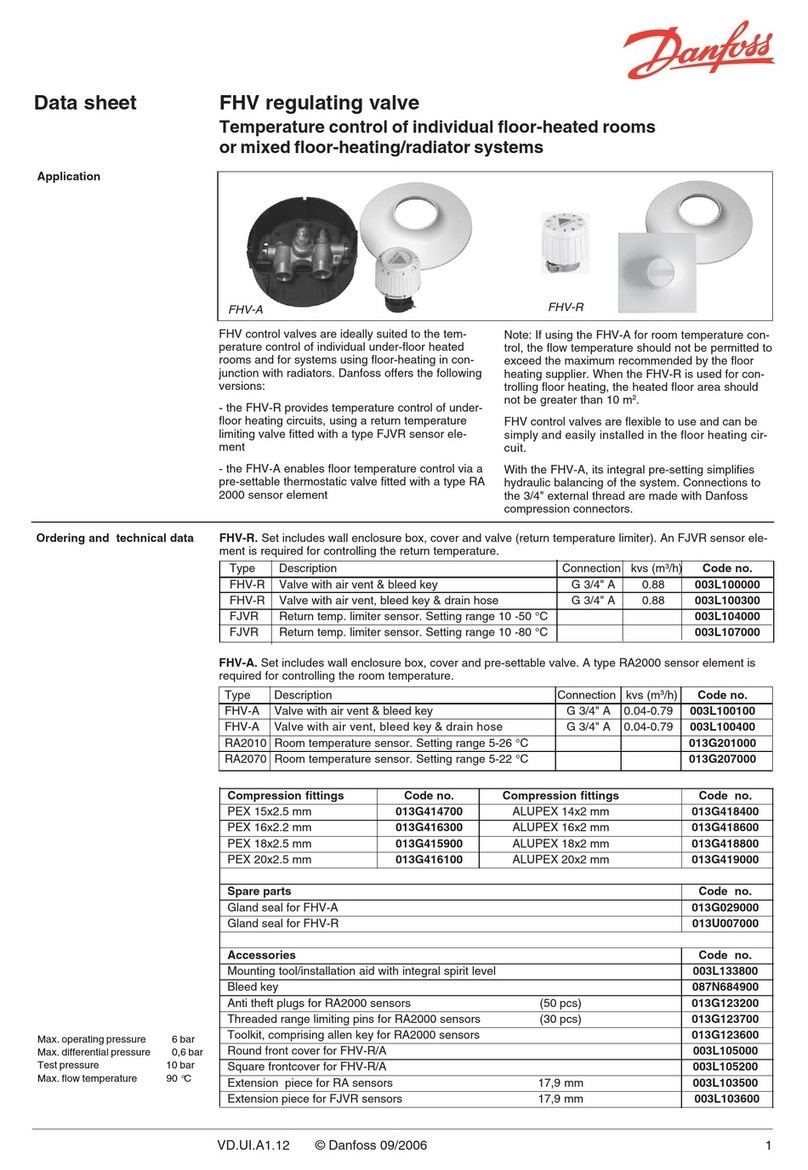

Nominal voltage: 115 or 230 V

(see type plate)

Max. load: 10 A

Frequency: 50...60 Hz

Power consumption: 6 W (w/o load)

Temperature sensor: Thermocouple

type J (-200...+1.000°C)

type K (-200...+1.370°C

(see type plate)

Control accuracy: ± 0,3% of the measuring range

Solid state relay: Zero crossing

Power connection: Power cable with CEE connector

IP44

Load connection: 6-pole Amphenol® plug socket

type “Ecomate” (standard)

Housing: Aluminium light grey

Protection grade: IP 65

Dimensions: 130x90x70 mm

Weight: 800 g

Ambient temperature: 0...+50 °C

BA/PSG/DC10/0.2/0513/EN

2.2 Technical specifications

Technical Data

4

5

The temperature controller is deemed to be used as intended only

if attention is paid to the following points:

• The temperature controller is designed for industrial

applications according to EN 61326.

• The temperature controller is used for the controlling of

non-inductive loads.

• The temperature controller is used interior and as mobile

device (hand-held or table-top unit) or as stationary device

(wall mounted).

• The directives of the operating company must be obeyed.

• The legal regulations for the prevention of industrial accidents

must be satisfied.

Considered as an unintended use in terms of a foreseeable mis-

use are:

• the controlling of inductive loads.

• the operation under conditions other than assumed in this ma-

nual

• the operation of the temperature controller by uninstructed or

unauthorized personnel.

BA/PSG/DC10/0.2/0513/EN

2.3 Intended use

Intended Use

Unintended Use

6

pursuant to EC low voltage directive 2006/95/EG

The manufacturer

PSG Petro Service GmbH & Co. KG

Industriestr. 8a

61449 Steinbach/Ts.

Germany

hereby declares, that the below-mentioned device

Temperature controller, type DC10

complies with the regulations of the following directives:

• EC low voltage directive 2006/95/EG

• EMC directive 2004/108/EG

Adopted standards and specifications:

• DIN EN 61010

Safety requirements for electrical equipment for measurement, control, and laboratory use

Steinbach/TS., 02.05.2013

Place, Date Signature

Jörg Erens, Managing Director

BA/PSG/DC10/0.2/0513/EN

2.4 EC Declaration of Conformity

In this chapter you will find the following sections:

• Safety symbols used

• Primary hazards

The following essential safety instructions are to be regarded

supplementary to already nationally applicable rules and legal

regulations for the prevention of industrial accidents. According to

this, you must always obey applicable rules and legal regulations

for the prevention of industrial accidents in addition to these es-

sential safety instructions.

This symbol indicates an electrical hazard arising from exposure

to electrical voltages.

Possible lethal hazards are indicated separately by the expression

“DANGER OF DEATH!”.

BA/PSG/DC10/0.2/0513/EN

3. Essential safety instructions

3.1 Safety symbols used

Summary

Preface

DANGER OF

DEATH!

7

The temperature controller utilizes voltages of 230 V with corre-

spondingly high amperages. Since amperages as of 40 mA can

be lethal, appropriate precautions are to be taken.

Preventive measures:

• Do not touch any current-conducting parts.

• Keep all coverings of the electrical installations shut.

• Immediately report damaged cables or parts to the person

responsible for the temperature controller.

• Installation work may only be carried out by qualified person-

nel.

Here you will find information on the essential safety instructions

that allow for a safe handling of the temperature controller.

BA/PSG/DC10/0.2/0513/EN

3.2 Primary hazards

Summary

DANGER OF

DEATH!

8

To install the tempeature controller on a wall take out the quick

coupling frame. To do so, unlock the latch by pushing it inside at

the lower face side using an appropriate tool.

Install the frame on a wall or another surface being suitable for

using the following pattern of drilling.

Once the quick coupling frame is installed attach the temperature

controller on the frame. To do so, hook the controller on the upper

connection fins being inclined backwards. Then tilt the controller

parallel to the frame until the latch is snapping into the controller

housing.

BA/PSG/DC10/0.2/0513/EN

4. Wall mounting

pattern of drilling

quick coupling frame

Coupling frame

attaching the

temperature controller

9

The electrical connection of the temperature controller may only

be carried out by “authorized personnel”.

The manufacturer assumes no liability for installation work per-

formed by the operator and for thereby resulting damages or

injuries.

The power supply of the temperature controller must be safe-

guarded by means of a residual-current circuit breaker (RCCB)

together with an overcurrent circuit breaker (OCB). Alternatively, a

combined residual current operated circuit-breaker with overcur-

rent protection (RCBO) can be employed.

BA/PSG/DC10/0.2/0513/EN

5. Electrical connection

Competence

Safeguarding

10

The temperature controller utilizes voltages of 230 V with corre-

spondingly high amperages. Since amperages as of 40 mA can

be lethal, appropriate precautions are to be taken.

Preventive measures:

• Do not touch any current-conducting parts.

• Immediately report damaged cables or parts to the person

responsible for the temperature controller.

• Installation work may only be carried out by qualified person-

nel.

BA/PSG/DC10/0.2/0513/EN

Wiring Diagram

DANGER OF

DEATH!

11

In this chapter you will find the following sections:

• Start-up (quick guide)

• Auto tuning

• Limiter function

• Set value limits

• Menu structure and parameter values

As long as the temperature controller is not factory-preset for your

application, obey the following instructions to put the controller

into operation.

Connect the controller to the power supply voltage. The controller

will display the following symbols for 3 seconds:

Press the ▲▼ keys synchronously for 3 seconds. The process

value display is showing the following symbols:

The set value display is showing the sensor type. To modify the

sensor type press the ▲ or ▼ key.

For a thermocouple type K select

_ _ for °C (-200...+1.370°C) or

_ _ for °F (-320...+2.500°F)

For a thermocouple type J select

_ _ for °C (-200...+1.000°C) or

_ _ for °F (-320...+1.800°F)

6. Configuration

BA/PSG/DC10/0.2/0513/EN

6.1 Start-up (quick guide)

power supply

temperature sensor

Summary

input type

12

Now press the mode key repeatedly until you get back to the PV/

SV display mode. Then the process value is empty (- - - -) and

the set value is showing zero (0).

Press the mode key again. The set value display is showing the

following symbol:

Adjust your specific set value using the ▲ or ▼ keys. By using the

shift key ► the digits can also be selected directly. The active digit

is blinking.

Finally press the mode key again to go back to the display mode.

Connect the heating circuit to the controller via the plug socket.

Ensure the connector pin assignment scheme corresponds to that

of the plug (see wiring diagram, chapter 5).

The orange coloured LED “ENERGIZED” indicates the status of

the output. The heating circuit is energized if the LED is lit.

To switch the controller on or off press the shift key ► for 3

seconds. If the controller is off the process value is showing the

following symbols:

The PID parameter of the temperature controller are factory-pre-

set to standard values. However, you can manually modify the

control performance in order to optimze it for your application. To

do so, select the corresponding parameter values according to

section 6.5.

You can also have the optimal PID values being automatically

determinded. To do so, proceed as follows:

Press the ▲ key and the mode key synchronously.

The process value display is showing the following symbols:

BA/PSG/DC10/0.2/0513/EN

6.2 Auto tuning

connecting

heating circuit

status output

ON / OFF

set value

set value (SV)

ENERGIZED

13

Press the ▲ or ▼ key until the set value display is also showing

.

Confirm the setting by pressing the mode key.

The controller is switching to the display mode and starting the

auto tuning function. While the controller is calculating the PID

values the yellow LED “AUTO TUNE” is lit. As soon as the values

are calculated the auto tuning function switches off automatically

and the LED “AUTO TUNE” is unlit.

The auto tuning procedure will take at least as long as the set

value is reached for the first time.

You can access the calculated values by selecting the corre-

sponding parameters as described under chapter 6.5.

The temperature controller offers a limiter function which opens

the output circuit, i.e. switches off the heating system, if a set tem-

perature limit is exceeded. Then the red LED “ALARM” is lit. The

controller output circuit remains open as long as the process value

exceeds the set limit value.

To use the limiter function proceed as follows:

Press the ▲ and ▼ key synchronously for 3 seconds. The proc-

ess value display is showing the following symbols:

Now press the mode key repeatedely until the process value dis-

play is showing

.

Press the ▲ or ▼ key until the set value display is showing the

following symbols:

BA/PSG/DC10/0.2/0513/EN

6.3 Limiter function

Auto Tune

inner event 3 type

ALARM

AUTO TUNE

14

.

Confirm the setting by pressing the mode key. The process value

display is showing the symbols

.

Set the digits in the set value display to

.

To do so, select the corresponding digit using the shift key ► and

change the value using the ▲ or ▼ key. Confirm the setting by

pressing the mode key. Then press the mode key as many times

until the process value display is showing

.

Press the ▲ or ▼ key until the set value display is showing

.

Confirm the setting by pressing the mode key. Then press the

mode key as many times until the process value is showing

.

Set the digits in the set value display to

.

To do so, select the corresponding digit using the shift key ► and

change the value using the ▲ or ▼ key. Confirm the setting by

pressing the mode key.

Now press the mode key repeatedly until you get back to the

display mode. Then the process value display and the set value

display are showing the messured value and the set value repsec-

tively.

Now you can set the limits in the “main setting mode”. To do so,

again press the mode key until the process value display is show-

ing the following symbols:

BA/PSG/DC10/0.2/0513/EN

inner event 3 function

reverse

control output type

AND operation

inner event 3

main setting

process high alarm

control output

allocation

A=MV

B=inner event 3

C=always ON

D=always ON

15

The temperature controller is able to indicate a defined tempera-

ture deviation by the green LED “IN RANGE” and the red LED

“OUT RANGE”. Therefore at first the limits must be set defining

the acctepable range of the process value.

The required settings will be demonstrated assuming a tolerable

temperature deviation of ± 2K as an example: The green LED “IN

RANGE” shall be lit as long as the process value is 2K or less

lower or higher than the set value. The red LED “OUT RANGE”

shall be lit as soon as the process value is 3K or more lower or

higher than the set value.

Press the ▲▼ keys synchronously for 3 seconds. The process

value display is showing the following symbols:

.

Press the mode key repeatedely until the process value display is

showing:

.

Press the ▲ or ▼ key until the set value display is showing

.

Confirm the setting by pressing the mode key. The process value

display is showing the symbols

.

Set the required limit value using the ▲ or ▼ key. Using the shift

key ► the digits can also be selected directly. The active digit is

blinking.

Now press the mode key repeatedly until you get back to the

display mode. Then the process value display and the set value

display are showing the messured value and the set value respec-

tively.

BA/PSG/DC10/0.2/0513/EN

6.4 Set value limits

inner event 1 type

high/low limit

range alarm

inner event 1 function

IN RANGE

OUT RANGE

16

Set the digits in the set value display to

.

To do so, select the corresponding digit using the shift key ► and

change the value using the ▲ or ▼ key. Confirm the setting by

pressing the mode key. Then press the mode repeatedely until the

process value display is showing

.

Press the ▲ or ▼ key until the set value display is showing

.

Confirm the setting by pressing the mode key. The process value

display is showing the symbols

.

Set the digits in the set value display to

.

To do so, select the corresponding digit using the shift key ► and

change the value using the ▲ or ▼ key. Confirm the setting by

pressing the mode key.

Now press the mode key repeatedely until you get back to the

display mode. Then the process value display and the set value

display are showing the messured value and the set value respec-

tively.

To define the admissibile temperature limits go to the “main set-

ting mode”. To do so, press the mode key until the process value

display is showing the following symbols:

Set the admissible positive temperature deviation using the ▲

or ▼ key (2 for a.m. example). Using the shift key ► the digits

can also be selected directly. The active digit is always blinking.

Confirm the setting by pressing the mode key. The process value

display is showing the symbols

.

BA/PSG/DC10/0.2/0513/EN

inner event 2 type

high/low limit alarm

inner event 3 type

no function

inner event 1

main setting

inner event 1

sub setting

no function

17

Set the admissible negative temperature deviation using the ▲ or

▼ key (2 for a.m. example). Confirm the setting by pressing the

mode key.

Now press the mode key repeatedely until you get back to the

display mode. Then the process value display and the set value

display are showing the messured value and the set value respec-

tively.

To set the inadmissible temperature limits go to the “sub setting

mode”. To do so, press the ▲ key and the mode key synchro-

nously. The process value display is showing the following sym-

bols:

.

Press the mode key repeatedely until the process value display is

showing:

.

Set the inadmissible positive temperature deviation using the ▲ or

▼ key (2+1=3 for a.m. example).

Confirm the setting by pressing the mode key. The process value

display is showing the symbols

.

Set the inadmissible negative temperature deviation using the ▲

or ▼ key (2+1=3 for a.m. example).

Confirm the setting by pressing the mode key.

Now press the mode key repeatedely until you get back to the

display mode. The process value display and the set value display

are then showing the messured value and the set value respec-

tively.

BA/PSG/DC10/0.2/0513/EN

inner event 2

main setting

inner event 2

sub setting

18

Table of contents

Popular Temperature Controllers manuals by other brands

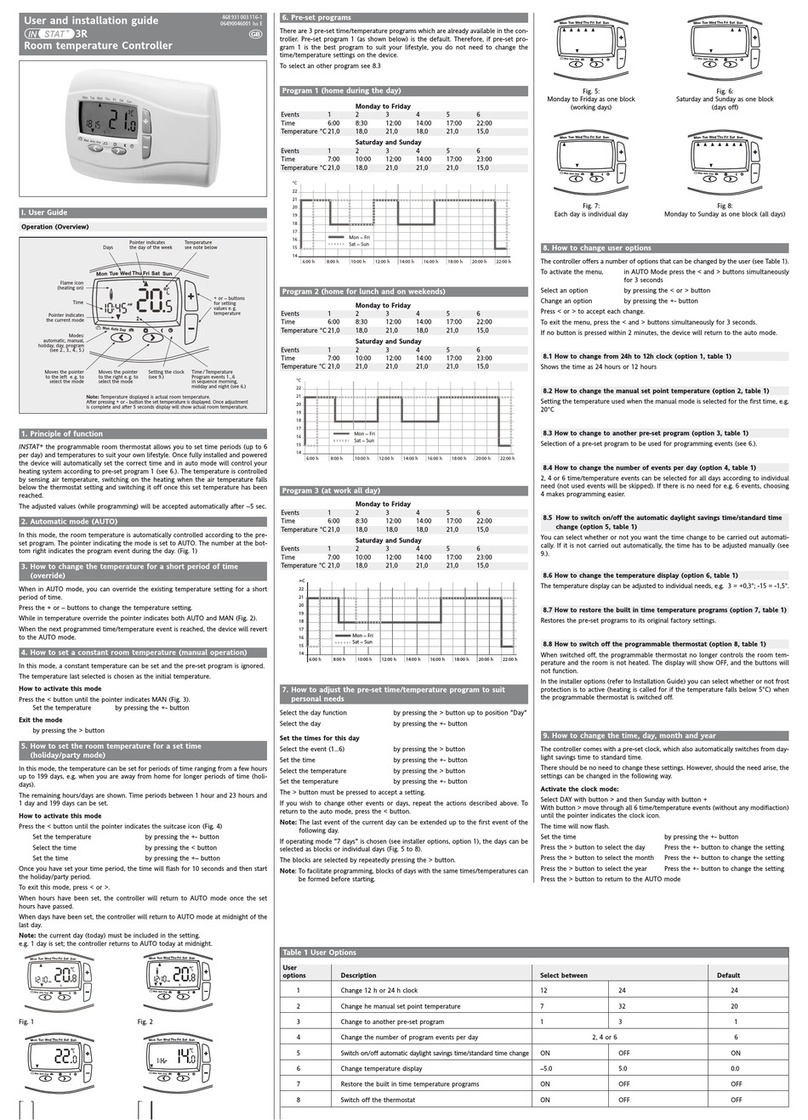

INSTAT+

INSTAT+ 3R User and installation guide

Brink

Brink Renovent Excellent300 installation instructions

Ropex

Ropex CIRUS UPT-6010 operating instructions

S+S Regeltechnik

S+S Regeltechnik THERMASGARD RSTF Operating Instructions, Mounting & Installation

Middleby Marshall

Middleby Marshall 75729 instructions

Nibe

Nibe HPAC 40 Installer manual

Distech Controls

Distech Controls Allure EC-Sensor-T Hardware installation guide

Ketotek

Ketotek KT1210W operating manual

Honeywell

Honeywell ASC02-01WM Installation and operating instructions

Tense

Tense DT-36Y manual

Maximum

Maximum MYSTIC installation guide

S+S Regeltechnik

S+S Regeltechnik THERMASGARD TF 43 Dimensions and installation information