GB

The pipes should be fitted in such a way that any pressure variation caused by temperature

changes do not to affect the pump.

If the piping is very long, it must be suitably supported in front of and behind the pump and

it is best to place a retention or anti-hydraulic ram valve in the drive.

The plastic pipes and connections should be screwed carefully.

If a hose is used in suction, it must be non-compressible (with a reinforcement spiral).

The suction pipe/hose must be as short as possible to assure optimum working conditions.

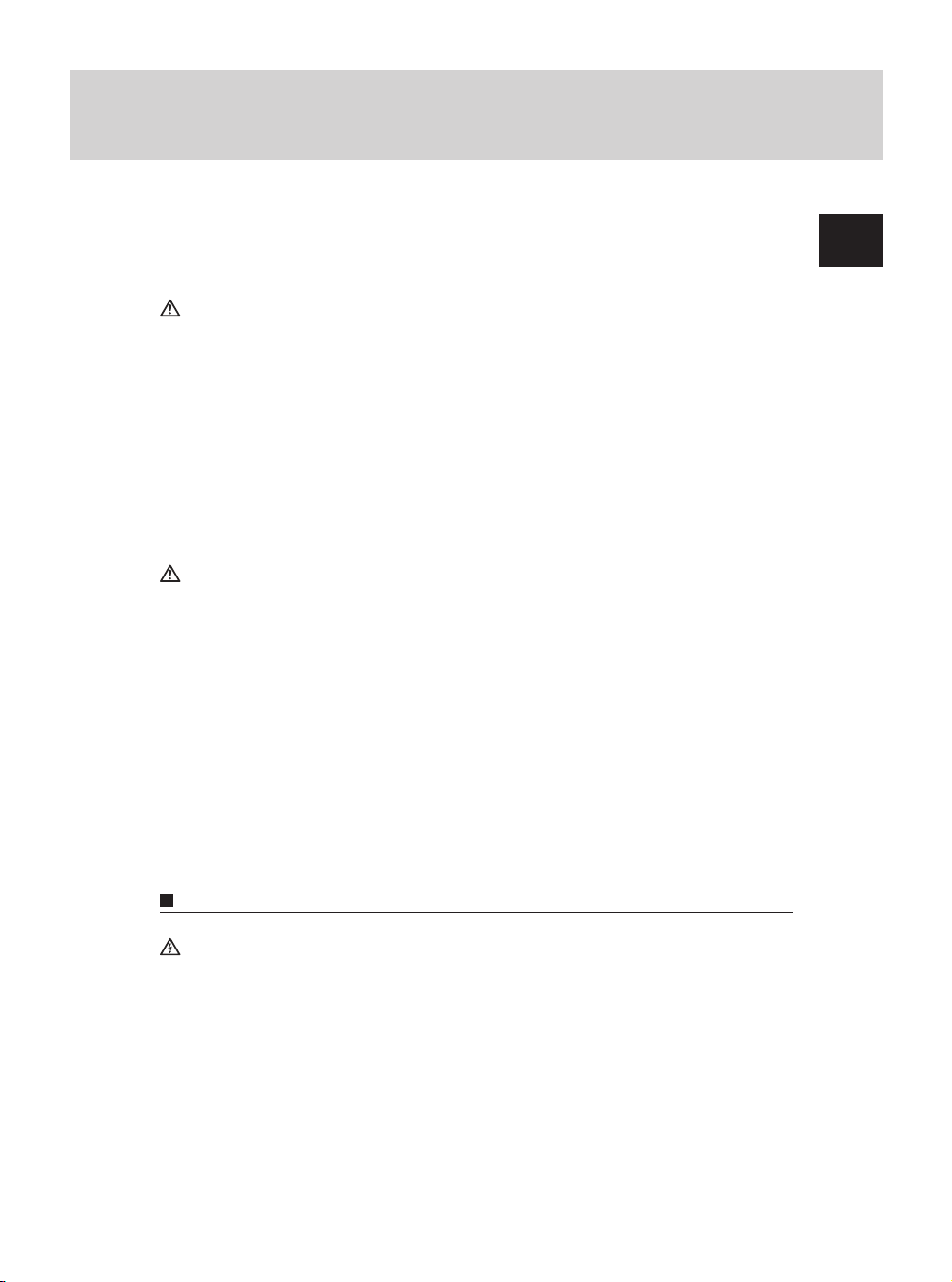

It is recommended to install close valves on either side to isolate the pump.

Note: The pump does not allow work with a closed discharge valve as it may cause an in-

crease in the temperature and steam formation which can damage the pump.

If there is any danger of the pump working against a closed discharge valve, a by-pass/purg-

ing valve must be connected in a discharge pipe to ensure minimum liquid flow through the

pump.

To minimise possible noise from the pump, it is recommendable to install an anti-vibrator in

the suction and drive inlets and between the base plate and the pump.

According to the IEC no. 364 publication, the pump must be installed at least 2 m from

the swimming pool edge.

Make sure that the electrical supply is turned off before removing the connection box

cover or before any moving or disassembling of the pump.

The electrical connections must be performed by an authorised electrician and according to

the local standards.

The pump must be connected to an external switch.

The voltage and the frequency are marked on the characteristics plate. Make sure that the

motor is suitable for the electrical supply in use.

The motor must be connected to the electrical supply as shown in the drawing, using an ap-

proved, watertight cable and in accordance with local standards.

4Electrical connections

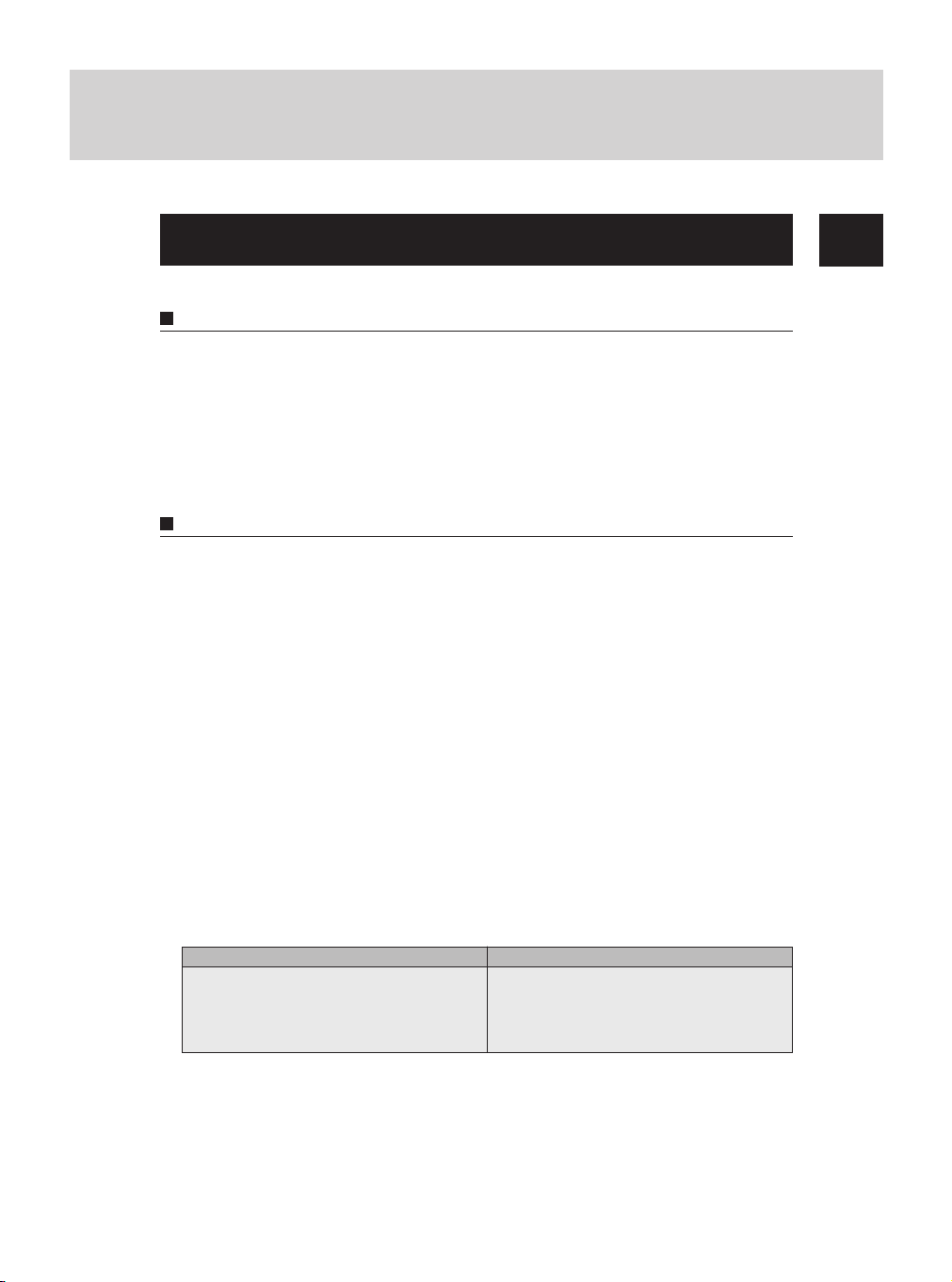

3.1 Ventilation

The pump motor is cooled by the fan on the rear. We will therefore preferably place the pump

in a WELL VENTILATED place (protected from possible freezing), preferably in a room.

a) If the pump is installed OUTDOORS, it must be protected from the rain and the elements

with a suitable cover.

b) If the pump is installed in an underground or semi buried plant housing, a SUFFICIENT AIR

ENTRY must be assured for the motor ventilation in order to not be damaged (the inside

temperature should not exceed 50ºC).

c) In order to assure efficient cooling , the minimum distance between fan cover and the wall

or another obstacle situated at the back side of the motor must be more than 2,5 times

than the fan diameter.

Instruction Manual for Series MAXI