23833A199 11/08/12 2

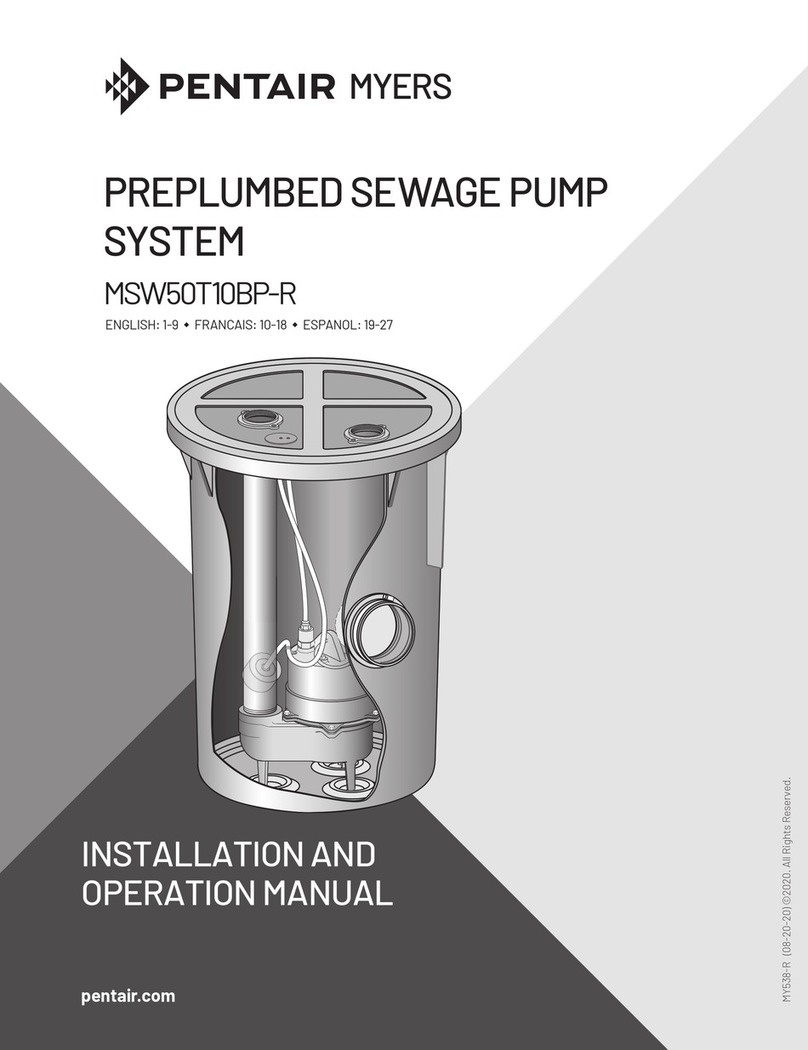

Note: When complete packaged system, including

fiberglass basin, is supplied from factory all parts are

mounted in basin except pump, check valve, and

guide plates. Piping and guide plates for pump are

shipped in separate package and must be mounted in

the field.

CALIFORNIA PROPOSITION 65 WARNING:

This product and related

accessories contain chemicals known to the

State of California to cause cancer, birth

defects or other reproductive harm.

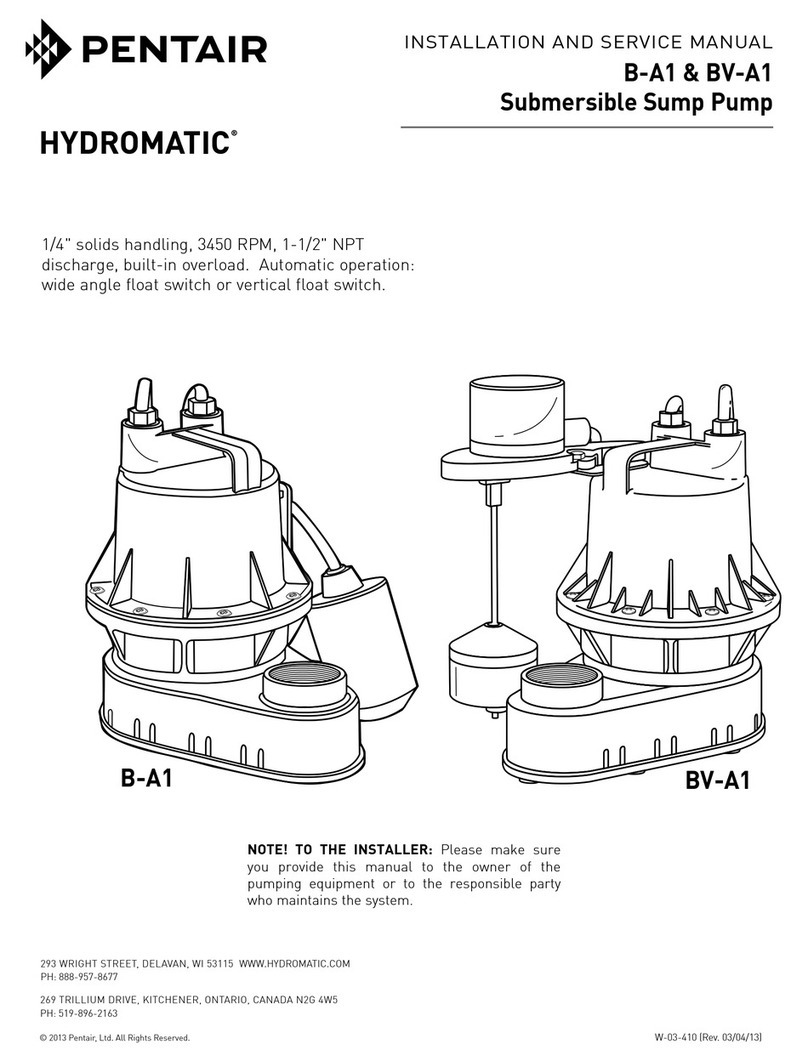

ASSEMBLING PIPING TO PUMP

Attach guide plate and piping to pump as shown in

Figure 1. Be sure piping is plumb, then tighten all set

screws. Attach lifting chain to lifting eye with clevis

supplied. Pump(s) can now be lowered into position

with lifting chain. Retain power and control cords

at surface as pump is lowered. When pump(s) is in

place, attach cords to connection box. Remove slack

from wires so that they will hang vertical without

tangling.

MECHANICAL ASSEMBLY

1. Inlet flange must be mounted to basin at depth

required to get gravity flow into basin. Bottom

of basin must be at least 36" below inlet pipe.

Two inlet flanges are supplied, one for use with

4 inch SDR 35 PVC pipe and one for use with 4

inch SCHEDULE 40 PVC pipe. Inlet flanges are

available for either 4 or 6 inch pipe and more than

one inlet may be used if desired.

2. Cut hole(s) through fiberglass basin at desired

location using the correct size hole saw. For 4

inch inlets use a 5 inch hole, for 6 inch inlets use

a 7 inch hole. Select the inlet that matches the

type of pipe being used (4 or 6 inch, SDR 35 or

SCH. 40). Insert the inlet into the previously cut

hole. Chamfer the ends of the plastic pipe for ease

of installation. Lubricate pipe with soapy water.

Insert pipe through inlet so that the pipe protrudes

through the inlet approximately one inch.

3. This unit is equipped with hold-down guides and

hold-down pipe. Upper guides hold to rail and

hold-down pipe with set screws. The hold-down

pipe is necessary to prevent hydraulic pressure

from lifting pump from base. The hydraulic

pressure keeps the pumps suspended when in

operation so there is no side load on the rails and

removal is easier when required.

ELECTRICAL ASSEMBLY

1. Adjust level controls on bracket for proper

pumping and alarm elevations. Off level control

must be set so that pump will turn off when sump

level is 1" to 2" above bottom of pump.

2. Connect level control and pump power cords to

connection box as shown on connection diagram.

Make certain that all compression fittings are tight.

3. Install control box.

4. Run wires to control box through conduit and

connect to cords coming into connection box.

Mark or trace each incoming wire so that it can be

connected to proper cord.

5. Do not install sealing compound into fitting until

pumps have been run, to be sure all connections

are correct.

INSTALLATION

1. The basin is fiberglass, and concrete must be

poured over antiflotation ring to prevent basin

from floating up. Do not leave basin in unfilled hole

without concrete as ground water or rain may float

basin up, breaking inlet, discharge and electrical

conduit connections.

2. Cubic feet of concrete to be poured around basin

to prevent flotation:

BASIN DIA.

CUBIC FEET OF CONCRETE

REQUIRED PER FOOT OF

BASIN DEPTH

24" 2 cu. ft.

36" 5 cu. ft.

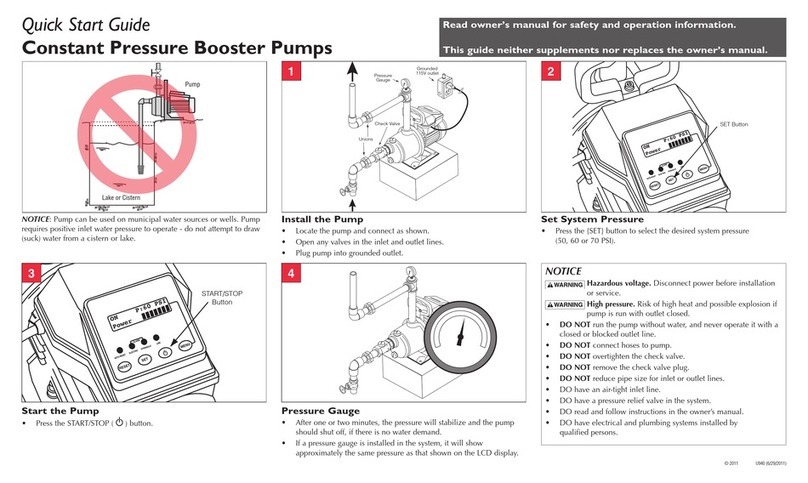

STARTING SYSTEM

1. Open 1-1/4" ball valve.

2. Set H-O-A switch on AUTO position and run water

into sump until ON level control starts pump.

Allow pump to operate until sump level drops,

deactivating OFF level control, stopping pump.

IMPORTANT – OFF level control should be set so that

sump level drops to within 1" to 2" from bottom of

pump before stopping pump.

3. Turn pump switch to OFF and fill sump over alarm

control. Red light should flash.

4. Set H-O-A switch to AUTO position. System is

now ready for automatic operation.

IN CASE OF TROUBLE, CHECK THE

FOLLOWING:

Pump will run but not deliver water.

Cause – 1. Probably air lock. Start and stop pump

several times using H-O-A switch. If this

does not clear air, turn pump to OFF

and run more water into sump 6" to 12"

higher. If air still does not clear, it may be

necessary to raise hold-down pipe and

lift pump so that lower seal fitting is out of

the discharge case to release air.

2. Be sure shut-off valve is open in

discharge line.