PTR 420 User manual

2207 EAST ONTARIO STREET, PHILADELPHIA, PA. 19134

VERTICAL BALERS

FOR DEPENDABLE, COST-SAVING RECYCLING

ENGINEERED FOR SUPERIOR DURABILITY & MAXIMUM SAFETY

Model #_______________

Serial #_______________

TABLE OF CONTENTS

INTRODUCTION 3

GENERAL 4

WARRANTY 5

SAFETY/TRAINING INFORMATION 6-10

CONTROL LAYOUT 11

BALER OPERATING MODES 12

OPERATING INSTRUCTIONS 13-16

SAFE BALE EJECTION PROCEDURE 17-18

BALING WIRE IMFORMATION 19

PLC TROUBLESHOOTING 20-25

GENERAL TROUBLESHOOTING 26-30

LOCKOUT PROCEDURES 31-32

BALER MINIMUM CLEARANCE CHART 33

INSTALLATION INFORMATION 34-36

MAINTENANCE INSTRUCTIONS 37-40

ELECTRICAL INFORMATION 41-48

ELECTRICAL CIRCUITS 49-54

HYDRAULIC SCHEMATIC 55-56

PRESSURE SETTING & CHECKING PROCEDURES 57-58

BALER CYLINDER REPLACEMENT 59

DECAL & INSTRUCTION PLATES PLACEMENT 60

PARTS & SERVICE 61

WALL BRACKET KIT 62

MECHANICAL PARTS INFORMATION 63

LIMIT SWITCH INFORMATION 64

BALER PARTS DESCRIPTION & NUMBERS 65-67

Revised 10/2016

Congratulations on your purchase of a PTR Baler.

PTR is known for producing balers with the highest safety and quality standards

in the industry.

All PTR Balers are factory tested and receive a vigorous quality assurance

inspection to insure top performance and safety in the field.

Many of the advanced design features on our balers make operation easy

without sacrificing safety.

At PTR Baler and ompactor, operator safety is our number one priority. We

ask that all operators read and fully understand this manual and view the

provided safety/operational video. All baler operators must be at least 18 years

old.

UL Approved and UL Approved.

***IMPORTANT***

A. The operating keys are located inside of the control panel. A tool is

re uired to open the control box and only trained and authorized

service personnel should enter following proper lockout/tagout

procedures.

B. When power has been properly connected, press the Down/Up button

and observe the direction of the rotation of the motor. Look at the

motor fan, proper rotation is clockwise. (As indicated by arrow on

motor). If fan rotation is not clockwise, follow lock out/tag out

procedures and interchange any two of the three power conductors, re-

check for proper rotation. This should correct the problem.

GENERAL

PTR’s vertical downstroke baler is designed with the operator’s safety in mind.

However, as with most industrial equipment, the ultimate responsibility for

safety rests with the operator.

It is the operator’s duty to be thoroughly familiar with this manual and video

before operating the baler.

Additional operator responsibilities are to insure that the units’ operation is in

accordance with safety requirements and codes, especially all applicable

Occupational Safety and Health Administration (O.S.H.A) standards and

American National Standard Institute (A.N.S.I) Regulations.

PTR strongly recommends that current, completed, applicable ANSI and

OSHA standards are available to operators at all times.

PTR Baler and ompactor ompany strongly recommends: Keep the baler

clean and free of contaminant. Failure may cause illness or death. Bale clean

ardboard only.

Note:

The information contained herein is subject to change without notice.

We reserve the right to make changes, and alterations to the equipment

and information contained herein at anytime.

WARRANTY

PTR BALER AND COMPACTOR COMPANY warrants all equipment when operated,

maintained and installed, and used in normal service for a period of three hundred sixty-five

(365) days after the date of installation to be free from defects in material and workmanship

The responsibility of PTR BALER AND COMPACTOR COMPANY, under this warranty to the

purchaser, except as to title, shall not in any case exceed the cost of correcting defects in the

equipment Warranty repair or replacements shall not extend the initial warranty period

PTR BALER AND COMPACTOR COMPANY shall under no circumstances be responsible for

any loss of business or profit to the purchaser or any other consequential damages in connection

with the sale of such equipment or any obligation under this warranty The foregoing shall

constitute the sole remedy of the purchaser, and the responsibility of PTR BALER AND

COMPACTOR COMPANY

Warranty repairs and/or replacements (at our option), will be made for both parts and labor The

authorized service center must use PTR BALER AND COMPACTOR COMPANY authorized

parts Labor will be allowed at a maximum of ($40) hourly rate Premium rates will be at the

customer’s accountability All warranty calls must be called into PTR BALER AND

COMPACTOR COMPANY for dispatch 1-800-523-3645

All parts, components or accessories requiring repair or replacement, within the warranty period,

shall be returned PREPAID, to the PTR BALER AND COMPACTOR COMPANY at the

expense of the buyer, lessee, or consignee The PTR BALER AND COMPACTOR COMPANY

will return at its expense replacement parts, components or accessories found to be defective

Shipment of parts under warranty shall be made via United Parcel Service or Parcel Post Cost

of any other means or transportation shall be paid by the equipment user

PTR BALER AND COMPACTOR COMPANY does not assume any responsibility of liability

for improper use of the equipment or improper installation of any unit, part or accessory which

may cause damage to the unit The installation of parts or accessories manufactured or sold by

any other supplier shall be deemed to void all warranties

Warranty claims for equipment ill not be proceeded unless a properly completed and

signed arranty card (attached to the installation checklist) has been received.

NON-WARRANTABLE REPAIRS

1 Routine adjustments; limit switches, pressure switch, or relief valve

2 Tightening of hydraulic fittings and terminal connections

3 Electrical fuses, tripped over loads or breakers

4 Power to the unit, phase change, motor rotation change, facility electrical problems, or

damage by customer from improper electrical hook up to unit

5 Addition of hydraulic oil

6 Ejector system parts such as chains, t-hooks, and shackles

7 Repairs necessitated by improper use such as failure to follow instructions and abuse of

equipment

8 Operator error (example: chamber door not closed tight enough or gate not pulled down flush

to top of chamber door)

9 Damage or install errors from customer supplied installer

NOTE: Always have Serial and Model Number of unit ready when calling for service

Baler Safety and Training Outline

I. Scope - Employers should designate a Safety/Risk Manager or equivalent person that has

qualifications necessary to evaluate and manage safety and operational training issues related to the

operation of baling equipment as part of their operator safety and training program. Each individual

baler owner should develop their own training program specific to their equipment, personnel,

processes, environment, and unique site application.

A. Your company safety official should conducted a hazard assessment of the various

baling equipment utilized at your facility and use the information from the hazard

assessment to develop a company specific baler safety training program. The

hazard assessment should include at a minimum the following:

1) Identification of material being baled. (clean cardboard only)

2) Hazards associated with the baling equipment and material baled.

3) An initial and then periodic review of the capabilities, qualifications, and

training of any person who may potentially encounter the identified hazards.

B. Your company safety official should evaluated the means and methods of controlling the hazards

identified in the hazard assessment; including information such as industry and regulatory

requirements, instructions for the operation, inspection and maintenance of balers, and other

information appropriate to the identified hazards.

1) Your company safety official should ensure compliance with applicable OSHA Code of

Federal Regulations under 29 CFR 1910 and applicable ANSI baling equipment

standards under ANSI Z245.5 and Z245.51.

2) Your company safety official should ensure that all employees (including supervisors)

engaged in the operation, cleaning, maintenance, service, or repair of the baling

equipment are properly trained according to their assigned jobs or tasks. The Baler

Safety Video supplied by PTR should be shown to all potential operators and the

manual should be read thoroughly.

3) Contractors should not be permitted to operate in-house baling equipment unless they

have been properly trained and authorized.

C. As a leading baler manufacture we recommend that your company utilizes the following baler

safety training outline and baler safety video which cover the following:

1) Pre-start up

2) Operation –(operation procedures are also posted on front of control box)

3) Safe bale ejection

4) Inspection / maintenance (see baler safety inspection checklist included in this manual)

5) Operator Safety / Prohibited practices

6) Training requirements (necessary training as identified from hazard assessment and use

of baler safety video.

7) Record keeping –(see Attachment A)

D. Your company safety official should periodically review their company specific program to

ensure the effectiveness of your safety program and make revisions as necessary.

Heed & Obey Warning Signs

Signs such as Danger, Caution, Warning, and Attention are on the machine for your protection.

Warning signs must remain in place and be kept in readable condition. Report and replace all

damaged or missing warning signs.

Operational carelessness and safety shortcuts can cause serious injury or death! Follow safety

Guidelines and be safety conscious.

Every operator should read operators manual and the operating instructions posted on the front of the

control box.

The operating key should not be left in the machine when the machine is left unattended.

Prior to Start Up

1. Wear proper safety equipment as recommended by your company safety official.

2. Never allow yourself or anyone involved with the baling system to be under the influence intoxicants or

narcotics while the baler is operating.

3. Walk around the baling system to check for proper equipment condition. Open hopper door and check

inside the baler.

4. Be positive no one is working on the baler or adjoining equipment. With ram in up position, lift gate and

look inside main chamber area to be sure no one is inside.

5. The following operational check should be conducted prior to each shift:

·With the gate raised, press all buttons in any order or combination. No motion should occur.

·Close gate and start machine, open gate during downward motion. Machine should immediately

stop.

·Close gate and start machine. Gate will automatically open with upward ram travel. During this

time, raise the gate off the ram. Machine should immediately stop.

·Demonstrate that the machine will not operate in “automatic” if the main bale door is open.

Operator should do this by having the ram in the up position and with the gate closed set the selector

switch to down and push. Release the button and the ram should stop.

6. It is imperative that proper housekeeping is performed in the area behind and around the baler.

·The areas behind the baler must be kept clean and free of debris, pallets and any other material.

·PTR recommends that this area be inspected daily to maintain the safe operation of vertical

balers.

·Bale wire stored in the area of the baler must be stored in an approved horizontal storage system.

7. If anything does not function as indicated, immediately report

problems to supervisor, remove key, lockout machine, and call for

service.

Operator Safety

Always Use Lockout/Tagout

Power must always be disconnected and locked out before working within or performing maintenance

on the baler or associated equipment. Standard Lockout/Tagout procedures should be followed in

accordance with the OSHA standard 1910.147 “The control of hazardous energy”.

A group safety lock should be used when multiple employees are working on the machine at one time so

that all locks need to be removed in order to be able to re-energize the baler. Every employee who

works on or with the baler should have his own lock and key. Never assume you are protected by

another employee’s safety lock.

Keep Safety Guards in Place

Safety guards must be kept in place and secure at all times. Keep the guards in good repair with

periodic maintenance. Keep limit switches free of debris or obstructions. Do not override of

bypass safety switches or features.

If feed gate becomes difficult to open or close, maintenance should be informed.

Operators should be instructed on how to conduct a brief visual safety inspection that includes areas

door hinges and latch. Also how to conduct a visual inspection of the ejector chains, t-hooks, and

shackles. Operator should know that maintenance should be called if there is any evidence of

damage or if anything looks “different” as opposed to prior inspections.

Practice Fire Prevention

·Keep fire extinguishers accessible at all times. Use the extinguisher recommended for the

material being baled. It should be rated safe for use of electrical fires.

·Never smoke close to combustible material.

·Clean the area before welding or other repair activities that produce sparks or source of ignition.

·Keep tank and motor areas free of oil, dust, or paper accumulations.

Keep a Clean Machine

1. Bale only clean cardboard.

2. Clean motor area monthly.

3. Remove any wedged cardboard from sides and back of ram. Remove any cardboard on the top of the ram

daily.

4. Remove any cardboard stuck on retainer dogs and limit switches.

5. Keep baler clean and free of dirt and other contaminants. Failure to do so may cause illness or death.

6. The areas behind the baler must be kept clean and free of debris, pallets and any other material.

7. PTR recommends that the area behind the baler be inspected daily to maintain the safe operation of vertical

balers.

Remember! All possible Dangers cannot be predicted. Your own safety

attitude and habits are your best protection.

Additional Safety Guidelines for Baler Operation

1. Only authorized personnel 18 years of age or older, who are trained in baler operation are

permitted to operate the baler.

2. The owner and operator are responsible for the safety of the employees and should be familiar

with applicable OSHA and ANSI standards.

3. Operate in accordance with the owner’s manual supplied with your baler.

4. Do not set the hydraulic pressure above factory specs. Specified pressures are listed inside the

control box. Severe baler damage and/or personal injury could result.

5. Bale only the specified material for which the baler was built. And also for which the hazard

assessment was conducted for.

6. Never overload the baler chamber.

7. Never enter the main chamber area unless the power is disconnected and locked out.

8. If work on or in the baler is required, disconnect the power to the baler, and lockout. Never

assume that you are protected by another employee’s safety lock. Before restarting, repeat the

“Prior to Start Up” procedures.

9. Anytime the baler is shut down, the “Prior to Start up” procedures should be repeated.

10. Never bale aerosol cans or containers filled with liquid.

11. Use of safety glasses and forearm length leather gloves are strongly recommended when

handling baling wire.

12. The areas behind the baler must be kept clean and free of debris, pallets and any other material.

13. PTR recommends that the area behind the baler be inspected daily to maintain the safe

operation of vertical balers.

14. Bale wire stored in the area behind of the baler must be stored in an approved horizontal

storage system.

Attachment A

TRAINING RECORD

Employee Name

Description of Training and other Notes

Date of

Training

Seen Video

Yes/No

Employee Signature

Store name and location: ______________________ Training Video Present at Store: ____________________

Manual present at Store: __________________

Store #: _______

Name or Trainer: ____________________

Store Manager Name: _________________________ Signature of Trainer: ___________________

Signature and Date: ____________________________

1R 4XDQWLW\ 'HVFULSWLRQ 3DUW1XPEHU

)86(+2/'(5

352;6:,7&+)86(

)86(

975$16)250(5

5('/,*+7

*5((1/,*+7

7(50,1$/%/2&.6

(1'6(&7,216

.$%/2&.

.$%/2&.

83'2:1%87721

.(<6:,7&+

5(6(7%87721

&2//$5&217$&7

$29(5/2$'

$&217$&725

%5$66/8*

)86(%/2&.

3/&

386+38//%87721

:$775(6,6725

%2;'(&$/

61$3,13/8*

;%2;

$03)86(

BALER MODES

There are three basic modes of operation a downstroke vertical baler will perform

–loading, compression, and ejection.

LOADING

Material is evenly loaded into the baler chamber while the safety charging gate and

ram are in the UP position. The baler chamber door is closed and locked.

COMPRESSION

With the safety gate down, the ram pushes the material down into the bottom of the

baler chamber area. Retainer Dogs located on baler chamber door help hold the

compressed material down while the ram travels up to the loading position,

opening the baler safety charging gate as it travels up.

EJECTION

When full bale indicator arrows on the ram face and baler frame match, the bale is

the proper size. Lift gate, unlatch and open chamber door at least 110 degrees,

slide baling wire through slots and tie off all wires.

Close feed gate by pulling it down completely.

Attach the ejector “T” hooks at back of baler to ram ejector lugs, set the

UP/DOWN switch located on baler electrical box to the UP position, press and

hold button in until the bale ejects. Keep clear of ejecting bale.

5HYLVHG

3/&%DOHU

&RQWURO'HVFULSWLRQDQG

2SHUDWLQJ,QVWUXFWLRQV

7KLVXQLWLVWR HRSHUDWHG \DXWKRUL]HGDQGWUDLQHGSHUVRQQHORQO\%\ODZQRRQH

XQGHU\HDUVRIDJHLVSHUPLWWHGWRRSHUDWHWKLVPDFKLQH%DOHUPDQXDODQGVDIHW\

YLGHRPXVW HUHYLHZHGDVSDUWRIRSHUDWRUDQGPDLQWHQDQFHWUDLQLQJ

&21752/6$1',1',&$7256

7KH375%DOHUFRQWUROVZLWK3/&DUHQHDUO\LGHQWLFDOWRWKHVWDQGDUG DOHURSHUDWRUFRQWUROV

.H\HG212))6ZLWFK±7KHVZLWFKLVDQDFFHVVFRQWUROGHYLFHWKDWOLPLWVXVHWRDXWKRUL]HG

DQGWUDLQHGRSHUDWRUVLQSRVLWLRQRIWKHNH\$OVRDOORZVWKH DOHURSHUDWLRQWR HWXUQHGRIIIRU

URXWLQHSURGXFWLRQVXFKDVW\LQJRIID DOH.H\6ZLWFKLV127DORFNRXWWDJRXWGHYLFHDV

UHTXLUHGIRUVHUYLFHRUHQWU\LQWRWKHPDFKLQH

(6WRS±$OORZVWKHPDFKLQHWR HVWRSSHGDWDQ\WLPHLQFDVHRIHPHUJHQF\:LOOLOOXPLQDWH

ZKHQSUHVVHGDQGPXVW HPDQXDOO\SXOOHG DFNRXW HIRUHPDFKLQHFDQ HUHVWDUWHG

8S'RZQ6HOHFWD OH6WDUW±7KLVLVWKH XWWRQXVHGWRVWDUWWKHPDFKLQH7KHRXWHUULQJFDQ H

WXUQHGWRVHOHFW HWZHHQVWDUWXSDQGVWDUWGRZQ7KHPDFKLQHZLOORSHUDWHLQDXWRPDWLFPRGH

ZKHQWKHPDLQ DOHGRRULVVKXWWKHJDWHLVFORVHGDQGWKHUHLVOHVVWKDQDIXOO DOHLQWKH

FKDP HU1RWH3UHVVLQJWKHVWDUWEXWWRQZKLOHWKHUDPLVQRWLQWKHIXOO\UDLVHGSRVLWLRQ

ZLOOUHVXOWLQWKHUDPUHWUDFWLQJWRWKHIXOO\UDLVHGSRVLWLRQDQGVWRSSLQJ3UHVVLQJWKH

EXWWRQDJDLQZLOOUHVXOWLQDQRUPDOF\FOH

7KLV XWWRQZLOORSHUDWHDVDVXVWDLQHGPDQXDOSUHVVXUHFRQWUROWRDOORZIRU DOHHMHFWLRQZKHQ

WKHPDLQ DOHGRRULVRSHQRUZKHQWKHIXOO DOHOLJKWLVLOOXPLQDWHG7KHUDPPXVW HUXQXS

HIRUHLWFDQ HUXQGRZQZKHQLQPDQXDORSHUDWLRQLIWKHSUHVVXUHVZLWFKZDVDFWXDWHGGXULQJ

WKHSUHYLRXVGRZQVWURNH

5HVHW±7KLV XWWRQLVQRWQRUPDOO\XVHG:KHQSUHVVHGLWZLOOUHVHWWKHRYHUORDGLQWKH

XQOLNHO\HYHQWWKDWWKHRYHUORDGKDVWULSSHGDQGWKHRYHUORDGWULSSHGOLJKWLVLOOXPLQDWHG

3OHDVHFDOO375VHUYLFHLIWKHRYHUORDGKDVWULSSHGPRUHWKDQWKUHHWLPHVLQDQ\JLYHQRQH

PRQWKWLPHSHULRGDVWKLVFDQ HLQGLFDWLYHRIDQLPSURSHUPDFKLQHSRZHUFRQQHFWLRQRURWKHU

HOHFWULFDOIDXOW

5HYLVHG

)XOO305HTXLUHG*DWH)DXOW/LJKW±7KLVOLJKWZLOOLOOXPLQDWHDQGUHPDLQLOOXPLQDWHGLID

IXOO DOHLVGHWHFWHGLQWKH DOLQJFKDP HU$XWRPDWLFRSHUDWLRQZLOO HGLVD OHGDQGWKLVOLJKW

ZLOOUHPDLQLOOXPLQDWHGXQWLOWKH DOHLVWLHGRIIHMHFWHGIURPWKHPDFKLQHDQGWKHPDLQ DOH

GRRUFORVHG7KHPDFKLQHLVVWLOORSHUD OHLQPDQXDOPRGHZLWKWKHIXOO DOHOLJKWLOOXPLQDWHG

7KHIXOO DOHDUURZVZLOOOLQHXSZKHQWKHPD[LPXPVL]H DOHLVLQWKH DOHFKDP HU'RQRW

PDNH DOHV H\RQGWKHSRLQWZKHUHWKHDUURZVOLQHXS

7KHPDFKLQHKDV RWKDQLQWHUQDOF\FOHFRXQWHUDQGKRXUFRXQWHUWRWUDFNPDFKLQHXVDJH7KH

30OLJKWZLOOUHSHWLWLYHO\VORZ OLQNRQHVHFRQGRQIROORZHG \RQHVHFRQGRIIZKHQWKHF\FOH

FRXQWRUKRXUFRXQWH[FHHGVWKHSUHVHWYDOXHWKDWLQGLFDWHVSUHYHQWDWLYHPDLQWHQDQFHLV

UHTXLUHG&DOO375SDUWVDQGVHUYLFHWRVFKHGXOHSUHYHQWDWLYHPDLQWHQDQFH7KHPDFKLQHZLOO

FRQWLQXHWRRSHUDWHQRUPDOO\

7KLVLQGLFDWRUOLJKWZLOODOVRUHSHWLWLYHO\IDVW OLQNRQHKDOIVHFRQGRQIROORZHG \RQHKDOI

VHFRQGRIILIWKHLQWHUQDOSURJUDPGHWHFWVWKDWWKHJDWHSUR[LPLW\VZLWFKKDV HHQ \SDVVHGRULV

LQRSHUDWLYH2SHQLQJDQGUHVKXWWLQJWKHJDWHZLOOXVXDOO\FOHDUWKH OLQNLQJOLJKWDQGUHWXUQ

WKHPDFKLQHWRQRUPDORSHUDWLRQ3OHDVHFRQWDFW375SDUWVDQGVHUYLFHLIWKHOLJKWFRQWLQXHVWR

OLQNDQGWKHPDFKLQHUHPDLQVLQRSHUD OHDIWHURSHQLQJDQGFORVLQJWKHIHHGJDWH

*DWH6KXW/LJKW±7KLVOLJKWLQGLFDWHVWKDWWKHIHHGJDWHLVFRPSOHWHO\DQGSURSHUO\FORVHG7KH

QRUPDODXWRPDWLFF\FOHFDQQRW HVWDUWHGLIWKHJDWHLVQRWIXOO\FORVHG

'RRU6KXW/LJKW±7KLVOLJKWLQGLFDWHVWKDWWKHPDLQ DOHHMHFWGRRULVWLJKWO\FORVHGDVLV

UHTXLUHGIRUQRUPDODXWRPDWLFRSHUDWLRQ:LWKWKHGRRURSHQWKHPDFKLQHZLOORQO\UXQLQ

PDQXDOPRGHZLWKVXVWDLQHGPDQXDOSUHVVXUHFRQWURORSHUDWLRQDVQHFHVVDU\WRHMHFWWKH DOH

,IWKLVOLJKWLVQRWLOOXPLQDWHGILUVWWU\WLJKWHQLQJWKHORFNLQJKDQGZKHHOWRHQVXUHDFRPSOHWH

DQGWLJKWGRRUFORVXUH

2YHUORDG7ULSSHG/LJKW±7KLVOLJKWLQGLFDWHVWKDWWKHLQWHUQDOPRWRURYHUORDGKDVWULSSHG6HH

D RYHGHVFULSWLRQRIWKH5HVHWSXVK XWWRQ

5HYLVHG

%$/(523(5$7,1*,16758&7,216

$3UHSDULQJWKH DOHUWRPDNHDQHZ DOHRIFDUG RDUG

,QVXUHSRZHUNH\VZLWFKLVLQWKH2))SRVLWLRQ

,QVXUH DOHUUDPLVLQWKH83SRVLWLRQ

:LWKJDWHLQWKH83SRVLWLRQRSHQ DOHFKDP HUGRRU

/D\DIODWSLHFHRIFDUG RDUGRQWKH RWWRPRIWKH DOHFKDP HURYHUWRSRIWKHHMHFWRU

FKDLQV

&ORVHDQGODWFKWKH DOHFKDP HUGRRU

%7RPDNHD DOH

)LOOWKHFKDP HUZLWKFDUG RDUG R[HVQHHGQRW H URNHQGRZQWKHPDWHULDOWR H

DOHGVKRXOG HORDGHGHYHQO\LQWKHFKDP HU

3XOOWKHJDWHGRZQWRWKHWRSRIWKHFKDP HUGRRU

7XUQSRZHUNH\VZLWFKWRWKH213RVLWLRQ

6HWWKH83'2:1VZLWFKWRWKH'2:1SRVLWLRQZKLFKLVDOVRWKH$872VHWWLQJ

3UHVVWKH'2:1 XWWRQDQGUHOHDVHWKHUDPZLOOWUDYHOGRZQDQGDXWRPDWLFDOO\UHYHUVH

ZKHQUHDFKLQJIXOOGRZQVWURNH

5HSHDWD RYHVWHSVXQWLOWKHIXOO DOHOLJKWLOOXPLQDWHVRUXQWLOWKHDUURZVRQWKHIUDPH

DQGUDPDUHDOLJQHG

127(,IWKHJDWHLVRSHQHGDWDQ\WLPHGXULQJWKHF\FOHSULRUWRDXWRPDWLFDOO\RSHQLQJRULIOLIWHGRII

WKHUDPVZLWFKGXULQJDXWRPDWLFJDWHRSHQLQJ±WKHUDPZLOOLPPHGLDWHO\VWRS5DPZLOOUHWUDFWWR

WKHIXOOXSSRVLWLRQRQUHVWDUWUHJDUGOHVVRIVHWWLQJRQ8S'RZQVHOHFWRU

&7RWLHRIIDQGHMHFWD DOH1RWH6WHSVWKUXDUHRSWLRQDOWRDOORZWKHDGGLWLRQRIDWRSIODW

VKHHWIRUHDVLHUW\LQJRIWKH DOH

7XUQWKH83'2:1VZLWFKWRWKH83SRVLWLRQ

3UHVVDQGKROGWKH83 XWWRQWRUDLVHWKHUDP

7XUQWKHNH\VZLWFKWRWKH2))SRVLWLRQ

/D\DIODWSLHFHRIFDUG RDUGRQWRSRIWKH DOHWRSURYLGHDIODWVXUIDFHIRUHDVLHUW\LQJ

RIWKH DOH±'2127UHDFKLQWRWKHFKDP HU

/RZHUWKHJDWHDQGWXUQWKHNH\VZLWFKWRWKH21SRVLWLRQ

7XUQWKH83'2:1VZLWFKWRWKH'2:1SRVLWLRQ

3UHVVDQGKROGWKH'2:1 XWWRQWLOOWKHUDPVWRSVDJDLQVWWKHIXOO DOH

7XUQWKHNH\VZLWFKRIIDQGUHPRYHWKHNH\

/LIWJDWHXQODWFKDQGRSHQFKDP HUGRRUDWOHDVWGHJUHHV'RQRWVWDQGLQIURQWRI

WKHGRRU

6OLGH DOLQJZLUHWKURXJKVORWVLQIORRUDQG DFNWKURXJKVORWVLQUDP7KH³SRNHUURG´

RUFDUG RDUGFOHDULQJWRROFDQ HXVHGLIQHFHVVDU\WRFOHDUDSDVVDJHIRUWKH DLOLQJ

ZLUH

7LHRIIDOOZLUHV

3RVLWLRQDSDOOHWKDQGWUXFNIRUNOLIWLQIURQWRI DOHURSHQLQJWRUHFHLYHWKH DOHZKHQ

LW¶VHMHFWLQJ

5HYLVHG

3ODFHHMHFWRUKRRNVRQWRWKHHMHFWRUUDPOXJVLQWKH DFNRIWKH DOHU

,QVHUWWKHNH\DQGWXUQWKHVZLWFK216HWWKH83'2:1VZLWFKWRWKH83SRVLWLRQ

3XOOJDWHGRZQXQWLOLWLVRQWKHUDPJDWHVZLWFKLIWKHUDPLVVWRSSHGKLJKHUWKDQWKH

GRRURUFORVHGFRPSOHWHO\LIWKHUDPLV HORZWKHGRRU

.HHSLQJWKHDUHDLQIURQWRIWKHPDFKLQHFOHDURIDOOSHUVRQQHO3UHVVDQGKROGWKH83

VZLWFKXQWLOWKH DOHHMHFWV

3XOOJDWHGRZQFRPSOHWHO\

7XUQWKH83'2:1VZLWFKWRWKH'2:1SRVLWLRQ

3UHVVWKH'2:1 XWWRQDQGKROGHMHFWRUFKDLQVDQGKRRNVZLOODXWRPDWLFDOO\

GLVHQJDJHGXULQJGRZQZDUGWUDYHO

7XUQWKH83'2:1VZLWFKWRWKH83SRVLWLRQ

3UHVVWKH83'2:1 XWWRQDQGKROGGRZQXQWLOWKHUDPLVLQWKH83SRVLWLRQ

7XUQWKHNH\VZLWFK2))/D\DIODWSLHFHRIFDUG RDUGRQWKH RWWRPRIWKH DOH

FKDP HURYHUWRSRIWKHHMHFWRUFKDLQV

&ORVHDQGODWFKWKH DOHFKDP HUGRRU

' 5HDG\IRUDQHZ DOHRIFDUG RDUG

)ROORZVWHSV$%&

x127

D2FFDVLRQDOO\FDUG RDUGZLOO HZHGJHGLQWKHUDPDUHD

7XUQRIIWKHSRZHUDWWKHGLVFRQQHFW R[DQGUHPRYHDQ\H[FHVVFDUG RDUGLIOHIWWR

XLOGXSLWFRXOGDIIHFWWKHRSHUDWLRQRIWKH DOHU

,IDQRSHUDWRUZLOOWU\VWRUXQWKH DOHUDQGLWGRHVQRWRSHUDWH

%HVXUHWKHSRZHUNH\VZLWFKLV21

%HVXUHJDWHLVSXOOHGGRZQFRPSOHWHO\DQGJDWHFORVHGOLJKWLVLOOXPLQDWHG

%HVXUHFKDP HUGRRULVFRPSOHWHO\FORVHGDQGGRRUFORVHGOLJKWLVLOOXPLQDWHG

%HVXUHQRWWROLIWWKHJDWHZKLOHUDPLVPRYLQJ DOHUZLOOVKXWGRZQDQGQRWVWDUWXQWLO

JDWHLVSXOOHGGRZQWRWKHWRSRIWKHFKDP HUGRRU

!""#

#

$%&%&#'"(%%%%

#)*"&#

+&",-,%--,##!""

&#"&%#

)%."&&%(%-%%#

%&(& !%&(%#

%-&%%"%%"&#/&

#

(%%%%(%

%&(%#0,,#%

%%%(#

%%"%%%

%(%&&%%%"#

1#%%(-2&%#

#"(%#

#%%-%&#

3#$%&%&("%"%

%(#

4#%%(-2&%#

5#6"#7-&%8#

6"&%",%-#

9#):-;%%"&%(%#

=%%&"((%""&#"%,

%(>

(>&%%""&#'"%"

"%%"(&&%%""&#

?#/%%%,%"&:;%%"%%

(&%%%&"%%"%%%

%#7%&%%(%#%&

%-"%&%&

%(8#

6#&%&%%(&"%:;#!%

&,%&%%"%"&%%%#!

"&%"%%&%%#!&"&

"&%%%"&#

1#/%%,-%&%:;(%%"%%(&

%%:;&"%%&%%

%#&%>"&(%#

11#@--%%%#

1#%:;%&%-&%

%&%%&&"%#

1#%:;%&%"%%"&#

13#A%&""%#

14#&%&%%"%%%%&(

:;%#

15#A(%%""%%:%-;%-#

19#%%-#

1?# '&%%%""#+%%

""&%%#!&%"&%#"

&%%"&%&""#

16#%%%%6

"%#

#%%#

1#(%%%#

#%&%"#

#%&""%%:%-;%-#

3#%--(%#

4#"%%"&#%

"&"%(%#

PTR Baler & Compactor Co.

2207 E. Ontario St Philadelphia, PA 19134

PHONE: 215-533-5100 * FAX 215-533-8907

Quality * History * Service* Value

Baling wire recommendation for PTR Baler and Compactor Company’s

standard built balers producing bales of ordinary cardboard. Consult

PTR Baler and Compactor for wire recommendations for non-cardboard

applications.

MODELS: 1800HD, 2318, 2300HD, 3400HD, 3600HD, 7230

Minimum of 14 Ga galvanized steel wire approximately 14’ long with one end looped for bale

tie off.

Wire is to have a tensile strength of approximately 70,000 to 85,000 psi or more and a break

strength of approximately 380 to 420 pounds or more.

MODELS: 360, 420

Minimum of 15 Ga galvanized steel wire approximately 9’ long with one end looped for bale tie

off.

Wire is to have a tensile strength of approximately 75,000 to 80,952 psi or more and a break

strength of approximately 300 to 340 pounds or more.

MODELS: 5000HD, 7200HD

Minimum of 12 Ga galvanized steel wire approximately 16’ long with one end looped for bale

tie off.

Wire is to have a tensile strength of approximately 70,588 to 76,136 psi or more and a break

strength of approximately 600 to 670 pounds or more.

Additional Information:

At least four baling wires must be used per bale. Slots are available for five or more bailing

wires to be used.

Care should be exercised when handling any potentially sharp objects such as bailing wire.

Follow appropriate precautions and procedures.

Always stand clear of ejecting bale.

Baling wire recommendation is based on industry standard and past history of success with this

wire in a wide variety of customer environments and usages of balers and other vertical balers

with comparable compression yielding bales of comparable size and weight.

5HYLVHG

0DQDJHUDQG6WRUH0DLQWHQDQFH,QVWUXFWLRQV

7KLVXQLWLVWR HRSHUDWHGDQGPDLQWDLQHG \DXWKRUL]HGDQGWUDLQHGSHUVRQQHORQO\1R

RQHXQGHU\HDUVRIDJHLVSHUPLWWHGWRRSHUDWHRUVHUYLFHWKLVPDFKLQH6WDQGDUG

DOHUPDQXDODQGVDIHW\YLGHRPXVW HUHYLHZHGDVSDUWRIRSHUDWRUDQGPDLQWHQDQFH

WUDLQLQJ2QO\TXDOLILHGWUDLQHGDQGDXWKRUL]HGSHUVRQQHOFDQSHUIRUPWKHVHDFWLRQVDV

WKHFRQWUROSDQHOPXVW HRSHQHGWRDFFHVVWKH3/&6DIHZRUNSUDFWLFHVLQDFFRUGDQFH

ZLWK1)3$(PXVW HIROORZHGZKHQDFFHVVLQJDOLYHHOHFWULFDOSDQHO

7528%/(6+227,1*±%DVLF$XWKRUL]HGSHUVRQQHORQO\

0DFKLQHZLOOQRWUXQDQG(VWRSSUHVVHGOLJKWLVLOOXPLQDWHG3XOORXWHVWRS

0DFKLQHZLOOQRWUXQDQGRYHUORDGWULSSHGOLJKWLVLOOXPLQDWHG3UHVVWKHUHVHW XWWRQDQGFDOO375

VHUYLFH

0DFKLQHZLOOQRWUXQDQGIXOO30UHTXLUHGJDWHIDXOWOLJKWLV OLQNLQJRSHQDQGUHVKXWWKHIHHG

JDWH,IWKLVVWLOOGRHVQRWUHVROYHWKHLVVXHFDOOIRUVHUYLFHRUIROORZWKHWURX OHVKRRWLQJJXLGHIRU

DXWKRUL]HGSHUVRQQHORQO\±6HHQH[WVHFWLRQ

0DFKLQHZLOORQO\UXQZLWKVXVWDLQHGPDQXDOSUHVVXUHFRQWUROVDQGIXOO DOHOLJKWLVLOOXPLQDWHG2SHQ

PDLQGRRUWLHRII DOHHMHFW DOHDQGUHFORVHPDLQGRRU

0DFKLQHZLOORQO\UXQZLWKVXVWDLQHGPDQXDOSUHVVXUHFRQWUROVDQGGRRUVKXWOLJKWLVQRWLOOXPLQDWHG

6KXWPDLQ DOHGRRUDQGWLJKWHQVLGHZKHHOORFN

0DFKLQHLVRSHUDWLRQDO XWIXOO30UHTXLUHGJDWHIDXOWOLJKWLV OLQNLQJ0DFKLQHLVGXHIRU

SUHYHQWDWLYHPDLQWHQDQFH&DOOVHUYLFHIRU300DFKLQHFDQFRQWLQXHWR HRSHUDWHGQRUPDOO\

This manual suits for next models

7

Table of contents

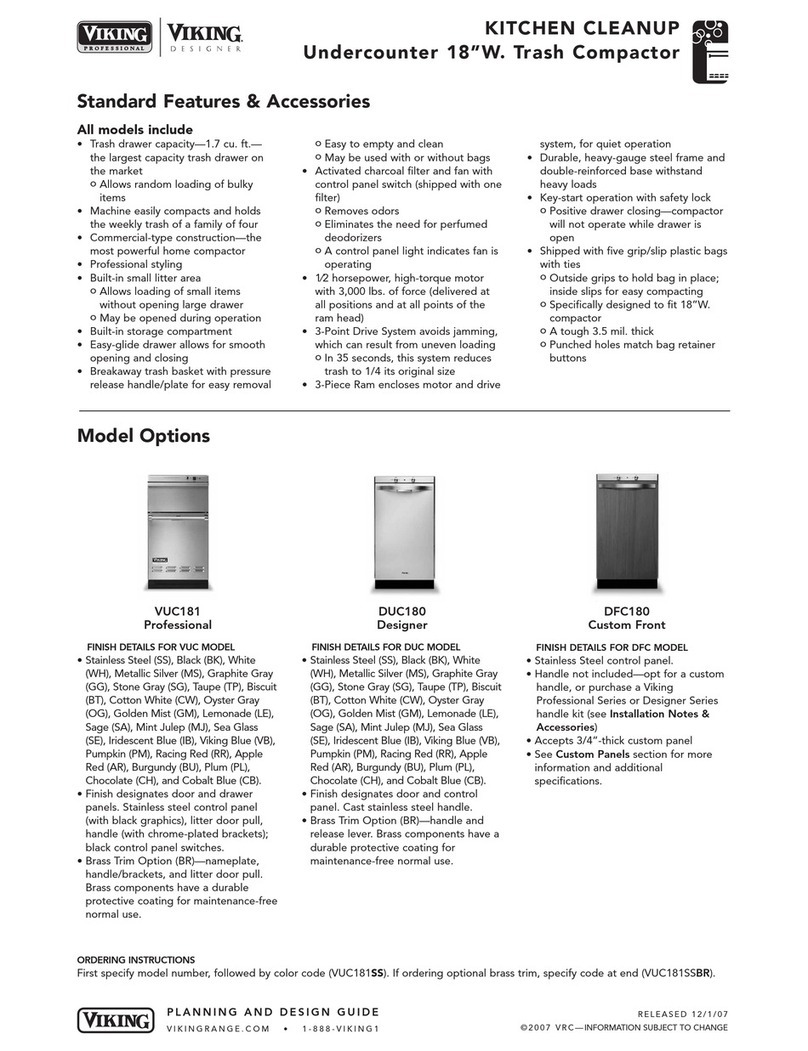

Popular Trash Compactor manuals by other brands

SUMMIT EQUIPMENT

SUMMIT EQUIPMENT SC-3248 Safety, operation & maintenance manual

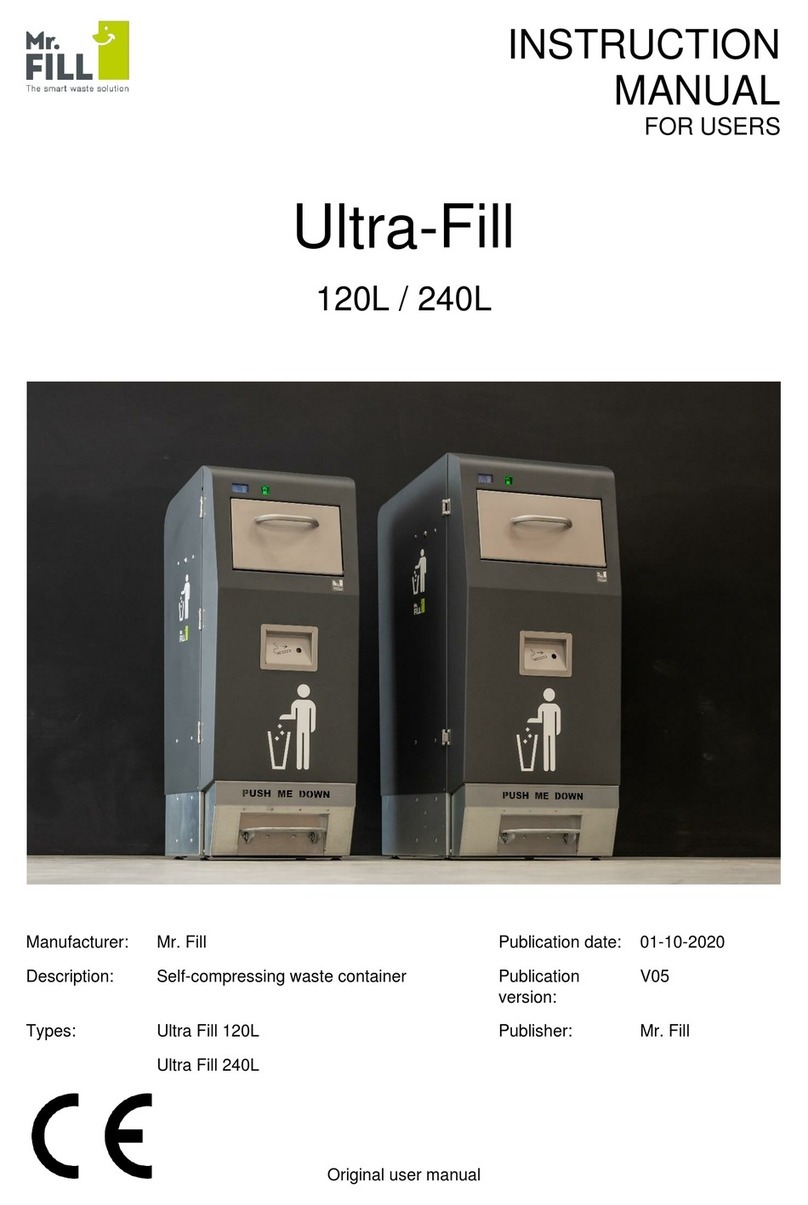

Mr. FILL

Mr. FILL Ultra Fill 120L instruction manual

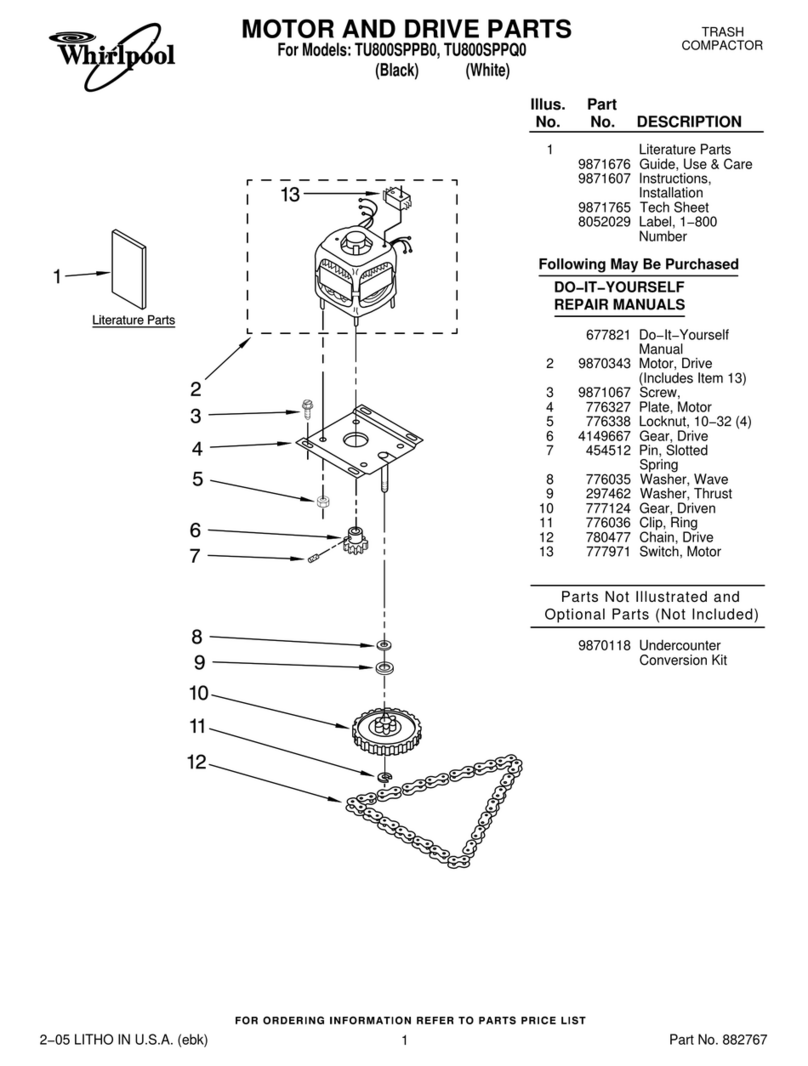

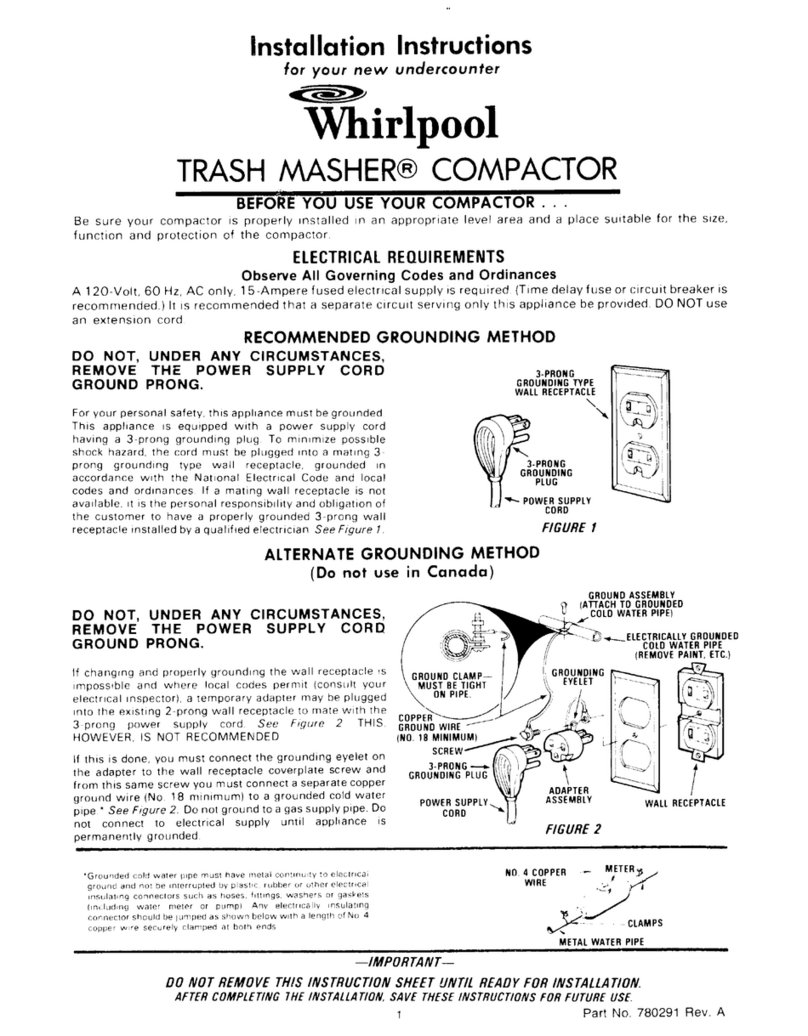

Whirlpool

Whirlpool GC900QPPQ User instructions

Jenn-Air

Jenn-Air TC507 Use & care guide

LDI

LDI SAFCO 9922 Assembly instructions

Whirlpool

Whirlpool Trash Masher installation instructions